Heat pump steam engine and phase change casing pipe type heat exchanger used for heat pump steam engine

A steam engine and heat exchanger technology, applied in the direction of indirect heat exchangers, heat exchanger types, steam generation, etc., can solve the problems of efficient use of unfavorable heat, large losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

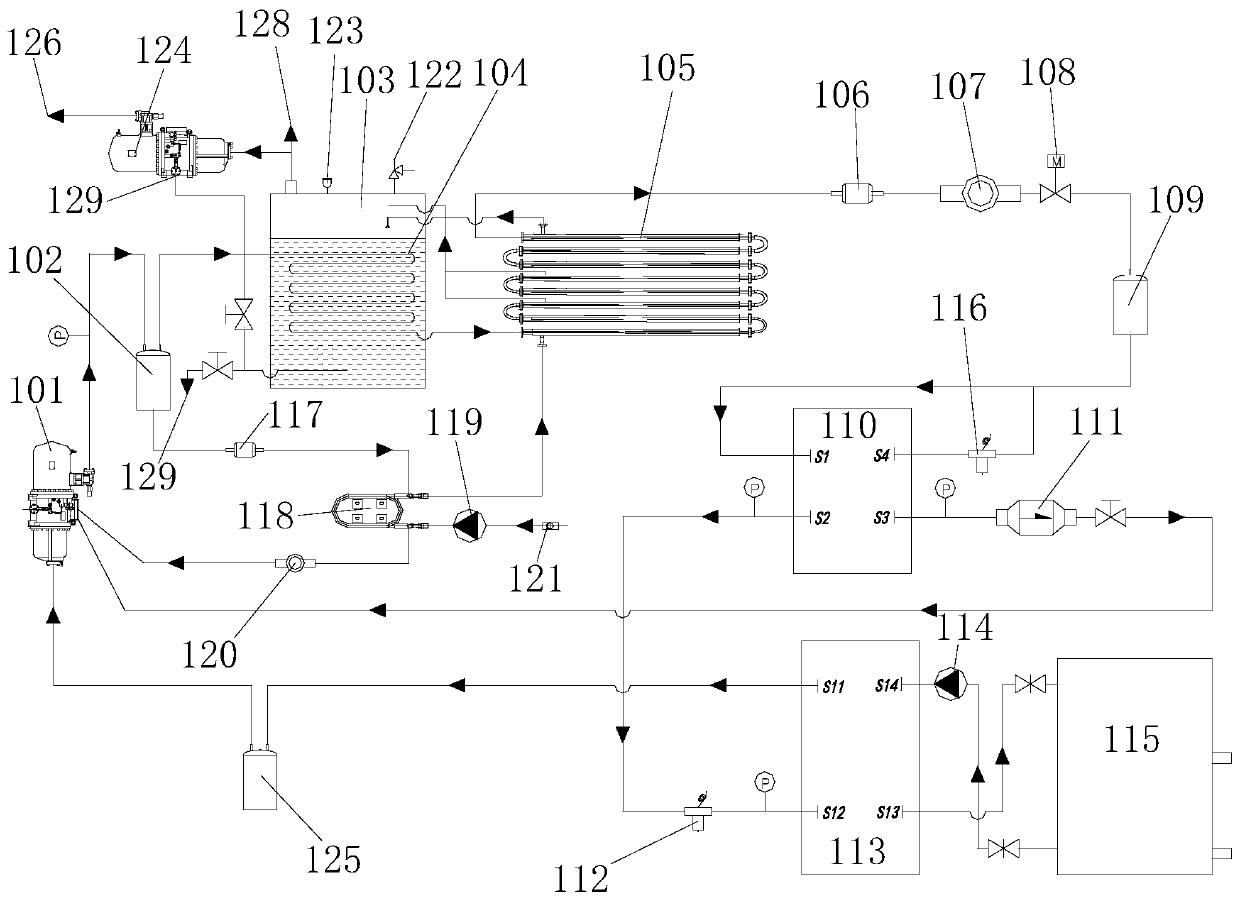

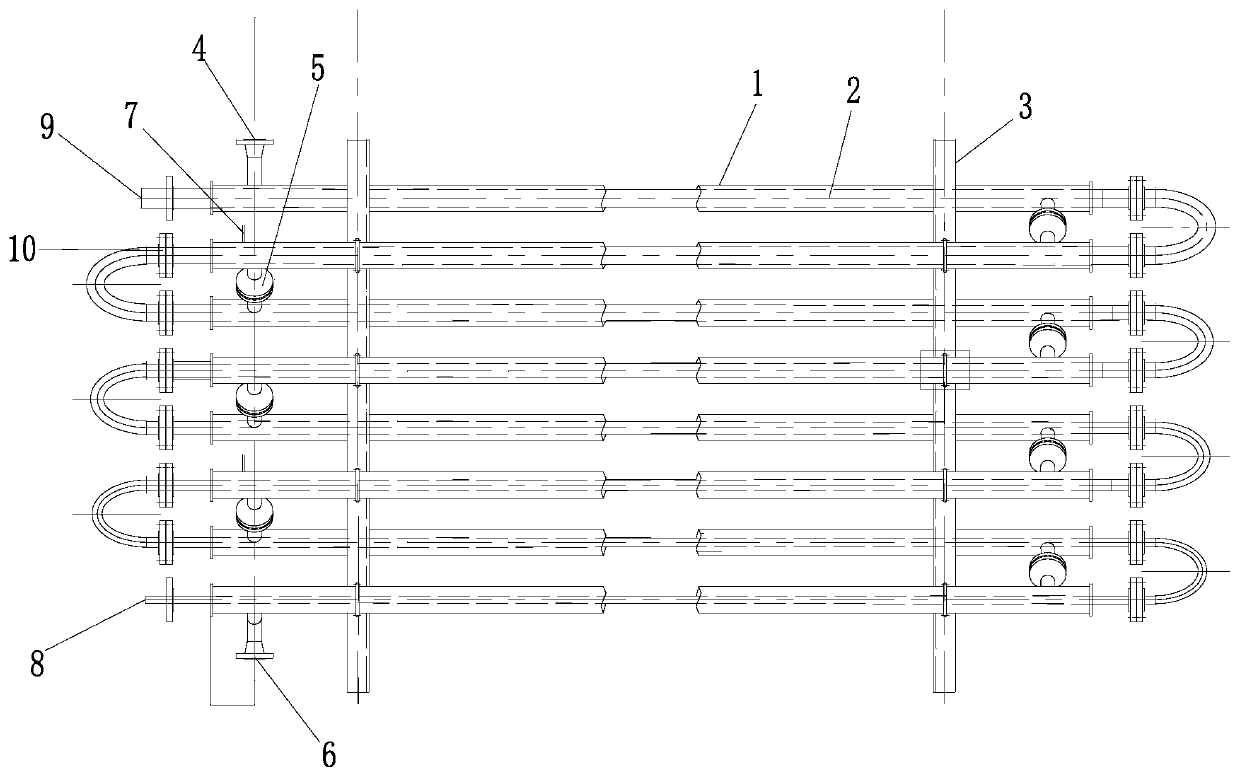

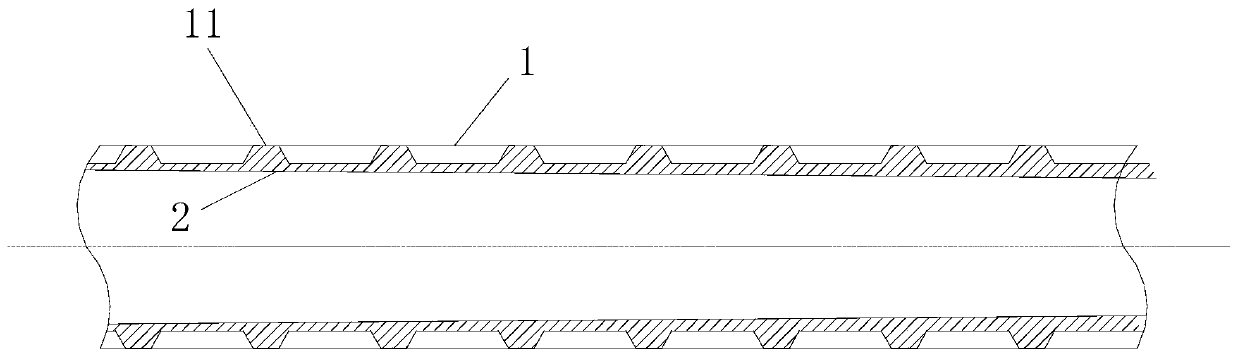

[0020] refer to Figure 1 to Figure 4 , is a heat pump steam engine, including a refrigerant compressor 101, a steam compressor 124, a primary condenser 104, a secondary condenser 105, an economizer 110, an evaporator 113, an oil cooler 118, a gas-liquid separator, and an oil separator Device 102, water inlet pump 119, circulating water pump 114, heat source water tank 115 and pressurized water tank 103, check valve 111, first filter 106, second filter 117, first sight glass 107, second sight glass 120 and related connecting pipes and valves; the primary condenser 104 is soaked in the pressurized water tank 103, and the refrigerant compressor 101 is sequentially connected to the oil separator 102, the primary condenser 104, the secondary condenser 105, the first filter 106, the second A sight mirror 107, a liquid storage tank 109, and an economizer 110; one outlet of the economizer 110 is connected to the refrigerant compressor 101 through a one-way valve 111, and the other ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap