Drying device for producing flaky gelatin

A drying device and gelatin technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problem of uneven drying process of sheet gelatin, achieve good drying effect, consistent wind pressure, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

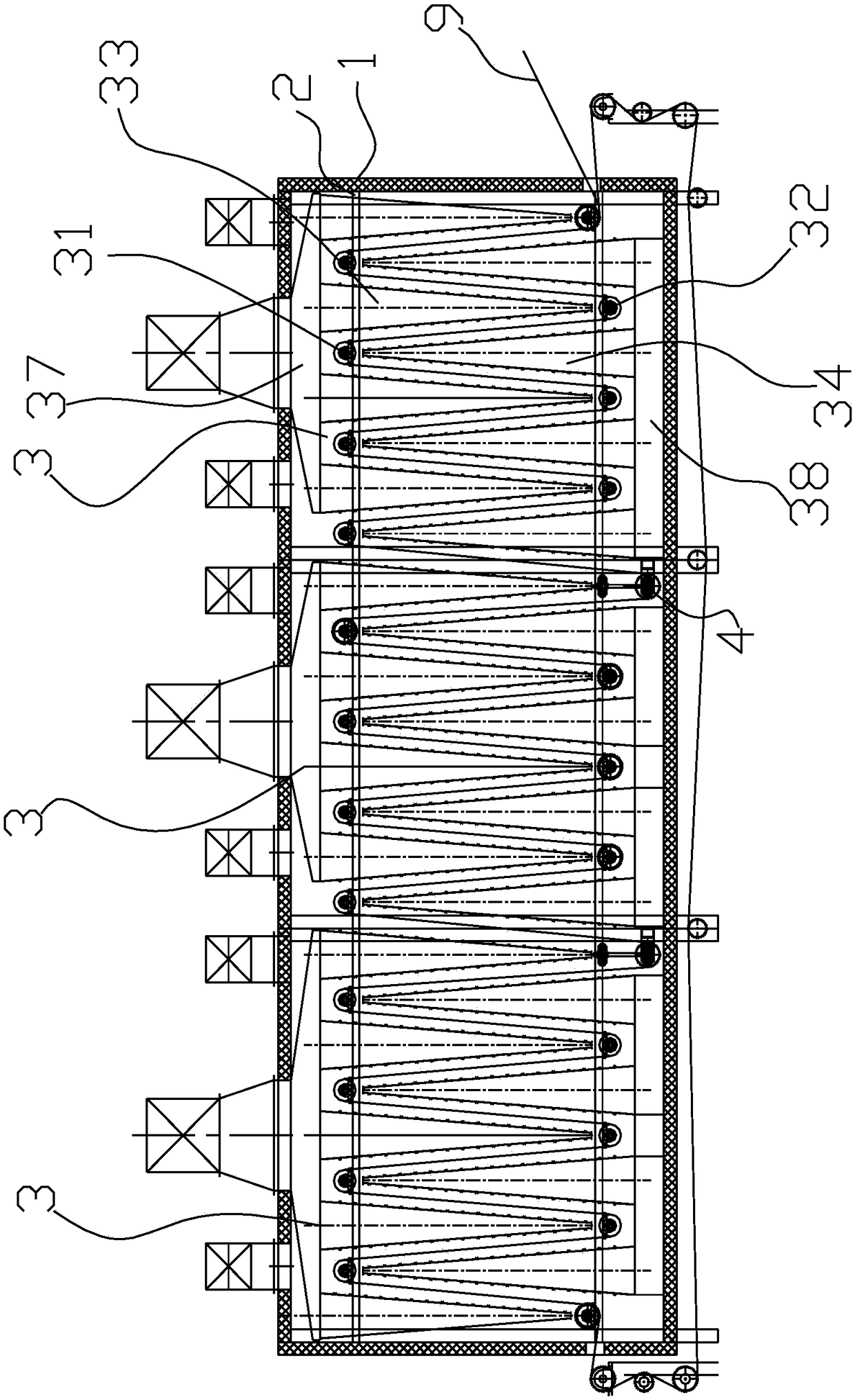

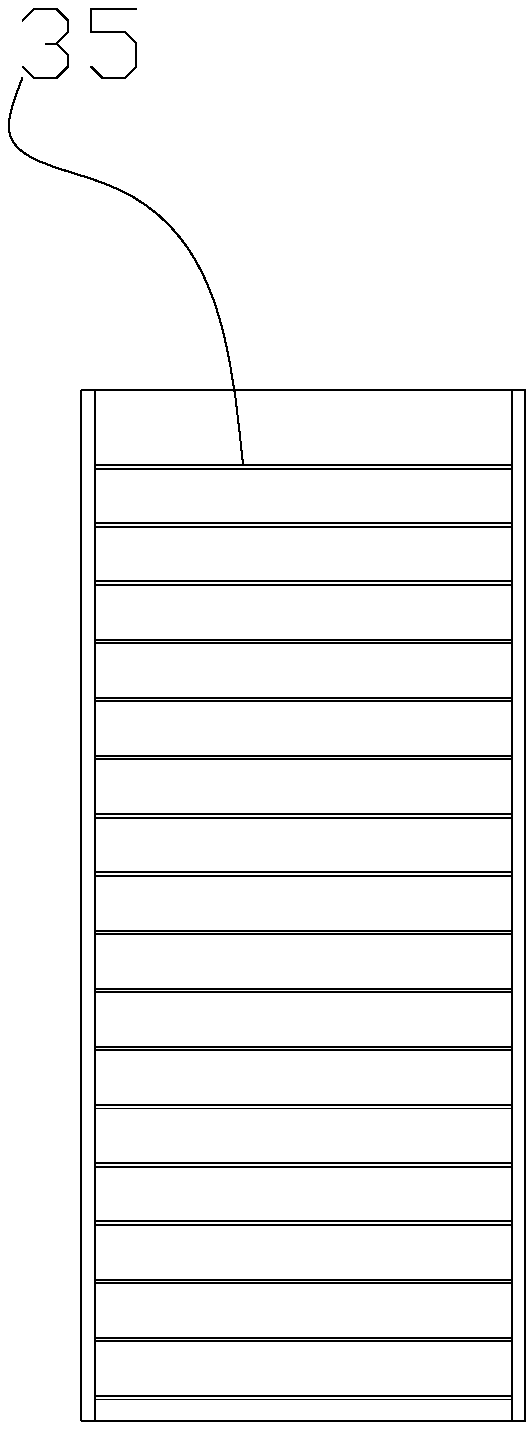

[0030] Embodiment 1: as image 3 , the gas injection hole is a strip-type slit type gas injection hole 35 arranged along the horizontal direction.

Embodiment 2

[0031] Embodiment 2: as Figure 4 , the jet hole is a mesh type jet hole 36.

[0032] A lift compensation device 4 is provided between two adjacent drying units 3 located between the upper material rollers 31 at the edge, and the lift compensation device 4 includes a floating