A shock absorbing device and a shock absorbing method for an electric control box

An electric control box and electric control technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of burning equipment, power distribution box performance failure, loss of property and personnel, etc., and achieve extended use Long life, good shock absorption effect, and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

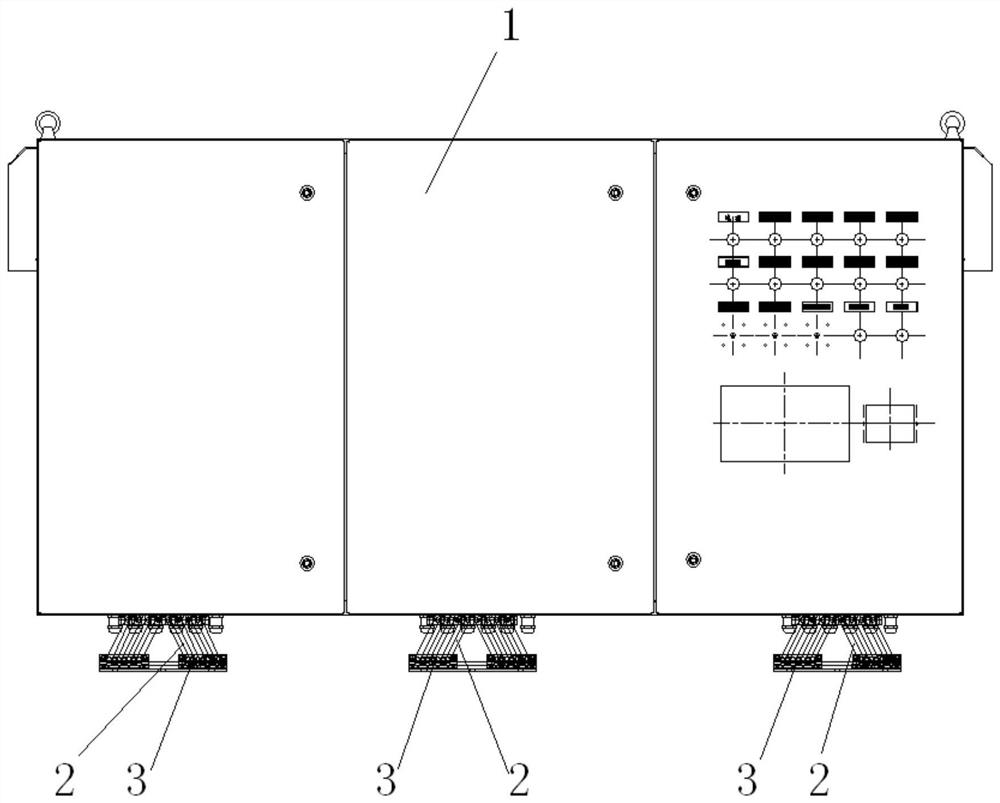

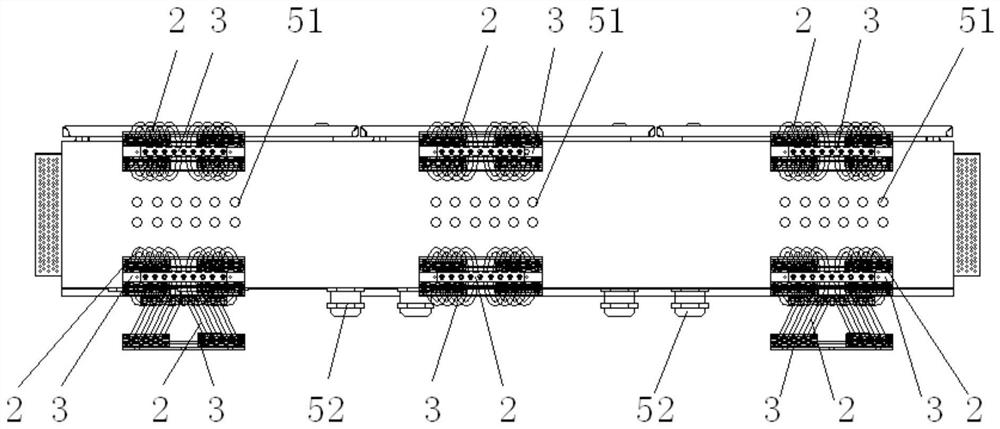

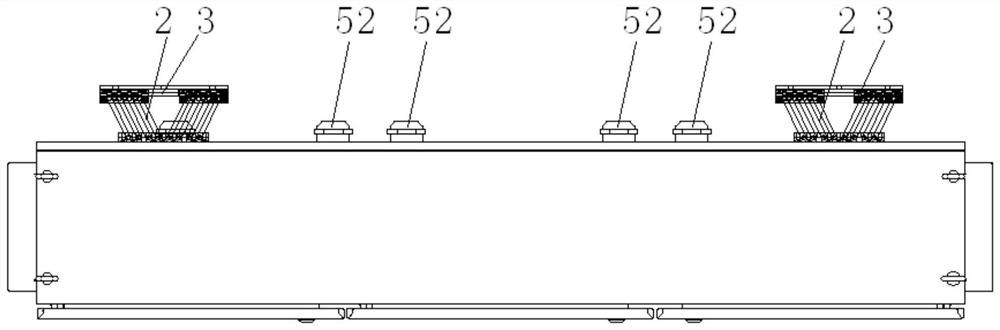

[0032] like Figure 1 to Figure 5 As shown, the shock absorbing device of the electric control box in this embodiment includes an electronically controlled shock absorbing damper 2, a vibration detector 3, an anti-vibration airbag, a shock absorbing control unit 4, an electronically controlled shock absorbing damper 2, and a shock absorbing device 3 The shock-absorbing airbag and the shock-proof airbag are both arranged on the installation surface of the electric control box 1, and the vibration detector 3 is connected with the electronically controlled shock-absorbing damper 2. The shock-absorbing control unit 4 is arranged in the electric control box 1, and can control the opening and closing of the shock-proof airbag. The electronically controlled shock absorber damper 2 can be controlled to generate damping. The electronically controlled shock absorption damper 2 can form the first heavy buffer; the anti-vibration airbag forms the second heavy shock, which cooperates with ...

Embodiment 2

[0038] like Image 6 As shown, the shock absorption method of the electric control box in this embodiment includes the following steps:

[0039] (1) The vibration detector 3 monitors the vibration parameters of the electronically controlled shock absorption damper 2 and feeds it back to the shock absorption control unit 4. If the obtained vibration parameters are less than the first preset value, the electronically controlled shock absorption damper 2 is in a natural state. In the elastic state, if the obtained vibration parameter is greater than the first preset value, go to step (2);

[0040] (2) If the obtained vibration parameter is less than the second preset value, the shock absorption control unit 4 controls the electronically controlled shock absorption damper 2 to enter an inelastic state, and the electronically controlled shock absorption damper 2 generates large damping to absorb the vibration energy. The vibration parameter is greater than the second preset value,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com