Garbage disposal device

A garbage disposal device and garbage technology, which are applied in recycling technology, solid waste removal, electronic waste recycling, etc., can solve the problems of needing space, low bag breaking efficiency, and high weather requirements, and achieve high reliability and high reliability. Wide range of use and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

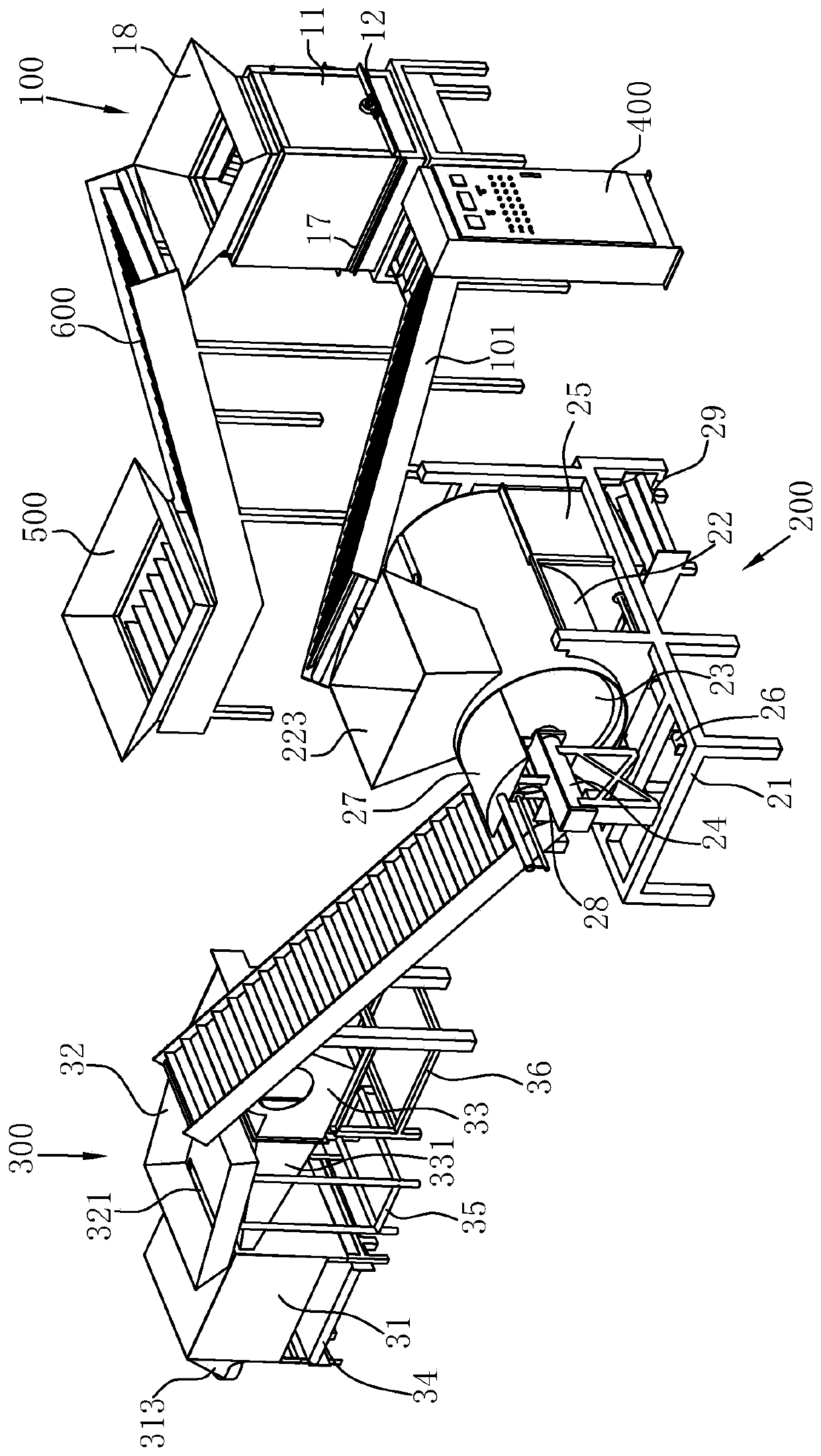

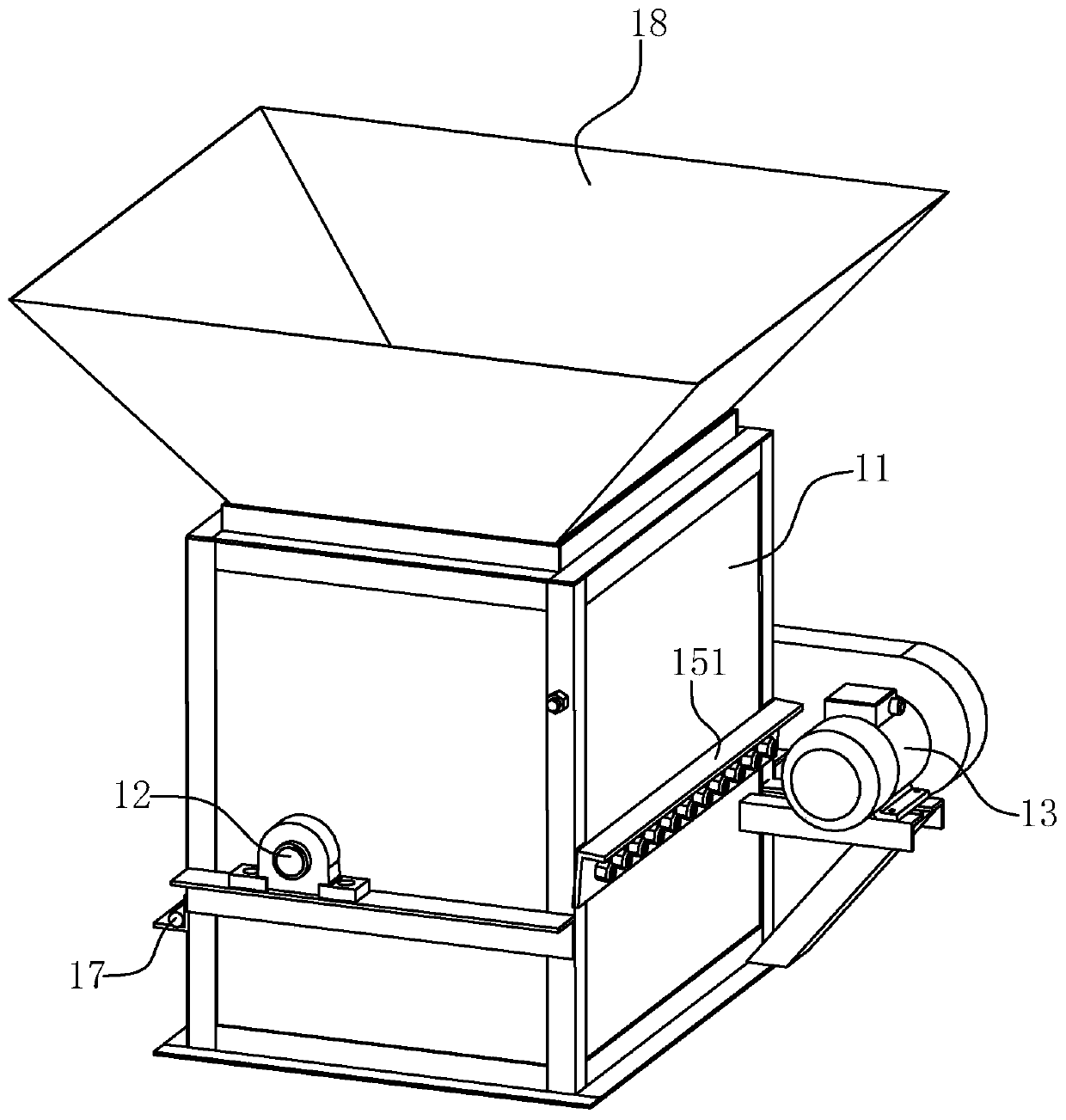

