Automatic production line of partition plate

An automated production line and partition wall panel technology, applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as heavy gravity, low production efficiency, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

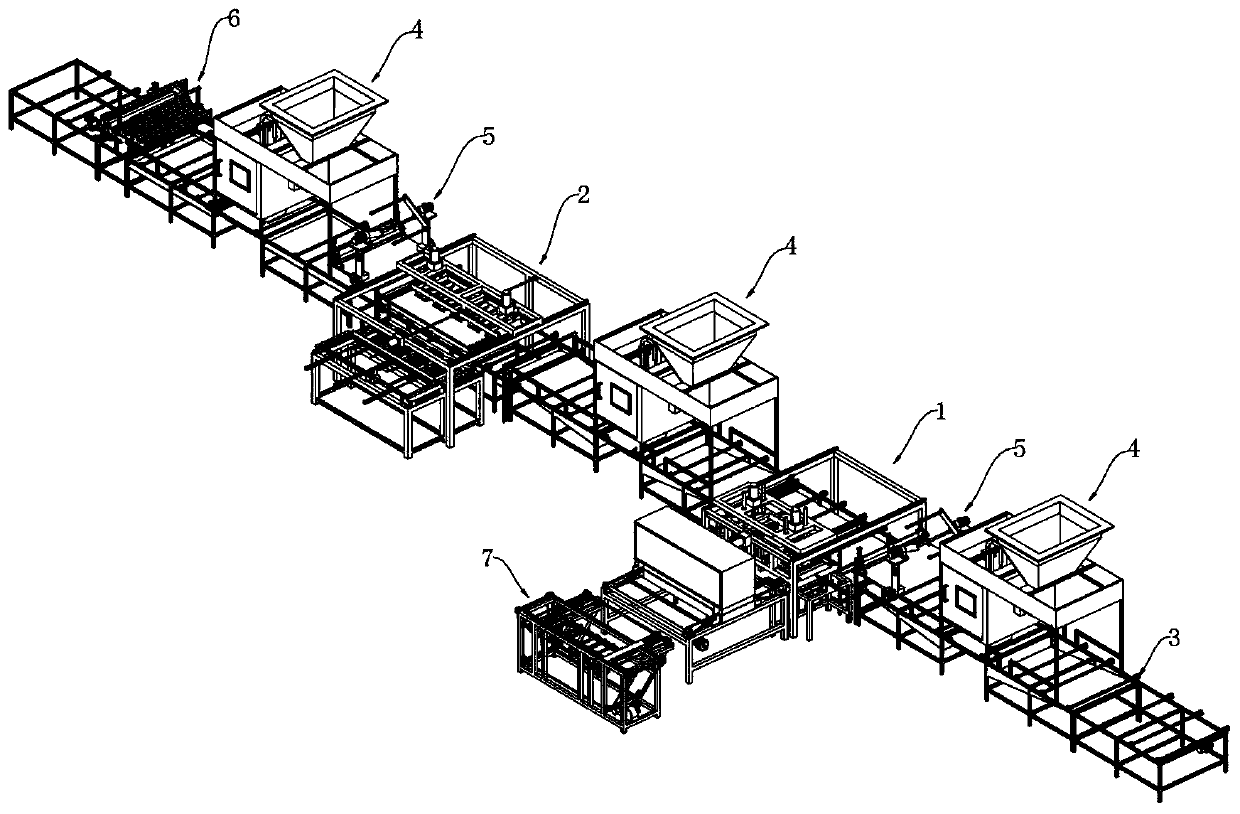

[0044] Such as figure 1 As shown, the present invention provides an automatic production line for partition wall panels, which is used to form partition wall panels on a mold a, including a hollow tube placing device 1, a steel bar placing device 2, a conveying device 3, a spraying device 4, and a grid Cloth laying device 5 and non-woven fabric bonding device 6, wherein:

