A method for monitoring and adjusting the vibration of a cold tandem rolling mill

A technology of vibration monitoring and adjustment method, applied in rolling mill control device, metal rolling, metal rolling and other directions, can solve the problems of not meeting the production needs of users, abnormal fluctuation of rolling force and tension between stands, poor effectiveness, etc. Achieve the effect of achieving normal and stable production, improving production efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings of the present invention. In order to keep the following description of the present invention clear and concise, a detailed description of known techniques is omitted in the detailed description.

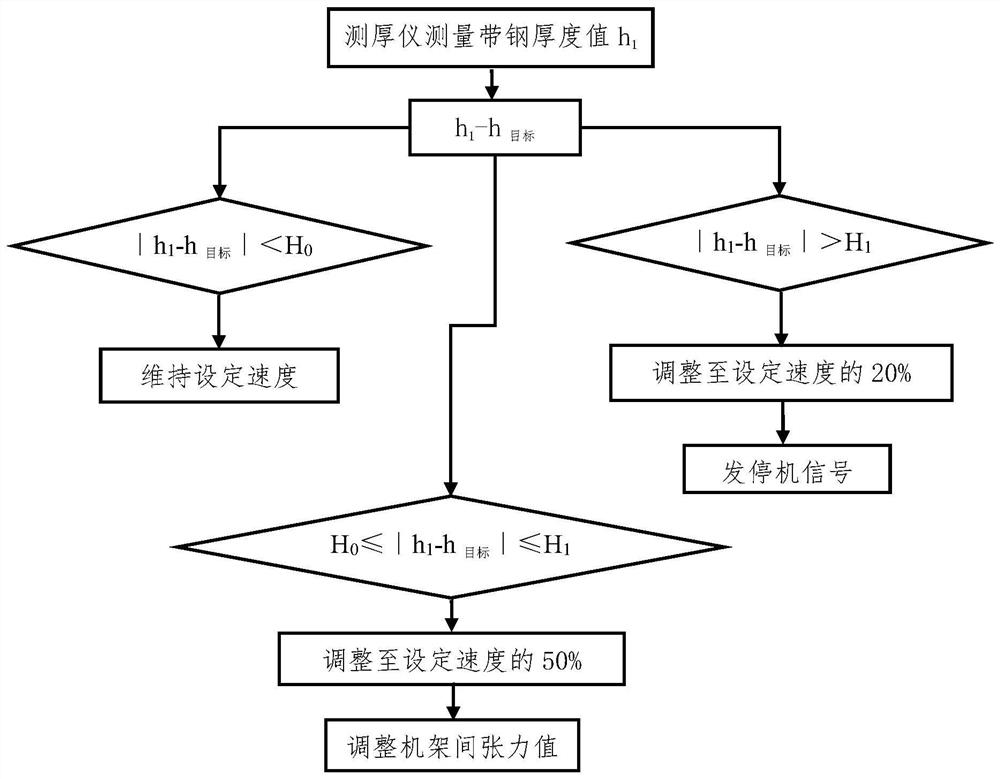

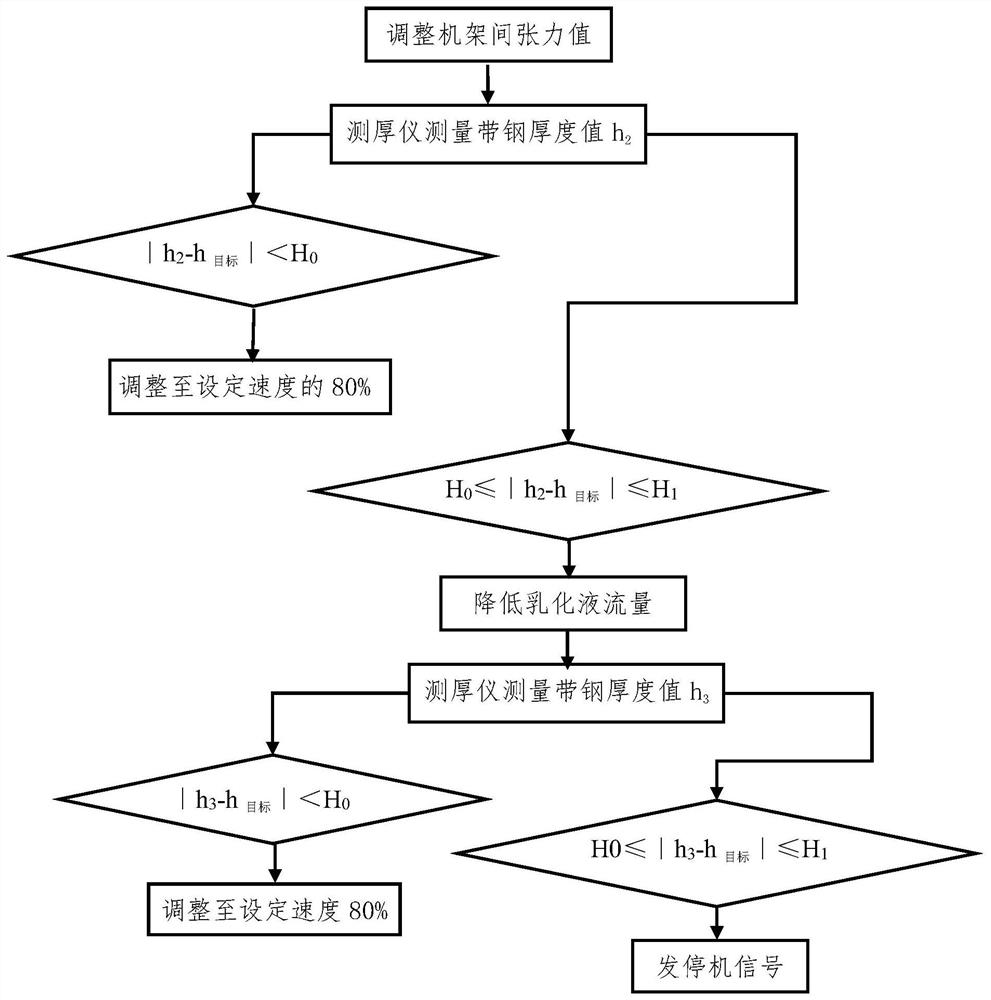

[0024] When the cold tandem rolling mill rolls the strip, the absolute value of the difference between the measured value of the strip thickness and the target value of the strip thickness, that is, the fluctuation of the strip thickness is considered to be a normal fluctuation when it is less than a certain safe value range, when the fluctuation of the strip thickness during the vibration process of the rolling mill exceeds a certain critical value, the risk of strip breaking due to the vibration of the rolling mill is very high, and the rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com