A device and method for uniform curing inside and outside of roll film

A roll film and curing technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of inconsistent curing degree, large deviation of room temperature, uneven curing temperature, etc., and achieve uniform curing degree, uniform curing degree, The effect of uniform curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

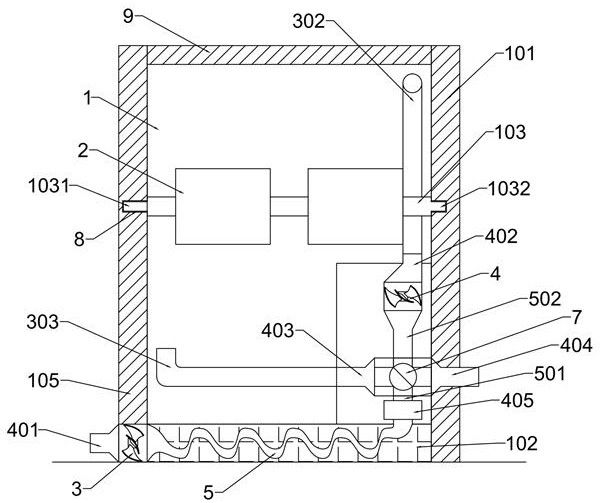

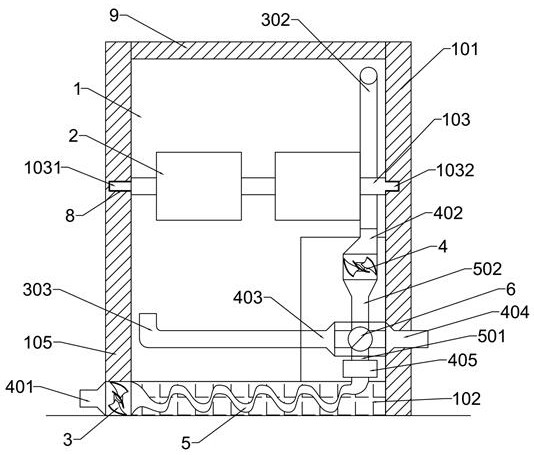

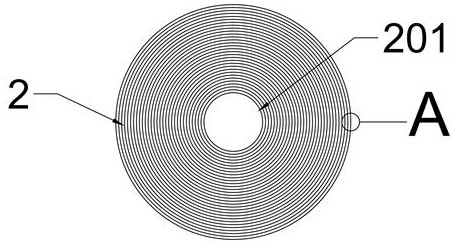

[0044] See figure 1 , image 3 and Figure 4, a device for uniform curing inside and outside the roll film, including a curing chamber 1 and a roll film 2, and the curing chamber 1 includes a curing chamber body 101, a heater 102, a transverse suspension rod 103 and an air circulation device 104, and the roll film 2. It also includes a paper core 201, a composite membrane 202 and a filter paper 203. The heater 102 is arranged at the lower part of the curing chamber body 101, and the horizontal suspension rod 103 is arranged at the middle part of the curing chamber body 101, between two opposite walls. The air circulation device 104 is arranged on one side of the curing chamber body 101, and the air circulation device 104 includes an external air inlet 401, an intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com