A method for the synthesis of α,α-dibromoketones by electrochemical oxidation of dihalogenated alkynes without diaphragm

A compound and electrochemical technology, which is applied in the field of diaphragmless electrochemical oxidation of dihalogenated alkynes to synthesize α,α-dibromoketones, which can solve the problems of inactive halide ions, low efficiency of halogen atoms, complex reactions, etc. , to achieve the effect of eliminating metal residues, high economic applicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

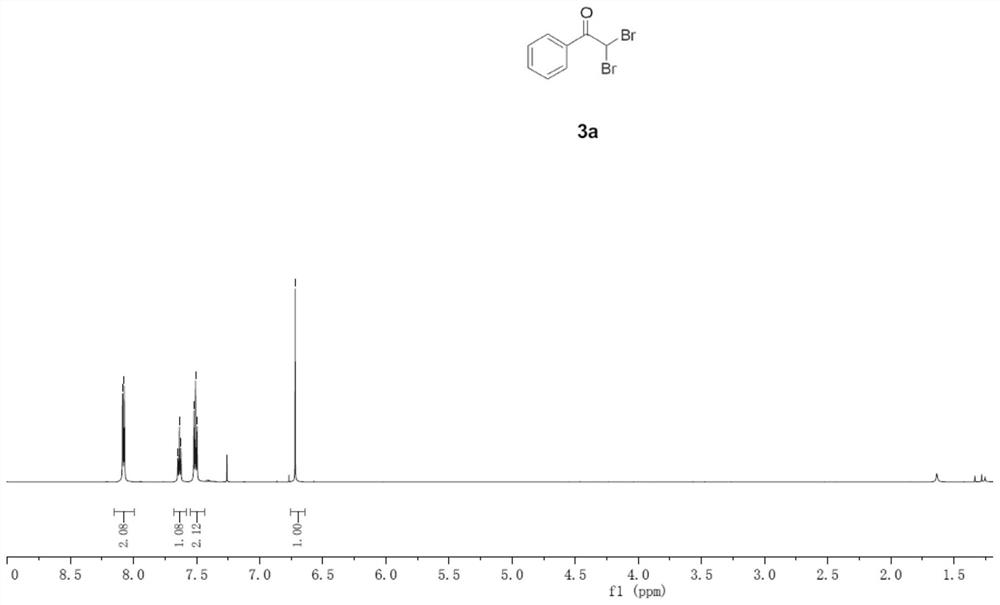

Embodiment 1

[0033] (1) In an oven-dried three-necked flask (25 mL) equipped with a stirring bar, phenylacetylene (0.3 mmol), LiClO4 (1.0 equivalent), nBu4NI (0.8 equivalent), H2O (2.0 equivalent), dibromomethane (33 equiv) and CH3CN (9.8 mL) were mixed and added to give a reaction mixture.

[0034] (2) Platinum electrodes (1.0 cm×1.0 cm×0.2 mm) were installed in the flask as anode and cathode. The reaction mixture was stirred and electrolyzed at room temperature at a constant current of 10 mA for 6 h. After completion, the reaction system in the test tube was transferred to a 25mL eggplant-shaped bottle without any post-processing operation. Using a Heidolph rotary evaporator, the rotation speed was 80-100rpm, the temperature was 38°C, the vacuum degree was 0.1Mpa, and the reaction system was treated for 3 minutes. The residue was subjected to column chromatography using 200-mesh column chromatography silica gel, and the developer was petroleum ether: ethyl acetate = 20:1, and 61.7 mg of...

