Top skin adsorption device for autoclaved aerated concrete blocks

A technology of concrete blocks and autoclaved air filling, which is applied in metal processing, ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting the adsorption operation, the hole blockage of the filter screen, and the air flow cannot pass through, so as to improve the adsorption effect, Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

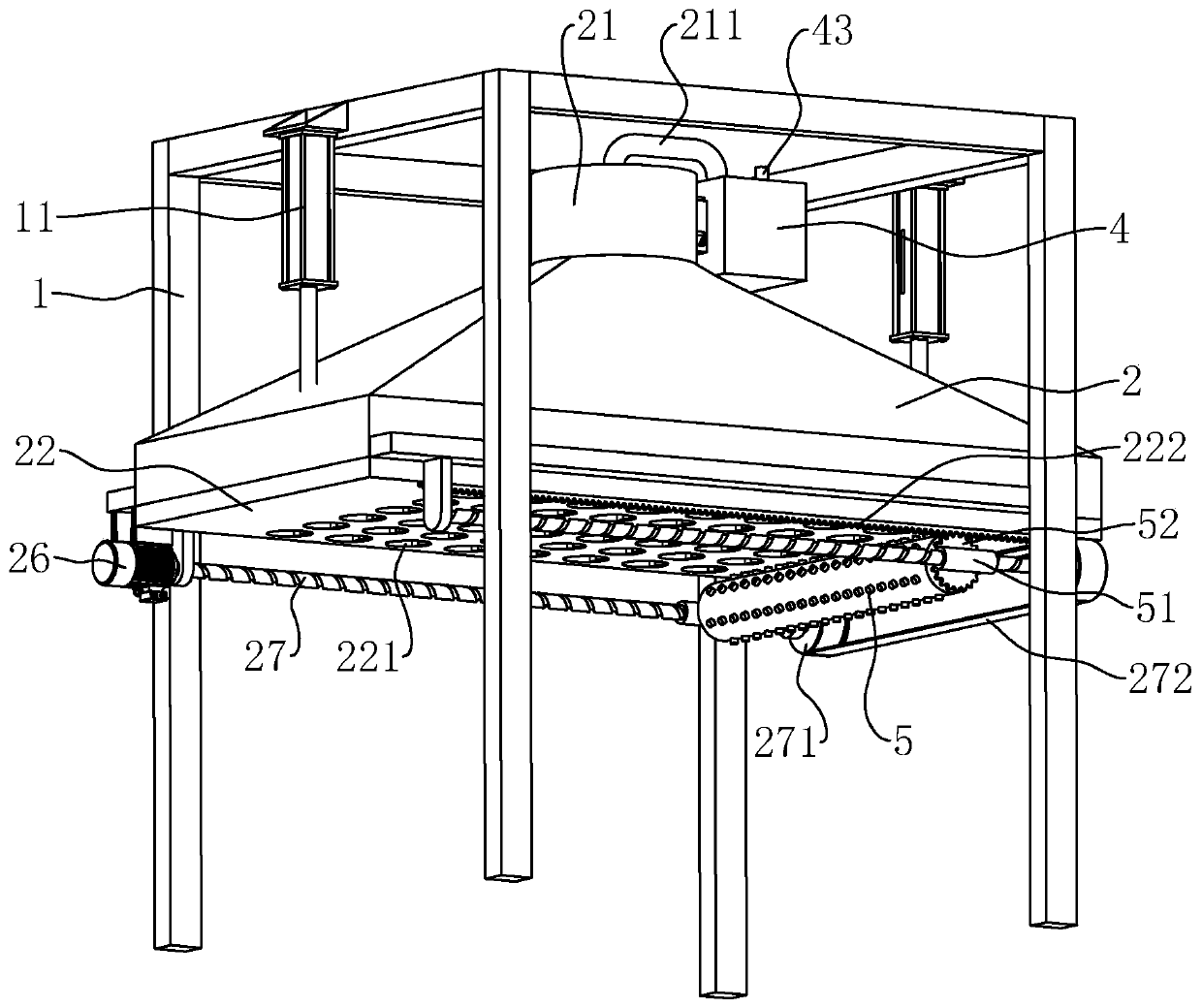

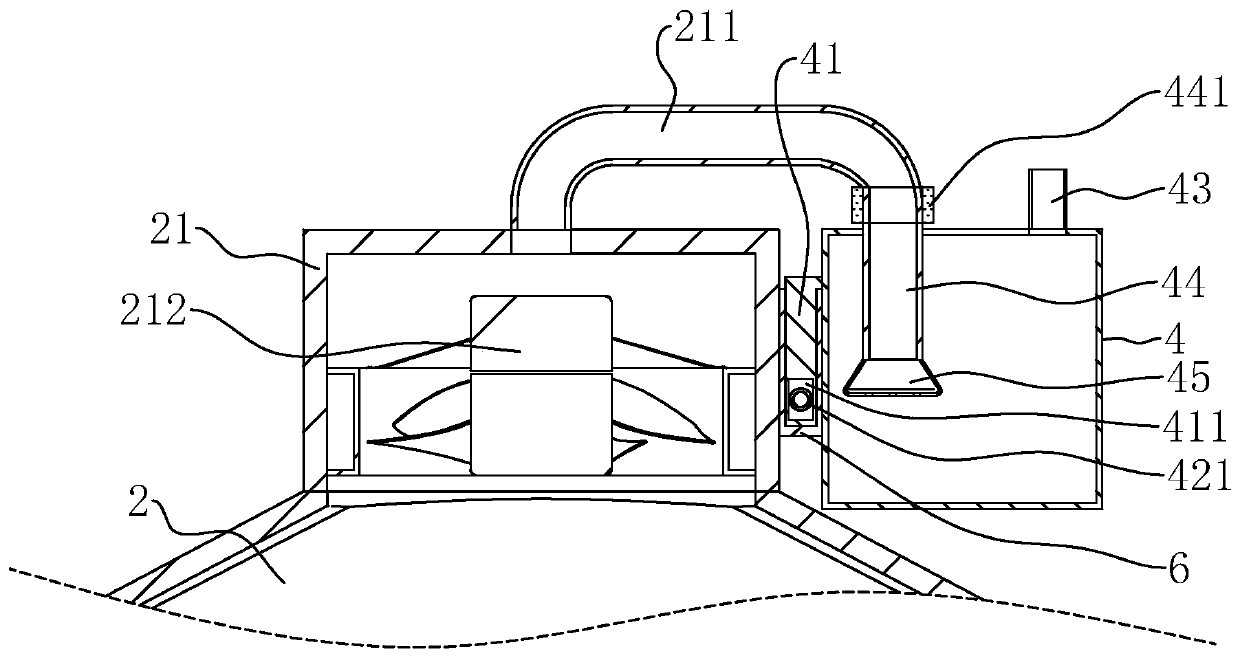

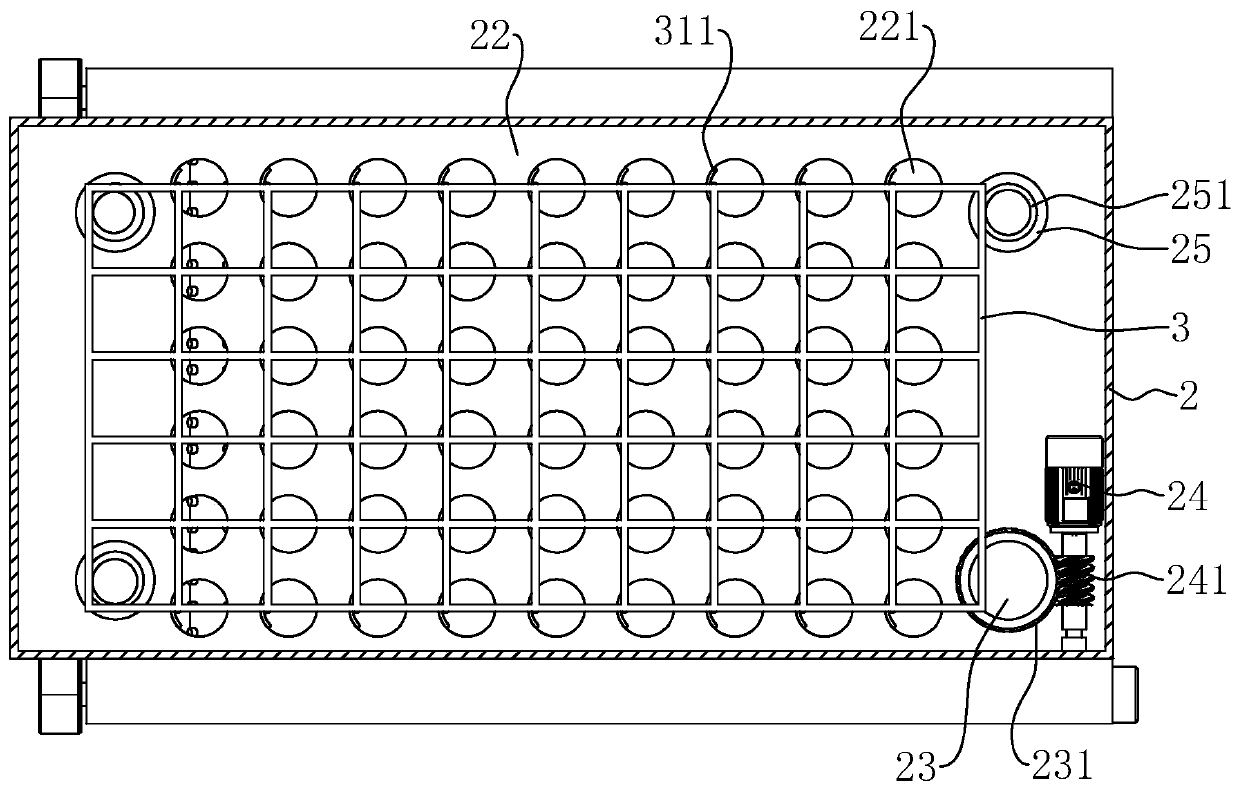

[0039] refer to figure 1 and figure 2 , is a top skin adsorption device for autoclaved aerated concrete blocks disclosed in the present invention, comprising a frame 1 and an adsorption cover 2, cylinders 11 are installed on both sides of the frame 1, and the hydraulic rods of the two cylinders 11 They are respectively fixedly connected with the two ends of the suction cover 2 . A bellows 21 is installed on the top of the adsorption cover 2, and a blower fan 212 for suctioning the adsorption cover 2 is installed in the bellows 21. The bottom surface of the adsorption cover 2 is provided with an adsorption plate 22, and the adsorption plate 22 is provided with a plurality of circular channels. Hole 221 , the through hole 221 communicates with the inside of the adsorption cover 2 . When the fan 212 is in operation, the top skin on the green body is fixed un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com