Spiral fluid disturbance and vibration suppression device for marine riser

A helical and riser technology, applied in the field of marine riser helical turbulence and vibration suppression devices, can solve the problem of poor omnidirectional vortex-induced vibration vibration suppression effect, high design, manufacturing and installation costs, and increased riser drag force, etc. problem, to achieve the effect of good omnidirectional vibration suppression efficiency, easy processing and installation, and good resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

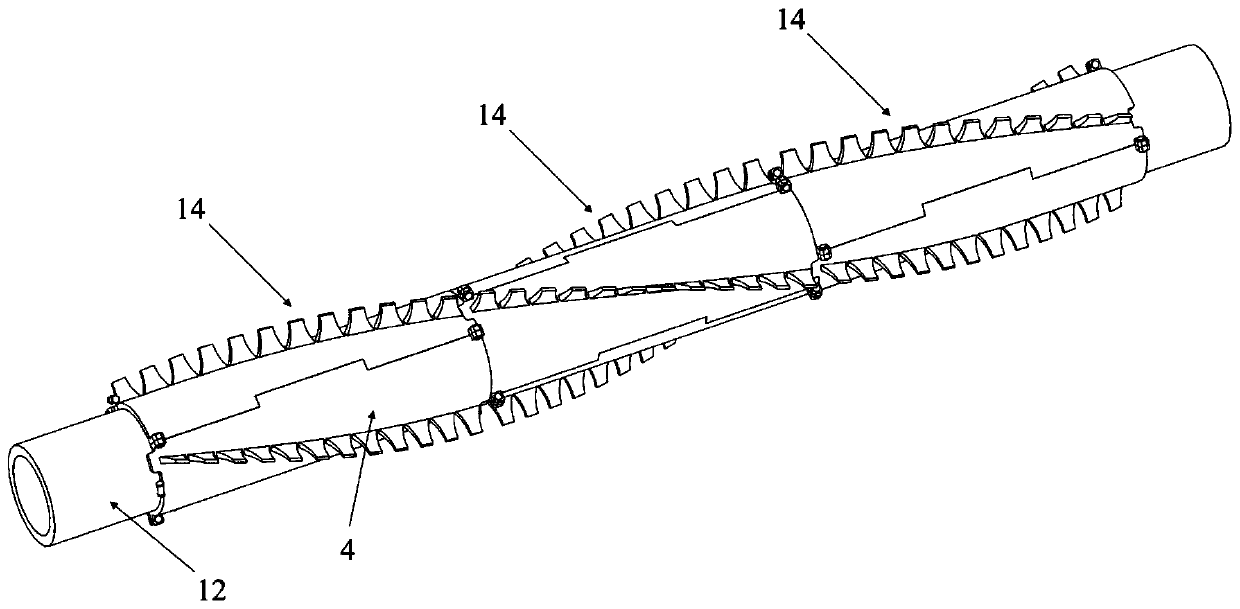

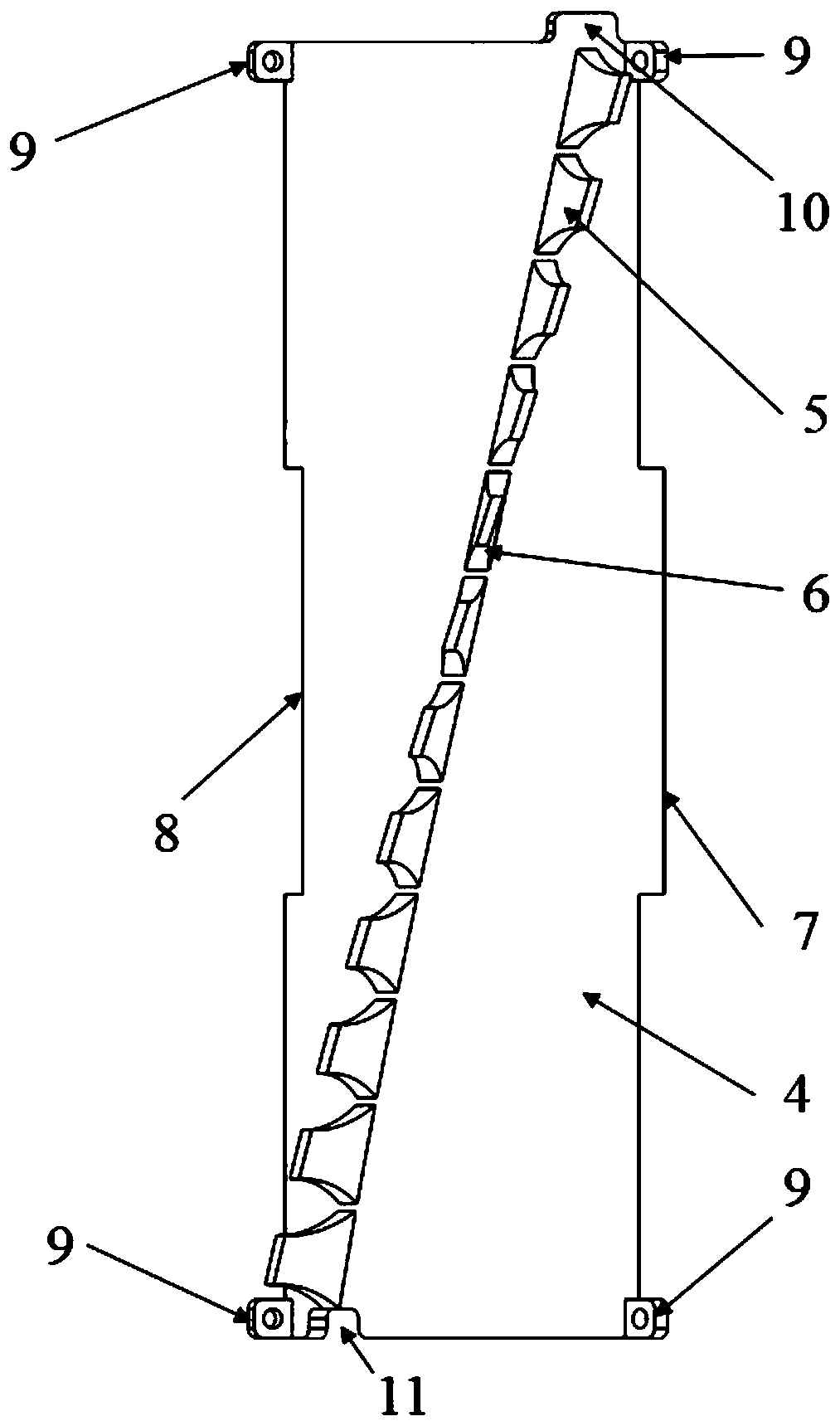

[0047] see figure 1 Referring to Fig. 4, the present invention provides a spiral turbulence suppression device for marine risers, including a riser 12;

