Heating type conveying mechanism for glass bottles

A conveying mechanism and heating technology, which is applied in the field of glass bottle heating conveying mechanism, can solve the problems of large environmental temperature difference of glass bottles, etc., and achieve the effects of strong heat storage capacity, improved stability, and reduced chance of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

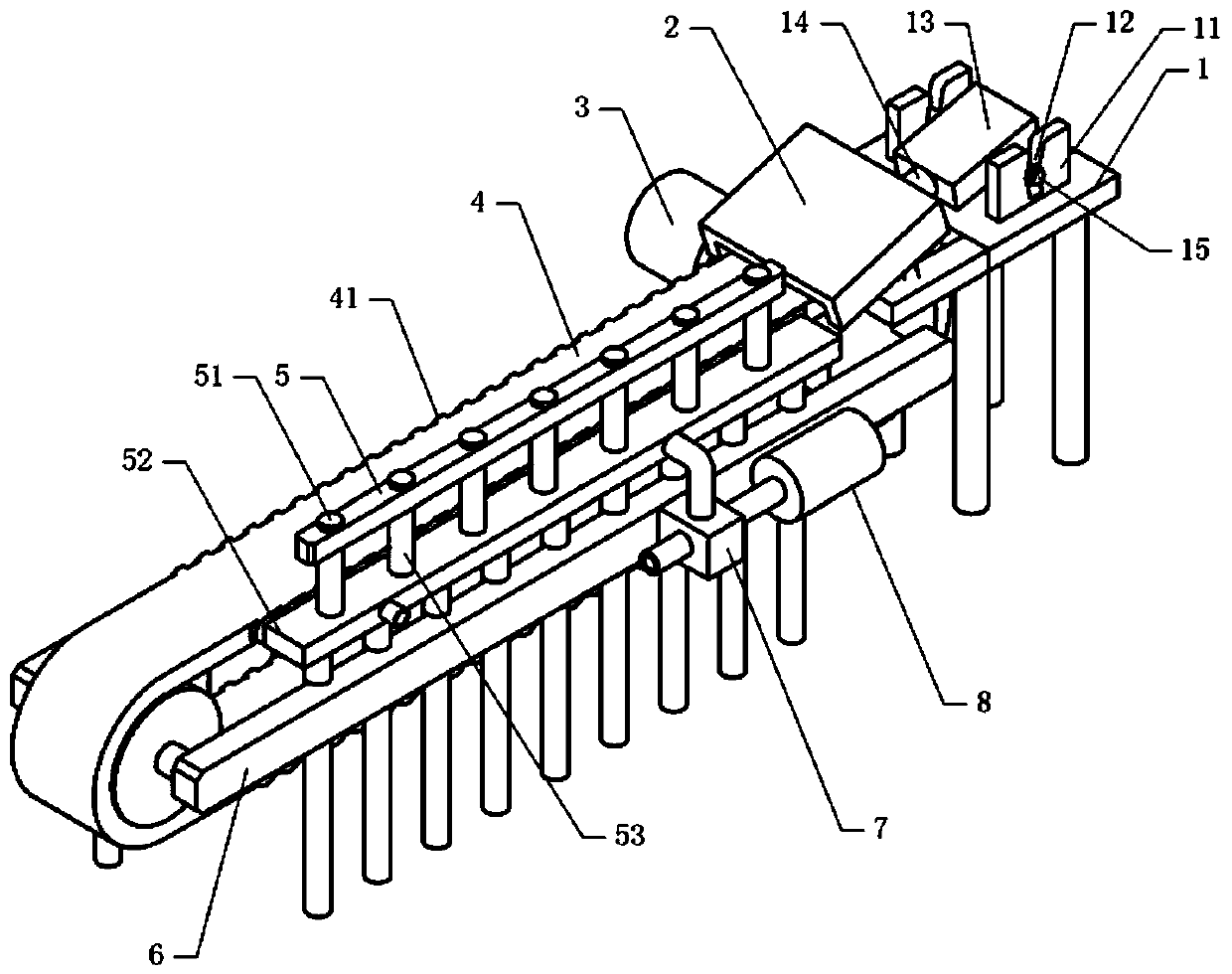

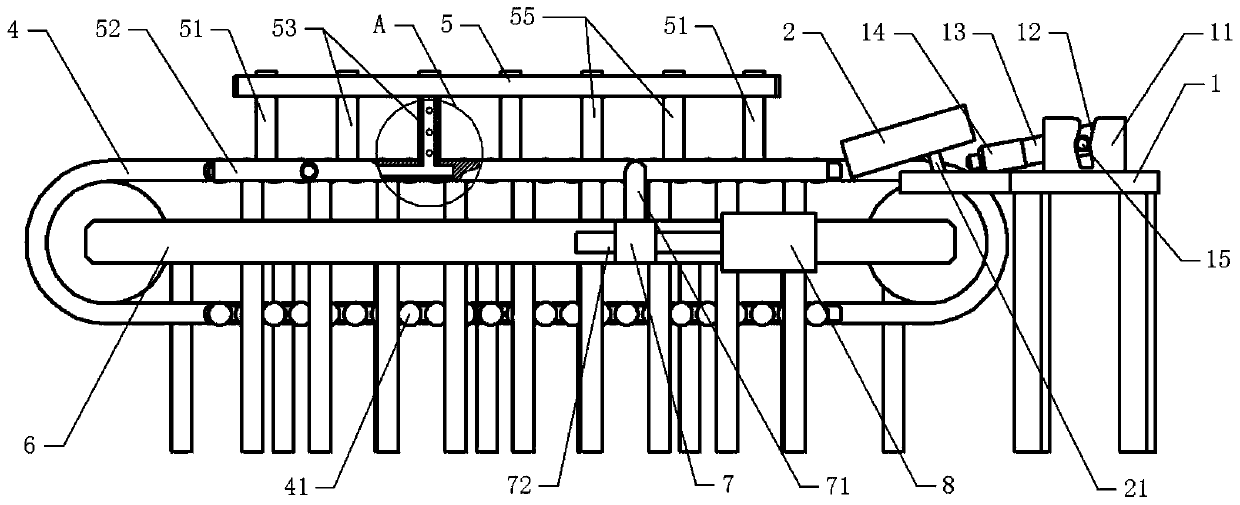

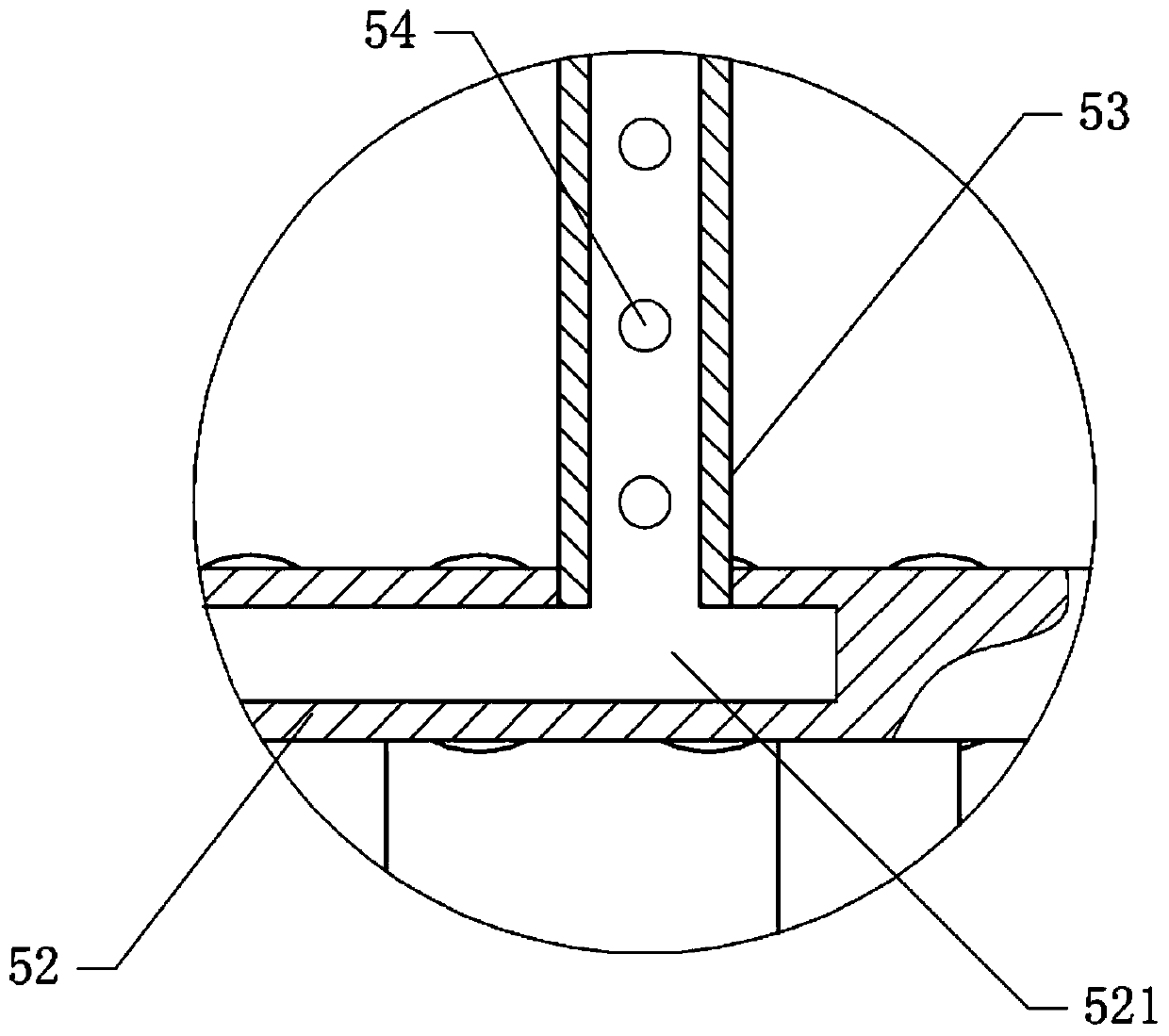

[0041] Basic as attached figure 1 And attached figure 2 As shown, a glass bottle heating conveying mechanism includes a frame 6 and a conveyor belt installed on the frame 6. In this embodiment, the belt 4 of the conveyor belt is made of aluminum alloy, and the frame 6 is fixed and installed by fastening bolts. There