A kind of lithium-ion battery low-temperature charging method

A lithium-ion battery and charging method technology, applied in the field of lithium-ion batteries, can solve the problems of poor kinetic conditions, prolonged charging time, battery performance deterioration, etc., so as to improve low-temperature performance, reduce low-temperature charging time, and avoid negative electrode lithium precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

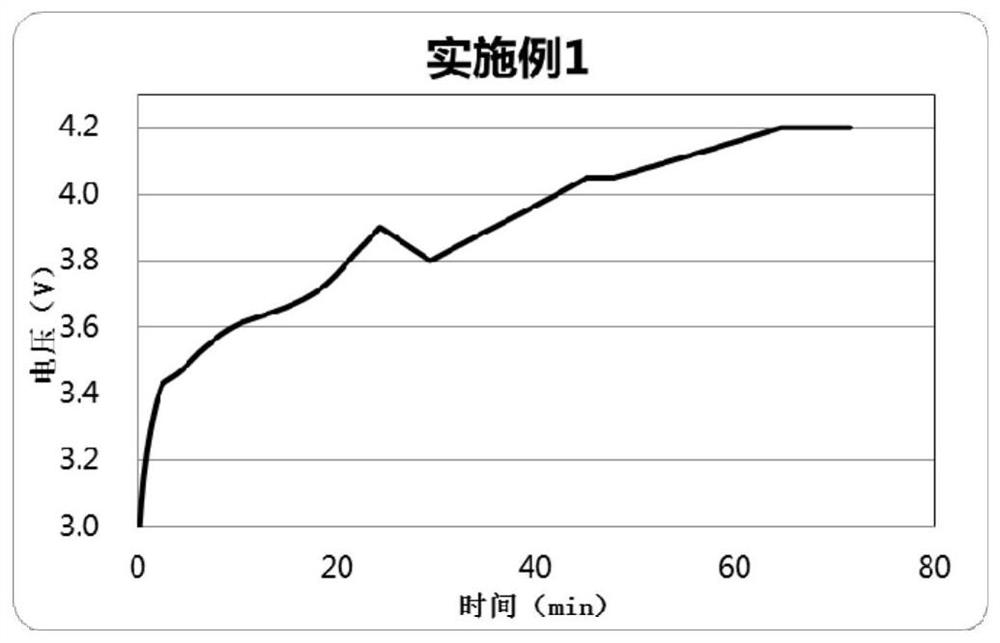

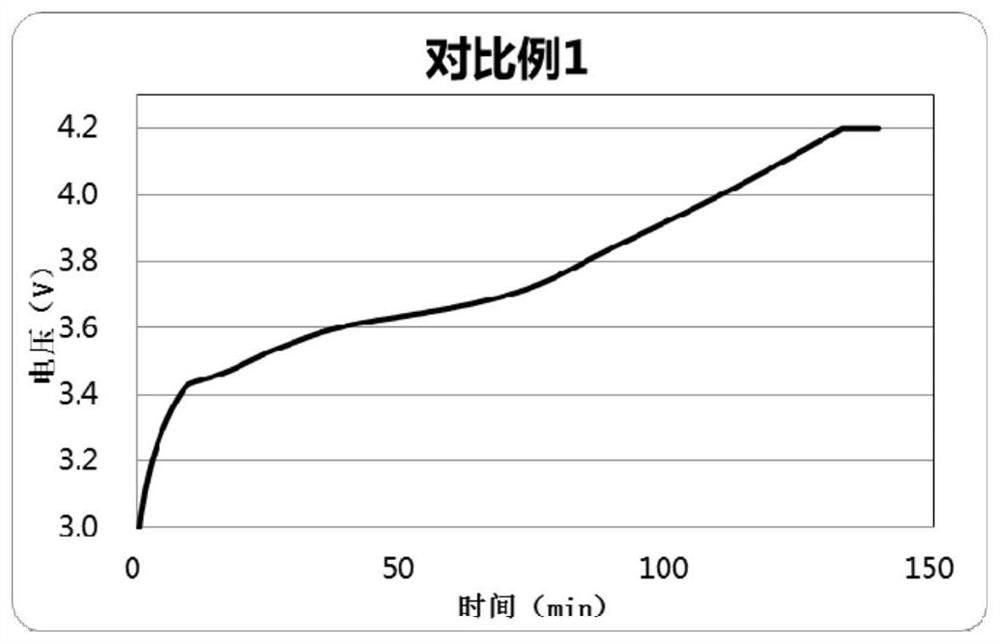

Embodiment 1

[0026] A ternary battery with a capacity of 50Ah (positive electrode material is NCM622, negative electrode material is artificial graphite, conductive glue is SP and CNTs, binder is PVDF, CMC, SBR) is selected as the experimental object, and it is charged at 0°C at low temperature. The maximum charging current specified by the battery manufacturer at 25°C is 100A (2C). Using the method for determining the critical lithium-analysis potential of the battery provided by the present invention, the critical lithium-analysis potential V2 of this battery cell at 0°C is 4.05V. By calculation, we can calculate the relevant values respectively, namely:

[0027] In the first step, use 100A current to charge the battery to 3.9V in a constant current mode, and let it rest for 5 minutes;

