U-shaped push rod for automobile electric tail-gate system

An electric and tailgate technology, applied in the direction of door/window accessories, power control mechanism, wing leaf control mechanism, etc., can solve the problems of reduced pushing and stabilizing effects, reduced service life of push rods, reduced motor torque, etc., to achieve reduction Effects of wear, prolonging service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

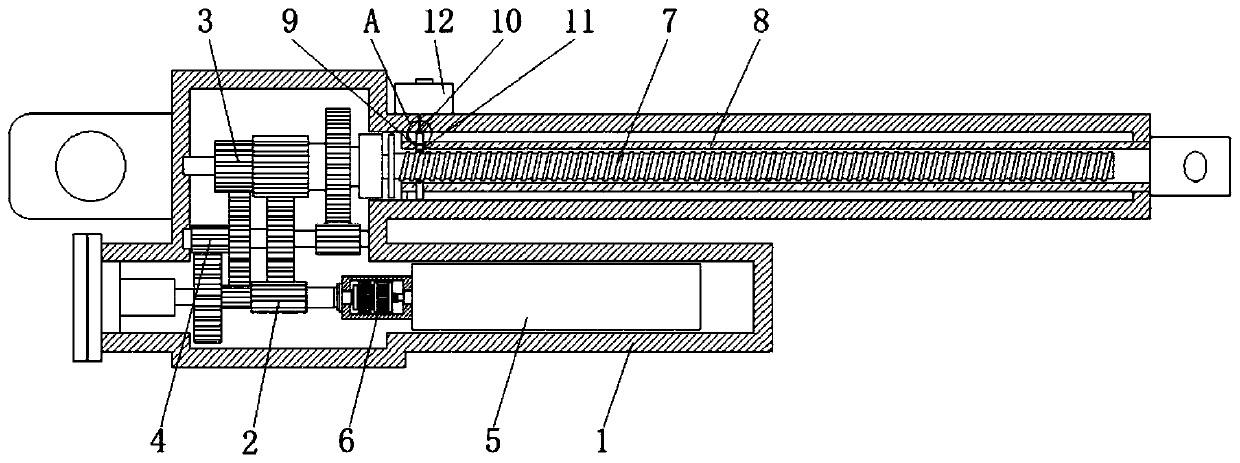

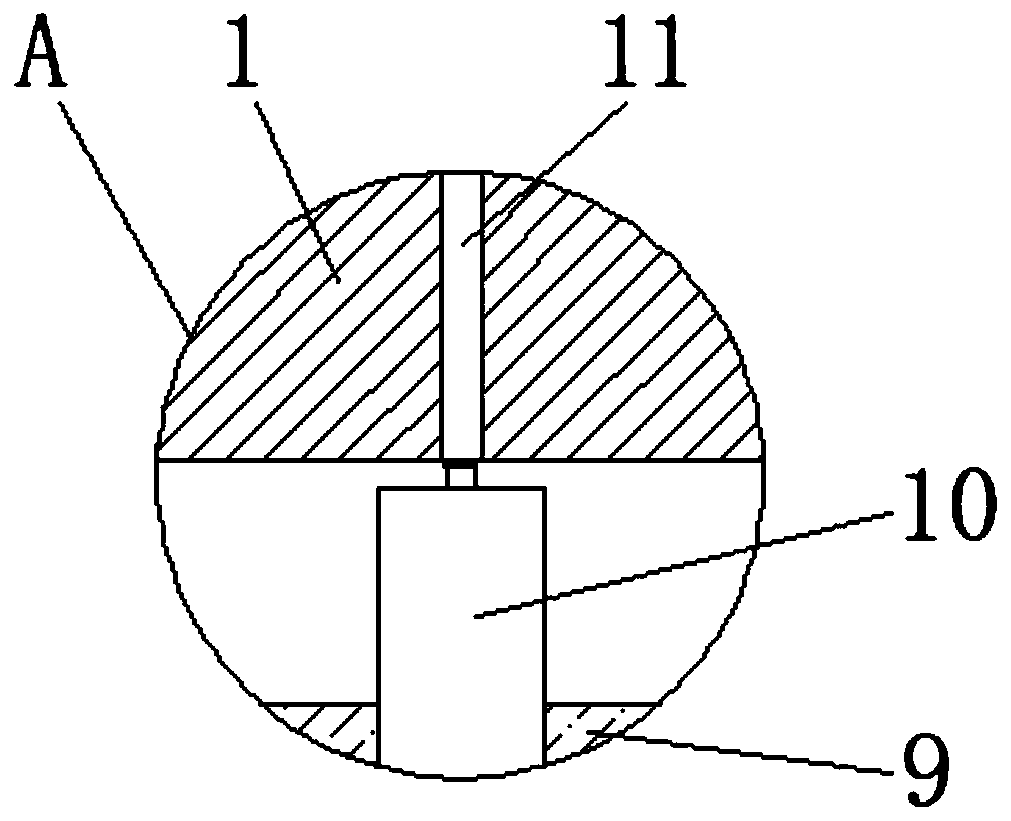

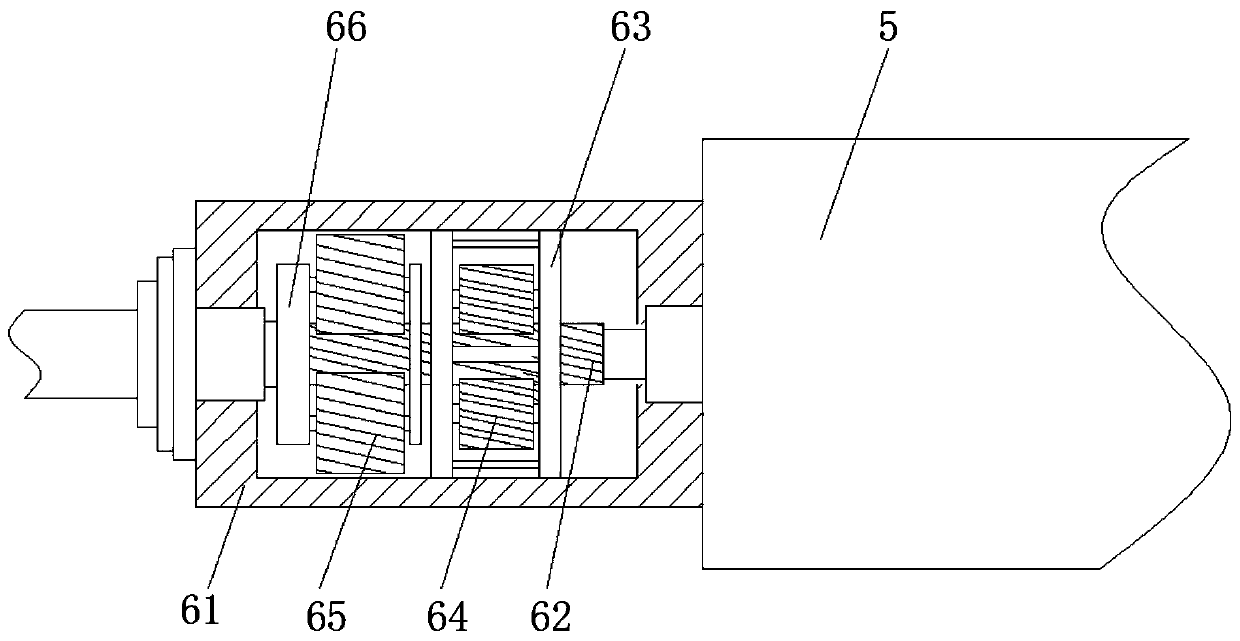

[0022] see Figure 1 to Figure 4 The present invention provides a technical solution: a U-shaped push rod used in an automobile electric tailgate system, including a casing 1, a permanent magnet motor 5 is fixedly installed inside the casing 1, and a rotating shaft of the permanent magnet motor 5 is fixedly sleeved with a transmission The device 6, the transmission device 6 includes the device body 61, the main inclined column rod 62, the installation card seat 63, the first helical gear 64, the second helical gear 65 and the swivel seat 66, the main inclined column bar 62, the installation card seat 63, the second helical gear One helical gear 64, the second helical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com