High-sensitivity piezoresistive single-axis force sensor design method based on topological optimization

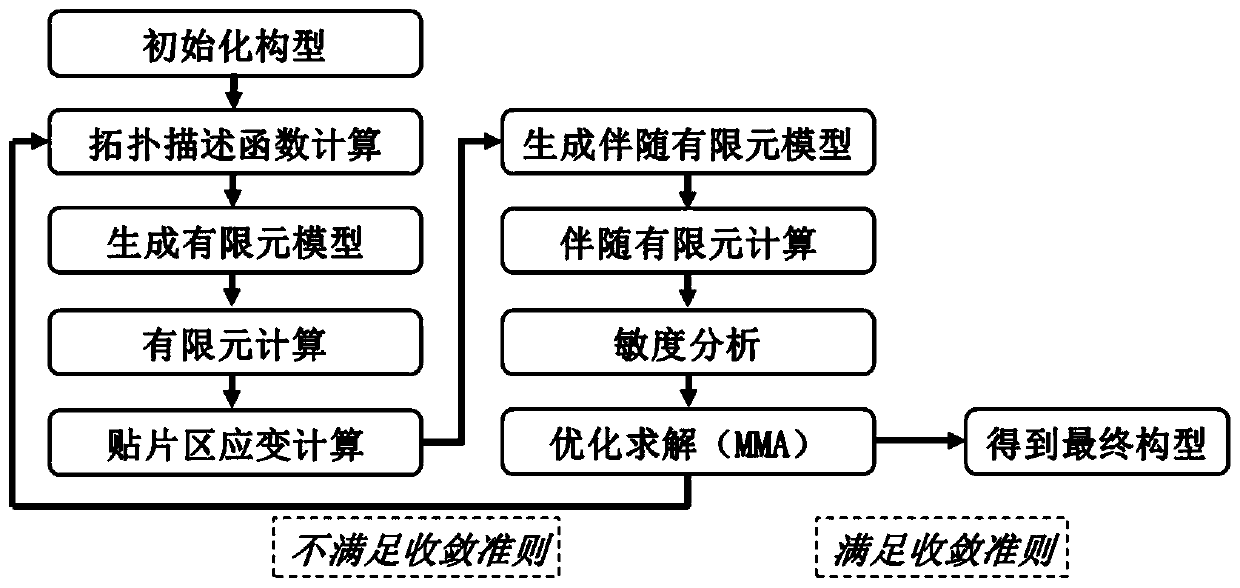

A technology of force sensor and topology optimization, which is applied in the field of sensor automation design, can solve the problems of difficult sensor configuration, high R&D cost, and speed up sensor R&D.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The effects of the present invention will be further described below in conjunction with specific examples.

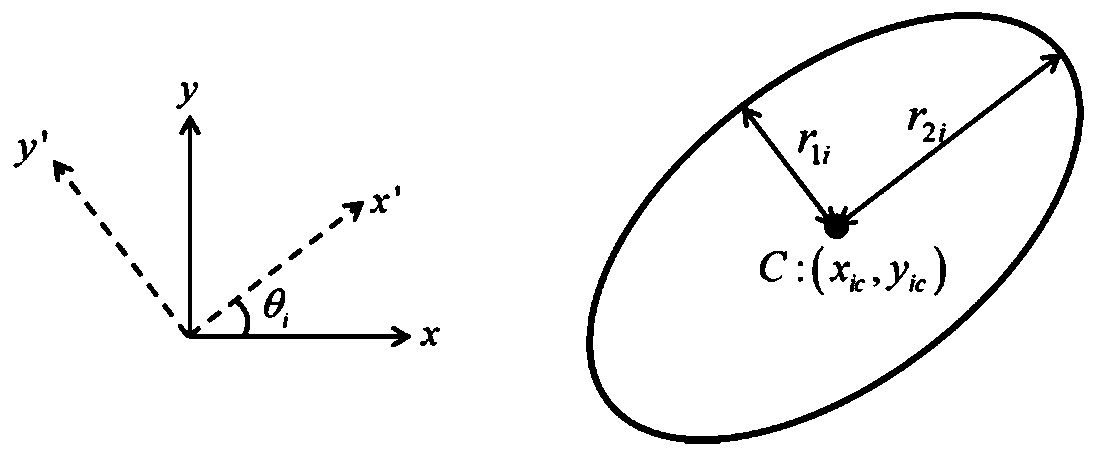

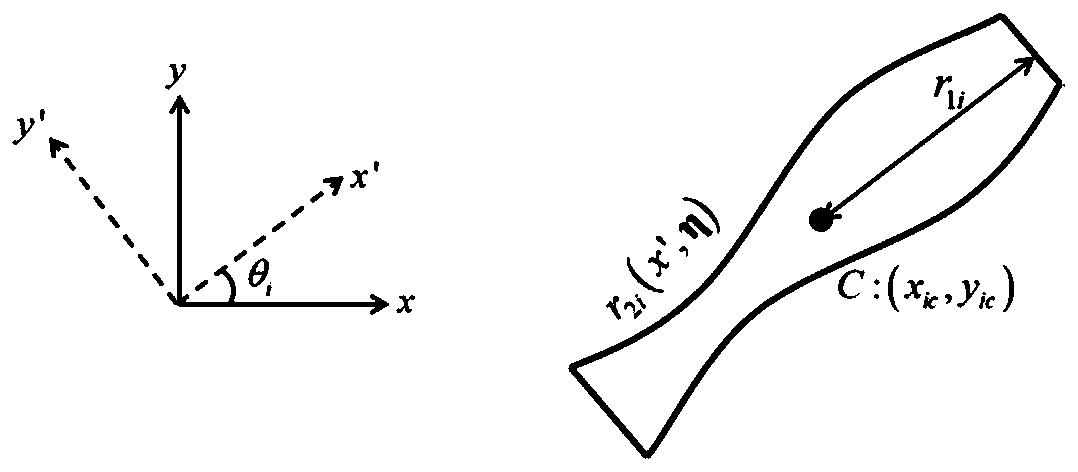

[0063] The method of the invention is used to carry out secondary design on a certain type of "bone type" uniaxial pressure sensor. The geometric information and finite element model of this type of sensor can be found in Figure 4 , the position of the patch is located on the upper and lower surfaces at x=40, and each piece of strain gauge is attached to form a half bridge. It can be obtained by calculation that the strain output value of this model is: ε g 2 = 6.76e-6. As a comparative example, here we only consider the lower limit of the unilateral strain constraint ( ε ) 2 , set the value to 7.0e-6. Here, four two-dimensional ellipses and one equal-section two-dimensional rod are selected to represent the topological description function of the "bone type". Only the geometric control parameters of the lower left ellipse and the height of the constant-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com