[0048] The outer surface of the riser 12 is nested with successively connected multi-section riser sleeves 14 (not limited to figure 1 the three shown);

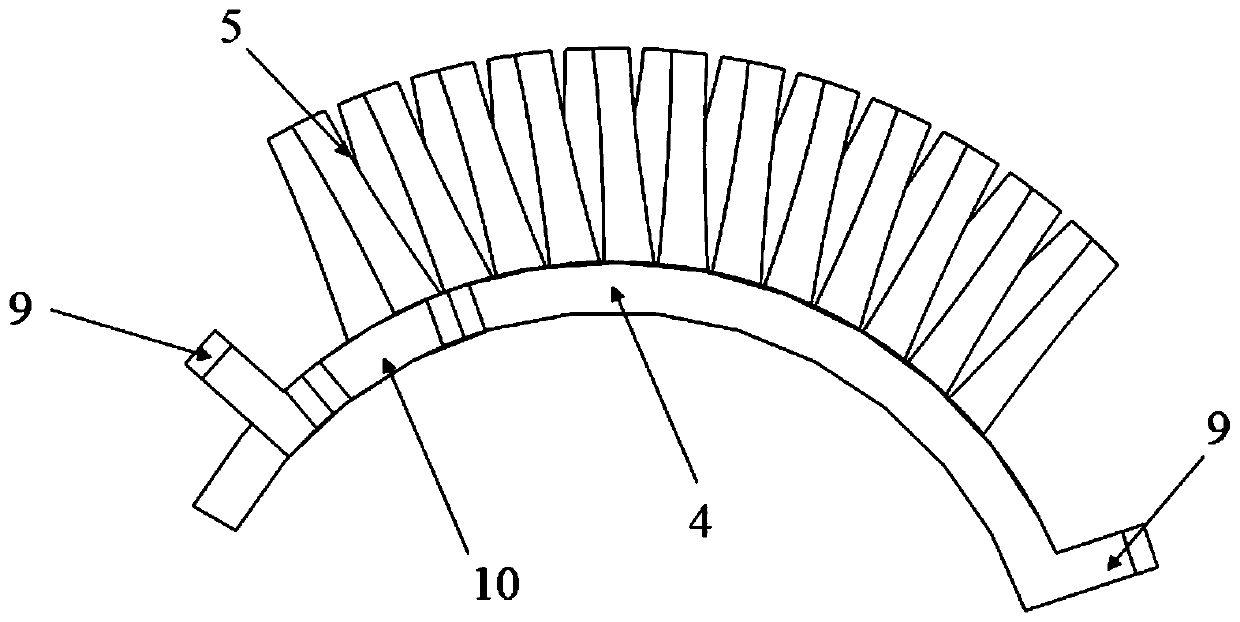

[0049] The outer surface of each riser sleeve 14 has three baffle sets 6 welded at equal intervals;

[0050] Each spoiler set 6 includes a plurality of spoilers 5 distributed in a spiral shape;

[0051] In each spoiler set 6 , the distance between any two adjacent spoilers 5 is equal.

[0052] In the present invention, the length of each riser sleeve 14 is 3 to 5 times the outer diameter of the standpipe 12;

[0053] The inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com