Electric C-shaped nail gun

A nail gun and electric technology, applied in nailing tools, nailing staple tools, manufacturing tools, etc., can solve the problems of C-shaped nails offset, poor running stability, and frustration, and avoid jamming and deviation. The effect of moving, running smoothly, and preventing occlusal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

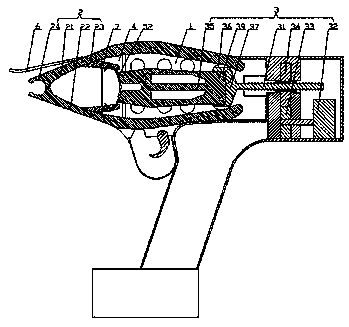

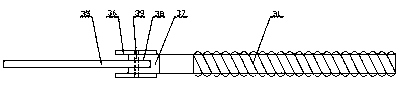

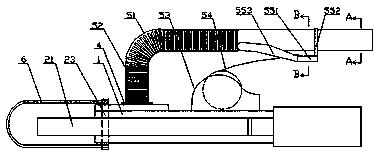

[0032] Such as figure 1 It shows an embodiment of an electric C-shaped nail gun of the present invention, including a gun housing 1, a clamp mechanism 2 and a driving mechanism 3 inside the gun housing 1, and one side of the gun housing 1 has a C-shaped nail 52 embedded in it. One end of the driving mechanism 3 is in contact with the C-shaped nail 52 and pushes the C-shaped nail 52 to move toward the outlet end of the clamp mechanism 2, and the outlet end of the clamp mechanism 2 gradually expands with the push of the driving mechanism 3 , the outlet end of the clamp mechanism 2 gradually gathers together with the contraction of the drive mechanism 3;

[0033] The driving mechanism 3 includes a screw mandrel 31, a motor 32, a first helical gear 33, a second helical gear 34, and a push block 35. The rotation of the motor 32 drives the first helical gear 33 and the second helical gear 34 meshing with each other to rotate so as to realize the rotation of the screw mandrel. 31 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com