Warmer heating assembly

A technology for heating components and heaters, applied in the field of heaters, can solve the problems of easy generation of working noise, short service life of heat sources, unstable heat sources, etc., and achieve the effects of easy removal, stable heat generation, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

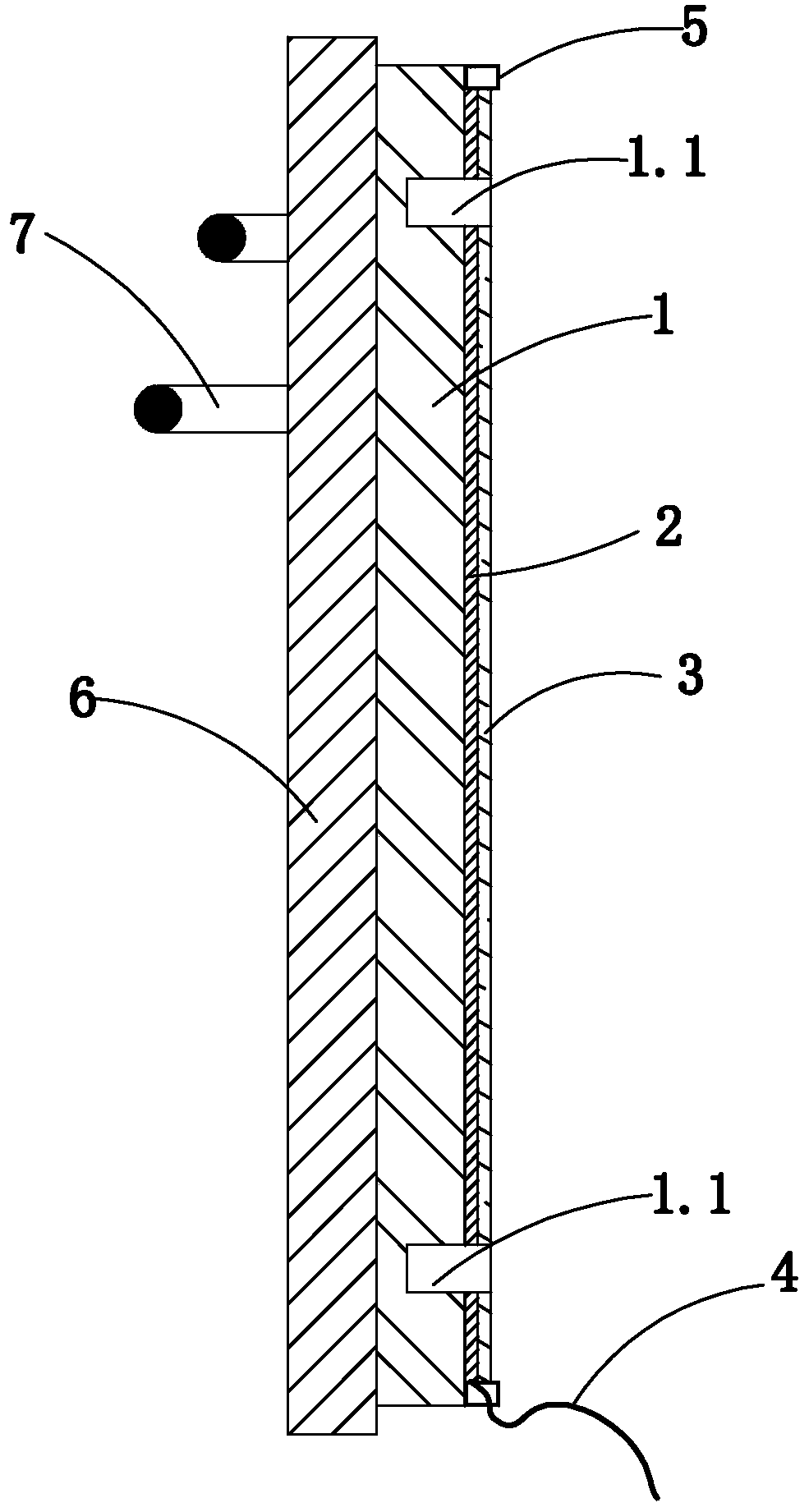

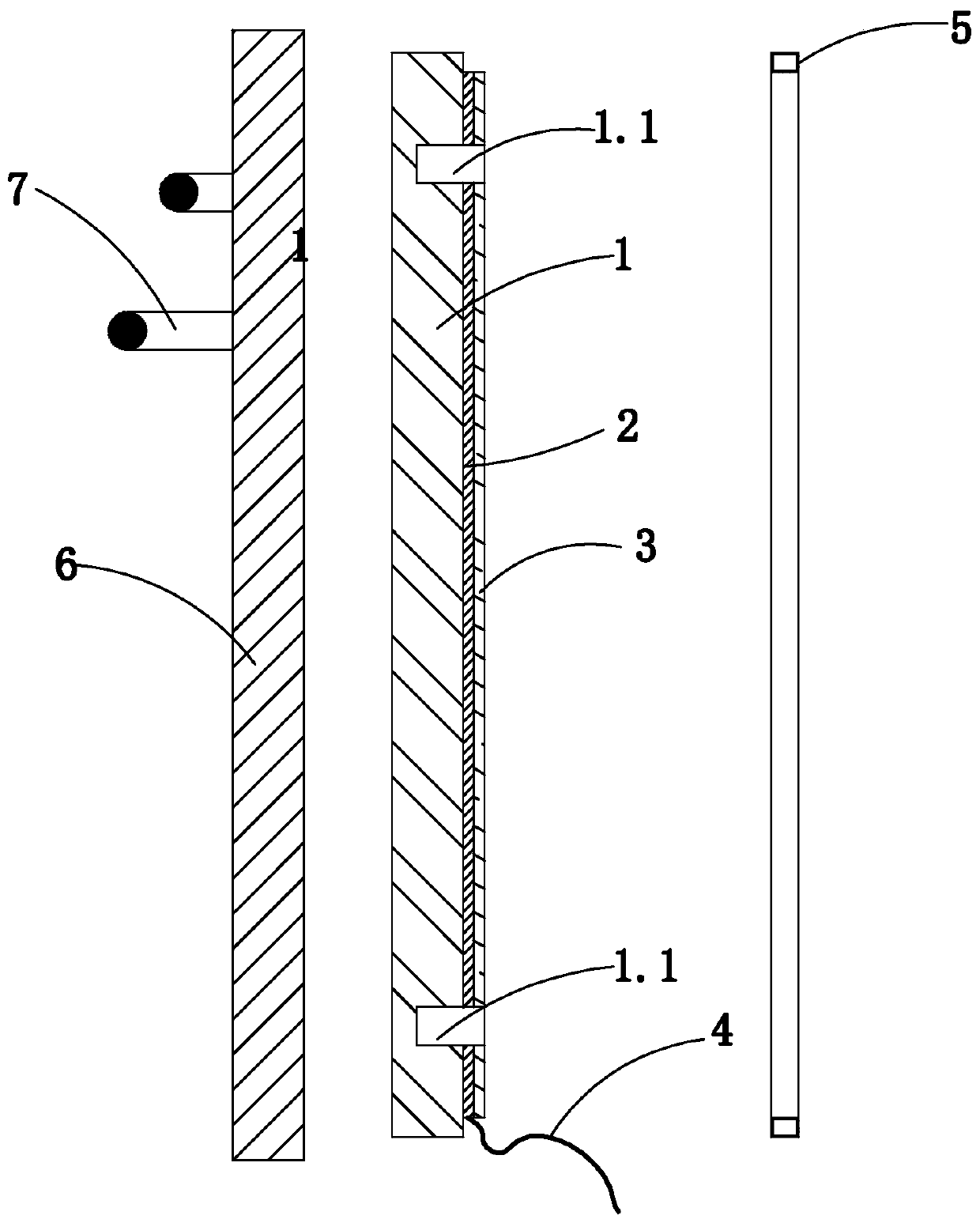

[0018] refer to figure 1 with figure 2 :

[0019] A heating component of a heater, comprising a decorative glass plate 6, two hanging rods 7 for hanging clothes are arranged in parallel on the front of the decorative glass plate 6, and a heating glass plate 1 is glued and fixed on the back.

[0020] The heating glass plate 1 is a toughened glass plate, and a thick film resistance circuit 2 and an insulating layer 3 are arranged on the back thereof. The thick film resistance circuit 2 is printed on the heating glass plate 1 and is connected with a power connection line 4. The glass plate 1 is covered with a thick film resistor circuit 2 .

[0021] The plate surface of heating glass plate 1 is provided with the installation hole 1.1 that is used for whole heating assembly is fixed on the heater shell, and its rear periphery is provided with the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com