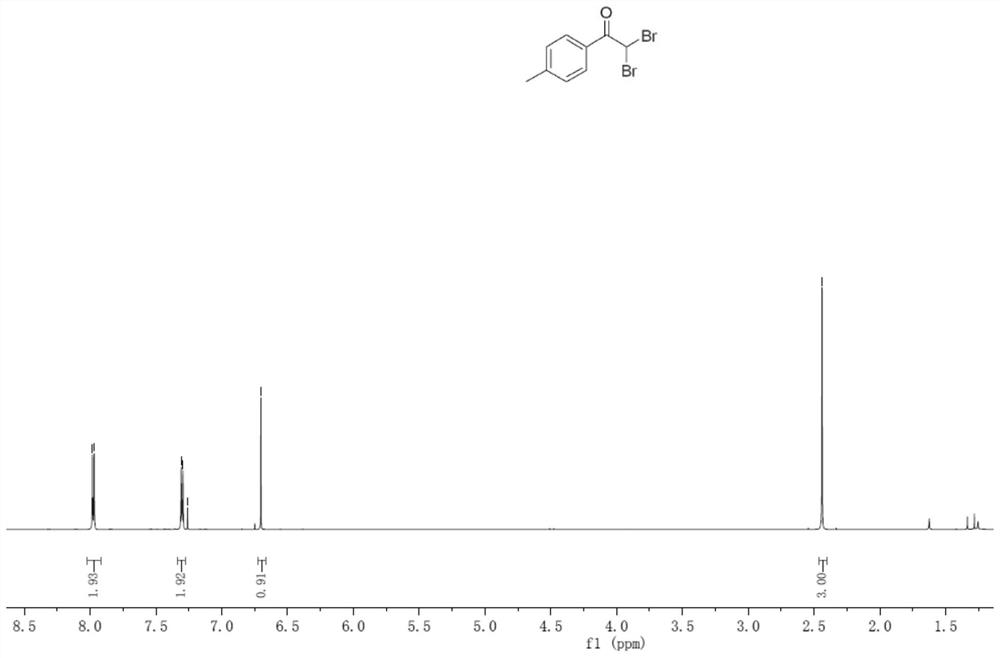

Embodiment 2

[0039] (1) In an oven-dried three-necked flask (25 mL) equipped with a stirring bar, p-tolylphenylene vinylene (0.3 mmol), LiClO4 (1.0 equivalent), nBu4NI (0.8 equivalent), H2O (2.0 equivalent) , dibromomethane (33 equiv) and CH3CN (9.8 mL) were combined and added to give a reaction mixture.

[0040] (2) The flask was equipped with platinum electrodes (1.0 cm x 1.0 cm x 0.2 mm) as anode and cathode. The reaction mixture was stirred and electrolyzed at room temperature at a constant current of 10 mA for 6 h. After completion, the reaction system in the test tube was transferred to a 25mL eggplant-shaped bottle without any post-processing operation. Using a Heidolph rotary evaporator, the rotation speed was 80-100rpm, the temperature was 38°C, the vacuum degree was 0.1Mpa, and the reaction system was treated for 3min. The residue was subjected to column chromatography using 200-mesh column chromatography silica gel, and the developer was petroleum ether: ethyl acetate = 20:1, a...

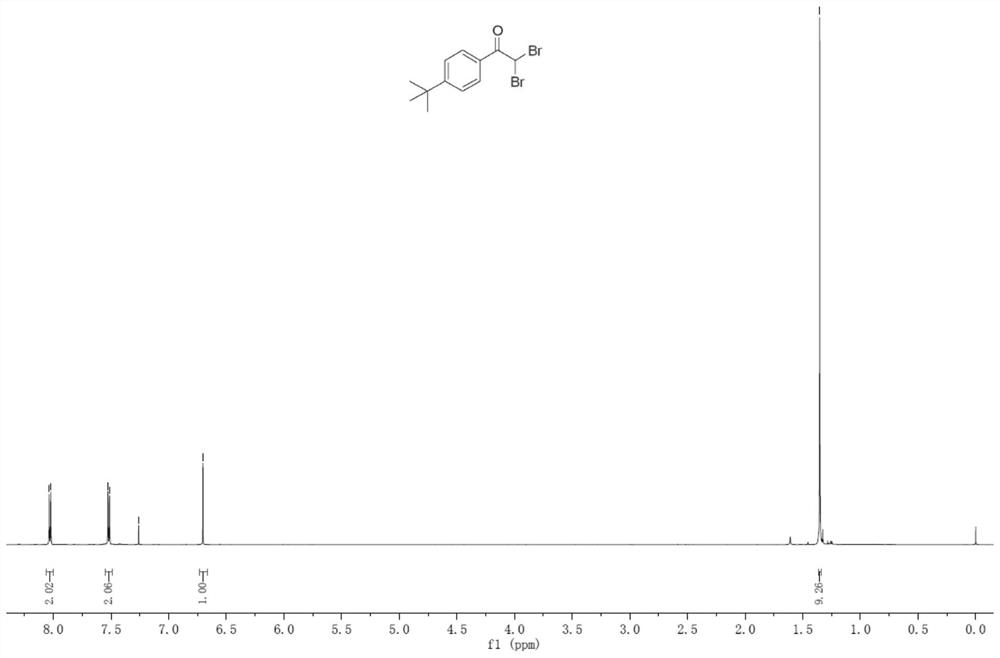

Embodiment 3

[0045] (1) In an oven-dried three-neck flask (25 mL) equipped with a stirring bar, mix p-tert-butylphenylacetylene (0.3 mmol), LiClO4 (1.0 equivalent), nBu4NI (0.8 equivalent), H2O (2.0 eq), dibromomethane (33 eq), and CH3CN (9.8 mL) were mixed and added to give a reaction mixture.

[0046] (2) The flask was equipped with platinum electrodes (1.0 cm x 1.0 cm x 0.2 mm) as anode and cathode. The reaction mixture was stirred and electrolyzed at room temperature at a constant current of 10 mA for 6 h. After completion, the reaction system in the test tube was transferred to a 25mL eggplant-shaped bottle without any post-processing operation. Using a Heidolph rotary evaporator, the rotation speed was 80-100rpm, the temperature was 38°C, the vacuum degree was 0.1Mpa, and the reaction system was treated for 3min. The residue was subjected to column chromatography using 200-mesh column chromatography silica gel, and the developing solvent was petroleum ether: ethyl acetate = 20:1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com