Socket and spigot telescopic type closing joint device

A telescopic, socket ring technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of harsh construction environment, difficult construction, and high construction cost, saving construction time for emergency repairs, The installation and operation are easy to learn and the effect of low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

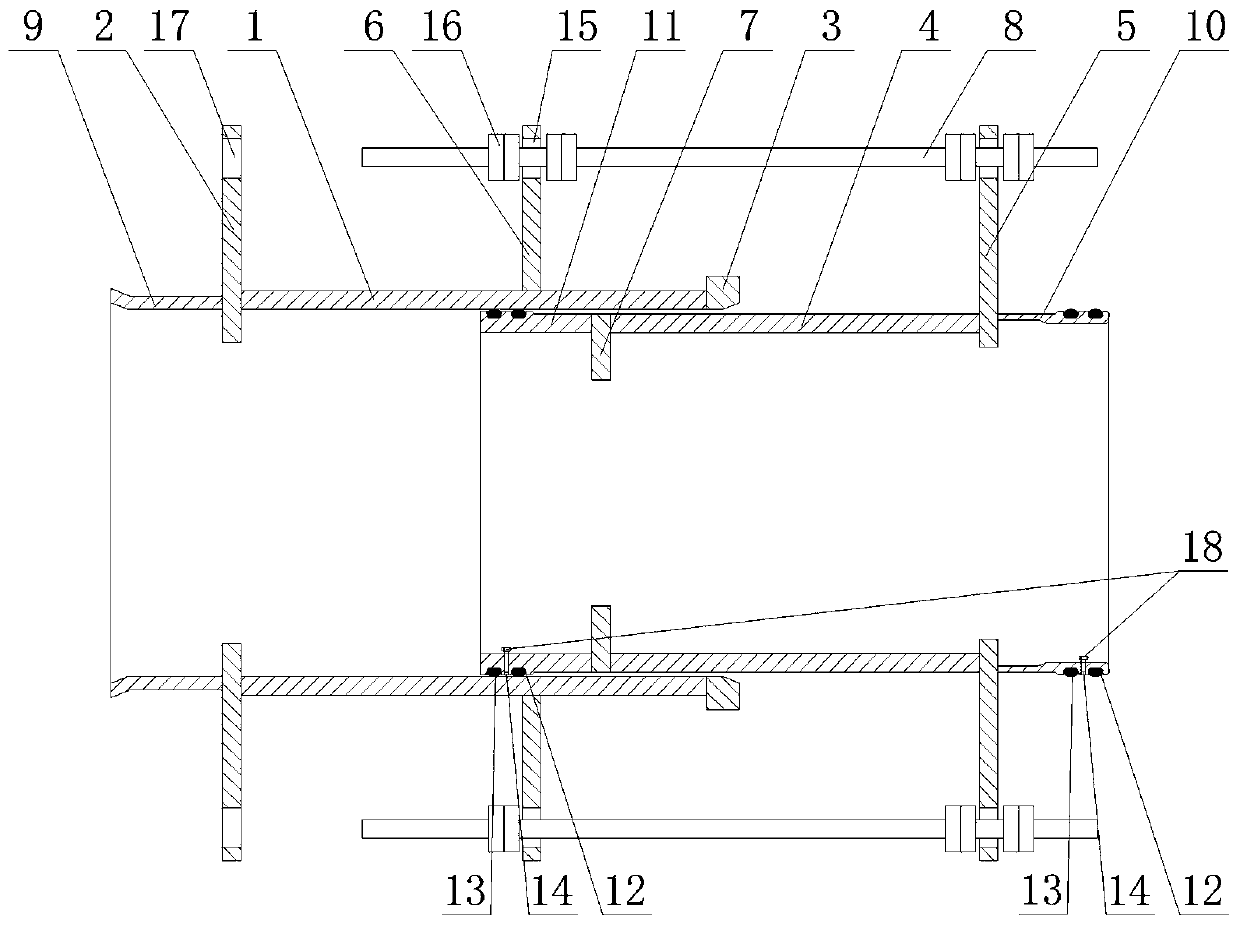

[0011] A socket telescopic closing joint device, comprising a socket pipe 1, a socket pipe connecting ring 2, a socket end ring 3, a socket pipe 4, a socket pipe connecting ring 5, an outer reinforcing ring 6, an inner reinforcing ring 7 and A plurality of limit screw rods 8, the main point of which is that the socket pipe connecting ring 2 is fixedly arranged on the nozzle of the socket pipe 1 outer end, and a socket ring 9 is fixedly arranged on the outer end surface of the socket pipe connecting ring 2 . The socket end ring 3 is fixedly arranged on the nozzle of the inner end of the socket pipe 1 , and the outer reinforcing ring 6 is fixedly sleeved on the outer wall of the socket pipe 1 . The socket pipe 4 is inserted in the socket pipe 1, the socket pipe connecting ring 5 is fixedly arranged on the nozzle of the socket pipe 4 outer end, and the socket ring 10 is fixedly arranged on the outer end surface of the socket pipe connecting ring 5, the described The inner reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com