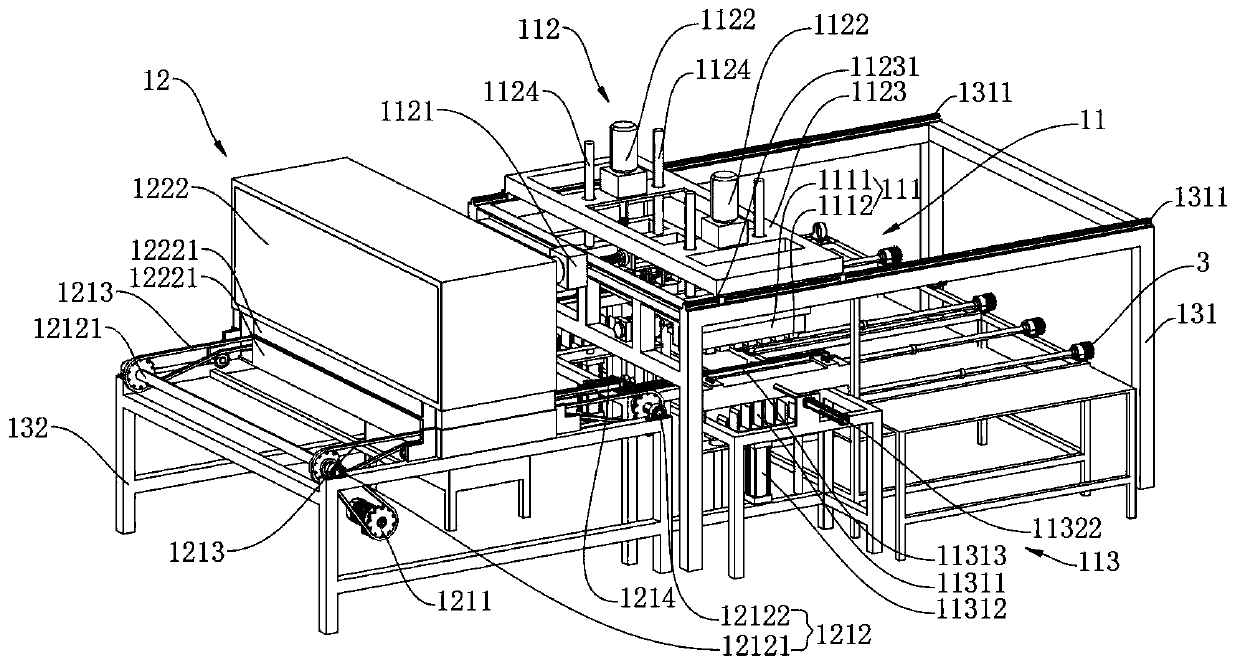

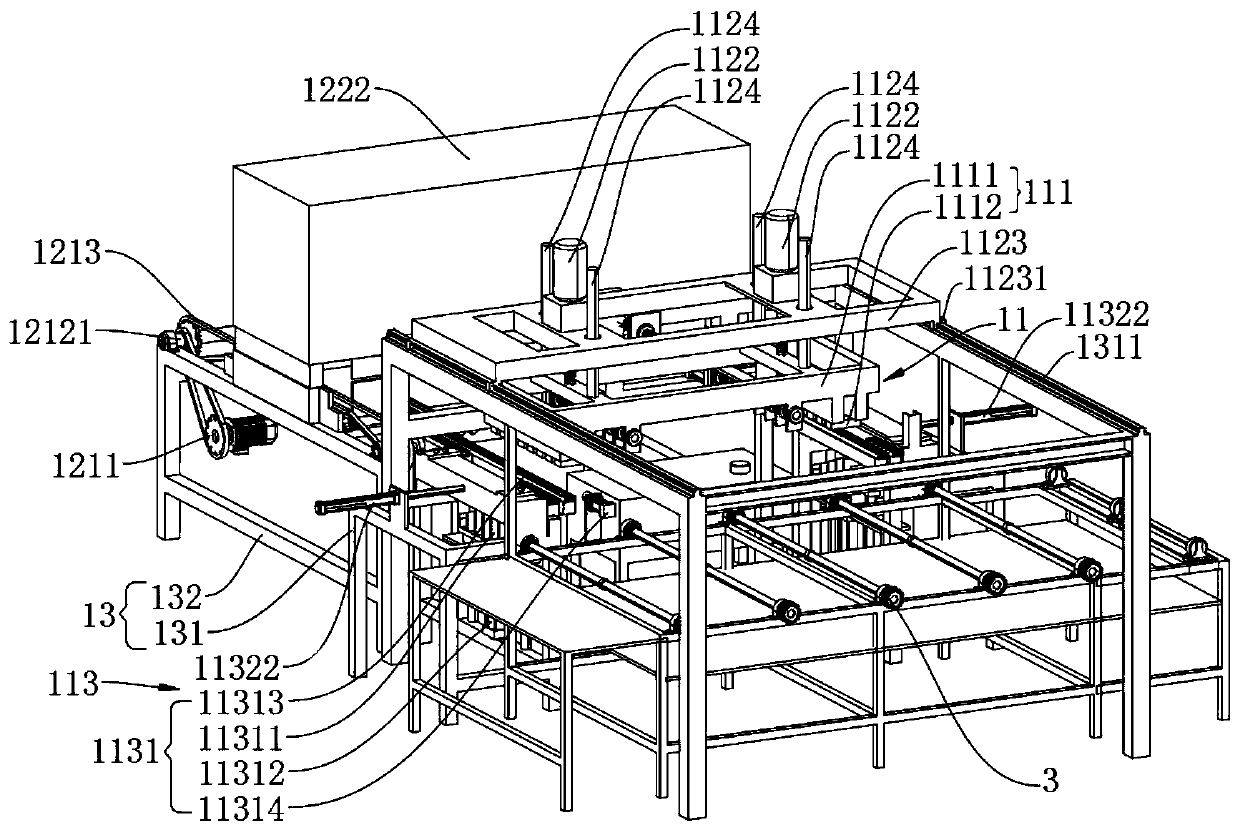

[0045] refer to figure 2 The shown hollow tube placement device 1 includes an adsorption mechanism 11, a fuel injection mechanism 12 and a hollow tube placement frame 13, and the hollow tube placement frame 13 includes a hollow tube adsorption frame 131 and a hollow tube fuel injection frame. 132. The front and rear end surfaces of the hollow tube adsorption frame 131 are respectively provided with slide rails 311 .

[0046] refer to figure 2 , 3 , 4, 5, 6, 7, and 8, the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com