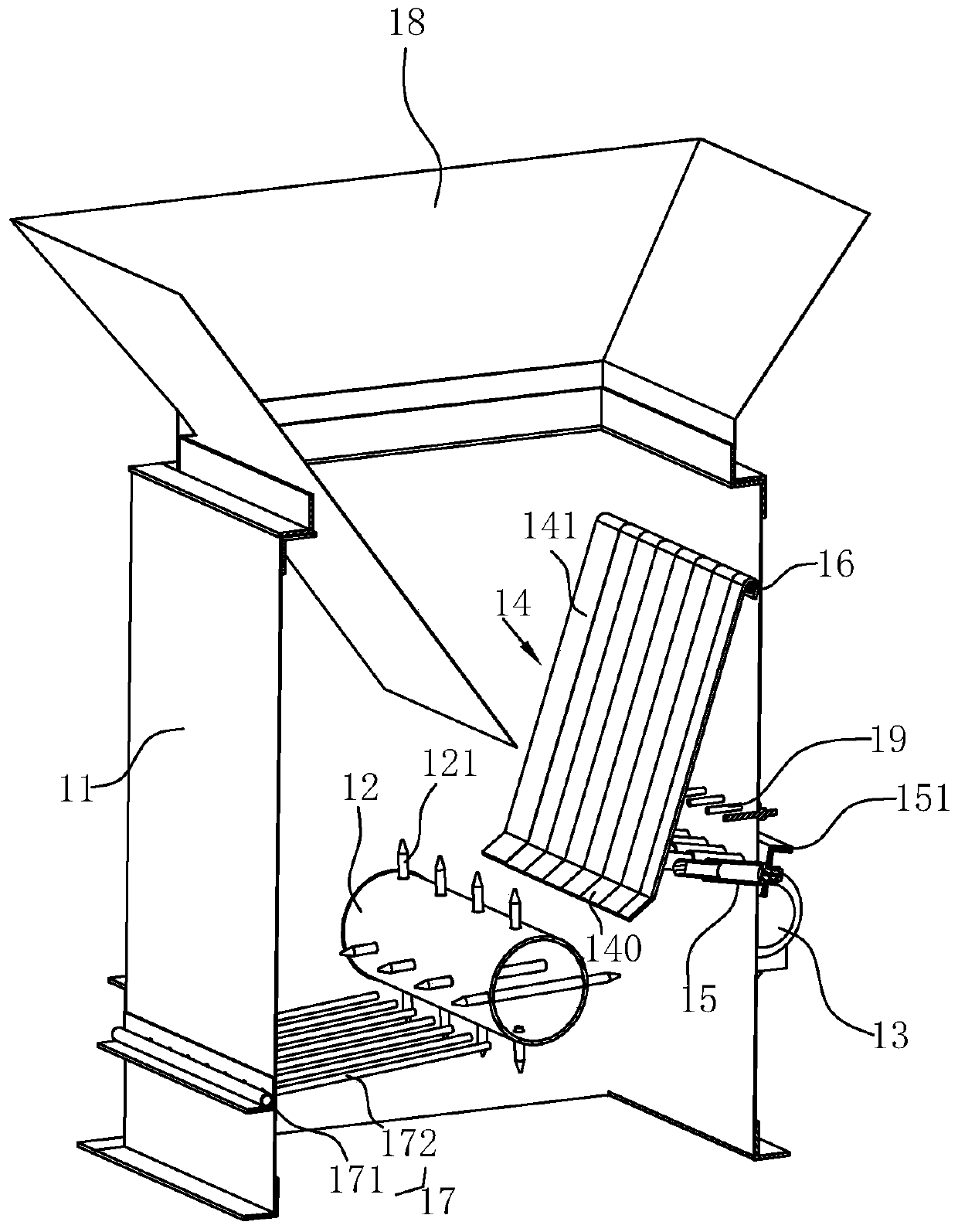

[0046] Such as figure 1As shown, the garbage processing device in this embodiment includes a garbage throwing unit 500 for putting garbage to be treated, and a garbage bag for breaking plastic bagged garbage so that the garbage in the garbage bag is scattered out of the garbage bag breaking unit 100 , the garbage solid-liquid separation unit 200 for realizing the solid-liquid separation of garbage, the garbage sorting unit 300 for separating light garbage and heavy garbage, and the garbage bag breaking unit 100 and garbage solid-liquid separation unit 200 that are scattered with garbage respectively 1. The control cabinet 400 electrically connected to the garbage sorting unit 300, and the units are connected by transmission belts, wherein the dispensing unit 500 is located upstream of the garbage bag breaking unit 100, and the dispensing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com