Process data fault classification method based on pseudo label method and weak supervised learning

A technology for labeling data and fault classification, applied in neural learning methods, character and pattern recognition, instruments, etc., can solve problems such as false labels and mislabeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

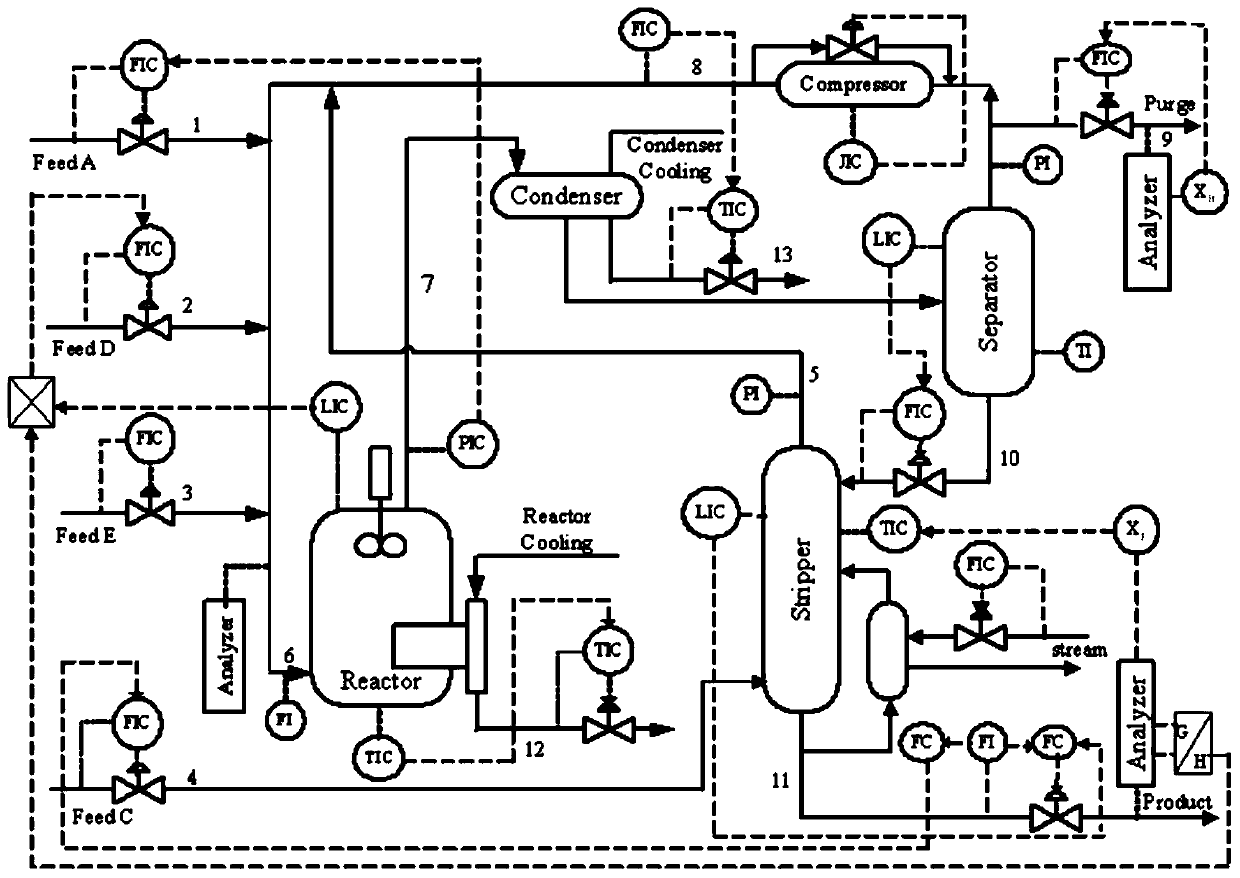

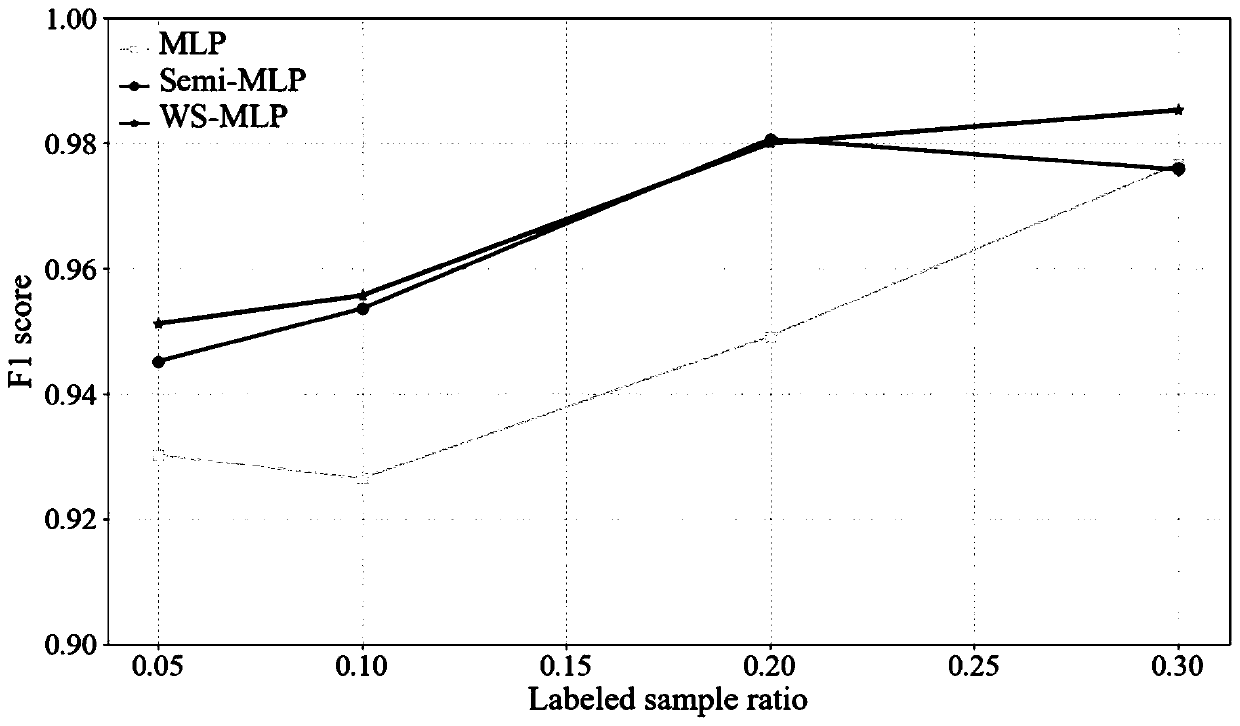

[0062] The fault classification method based on weakly supervised learning of the present invention will be further described in detail below in combination with specific implementation methods.

[0063] A fault classification method based on pseudo-label method and weakly supervised learning. The training process of this method based on pseudo-label method and weakly supervised learning can be divided into two stages:

[0064] (1) MLP labeled sample learning stage based on pseudo-label method

[0065] The MLP network pairs a labeled sample set D l_std Perform supervised training and use the cross-entropy loss function:

[0066]

[0067] in,(.) T represents a transpose operation, is the representation of the last layer of the MLP network, and θ is the MLP network parameter.

[0068] The loss adjusts the parameters of the entire MLP network through the backpropagation algorithm (BP). After multiple iterations of loss convergence, the optimal parameters of the entire net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com