Test device and test method for low superheat and large span test of compressor

A test device and compressor technology, applied in the direction of measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of small span of cooling capacity, inability to provide low superheat, and gas coolers that cannot meet the test requirements, etc., to achieve Reduced construction costs, reduced space, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

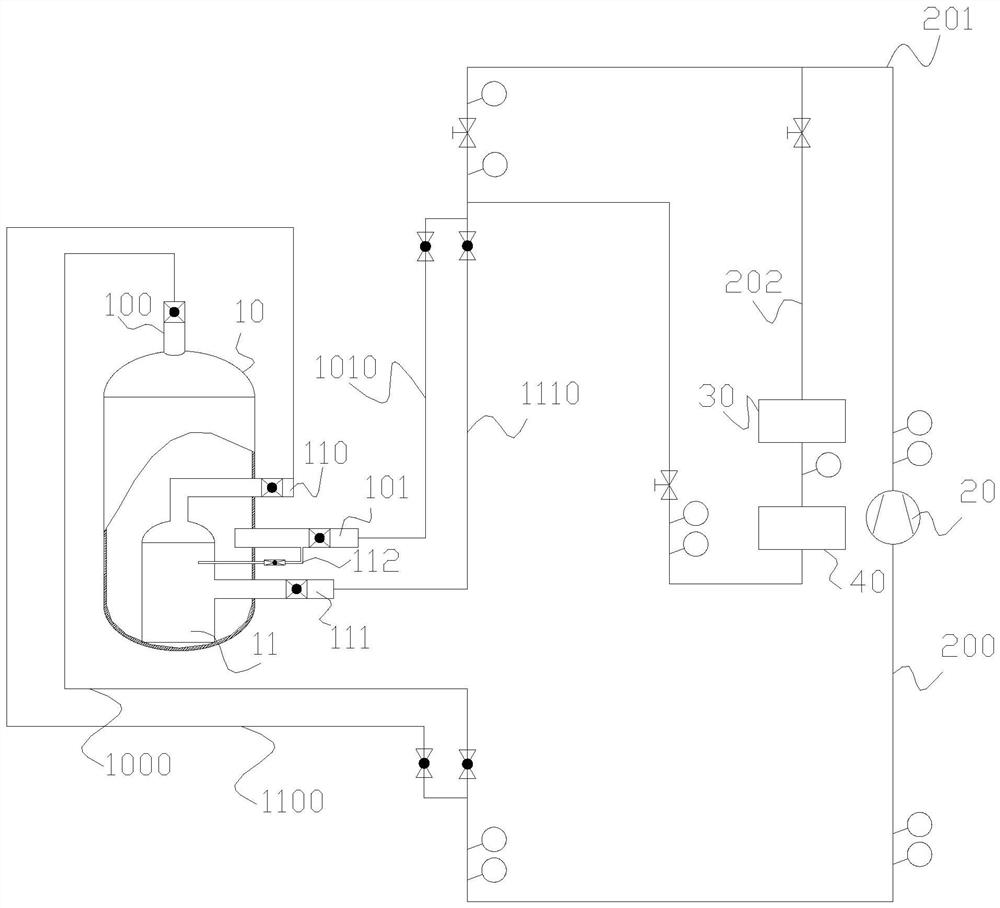

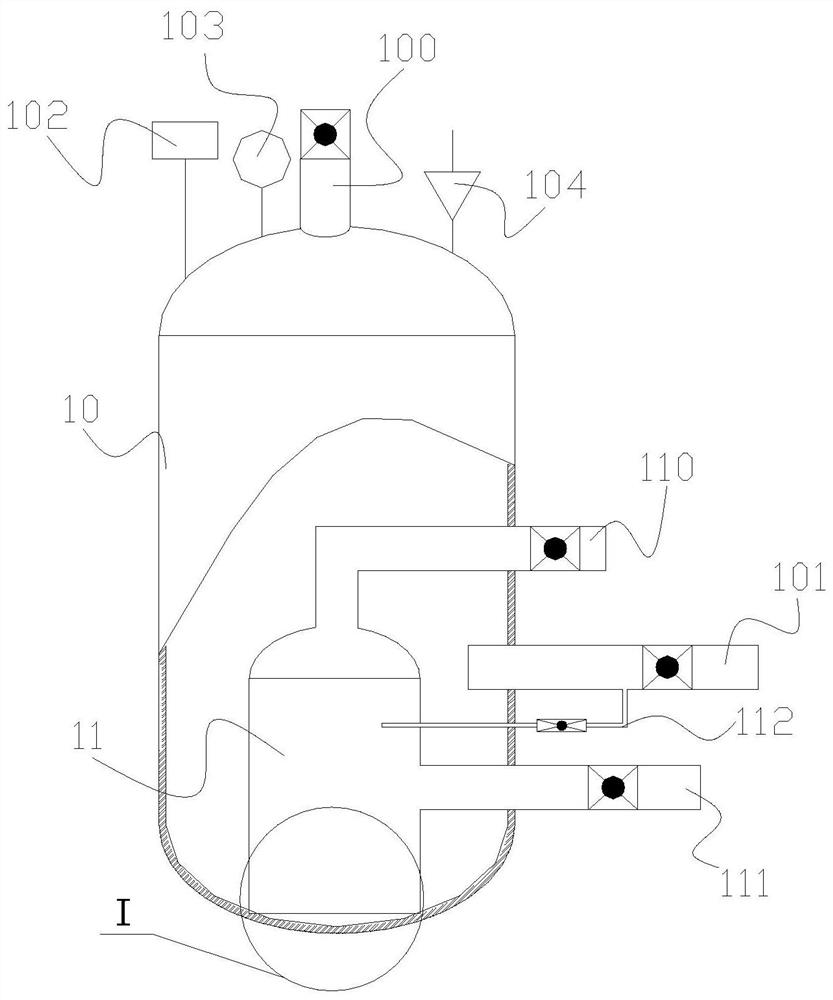

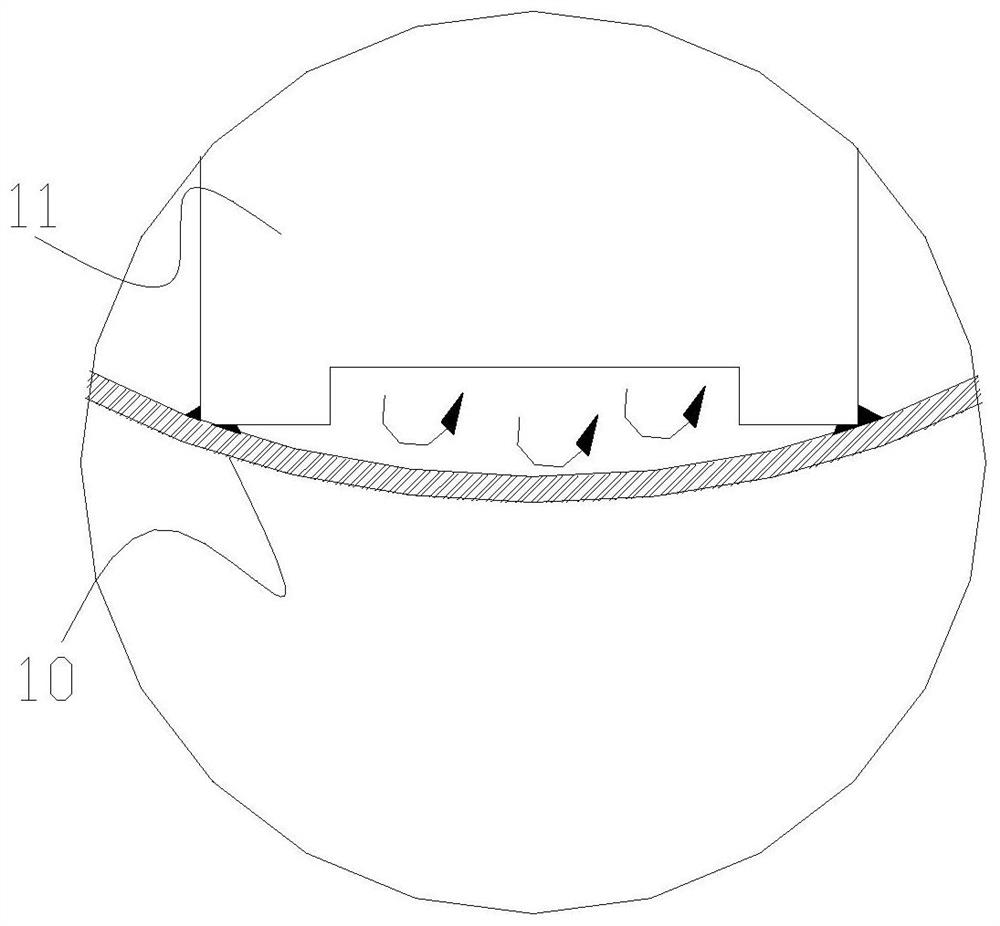

[0044] Test rig for low superheat, long-span testing of compressors, including gas coolers and compressors under test 20, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the gas cooler includes an outer cylinder 10 and an inner cylinder 11 disposed inside the outer cylinder 10 . The gas outlet of the outer cylinder 10 is provided with an outer cylinder gas outlet joint 100 , and the liquid inlet of the outer cylinder 10 is provided with an outer cylinder liquid inlet joint 101 . The gas outlet of the inner cylinder 11 is provided with an inner cylinder gas outlet joint 110 , and the liquid inlet of the