Reaction cup lifting and rotating device and transfer mechanism

A technology for lifting, rotating and rotating mechanisms, applied in the field of medical devices, can solve the problems of easy damage of rotating mechanisms, complicated control circuits, and increased maintenance costs, and achieve the effect of reducing the depreciation speed, the range of lifting or rotating, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

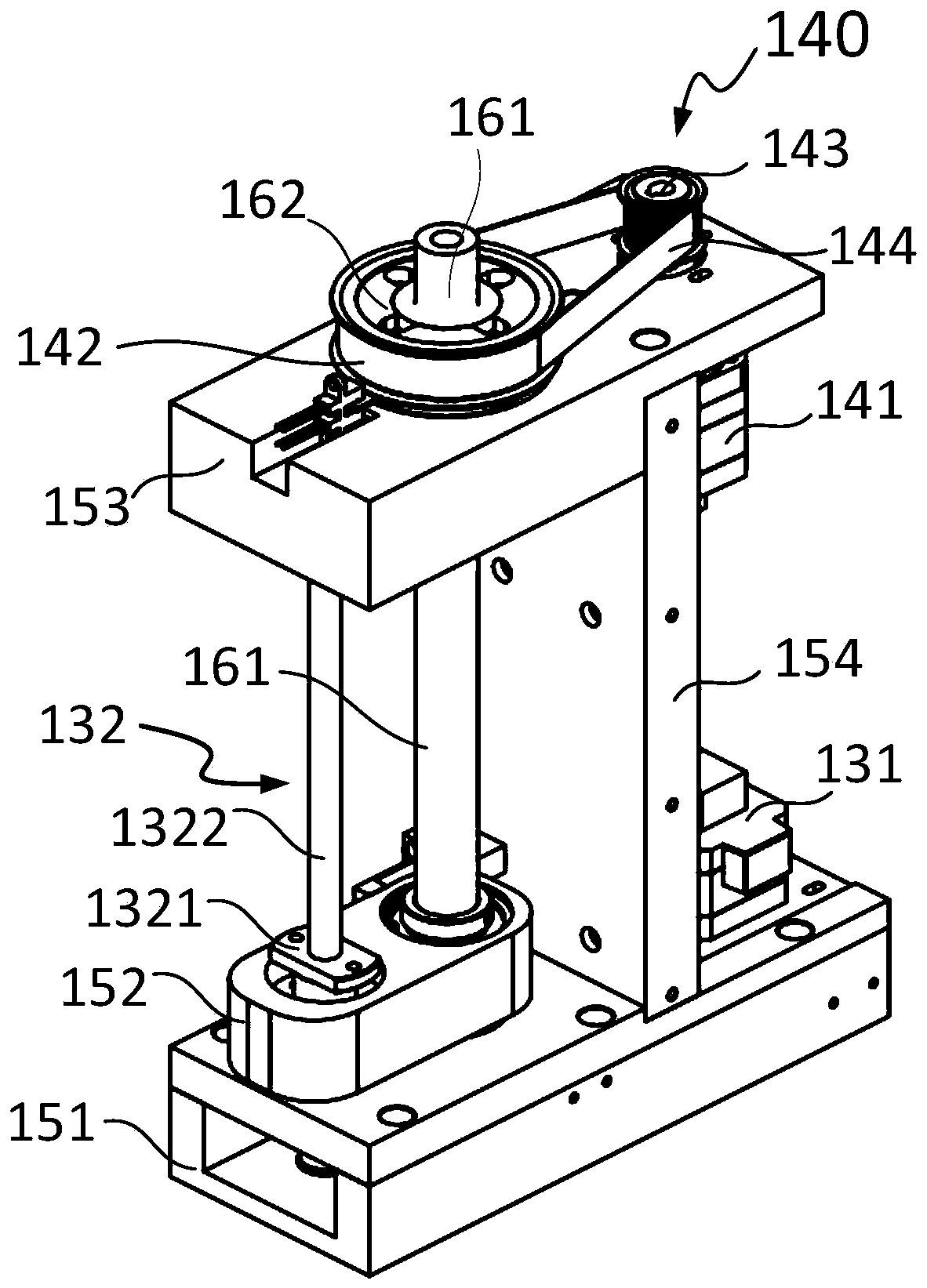

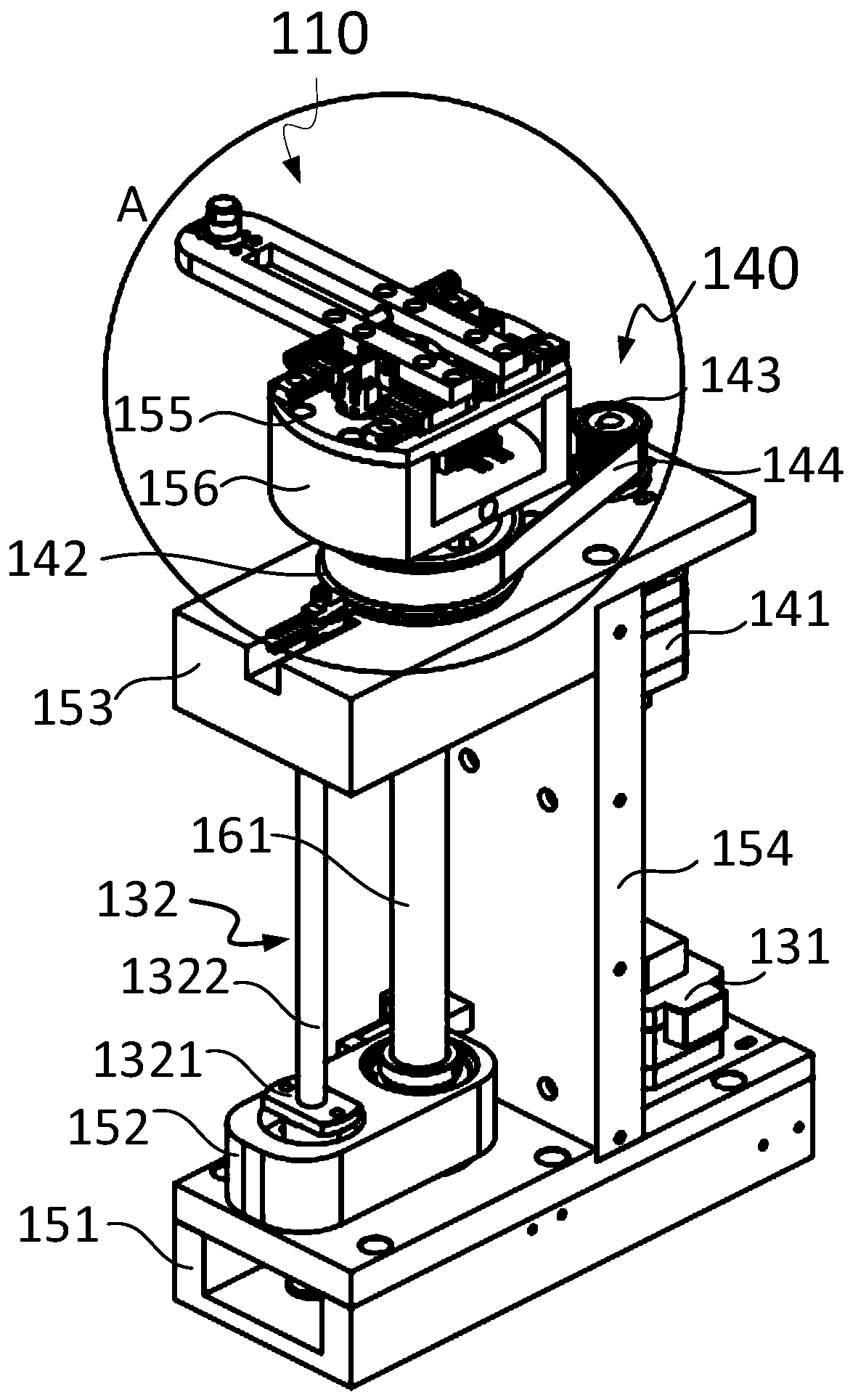

[0042] Such as Figure 1 to Figure 5As shown, the present invention provides a cuvette lifting and rotating device, which includes a lifting and rotating device body connected to a manipulator body 110 for grabbing a cuvette 200. The lifting and rotating device body includes a lifting mechanism 130 and a rotating mechanism 140. . A spline coupling assembly 160, the spline coupling assembly 160 includes a spline shaft 161 provided with a keyway and a rotating member 162 provided with a keyway, the rotating member 162 is sleeved on the outside of the spline shaft 161, the One end of the spline shaft 161 is connected with the lifting mechanism 130, the other end is used for connecting with the manipulator body 110, and the rotating mechanism 140 is connected with the rotating member 162; wherein,

[0043] The lifting mechanism 130 drives the spline shaft 161 to reciprocate axially in the rotating member 162, the rotating mechanism 140 drives the rotating member 162 to rotate, and...

Embodiment 2

[0053] Such as Figure 2 to Figure 7 As shown, the present invention also provides a cuvette transfer mechanism, including a manipulator body 110, a lifting and rotating device body as described in Embodiment 1, and a spline coupling assembly 160 between the manipulator body 110 and the lifting and rotating device body The spline shaft 161 is connected.

