Automatic sampling device for powdery or granular materials

An automatic sampling device and a technology for granular materials, applied in the direction of sampling devices, etc., can solve the problems that the sampling frequency cannot meet the sampling frequency and manual sampling is difficult, and achieve the effect of reducing manual workload, reducing manual operation errors, and increasing sampling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In order to solve the difficulty of manual sampling, the sampling frequency of the existing sampling system cannot meet the sampling frequency. We propose a motor-driven sampling system with adjustable speed, timing, and quantity to meet the demand for high sampling frequency in high-speed and large-volume material production. Such as figure 1 As shown, the present invention provides an automatic sampling device for powdery or granular materials, including a material delivery pipeline 1, a single-tube sampling system connected at a fixed angle to the material delivery pipeline 1, and a sampling system connected with the sampling System connected motor 2.

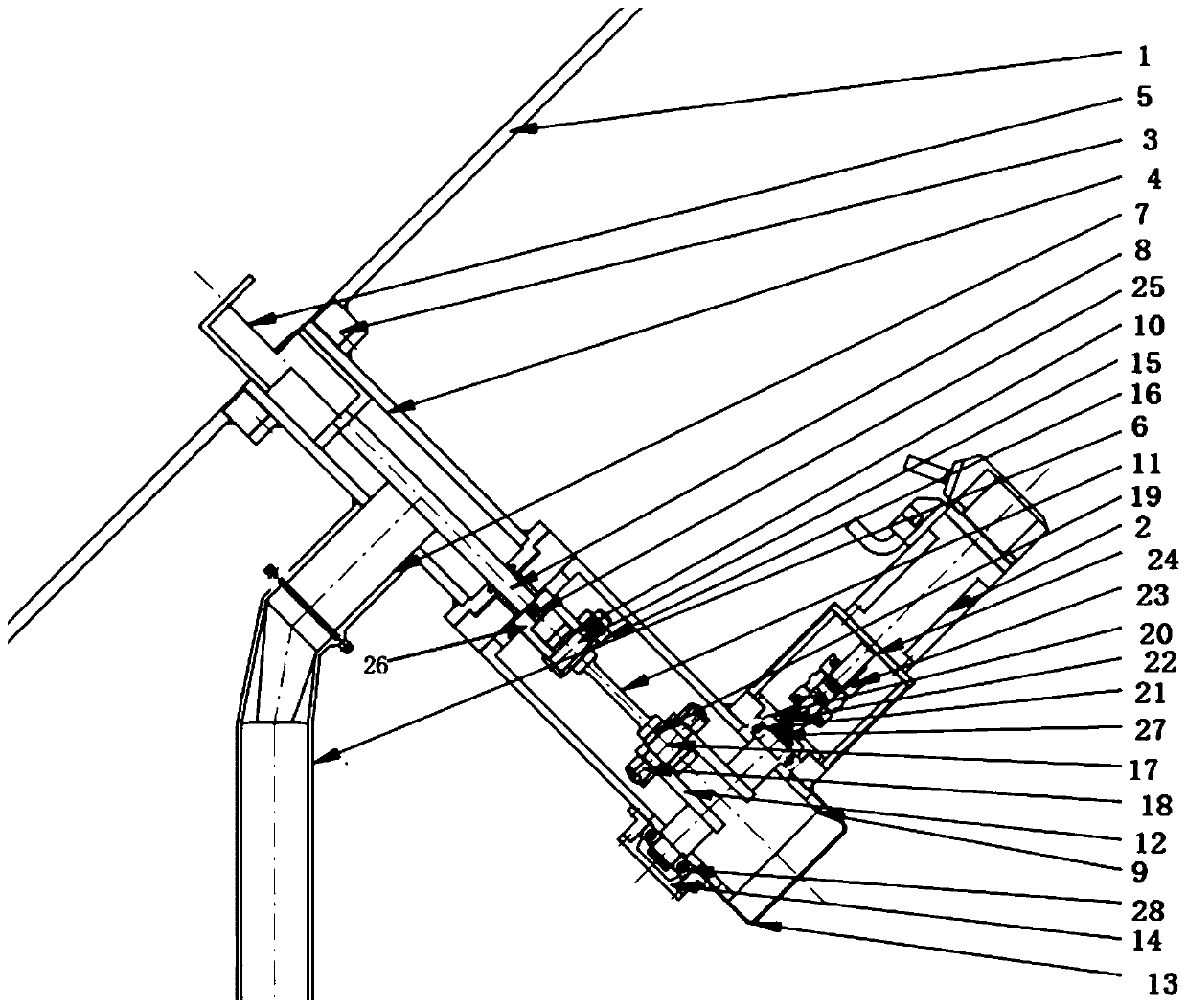

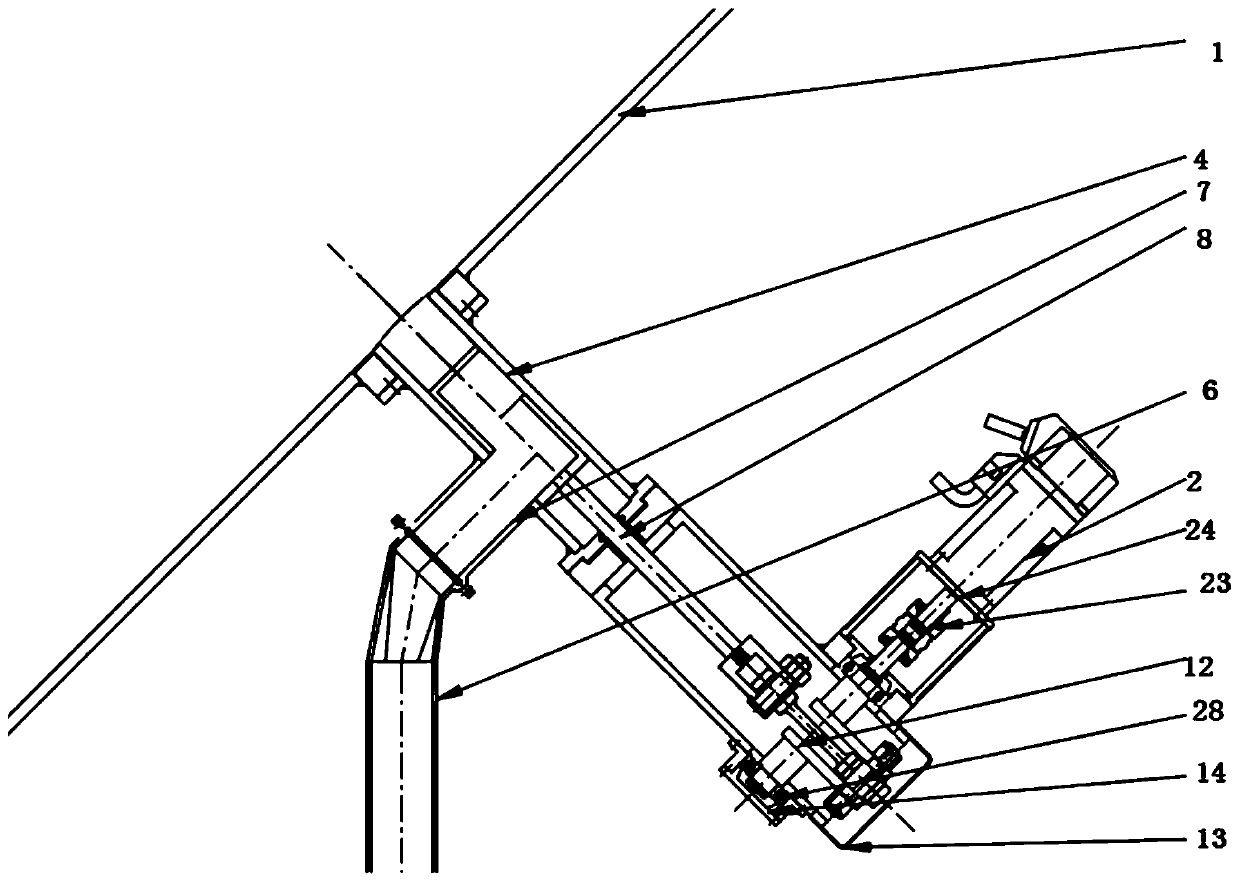

[0033] Such as Figure 2-Figure 3 As shown, the sampling system includes a sampler mounting support 3 welded with the material delivery pipeline 1, and a sampling cup cover 4 connected to the sampler mounting support 3, located in the sampling cup cover 4 and worn The sampling cup 5 passing the shaft hole at the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com