Lightweight cooperative robot with quick-disassembly connection mode

A connection method and robot technology, applied in the field of robots, to achieve the effects of easy batch processing, increased service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

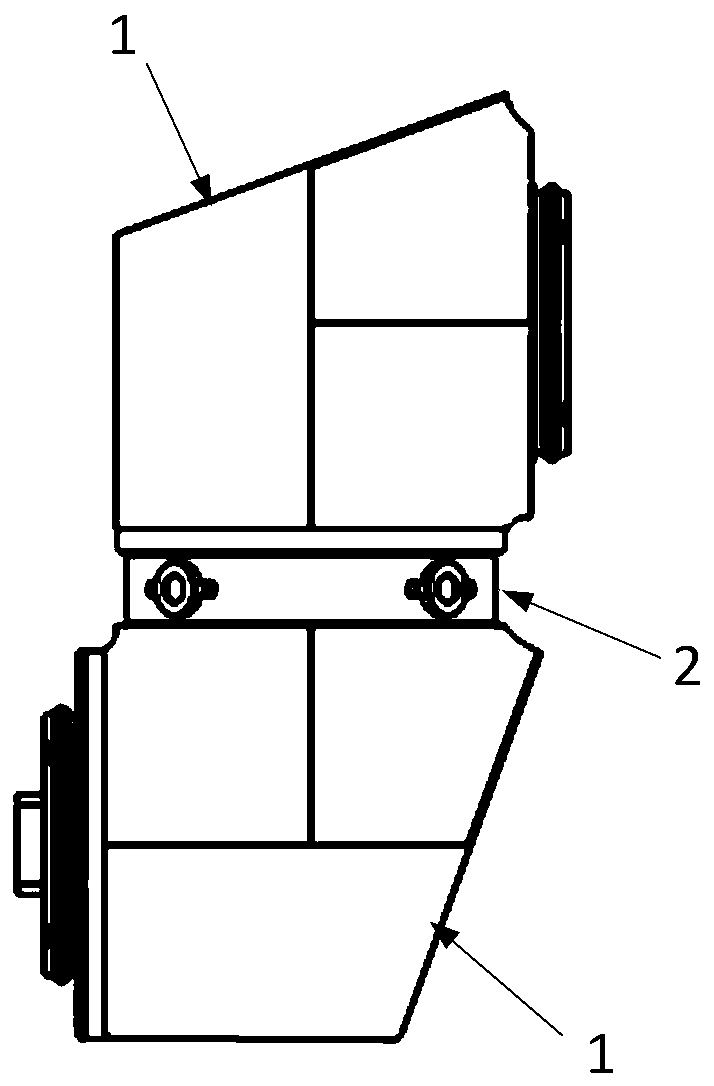

[0037] The light-weight collaborative robot with a quick-release connection method of the present invention is composed of a plurality of modular joints 1 connected in series, and the adjacent modular joints 1 are connected by a quick-release structure 2, which can realize the power transmission between the modular joints 1, such as figure 1 shown.