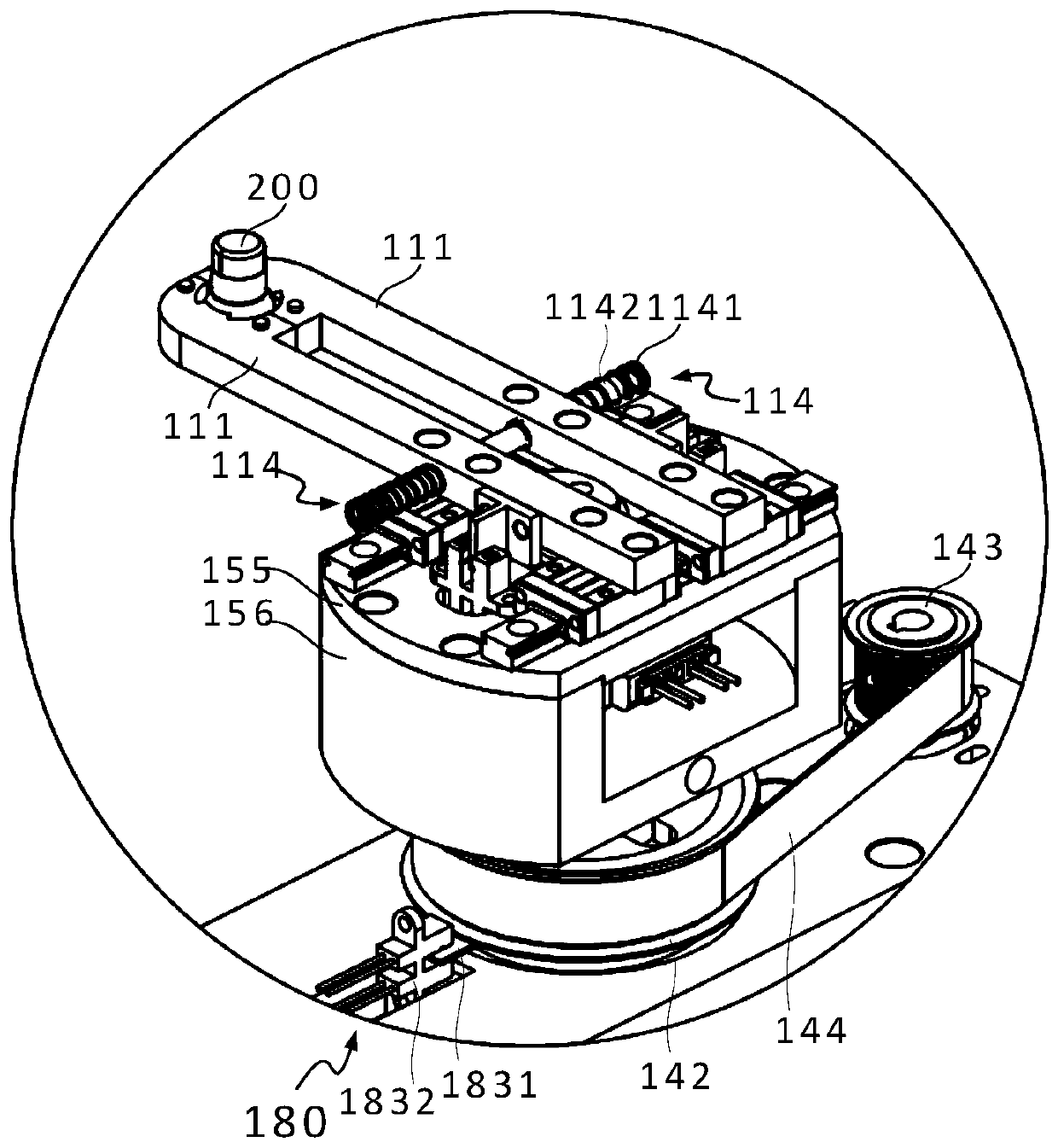

[0054] The manipulator body 110 includes two opposing jaws 111, a rotating device, a cam 113, two guide rails 115, and four sliders 116. One end of the two jaws 111 is provided with a clamp for grabbing the cuvette 200. The holding area 1111, the two jaws 111 are respectively connected with two sliders 116, and each guide rail 115 is respectively slidably connected with a slider 116 connected to the two jaws 111, and the outer sides of the two jaws 111 are respectively provided with reset members; wherein,

[0055] Described cam 113 is positioned at the middle of two jaws 111, and the length and width of described cam 113 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com