inner cylinder 11 is provided with an inner cylinder liquid inlet joint 111 . Such as figure 2 As shown, the bottom of the inner cylinder 11 is open for communicating with the interior of the outer cylinder 10 and the interior of the inner cylinder 11 .

[0045] In the example, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the bottom...

Embodiment 2

[0050] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 and Figure 7 As shown, the air outlet of the compressor 20 is connected with a compressor air outlet pipe 201, and the compressor air outlet pipe 201 is connected with a measuring pipe section 202 in parallel. The measuring pipe section 202 is provided with a condensing part and a parameter measuring part. The high-pressure hot gas entering the measuring pipe section 202 from the air outlet pipe 201 becomes a high-pressure gas-liquid mixture, and the parameter measuring part is used to test the cooling capacity of the compressor 20 . The outer cylinder liquid inlet joint 101 is connected to the outlet of the compressor air outlet pipe 201 through the outer cylinder liquid inlet branch pipe 1010 , and the inner cylinder liquid inlet joint 111 is connected to the outlet of the compressor air outlet pipe 201 through the inner cylinder liquid inlet branch pipe 1110 . An outer cylinder air outlet branch ...

Embodiment 3

[0056] On the basis of Examples 1 and 2, a test method based on a test device for low superheat and long-span testing of compressors.

[0057] Such as Figure 5 As shown, when the test device is running at full load, that is, when the test environment is provided for the compressor 20 that needs the maximum cooling capacity, open the on-off valves on the liquid inlet joint 101 of the outer cylinder and the gas outlet joint 100 of the outer cylinder, and close the inlet and outlet valves of the inner cylinder. The opening and closing valves of the liquid joint 111 and the gas outlet joint 110 of the inner cylinder open the valve on the communication pipe 112, so that the heat exchange space provided by the outer cylinder 10 and the inner cylinder 11 communicates. At this time, the heat exchange that the gas cooler can provide The area is the sum of the volume of the outer cylinder 10 and the volume of the inner cylinder 11 .

[0058] The compressor 20 discharges high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com