High-pressure cleaning machine achieving non-loaded starting and automatic starting and stopping

A high-pressure cleaning machine, automatic start-stop technology, applied in the field of cleaning machines, can solve the problems of burning the motor, not being intelligent enough, reducing the convenience of the operator, and achieving the effect of prolonging the service life and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

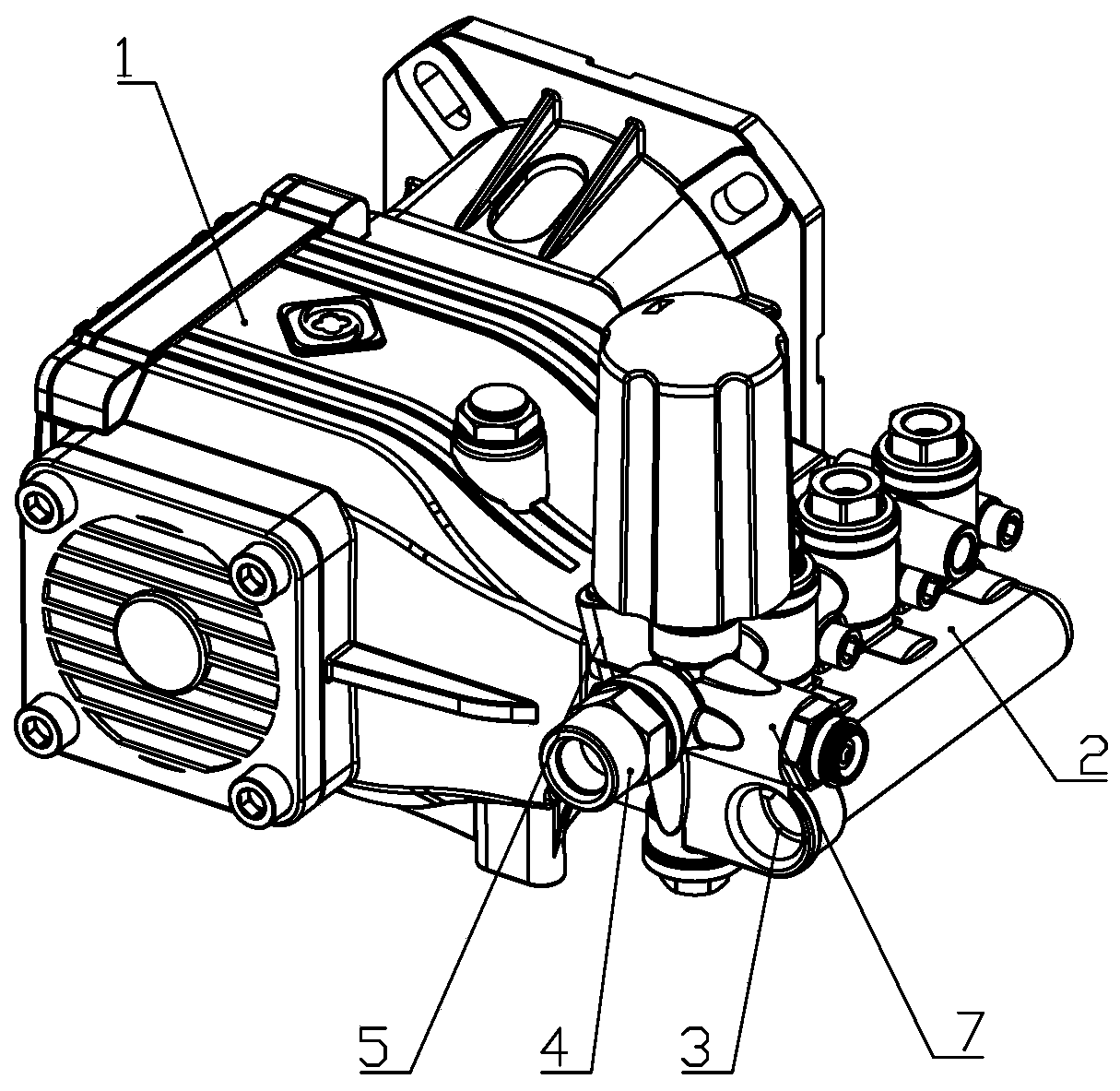

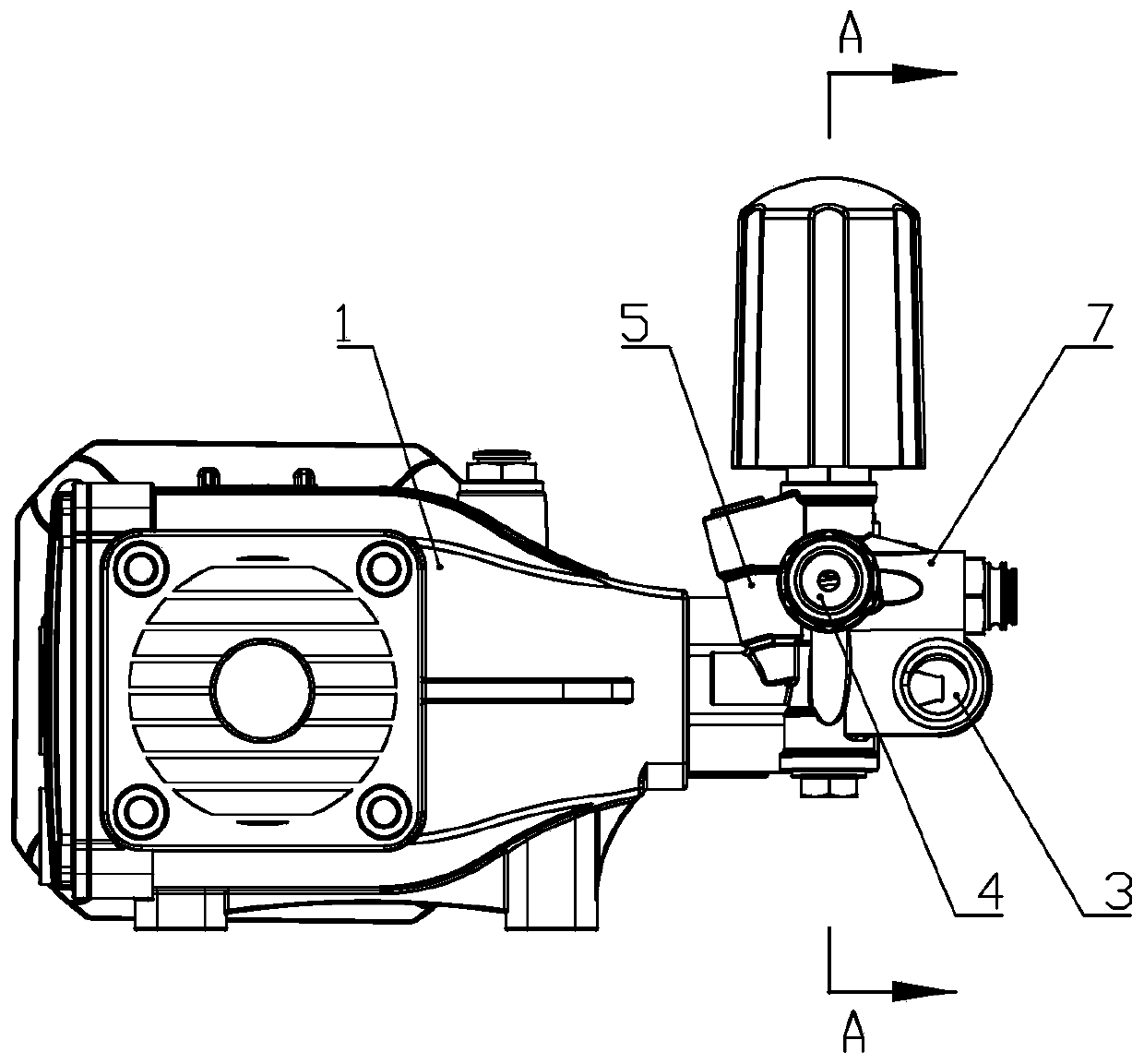

