Bearing saddle detection system

A detection system and a technology for a load-bearing saddle, which are used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems that restrict the detection speed and efficiency of load-bearing saddles, are not suitable for online inspection of load-bearing saddles, and are easy to damage. Bearing saddle working face and other problems, to avoid human detection factors, fast detection speed, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

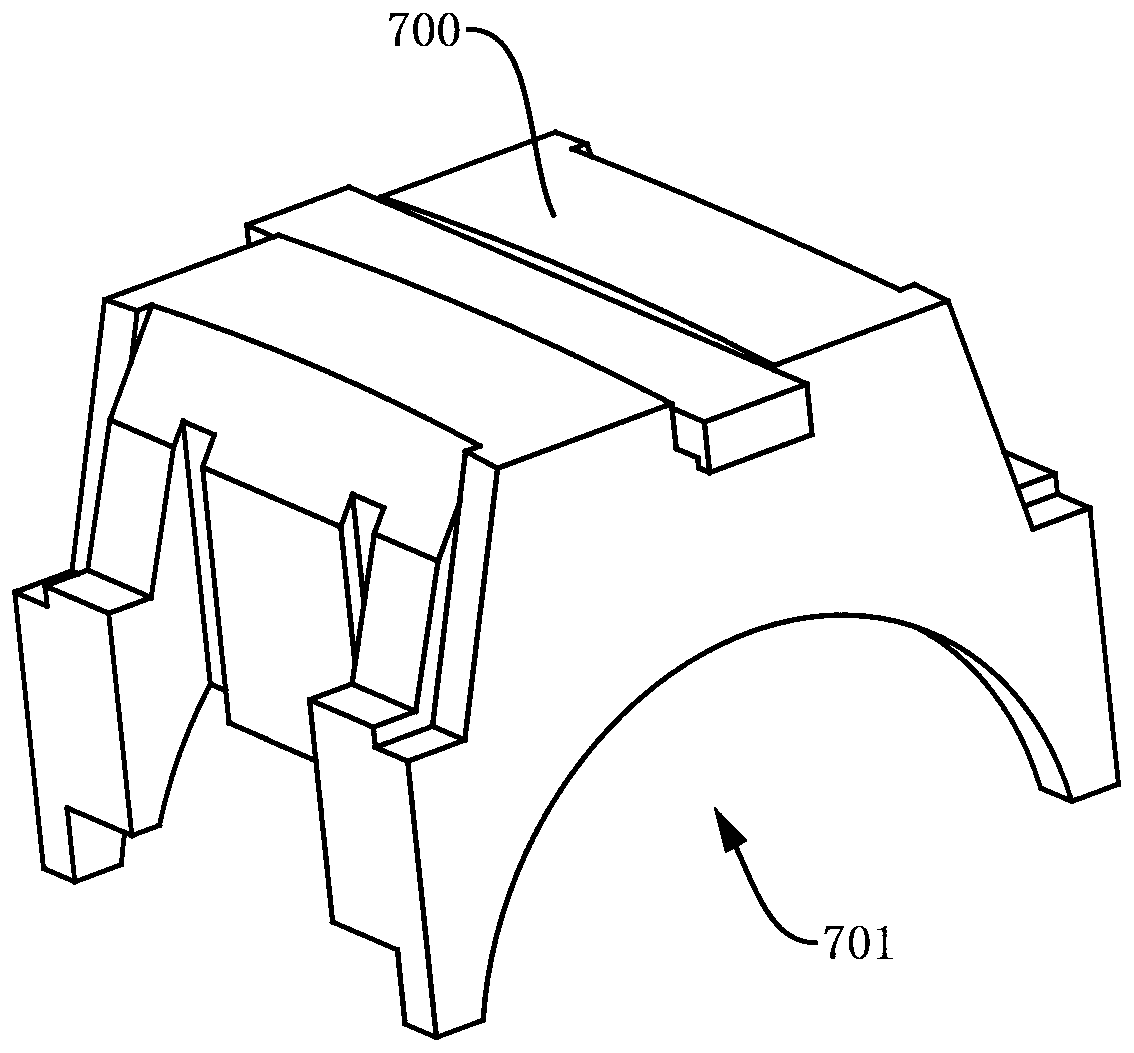

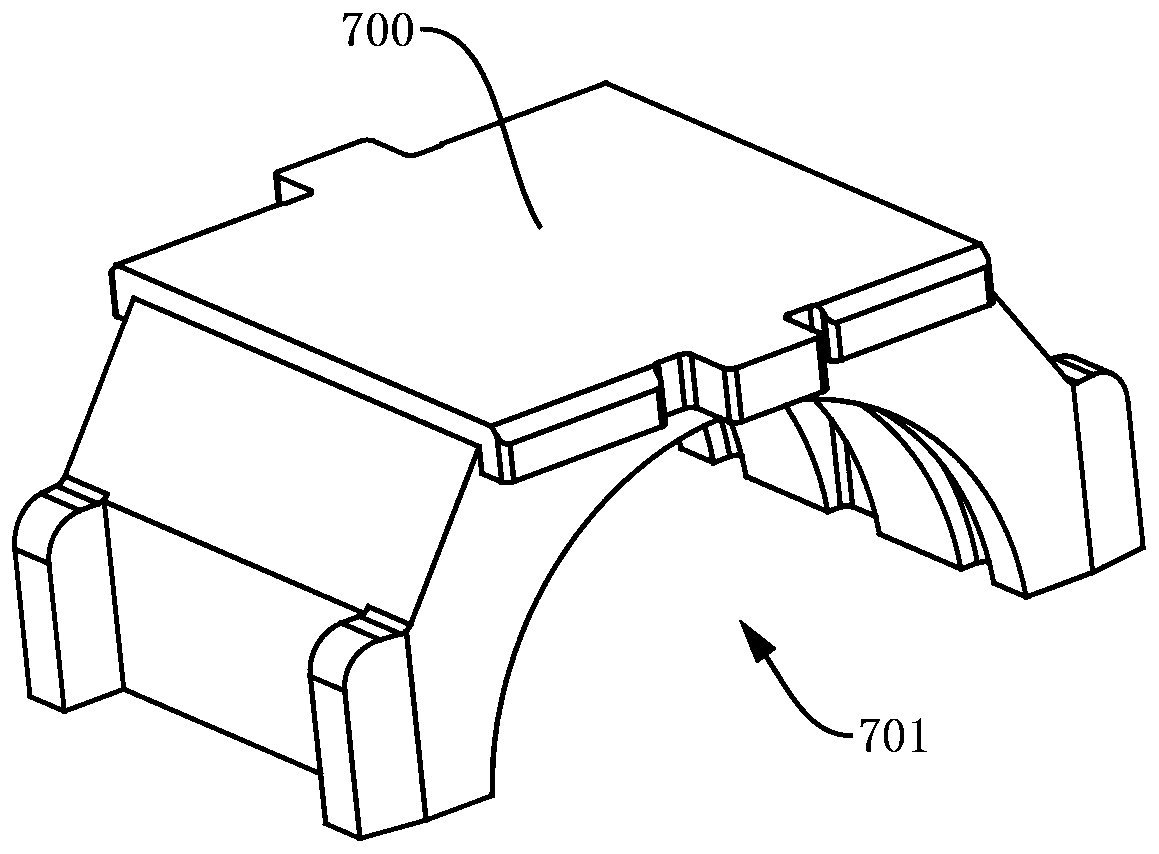

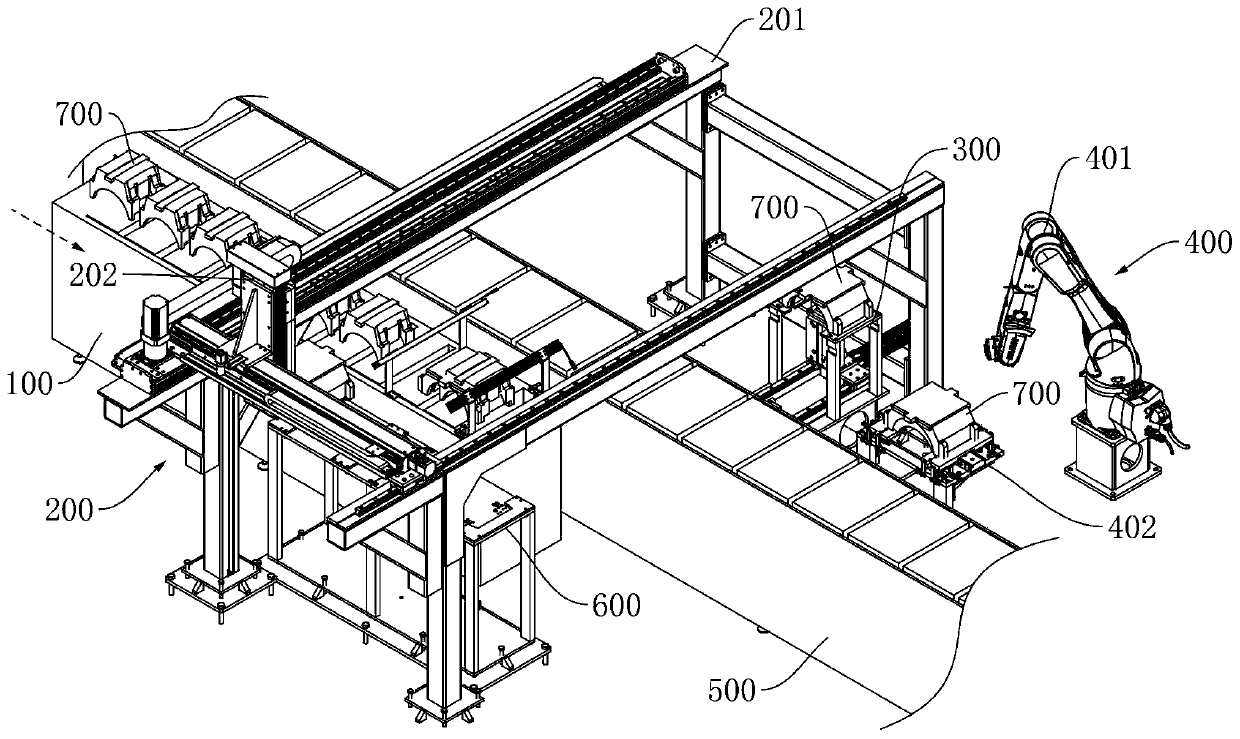

[0051] see Figure 3-Figure 6 , the present embodiment provides a bearing saddle detection system, including an entry conveyor line 100, a transfer module 200, a detection module 400, an exit conveyor line 500, and a controller, wherein the entry conveyor line 100, the transfer module 200 And the detection module 400 is respectively connected with the controller, the entry conveying line 100 is used to transport the bearing saddle 700 to be detected under the control of the controller, the detection module 400 is used to detect the bearing saddle 700, the The transfer module 200 is used to transfer the load bearing saddle 700 to be detected to the detection module 400 under the control of the controller, so that the load saddle 700 can be detected in the detection module 400, and the transfer module 200 is also used to transfer the load saddle 700 to be detected in the detection module 400. The loaded saddles 700 are transferred to the outgoing conveyor line 500, and the loade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com