Edge defect inspection method

An inspection method and edge defect technology, applied in the field of inspection, can solve problems such as undetected cracks in protective structures, distortion of grain edge search, collapse of protective structures or undetected cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

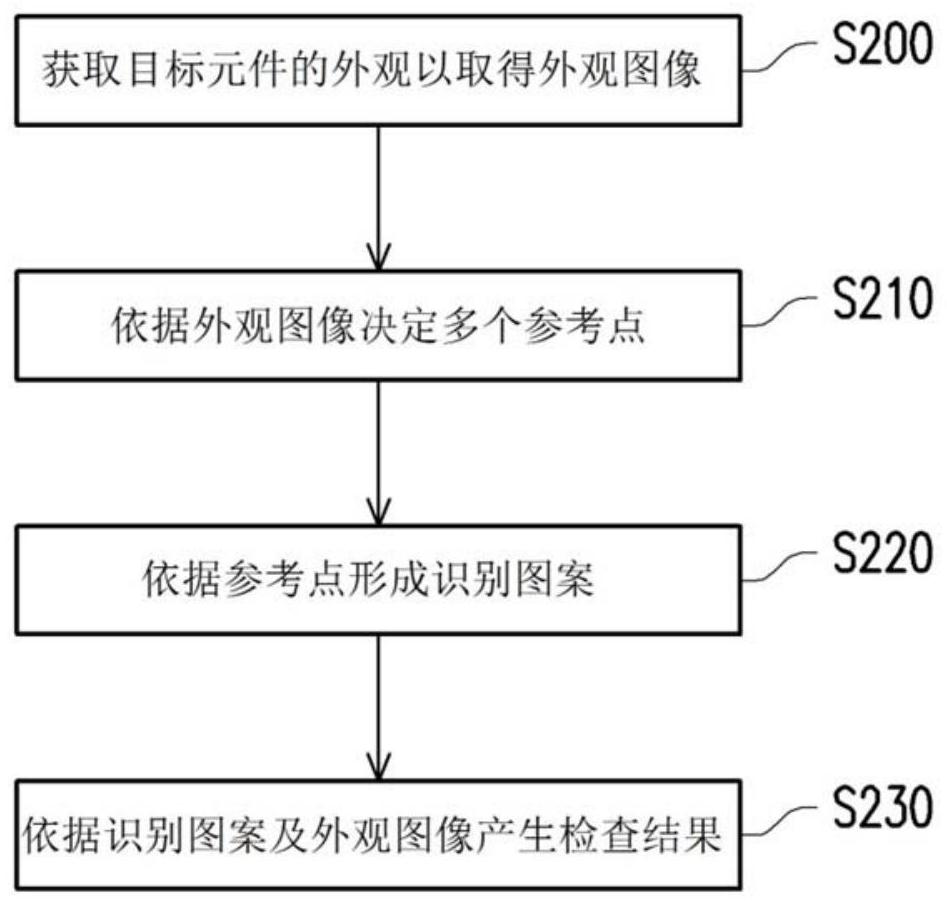

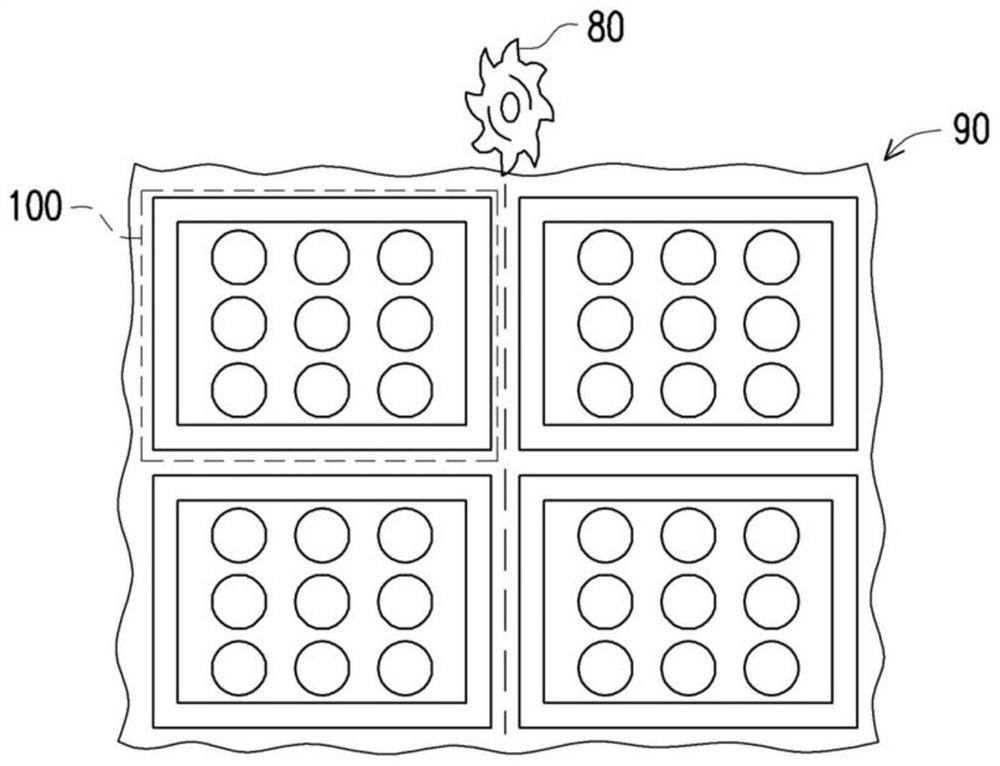

[0036] figure 1 It is a flow chart of steps of an edge defect inspection method according to an embodiment of the present invention. figure 2 It is a schematic diagram of cutting out a target element in an embodiment of the present invention. Please refer to figure 1 and figure 2 . The present embodiment provides an edge defect inspection method, and the edge defect inspection method is suitable for inspecting a target device 100, such as a die or a wafer-level chip package separated by wafer dicing. In this embodiment, the target element 100 is a wafer-level chip package cut out from a wafer 90 by the cutting equipment 80 , such as figure 2 shown, but the invention is not so limited.

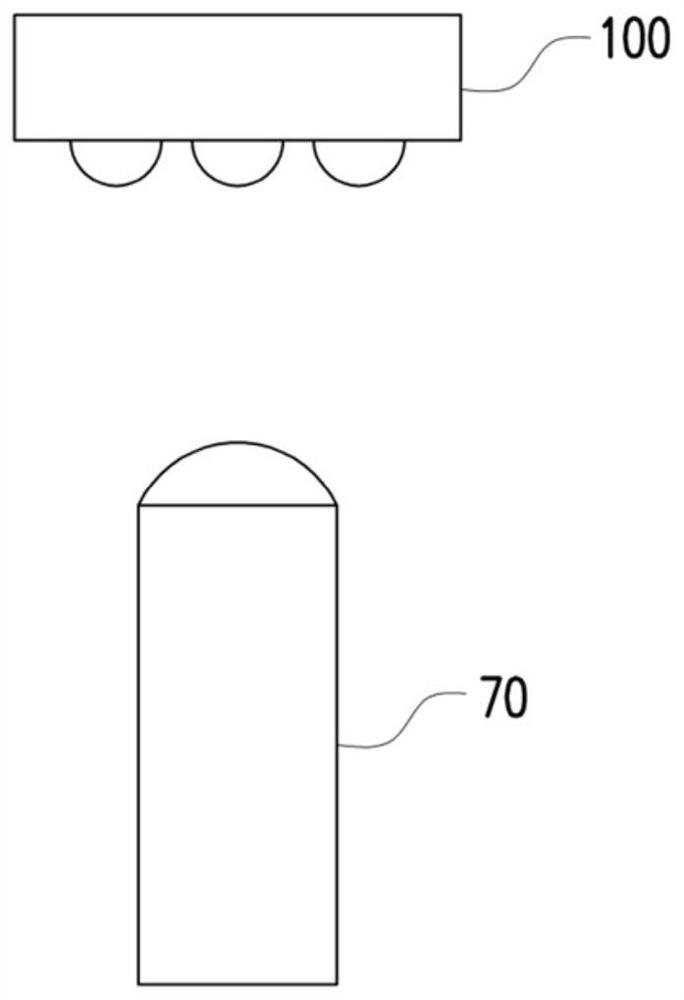

[0037] image 3 It is a schematic diagram of acquiring the appearance of a target element in an embodiment of the present invention. 4A to 4D It is a top view of an edge defect inspection method of a target component in an embodiment of the present invention. Please also refer to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com