Water cut monitoring method based on microwave three-probe oil well online water cut monitor

A technology of microwave detection and microwave probe, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc. It can solve the problems that cannot meet the real-time online monitoring of oilfield production, cannot guarantee real-time data, and takes a long time for sampling and testing. To achieve the effect of being easy to promote and use, ensuring accuracy and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

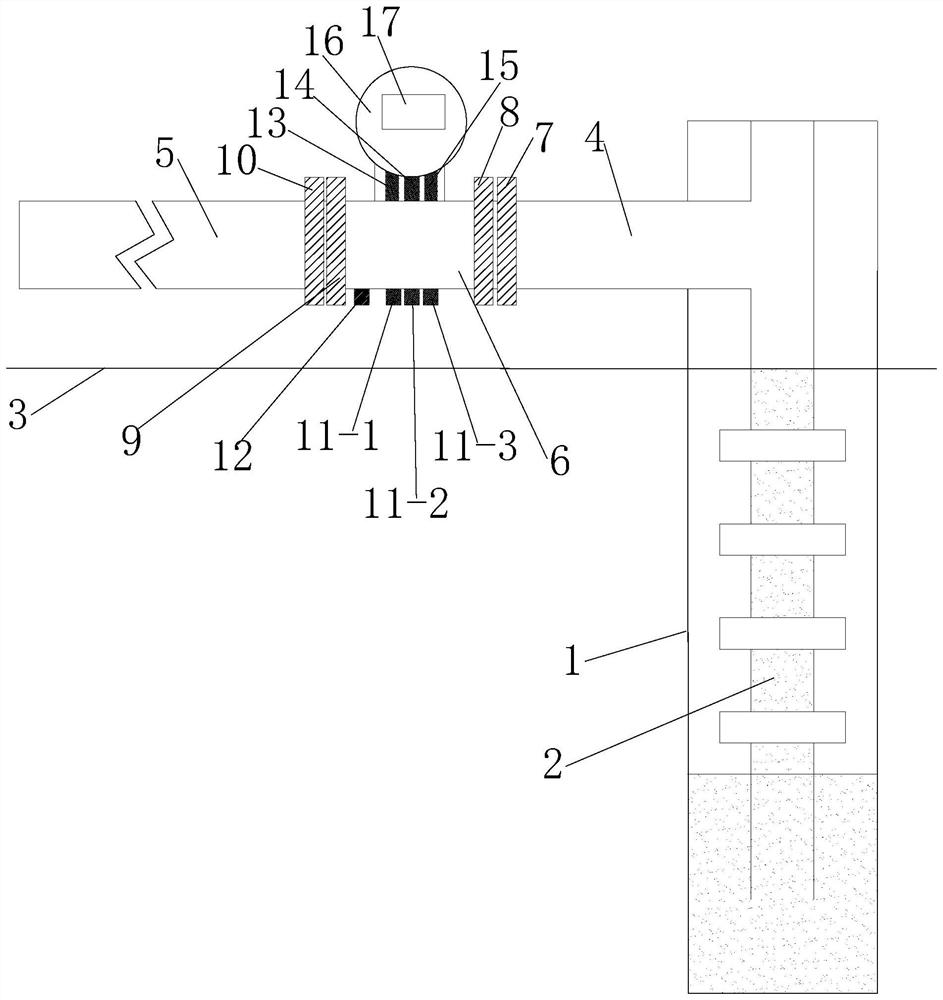

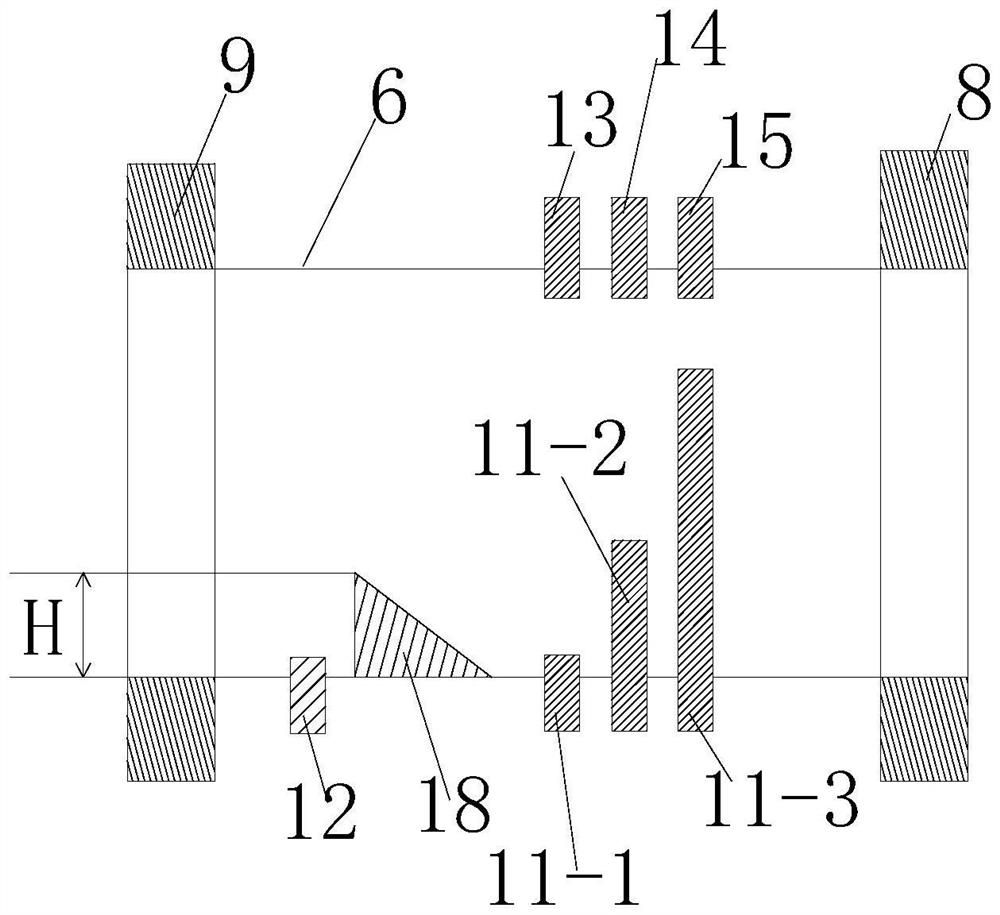

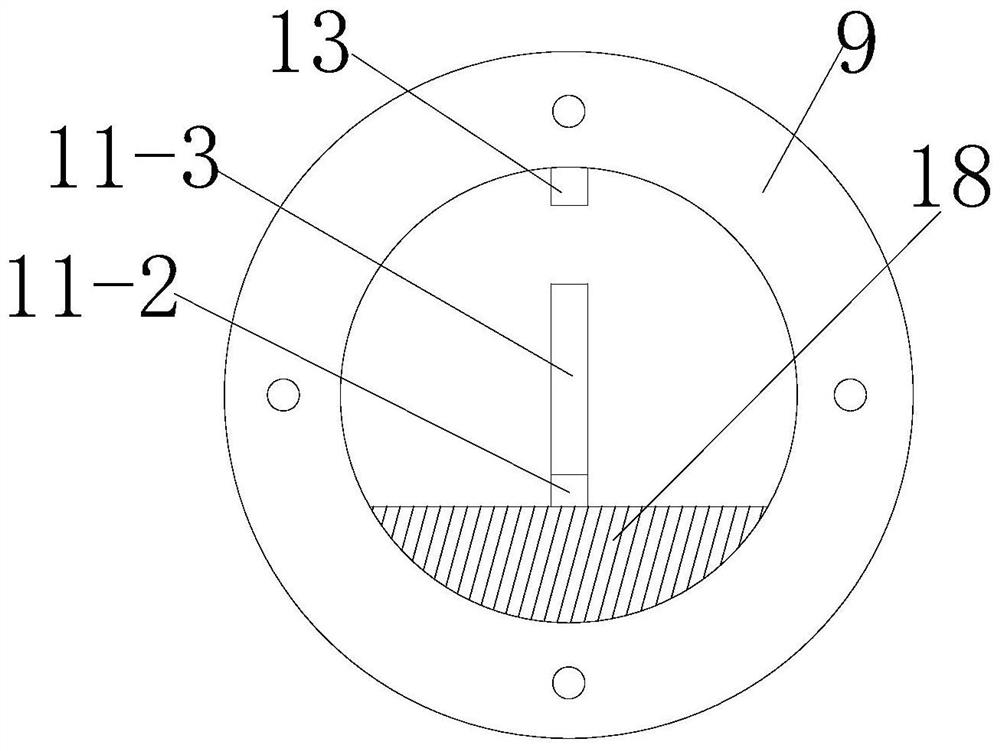

[0046] Such as Figure 1 to Figure 4 As shown, the water cut monitoring method based on the microwave three-probe oil well on-line water cut monitor of the present invention, the described microwave three-probe oil well on-line water cut monitor includes an uphole oil pipe 5 installed on the ground 3 and a wellhead connecting oil pipe The test tubing 6 between 4, the wellhead connecting tubing 4 communicates with the in-well tubing 2 in the oil well 1, the outside of the testing tubing 6 is equipped with a water cut monitoring instrument 16 for testing the water content of the extracted oil, and the moisture content monitoring instrument 16 is provided with an electronic A circuit board, the main controller and a communication module connected with the main controller are integrated on the electronic circuit board, and a flow plate 18 is arranged in the test oil pipe 6, and the flow plate 18 has an inclined surface and is connected to the The arc surface matched with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com