is a driving part. In this embodiment, the driving part is a single-phase motor 3, and the output shaft of the single-phase motor 3 is welded coaxially with the transmission shaft of the conveyor belt. as attached Figure 4 , attached Figure 5 And attached Figure 6 As shown, a heat conduction shaft 41 is welded and fixed on the belt 4. The heat conduction shaft 41 is made of a metal material. A heat storage tank 43 is opened on the heat conduction shaft 41. A heat storage sheet 42 made of a ceramic material is installed in the heat storage tank 43. .

[0042] as attached figure 2 As shown, the right end of the conveyor belt is provided with a heating plat...

Embodiment 2

[0051] The difference between embodiment two and embodiment one is that, as attached Figure 7 And attached Figure 8 As shown, two partitions 61 are fixed on the support plate 52 by fastening bolts, and a medium temperature chamber 522 between the hot air chamber and the cold air chamber is formed between the partitions 61, and air holes 62 are opened on the partitions 61, and the medium temperature chamber 522 respectively communicates with the hot air cavity and the cold air cavity through the air hole 62 . The support plate 52 is welded with a number of medium-temperature tubes 57 vertically slidingly connected to the support plate 52. A cavity is opened in the medium-temperature tube 57. A medium-temperature hole 58 facing the conveyor belt is opened on the medium-temperature tube 57. A spiral channel is opened in the medium-temperature tube 57. 59. The spiral channel 59 communicates with the medium temperature cavity 522 and the cavity.

[0052] The specific implementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com