Three-dimensional tailored thermal bonding invisible sock

A three-dimensional cutting and thermal bonding technology, which is applied to socks, pantyhose, clothing, etc., can solve the problems of unable to meet the actual needs of users, easy to fall off, poor comfort, etc., to protect human ankles, avoid easy fall off, protect ankle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is a detailed explanation and description of the technical solution of the three-dimensional cutting heat-bonded invisible socks provided by the present invention in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present invention.

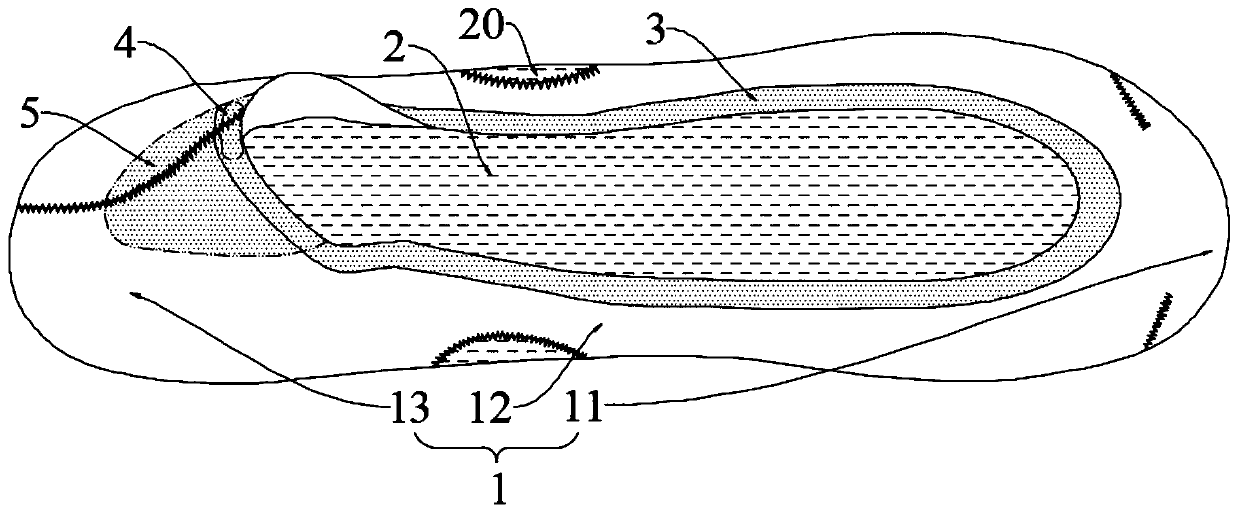

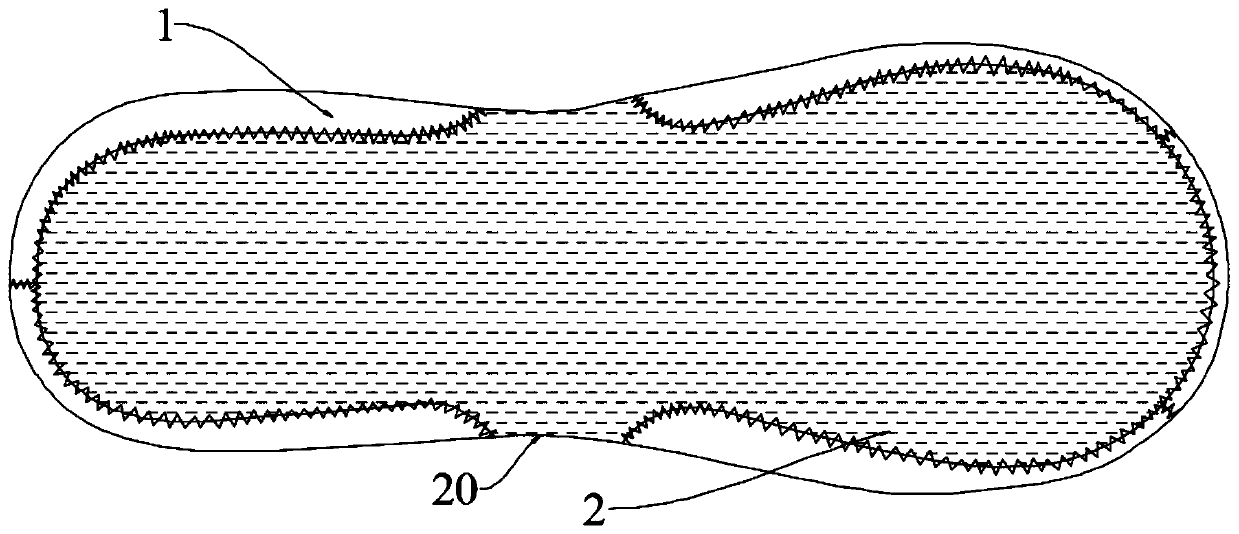

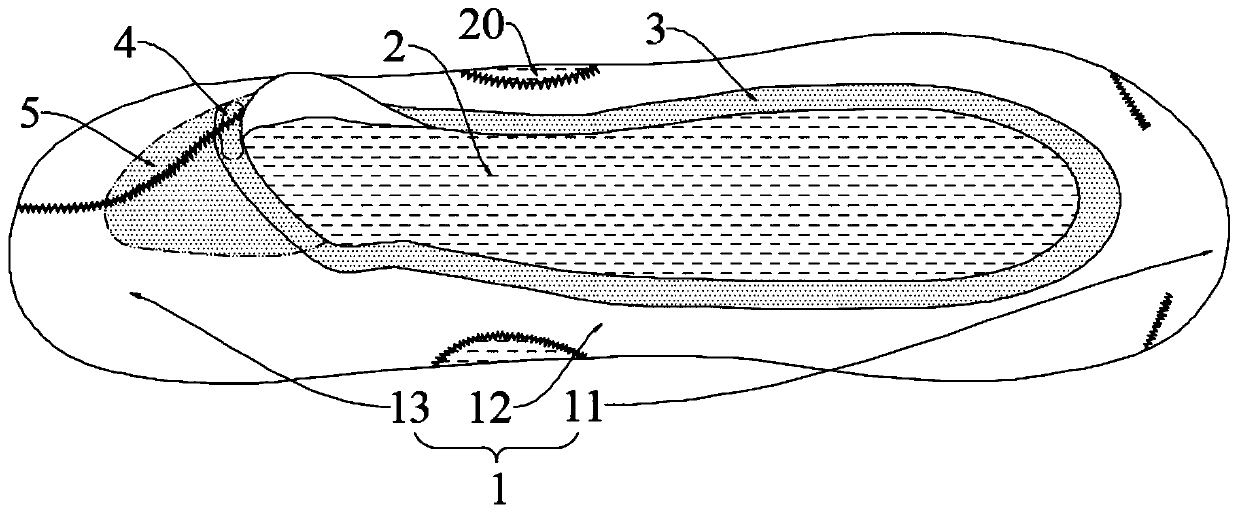

[0033] figure 1 The schematic diagram of the front of the heat-bonded invisible socks for draping, figure 2 Schematic diagram of the reverse side of thermally bonded invisible socks for draping, such as figure 1 and 2 As shown, this embodiment specifically discloses a three-dimensional cutting heat-bonded invisible socks, the three-dimensional cutting heat-bonded invisible socks include a sock top 1 and a sock bottom 2, and the lower edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com