Method for recovering activity of low-activity hydro-upgrading pour point depressing catalyst

A hydrogenation-upgrading, low-activity technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The selection method is simple and the effect of high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

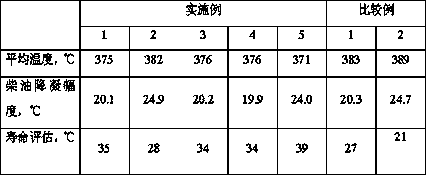

Embodiment 1

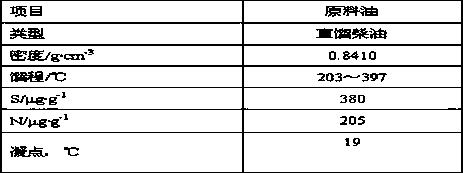

[0025] Feed the feedstock oil after hydrofining treatment into the bed of the low-activity hydrogenation-modifying-point-point-depressing catalyst. Contain 5% β molecular sieve and 0.20% nitrogen element by weight, increase the reaction temperature to 380°C, adjust the temperature, control the freezing point of diesel products to drop by 10°C, and stabilize for 36 hours; continue to adjust the reaction temperature to control diesel products Decrease in freezing point by 20°C and stabilize for 36 hours; continue to adjust the reaction temperature to control the decrease in freezing point of diesel products by 30°C and stabilize for 36 hours; after the recovery process is over, adjust the process conditions and enter normal production. .

Embodiment 2

[0027] Feed the feedstock oil after hydrofining treatment into the bed of the low-activity hydrogenation-modifying-point-point-depressing catalyst. Contain 5% β molecular sieve and 0.20% nitrogen element by weight, increase the reaction temperature to 380°C, adjust the temperature, control the freezing point of diesel products to drop by 15°C, and stabilize for 36 hours; continue to adjust the reaction temperature to control diesel products The freezing point drops by 25°C and stabilizes for 36 hours; continue to adjust the reaction temperature to control the freezing point of diesel products to drop by 35°C and stabilize for 36 hours; after the recovery process is over, adjust the process conditions and enter normal production, and the controlled pour point depression depth is the same as that of Comparative Example 2 .

Embodiment 3

[0029] Feed the feedstock oil after hydrofining treatment into the bed of the low-activity hydrogenation-modifying-point-point-depressing catalyst. The medium contains 5% β molecular sieve and 0.20% nitrogen element by weight. Increase the reaction temperature to 380°C, adjust the temperature, control the freezing point of diesel products to drop by 15°C, and stabilize for 24 hours; continue to adjust the reaction temperature to control diesel products. Decrease in freezing point by 20°C and stabilize for 24 hours; continue to adjust the reaction temperature to control the decrease in freezing point of diesel products by 35°C and stabilize for 24 hours; after the recovery process is over, adjust the process conditions and enter normal production. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com