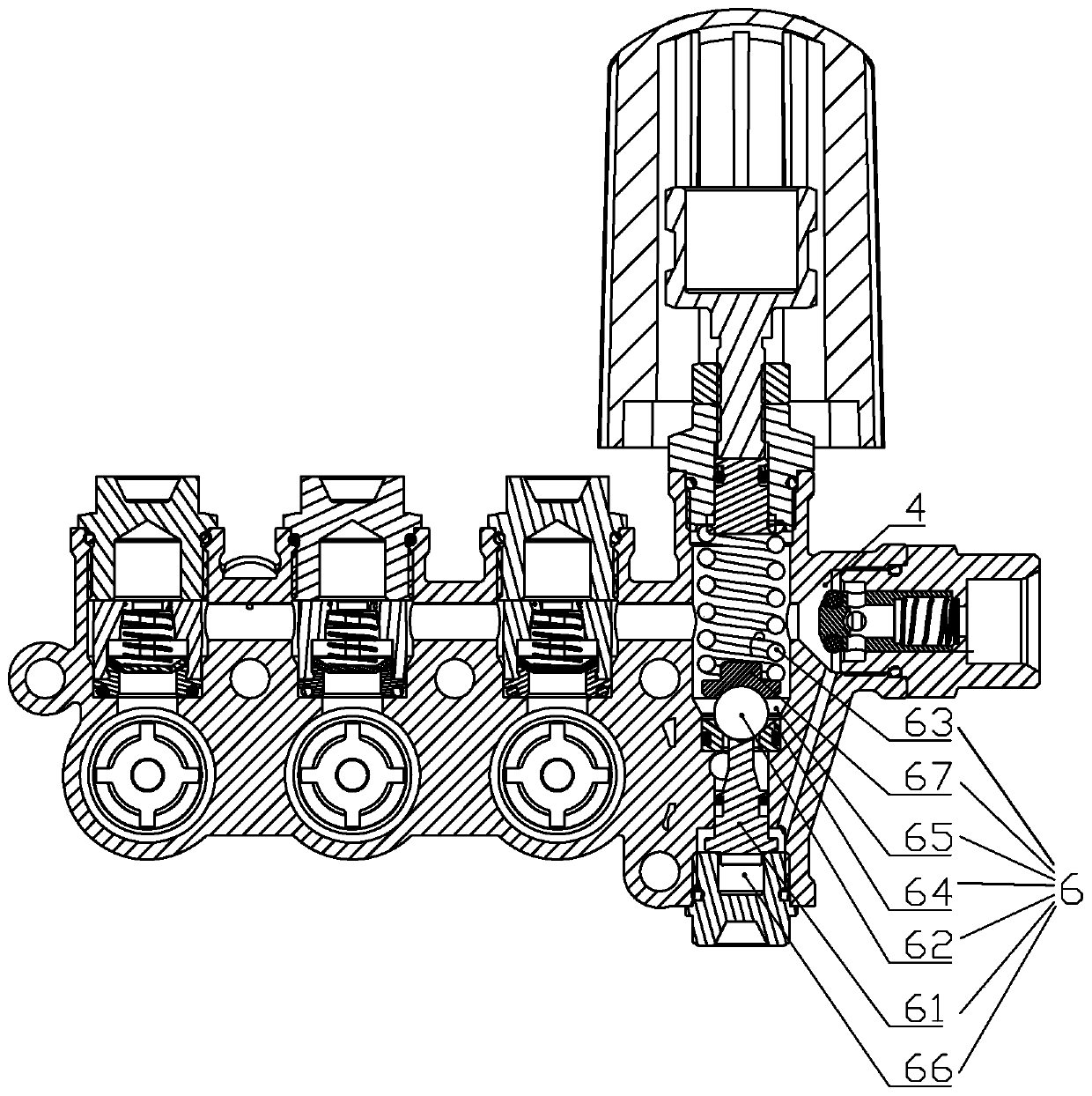

[0027] The present invention will be further described below with specific embodiment, see figure 1 -7:

[0028] A high-pressure cleaning machine with no-load start and automatic start and stop, including a motor, a pump body 1 linked with the motor, a pump head 2, a water inlet pipeline 3 connected to the pump head 2, a water outlet pipeline 4, and a water outlet pipeline connected to the 4, the pump head 2 is provided with a no-load starting valve 5, an unloading valve 6 and a start-stop control valve 7, and the no-load starting valve 5 includes a pressure control chamber with a steel ball 52 sliding inside, The steel ball 52 separates the pressure control chamber into a high-pressure chamber 55 and a low-pressure chamber 56; the unloading valve 6 includes an installation chamber communicated with the pump body 1, and the unloading valve stem 61 is connected with a sliding seal in the installation chamber. The loading valve stem 61 divides the installation chamber into a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com