A pressure control system and method for no-load start-up of an emulsion pump

A no-load start-up, pressure control technology, applied in pump control, machine/engine, liquid variable-capacity machinery, etc., can solve the problems of thick power supply circuit path, large vibration of the pump body of the emulsion pump, large current, etc. To achieve the effect of solving the large starting current and avoiding the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

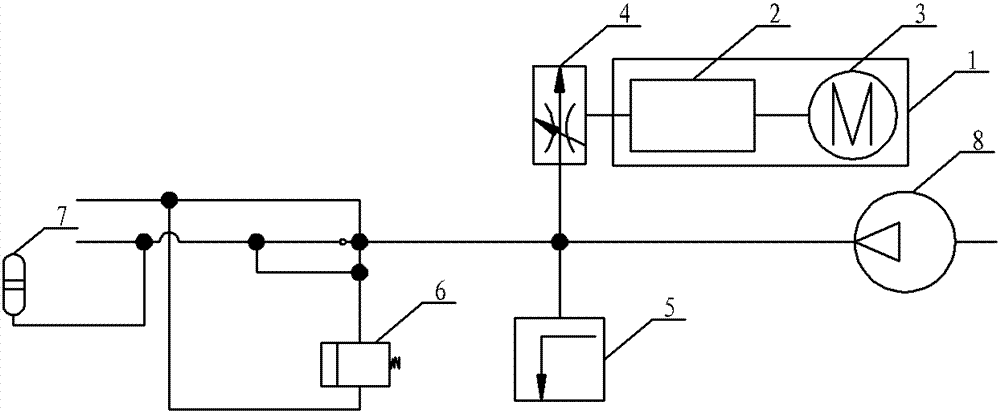

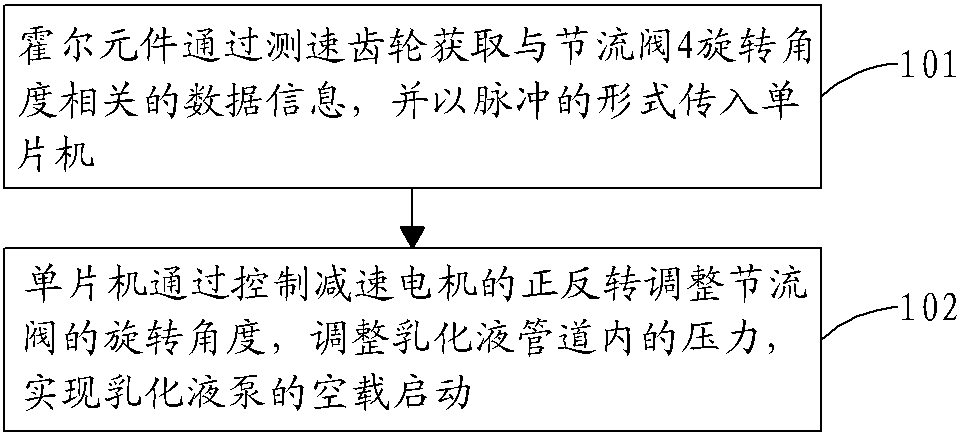

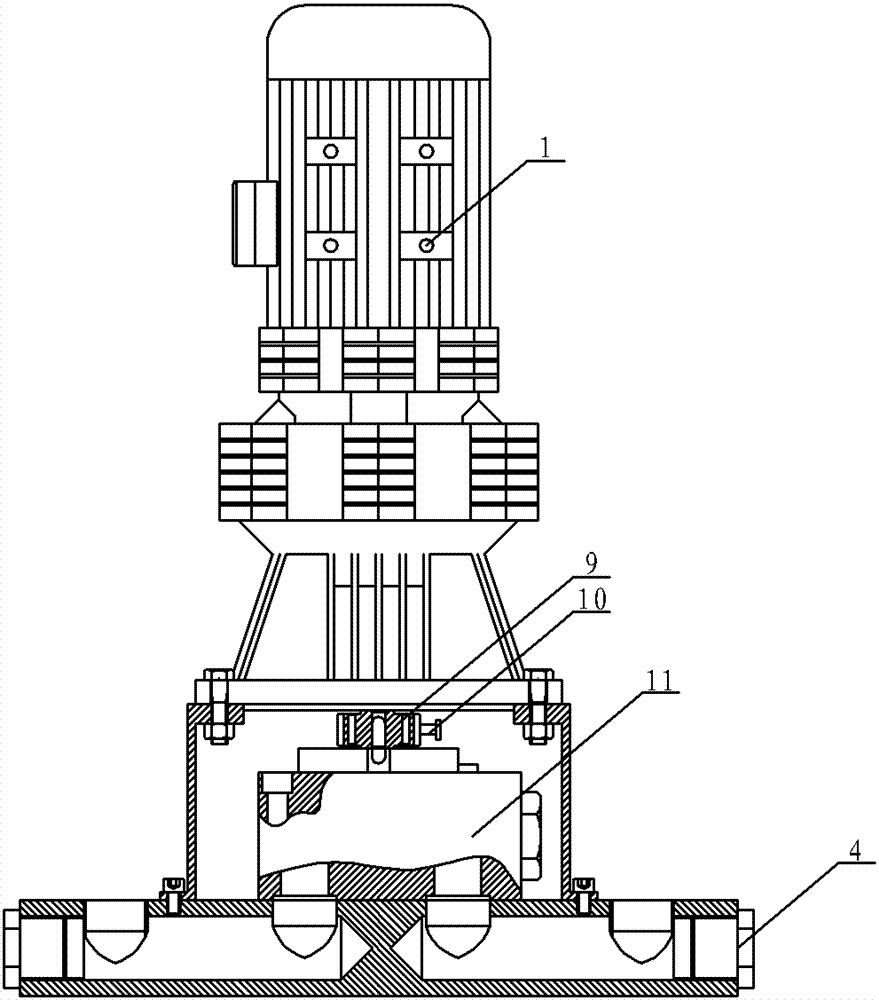

[0024] Please refer to figure 1 and image 3 as shown, figure 1 It is a structural schematic diagram of the pressure control system for the no-load startup of the emulsion pump of the present invention; image 3 It is a schematic diagram of the installation relationship between the geared motor and the throttle valve in the present invention.

[0025] In this embodiment, a pressure control system for no-load startup of an emulsion pump includes: a geared motor 1, a throttle valve 4, an opening measurement unit, and a motor control board. The geared motor 1 includes: a geared motor 2 and a motor 3; the opening measurement unit includes a speed measuring gear 9 and a Hall element 10; the motor control board includes: a single-chip microcomputer, a thyristor unit, an interlock circuit and a bidirectional thyristor optocoupler; the thyristor unit is Five-way thyristor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com