Safety valve using compressed gas to replace spring and using method of safety valve

A technology for compressing gas and safety valves, applied in the field of safety valves, which can solve the problems of large diameter, rigidity, volume and weight of the valve body through liquid and sealing, and achieve the effect of reducing product failure points and improving dynamic response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

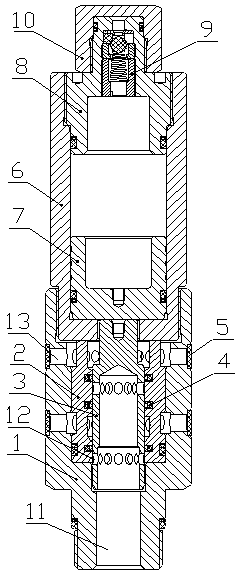

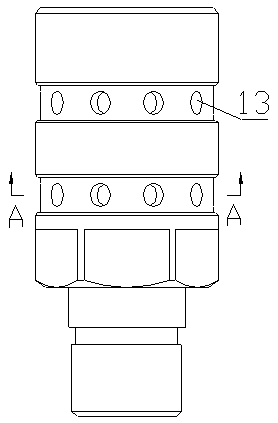

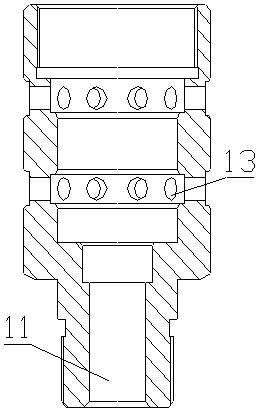

[0035] Such as Figure 1~10 As shown, a safety valve using compressed gas instead of a spring in the present invention includes a valve body 1 and a cylinder 6 affixed to one end of the valve body 1. The cylinder 6 is cylindrical with two ends open. The end of the body 6 away from the valve body 1 has an internal thread, and the internal thread is equipped with a gas nozzle 8, and an O-ring is installed between the gas nozzle 8 and the cylinder body 6, and the gas nozzle 8 is provided with a valve coaxial with the cylinder body 6. The penetrating circular hole, check valve 9 is housed in the circular hole.

[0036] The part of the air nozzle 8 protruding from the cylinder body 6 is covered with a nut 10, the nut 10 is connected to the air nozzle 8 through threads, and the outer ring of the air nozzle 8 is equipped with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com