Plate and preparation method thereof, and electronic equipment

A technology of electronic equipment and boards, which is applied in the field of boards and electronic equipment with gradient color visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

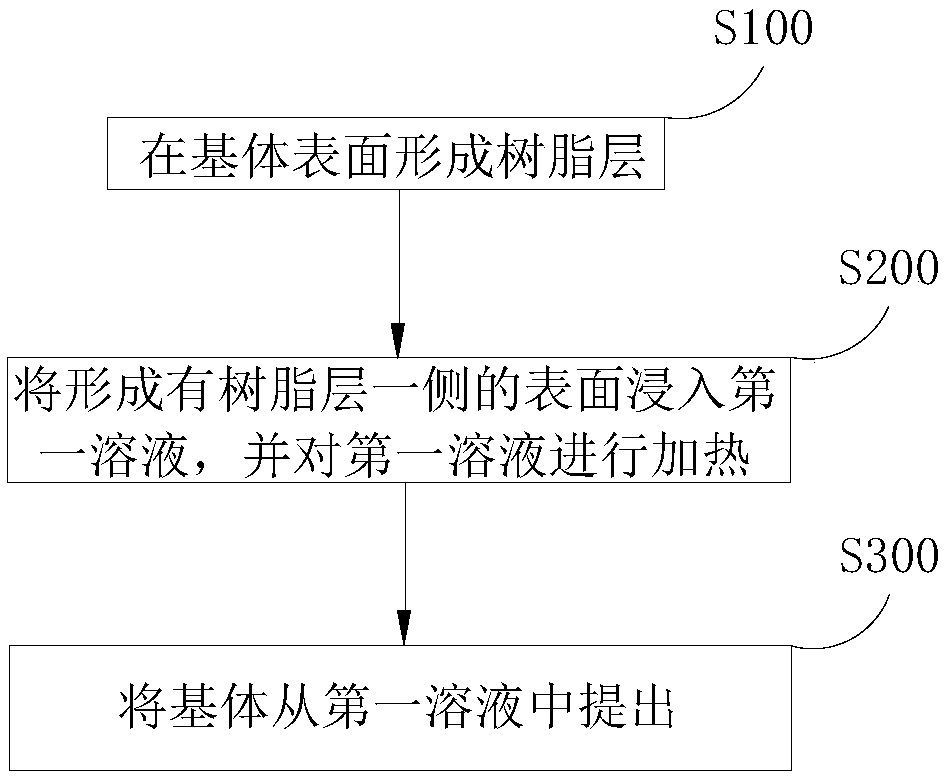

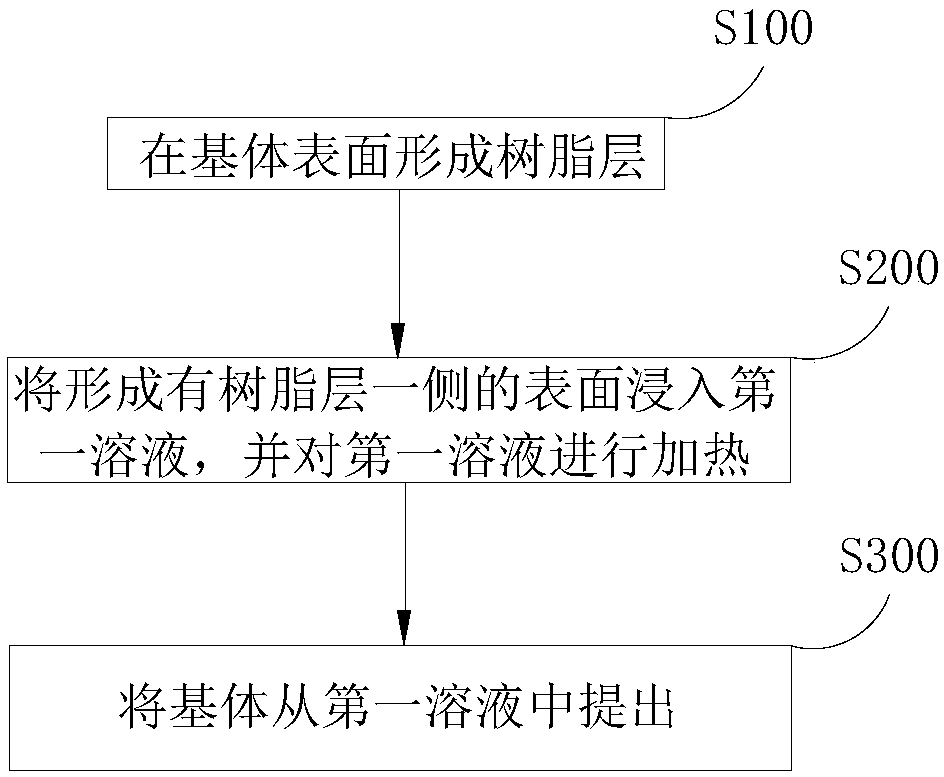

Method used

Image

Examples

Embodiment 1

[0058] The substrate is made of glass with a thickness of 0.5 mm. The procedure for staining the peel is as follows:

[0059] 1) Clean the glass surface with degreasing agent, rust remover and water, and dry the cleaned glass.

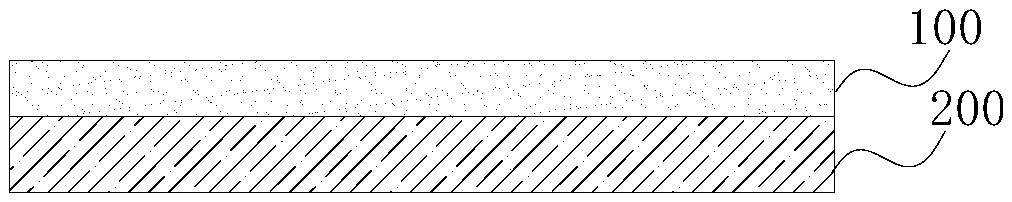

[0060] 2) A textured acrylic resin layer is screen-printed on the surface of the dried glass by screen printing technology, and the thickness of the acrylic resin layer is 20 μm.

[0061] 3) Configure a purple-blue dye solution, and add a dispersant and a leveling agent in sequence, and after stirring evenly, heat the above dye solution to 88 degrees Celsius.

[0062] 4) The glass formed with the acrylic resin layer is soaked slowly and uniformly in the heated dye solution.

[0063] 5) After the glass is immersed in the dye solution for 65 seconds, the glass substrate is lifted out of the dye solution at a uniform speed at a lifting speed of 35 mm / min.

[0064] 6) After the glass substrate is lifted, the glass substrate is washed through three washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com