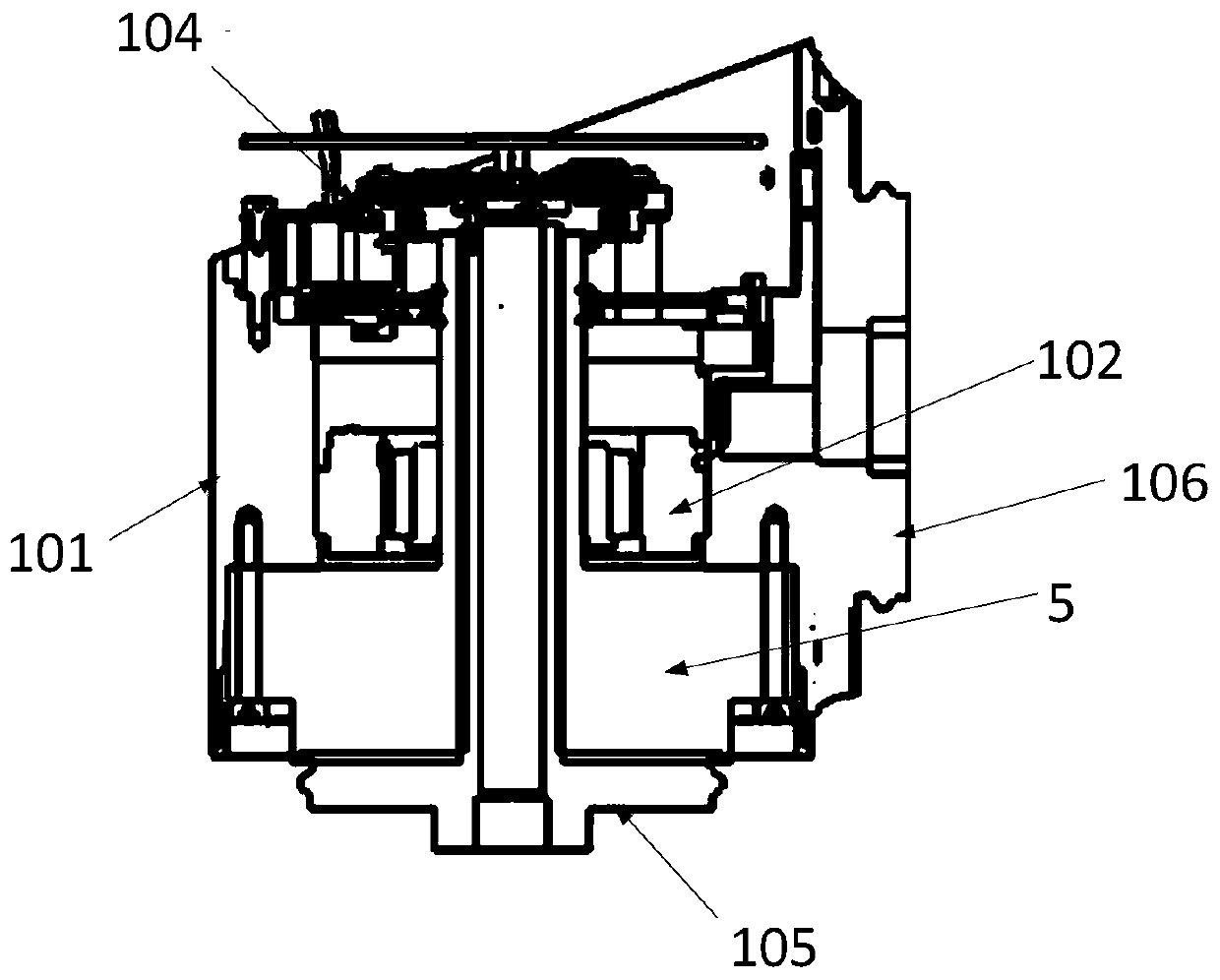

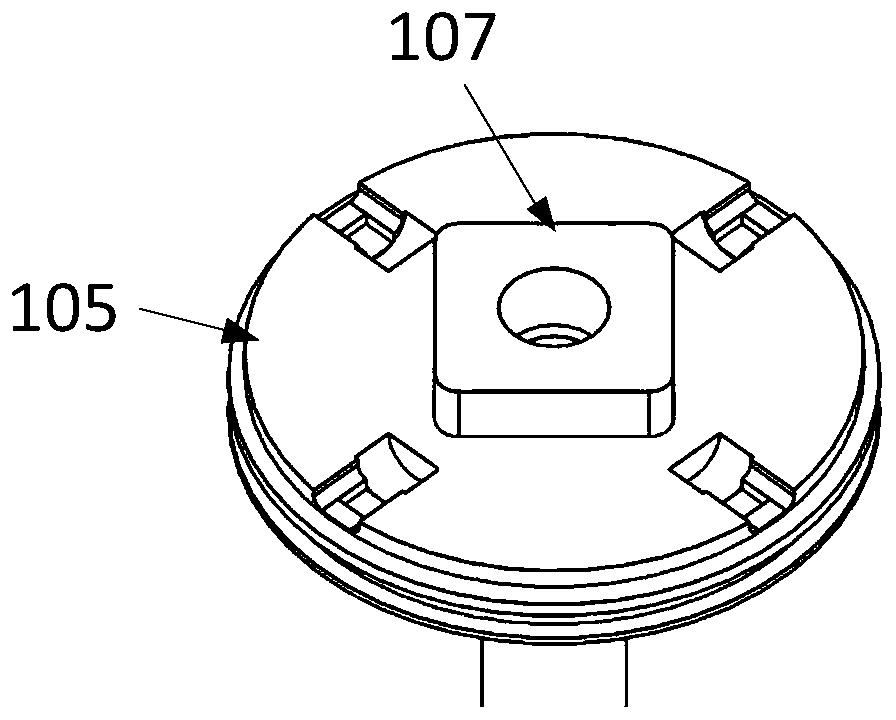

[0038] The modular joint 1 includes a housing 101, a driver 102, a reducer 103, an encoder 104 and a positioning plate, as figure 2 shown. Wherein, the housing 101 has two connecting end surfaces, which are respectively the active surface and the passive surface. The active surface is perpendicular to the passive surface. The driver 102 is mounted on the casing 101 through a bracket, and a reducer 103 is installed on the output shaft of the driver 102. The axis of the output shaft of the reducer 103 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com