roller 41 and a driving device for driving the floating roller 41 to move up and down. The function of the automatic lifting compensation device 4 is to automatically compensate the shrinkage caused by the gelatin film 9 during the drying process, and effectively solve the problem of the gelatin film 9 wearing and cutting during production.

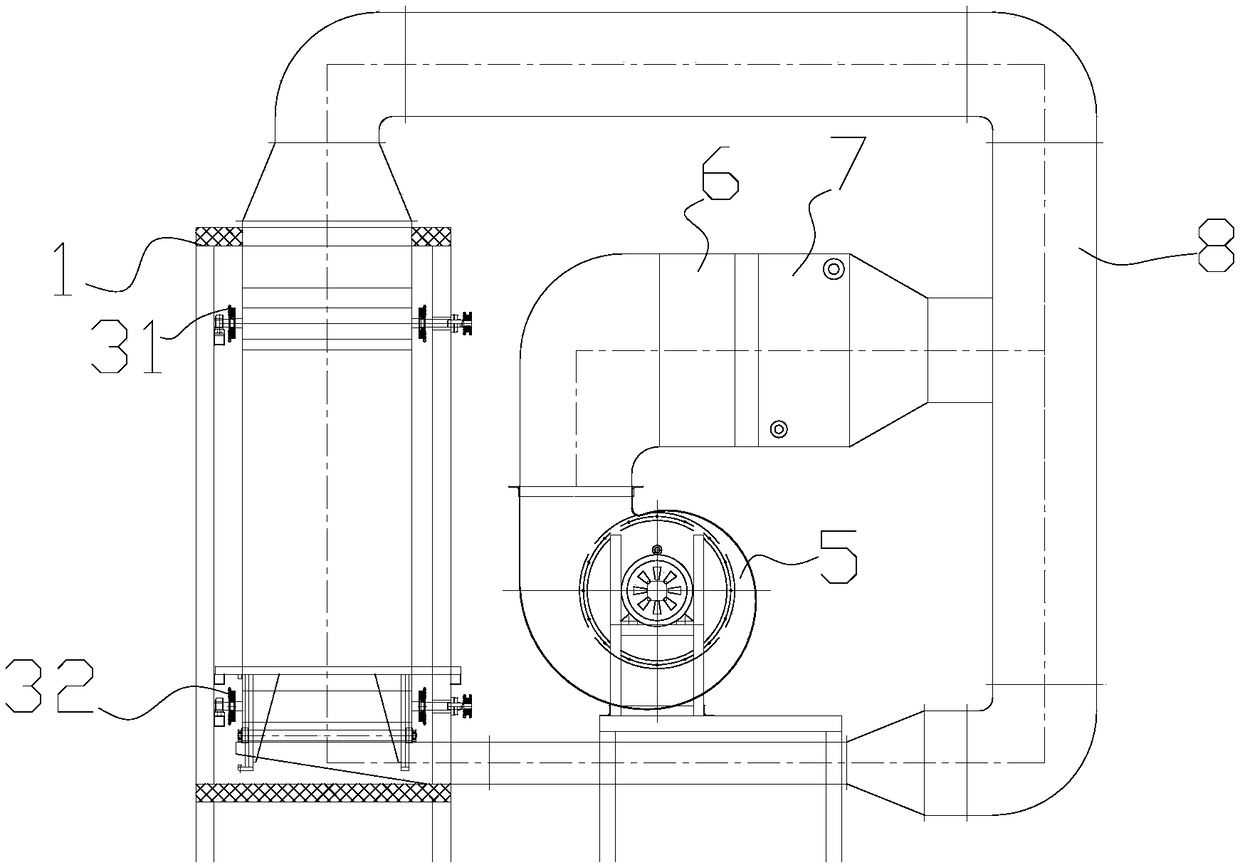

[0033] Each drying unit 3 also includes an upper static pressure box 37 and a lower static pressure box 38, and the upper air supply pipe 33 in each drying unit 3 communicates with the upper static pressure box 37, and the air supply pipe 33 in each drying unit 3 communicates with the upper static pressure box 37. The lower air supply pipe 34 is all communicated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com