A high-strength precipitation-hardening stainless steel for laminates and its manufacturing method

A technology of precipitation hardening and manufacturing method, applied in the field of high-strength precipitation hardening stainless steel and its manufacturing, which can solve the problems of reduced polishing performance, brittleness and hardness, poor polishing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

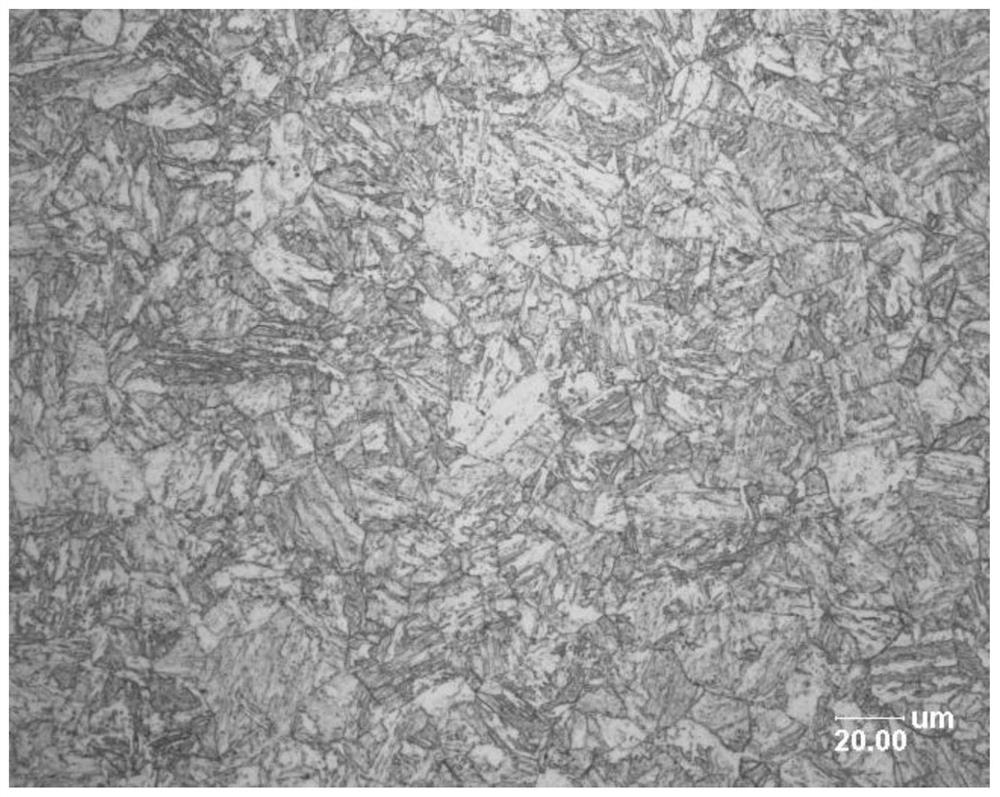

[0058] Example 1: Cast the smelted molten steel that meets the above composition requirements into a continuous casting slab, and the chemical composition of the slab is shown in Table 1. After hot rolling, solution heat treatment at 1050 °C for 10 minutes, water cooling to 30 °C, pickling, easy and good control of the plate shape. The cold rolling reduction is 55% cold rolling, the heat treatment process is adjusted to 730 ° C for 1 hour, the cryogenic treatment process is -73 ° C for 2 hours, and finally the aging treatment is performed at 470 ° C for 4 hours, and the air is cooled to 30 ° C. This example Microstructure photos see figure 2 , the structure is martensite and precipitated Mo and Cr carbonitride precipitation strengthening phase, the precipitation phase is fine and uniform, and the yield strength and tensile strength are respectively 1450MPa and 1500MPa. The stainless steel for laminates is obtained.

Embodiment 2

[0059] Example 2: Cast the smelted molten steel that meets the above composition requirements into a continuous casting slab, and the chemical composition of the slab is shown in Table 1. After hot rolling, carry out solution heat treatment at 1100°C for 10 minutes, water-cooled to 60°C, pickled, the shape is good, cold rolling reduction is 80% cold rolling, the adjustment treatment process is 760°C for 3 hours, and the cryogenic treatment process is -80°C for 4 hours, and finally, aging treatment at 480°C for 3 hours, and air-cooled to 20°C. The stainless steel for laminates with yield strength and tensile strength of 1435 MPa and 1508 MPa, respectively, can be obtained.

Embodiment 3

[0060] Example 3: Cast the smelted molten steel meeting the above composition requirements into a continuous casting slab, and the chemical composition of the slab is shown in Table 1. After hot rolling, carry out solution heat treatment at 1080 °C for 3 minutes, water-cooled to 80 °C, pickling, the shape of the plate is good, cold rolling reduction is 60% cold rolling, the adjustment treatment process is 730 °C for 2 hours, and the cryogenic treatment process is -115°C for 3 hours, and finally an aging treatment at 500°C for 2 hours, and air-cooled to 25°C. The stainless steel for laminates with yield strength and tensile strength of 1465 MPa and 1510 MPa, respectively, can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap