Heating device for mixer heads

A stirring head and stirring blade technology are applied in the field of heating devices for stirring heads, which can solve the problems of increased risk of burns and inability of stirring heads to be heated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

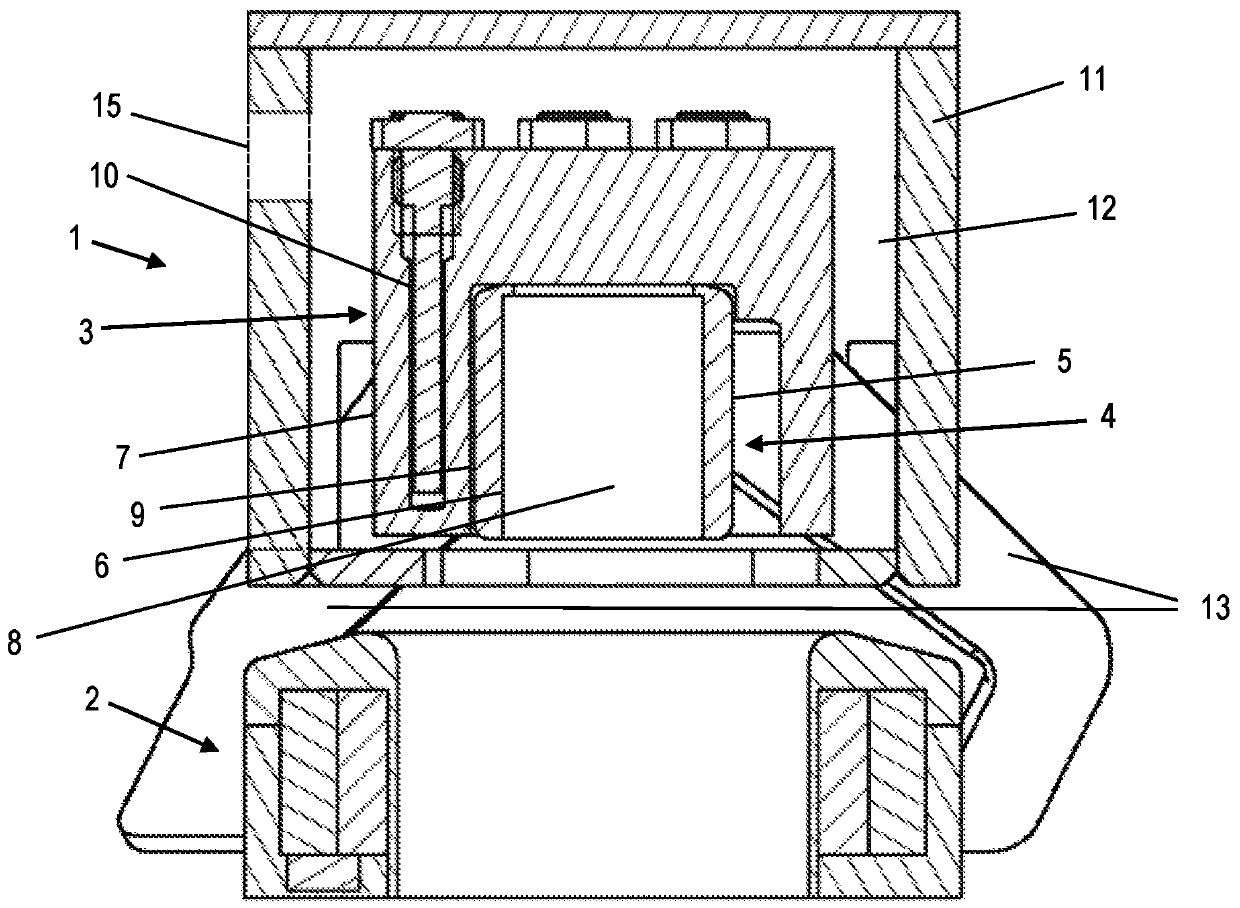

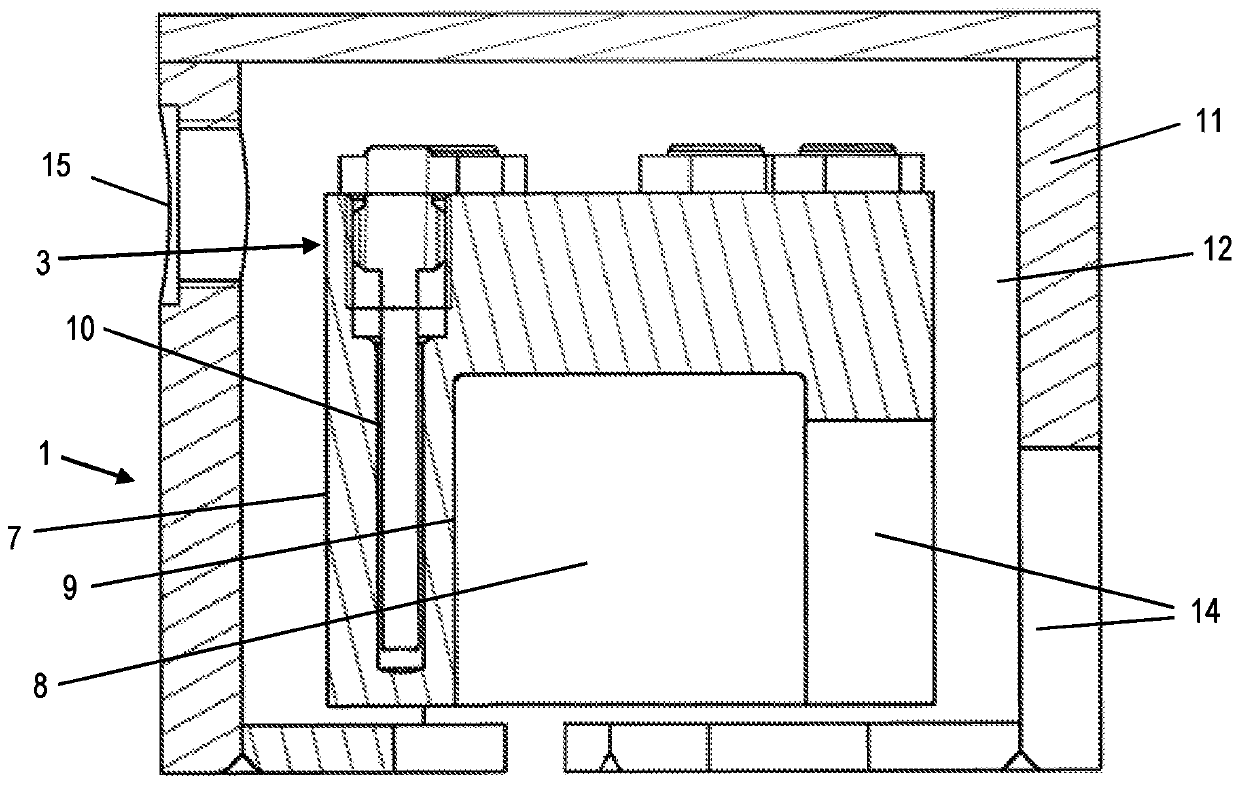

[0013] figure 1 A cross-sectional view of the arrangement consisting of the temperature control device 1 and the stirring head 2 in a preferred embodiment variant is shown in side view. The temperature control device 1 includes an adapter 3 , and the stirring head 2 includes a bearing hub 4 accommodated in the adapter 3 . Bearing hub 4 comprises outer bearing hub surface 5 and inner bearing hub surface 6 and bearing bushing ( figure 1 not shown in ), the bearing bush is form-fitted into the bearing hub 4 while abutting against the inner bearing hub surface 6 . To provide a better illustration, the temperature control device 1 is in figure 2 is depicted in detail in cross-section in , which does not accommodate the stirring head 2 . The adapter 3 of the temperature control device 1 has an outer adapter surface 7 and is open on the front side facing the adapter interior 8 . The adapter interior 8 in turn has an inner adapter surface 9 . Such as figure 1 As shown, the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com