Reaction device and method for preparing styrene alternating copolymerization microsphere

A reaction device and alternating copolymerization technology, applied in chemical instruments and methods, microsphere preparation, chemical/physical/physical-chemical stationary reactors, etc. The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

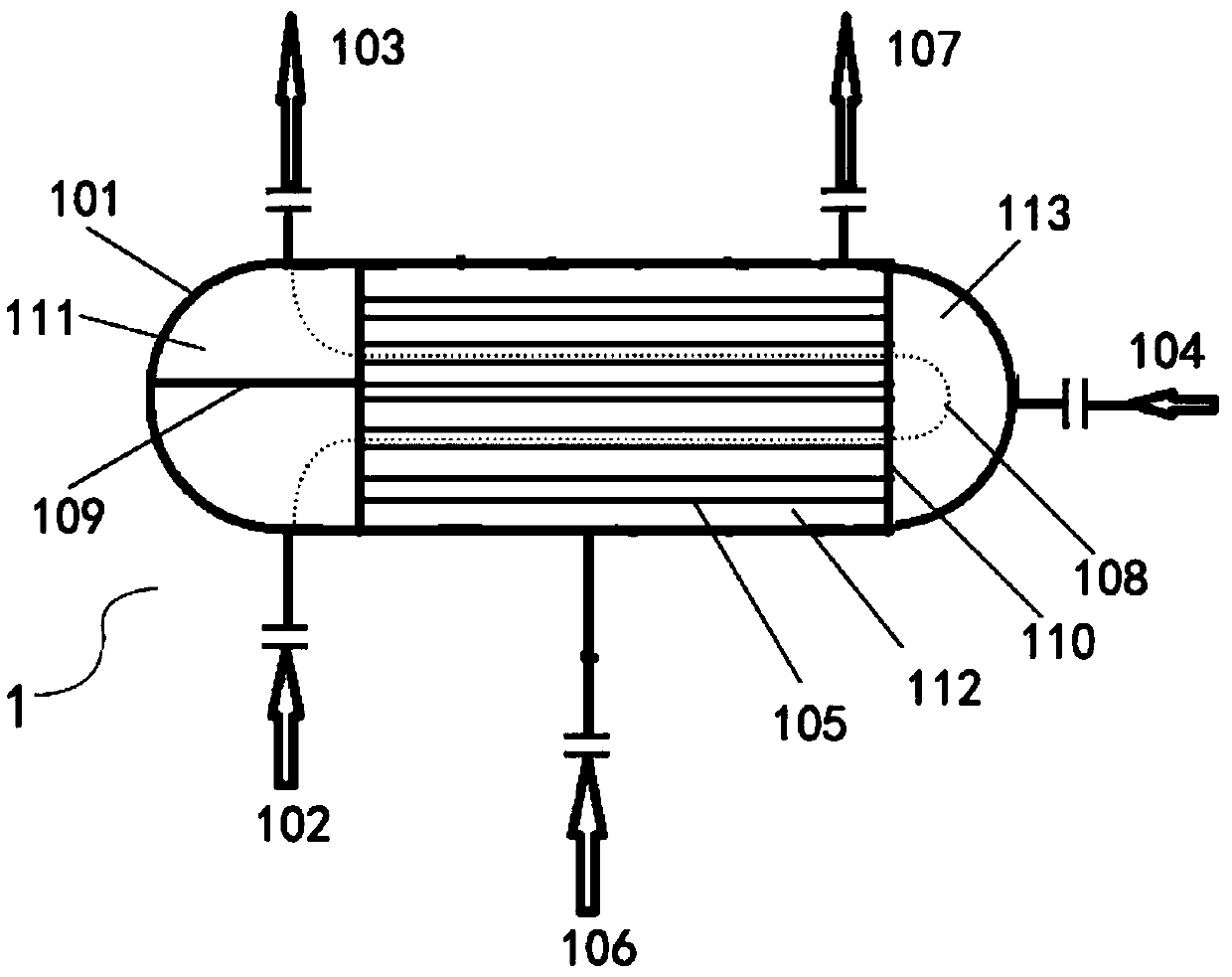

[0085] use as figure 1 The reaction apparatus shown for the preparation of styrenic alternating copolymer microspheres was carried out. The reaction device includes a reactor 1 and a centrifuge (not shown in the figure) connected in sequence.

[0086] The reactor 1 includes: a horizontally arranged reactor shell 101 with a circular cross-section,

[0087] Two guide baffles 110, which are vertically arranged inside the reactor shell 101, divide the inside of the reactor shell 101 into a heat exchange chamber 112 between them and the first reaction chamber 111 and the second reaction chamber on both sides. reaction chamber 113,

[0088] 8 hollow guide tubes 105, the length is 70% of the length of the reactor shell 101, and the diameter is 50 cm, which are evenly arranged and horizontally arranged between the two guide baffles 110, and the openings at both ends are respectively opened In the first reaction chamber 111 and the second reaction chamber 113,

[0089] A baffle baffl...

Embodiment 2

[0100] Carry out according to the method for embodiment 1, difference is:

[0101] The organic reaction solution is composed of 10.1kg α-methylstyrene, 11kg maleic anhydride, 1.2kg azobisisobutyronitrile, 1.3kg divinylbenzene and 100L isoamyl acetate;

[0102] The copolymerization reaction temperature is 80°C, the first copolymerization reaction time is 3h, and the second copolymerization reaction time is 2h;

[0103] The reaction product was centrifuged at 4000rpm for 20min,

[0104] Thus, solid copolymer particle powder B was prepared.

Embodiment 3

[0106] Carry out according to the method for embodiment 1, difference is:

[0107] The organic reaction solution is composed of 5kg α-methylstyrene, 5kg maleic anhydride, 0.6kg azobisisobutyronitrile, 0.65kg divinylbenzene and 100L isoamyl acetate;

[0108] The copolymerization reaction temperature is 90°C, the first copolymerization reaction time is 3h, and the second copolymerization reaction time is 4h;

[0109] The reaction product was centrifuged at 4000rpm for 20min,

[0110] Thus, solid copolymer particle powder C was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com