[0028] In the second step, use 50A to charge the battery to 4.05V in a constant current mode, and turn to constant voltage charging until the current drops to 10A;

[0029] The third step is to charg...

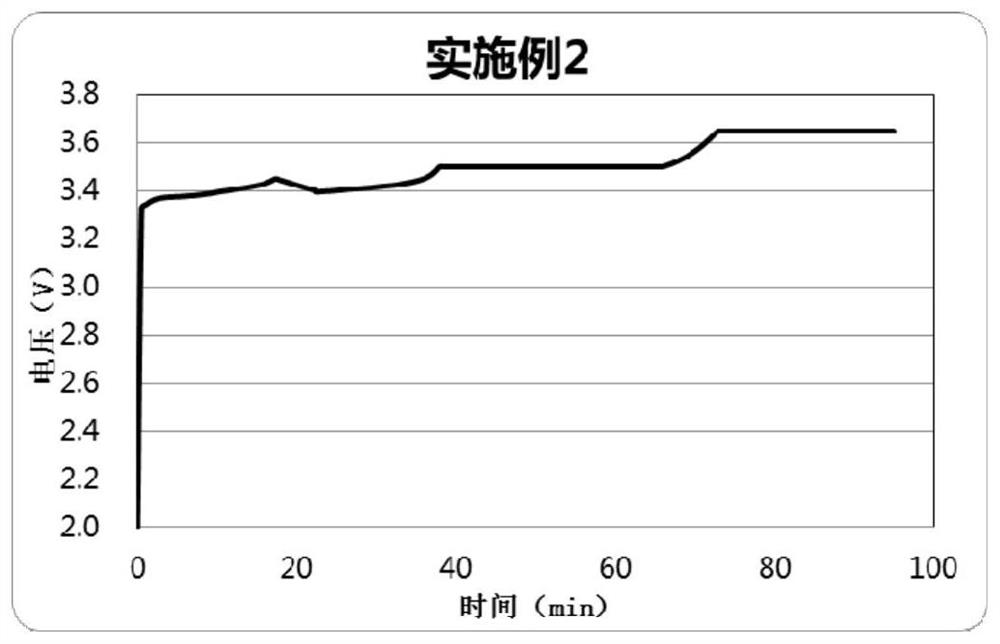

Embodiment 2

[0033] Select a lithium iron phosphate battery cell with a capacity of 27Ah (the positive electrode material is LFP, the negative electrode material is artificial graphite, the conductive glue is SP and CNTs, the binder is PVDF, CMC, SBR) as the experimental object, and charge at -10°C at low temperature . The maximum charging current specified by the battery manufacturer at 25°C is 54A (2C). Using the method for determining the critical lithium-evolution potential of the battery provided by the present invention, the critical lithium-evolution potential V2 of this battery cell at 0°C is 3.5V. By calculation, we can calculate the relevant values respectively, namely:

[0034] In the first step, use 54A current to charge the battery to 3.45V in a constant current mode, and let it rest for 5 minutes;

[0035] The second step is to use 27A to charge the battery to 3.5V in a constant current mode and turn to constant voltage charging until the current drops to 5.4A;

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com