Finished granule conveying and screening device for elastic granule production

A technology for conveying sieves and granules, which is applied in the directions of filtration, packaging, solid separation, etc., and can solve problems such as troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

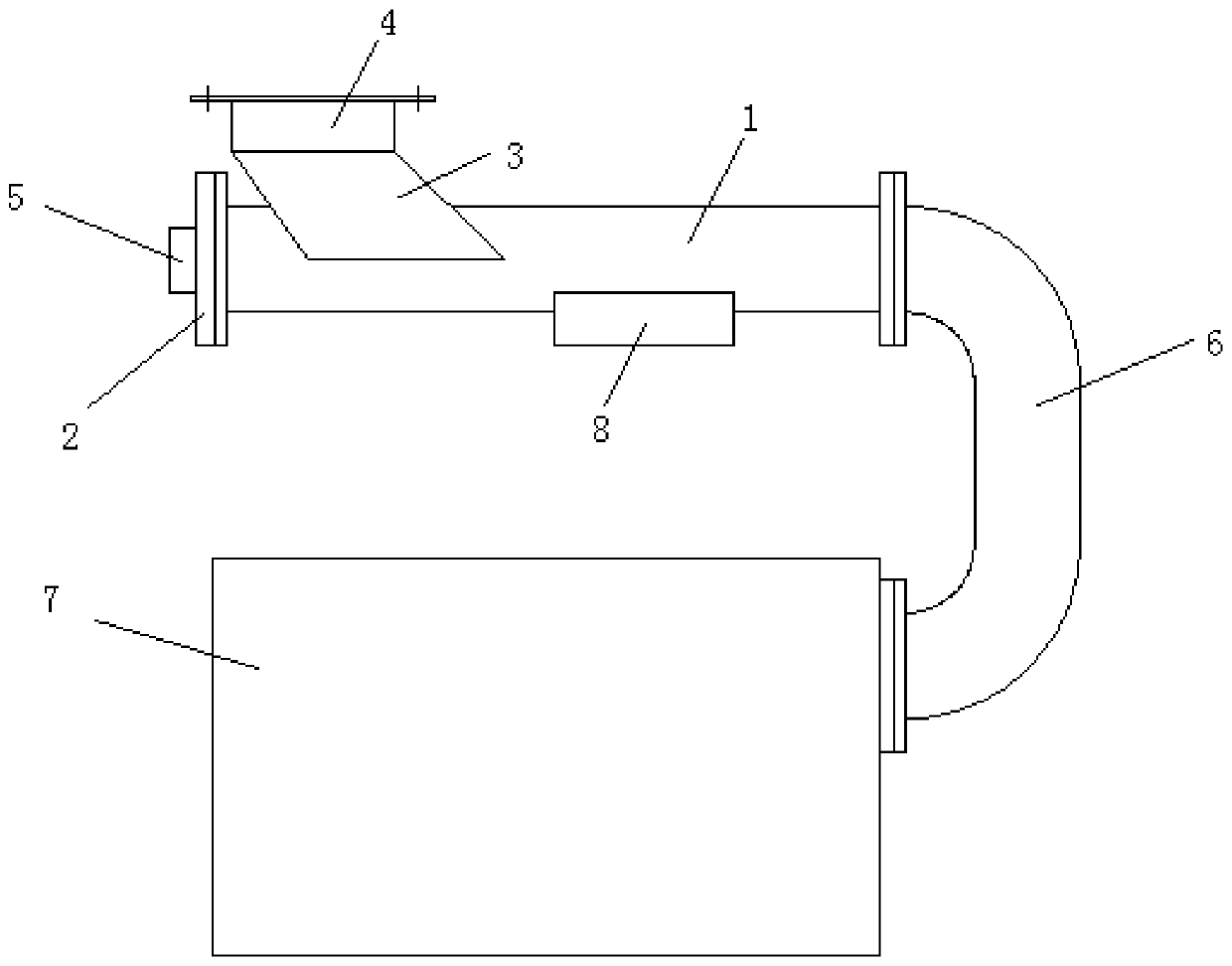

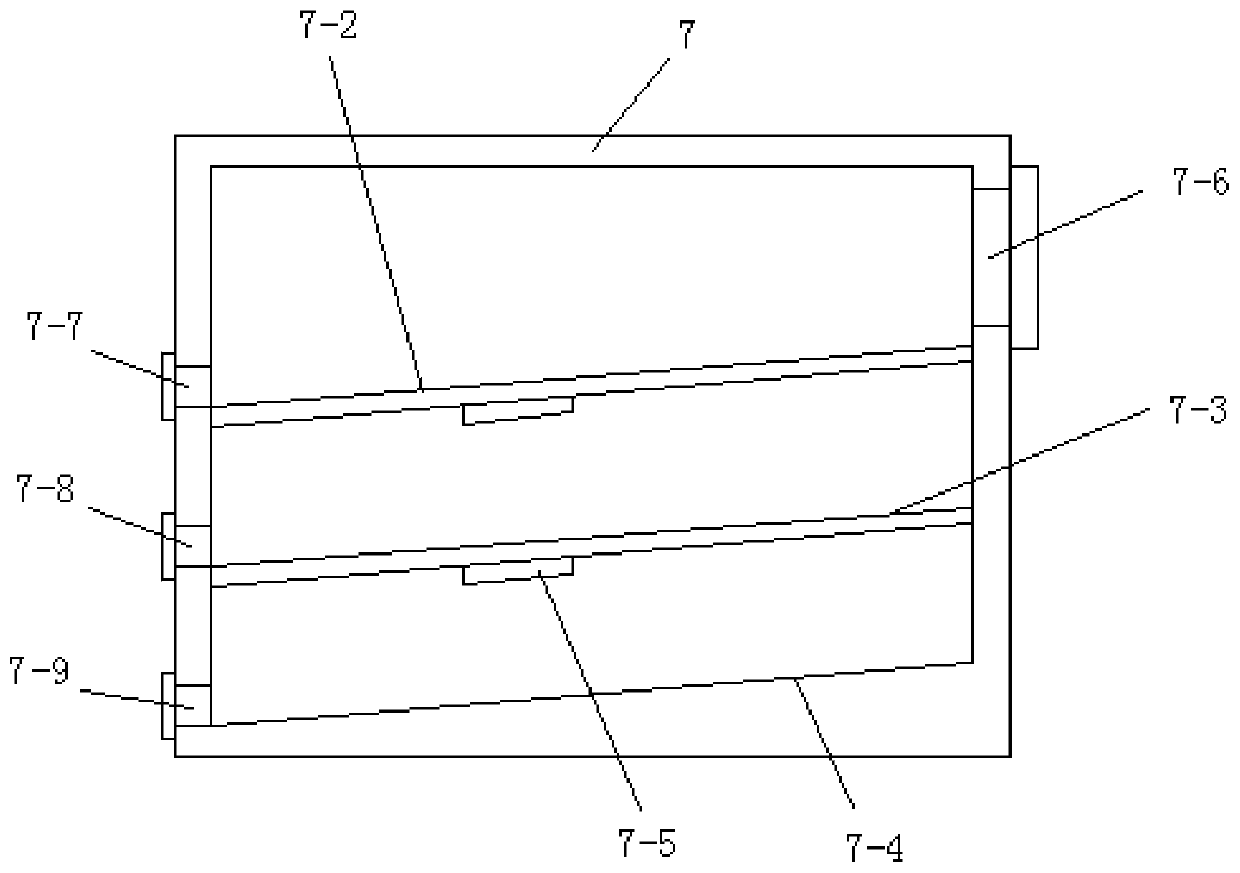

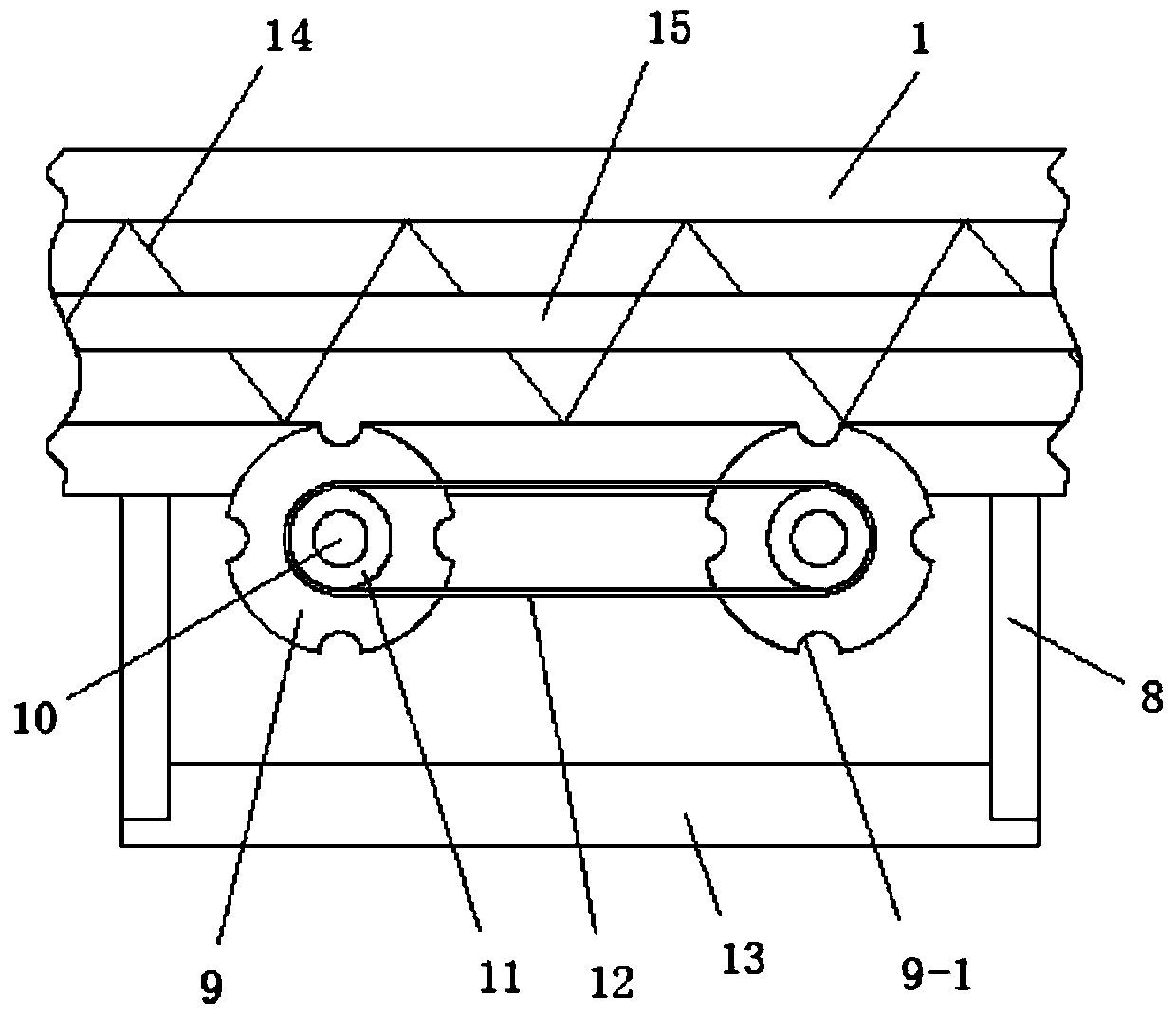

[0015] Such as figure 1 The shown one is used for the conveying and screening device of finished pellets for the production of elastic pellets, including a conveying pipeline 1, a material guide cover 3, an elbow 6 and a screening box 7, and the upper end of the guide material cover A connecting flange 4 is provided, the lower end of the material guide cover is integrated with the outer wall of the conveying pipeline, the left end of the conveying pipeline is fixed with a sealing end cover 2, and the right end of the conveying pipeline is connected to the screen through an elbow. On the side wall of the box body, a screw conveying mechanism is arranged inside the conveying pipeline, and a sampling mechanism is arranged at the bottom of the conveying pipeline. The present invention is also equipped with a sampling mechanism at the bottom of the conveying pipeline, through which the finished pellets can be sampled, which plays a role in monitoring the production quality of elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com