A charge structure of solid rocket motor with adjustable combustion surface ratio and rocket motor

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems that the thrust cannot be adjusted in a large range, the combustion surface ratio cannot be adjusted in a large range, etc., and achieve easy thrust design and large firepower coverage. Scope, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

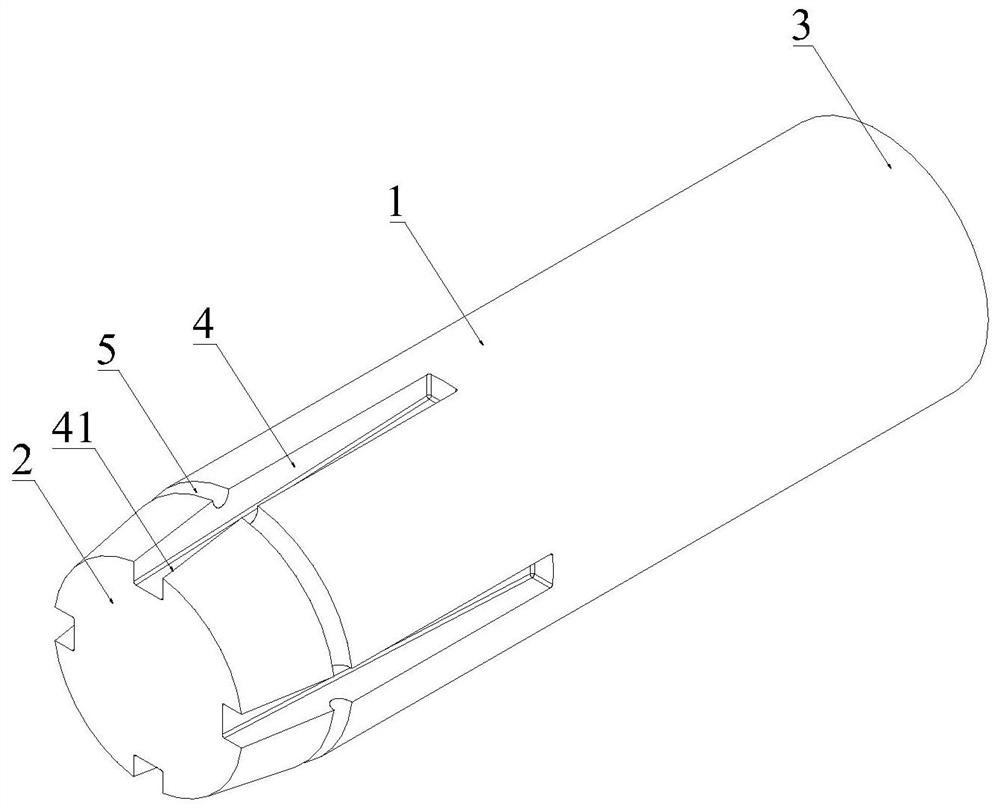

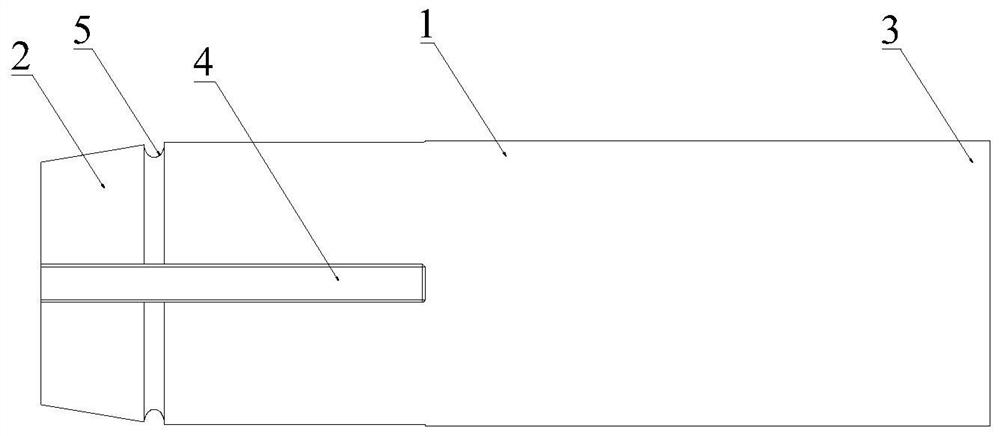

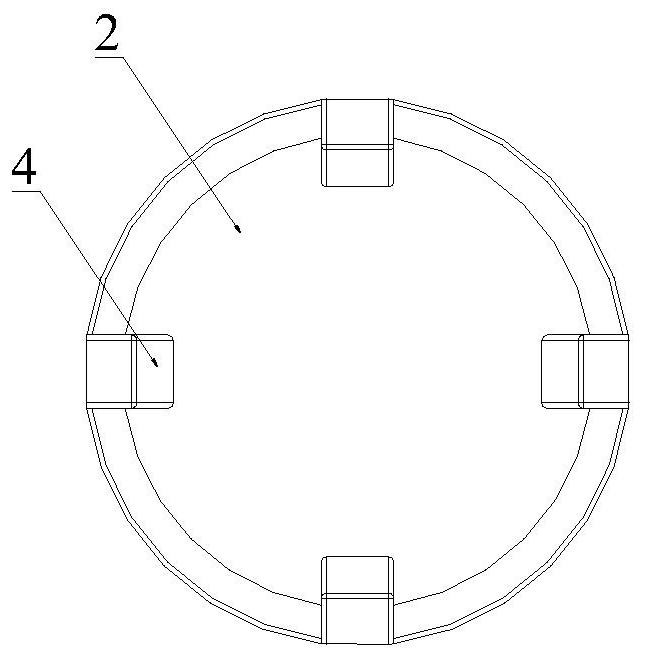

[0031] Such as Figure 1-3 As shown, the present application provides a solid rocket motor charge structure with adjustable combustion surface ratio, including: a charge body 1, a charge head 2 and a charge tail 3 integrally formed at both ends of the charge body 1, The charge body 1 is columnar, and the charge body 1 is a solid cylinder; the charge structure starts to burn from the outer surface of the charge head 2, and then burns the charge body 1 and the charge tail 3.

[0032] Such as figure 1 As shown, the charge head 2 is frustum-shaped, and the end of the charge head 2 with a larger diameter is connected to the charge body 1; the axial combustion of the charge structure is realized through the frustum-shaped charge head 2, and the shaft Combustion is burning from one end with a smaller diameter of the charge head 2 to an end with a larger diameter.

[0033] Such as figure 1 , figure 2 with image 3 As shown, the outer peripheral surface of the charge head 2 is ev...

Embodiment 2

[0061] A rocket motor, comprising a solid rocket motor charge structure with adjustable combustion surface ratio, and also includes a combustion chamber, a drug baffle and a nozzle, the solid rocket motor charge structure is arranged in the combustion chamber, the nozzle communicates with the combustion chamber, and the baffle The medicine plate is arranged at the junction of the nozzle and the combustion chamber.

[0062] The beneficial effect that this application realizes is as follows:

[0063] (1) The fuel-to-surface ratio of the charge structure of the present application can be adjusted to realize the reasonable distribution of the thrust of the solid rocket motor in the working time, and realize the dynamic characteristics of the single chamber and double thrust of the solid rocket motor. The solid rocket motor produces greater acceleration under the action of high thrust in the early stage of work, which can make the missile fly away quickly and avoid exposing the lau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com