Measuring device for measuring orifice chamfer angle

A technology for measuring devices and measuring holes, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problem that the measuring device cannot easily and quickly measure the chamfering angle of the workpiece hole, so as to facilitate manufacturing and improve convenience Sexuality and ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

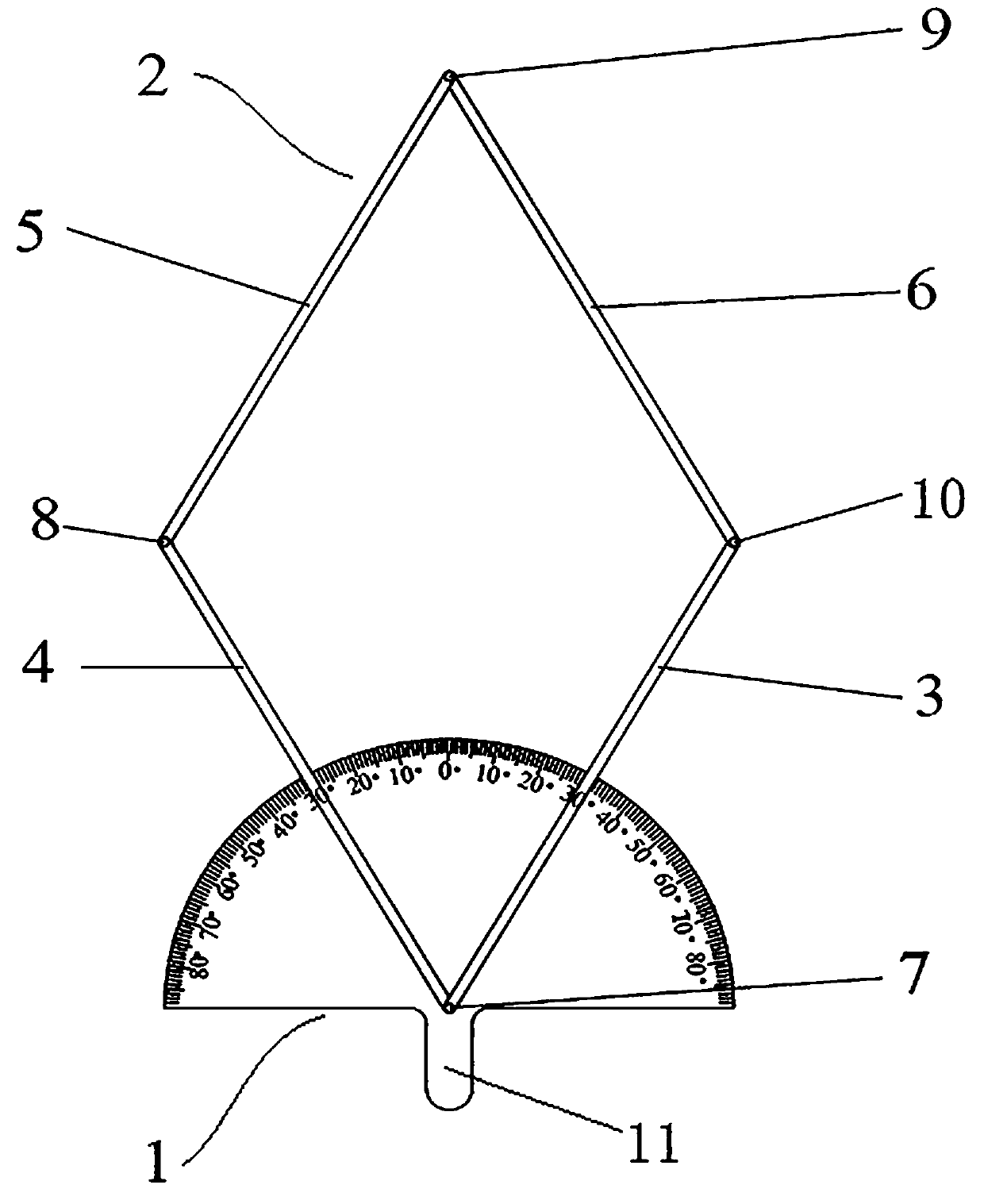

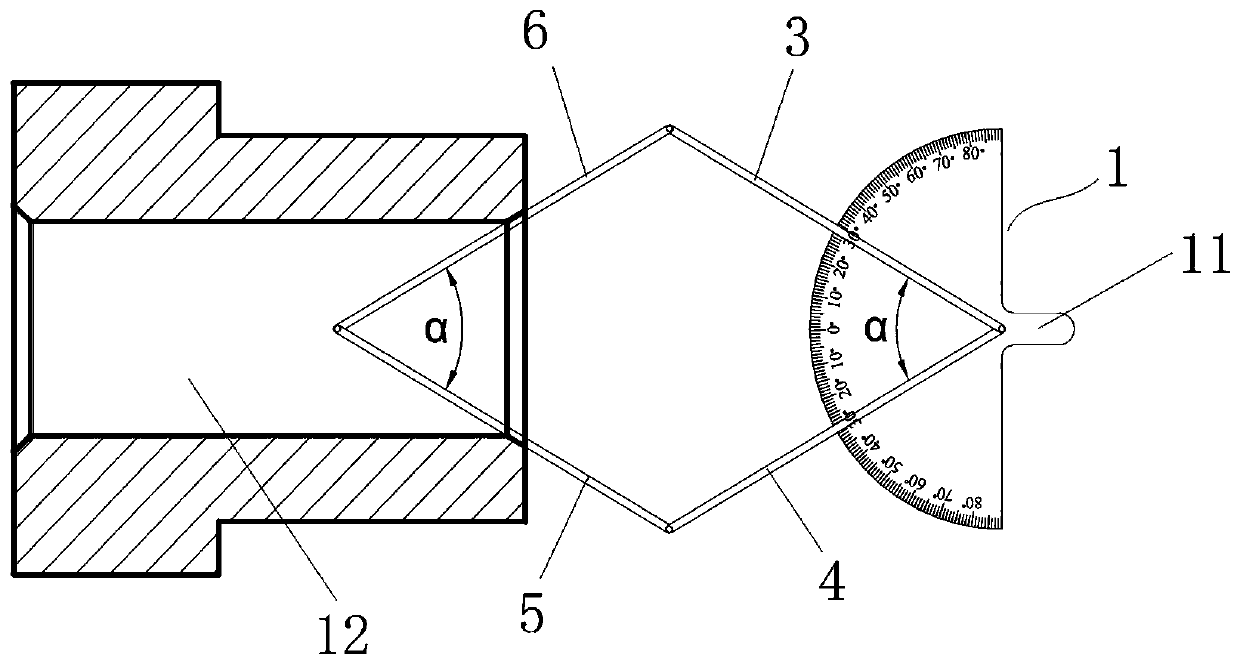

[0027] Specific embodiment 1 of the measuring device of the measuring orifice chamfering angle of the present invention: as figure 1 As shown, the measuring device includes a protractor 1 and a measuring stand 2 .

[0028] The measuring frame 2 is a planar four-bar linkage, including a first link 3, a second link 4, a third link 5 and a fourth link 6. The four links have equal lengths and are hinged from head to tail in turn. Wherein, the hinge axis between the first and second connecting rods is the first hinge axis 7, the hinge axis between the second and third connecting rods is the second hinge axis 8, and the hinge axis between the third and fourth connecting rods is The third articulated shaft 9 , the articulated shaft between the fourth and the first connecting rod is the fourth articulated shaft 10 .

[0029] While the first hinge shaft 7 realizes the hinged connection between the first and second connecting rods, it is also installed on the protractor 1 perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com