Automobile fender trim cover assembly

A technology for automobile fenders and fenders, which is applied to vehicle parts, superstructures, radiators, etc., can solve the problems of difficult to control the size, difficult to control the gap and surface difference, etc., to achieve stable dimensional control, use of assembly space, and strength. good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

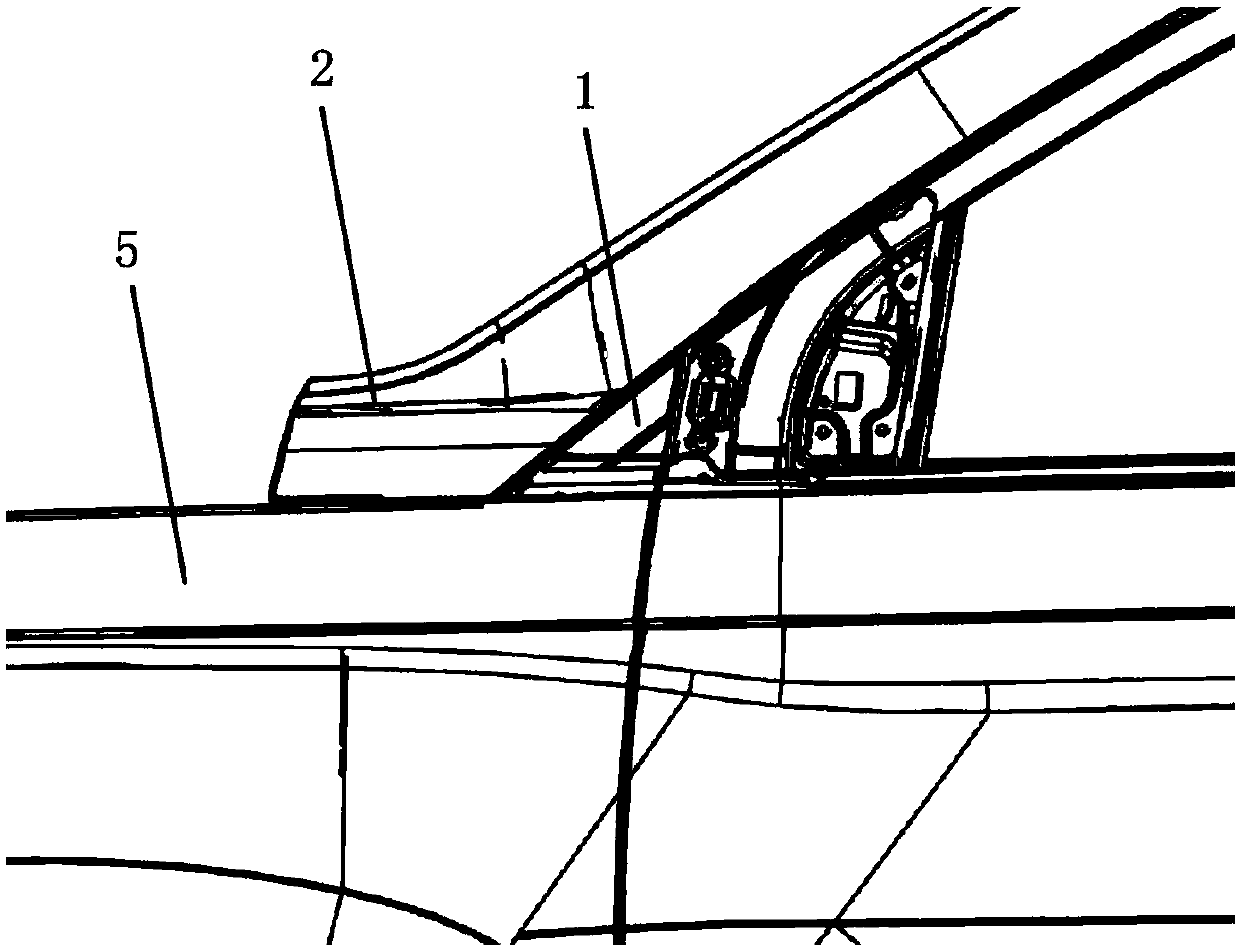

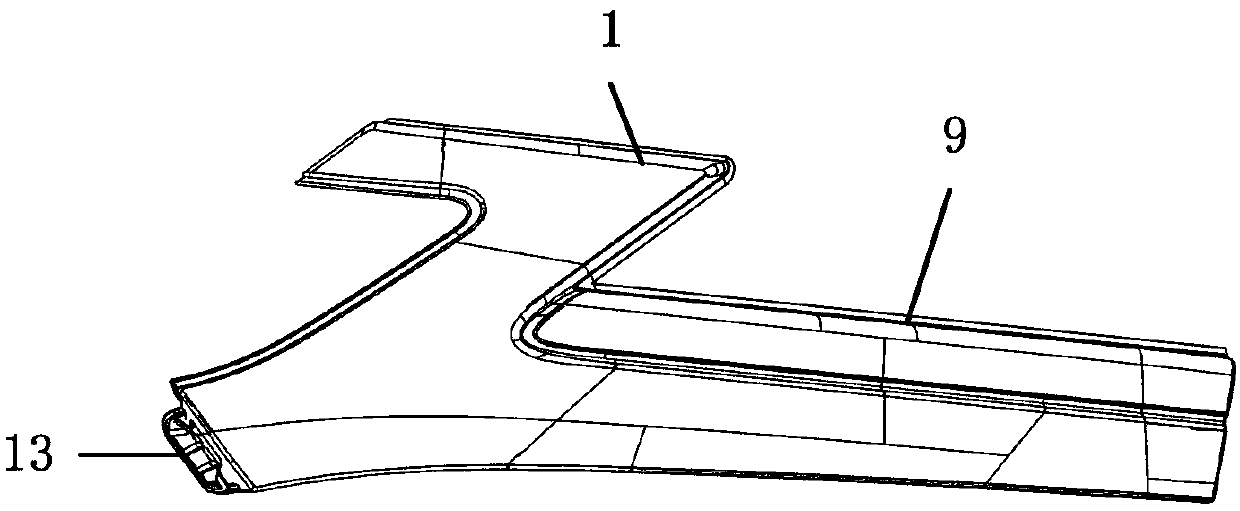

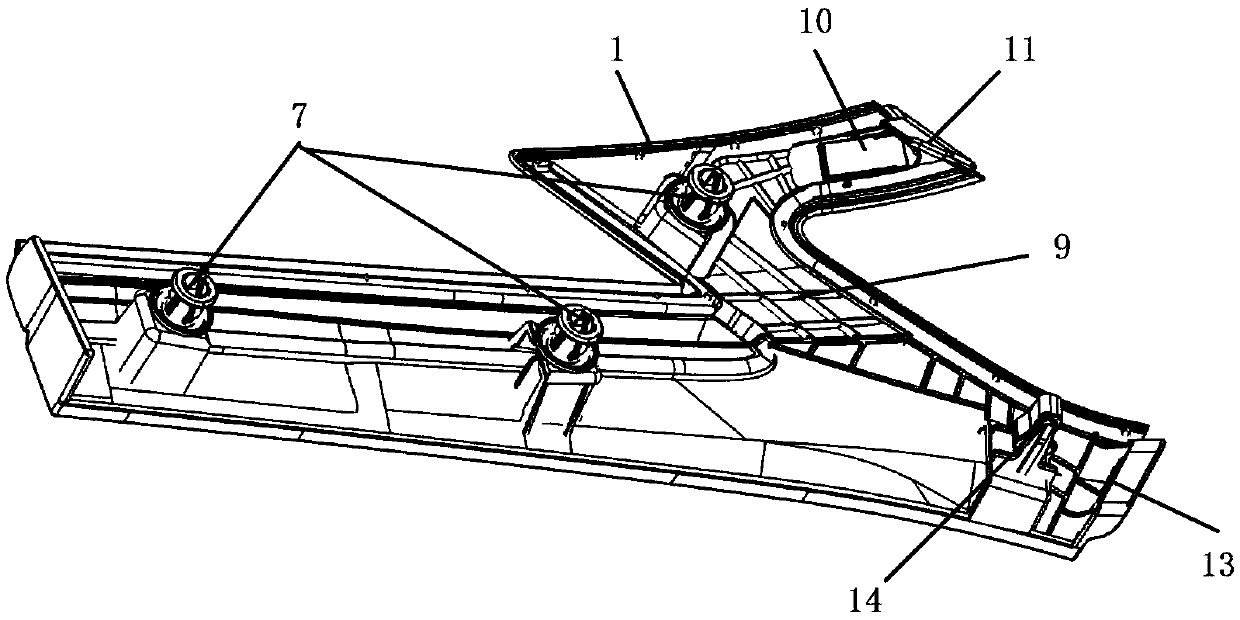

[0033] The following with attached Figure 2 to Figure 11 A car fender trim cover assembly of the present invention will be further described in detail.

[0034] A kind of automobile fender decorative cover assembly of the present invention, please refer to Figure 2-11 , including a decorative cover main body 1 with a longitudinal cross-sectional shape of "Z" shape, the upper part of the decorative cover main body 1 is detachably fastened to the side wall outer panel 2, and the front middle part of the decorative cover main body 1 is fixedly connected with the front ambient light 3 The lower front end of the decorative cover main body 1 is detachably and fixedly connected to the front grille 4, the lower part of the decorative cover main body 1 is detachably fastened to the fender main body 5, and the rear middle part of the decorative cover main body 1 is connected to the triangular window glass. 6 Sealed and fixed connection. In this way, the upper part of the decorative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com