Steel wire rope driving mechanism for optical inspection outside material cabin and exposure platform

A technology of driving mechanism and steel wire rope, which is applied in the direction of analyzing materials, analyzing materials through optical means, scientific instruments, etc. It can solve the problems that the driving mechanism cannot adapt to the space environment, and the safety and reliability cannot meet the space station, so as to save uplink resources , Satisfy the effect of safety and reliability, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

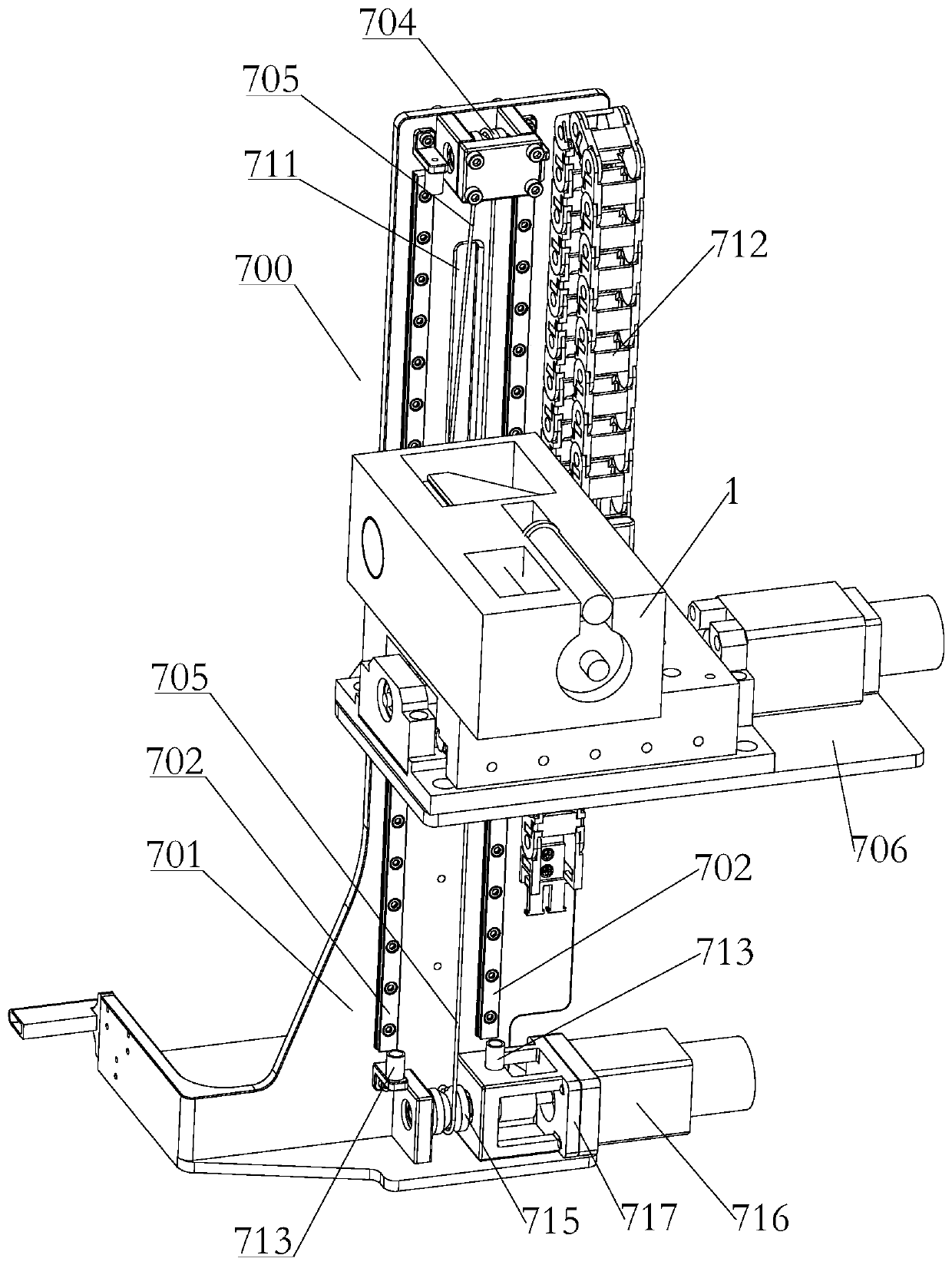

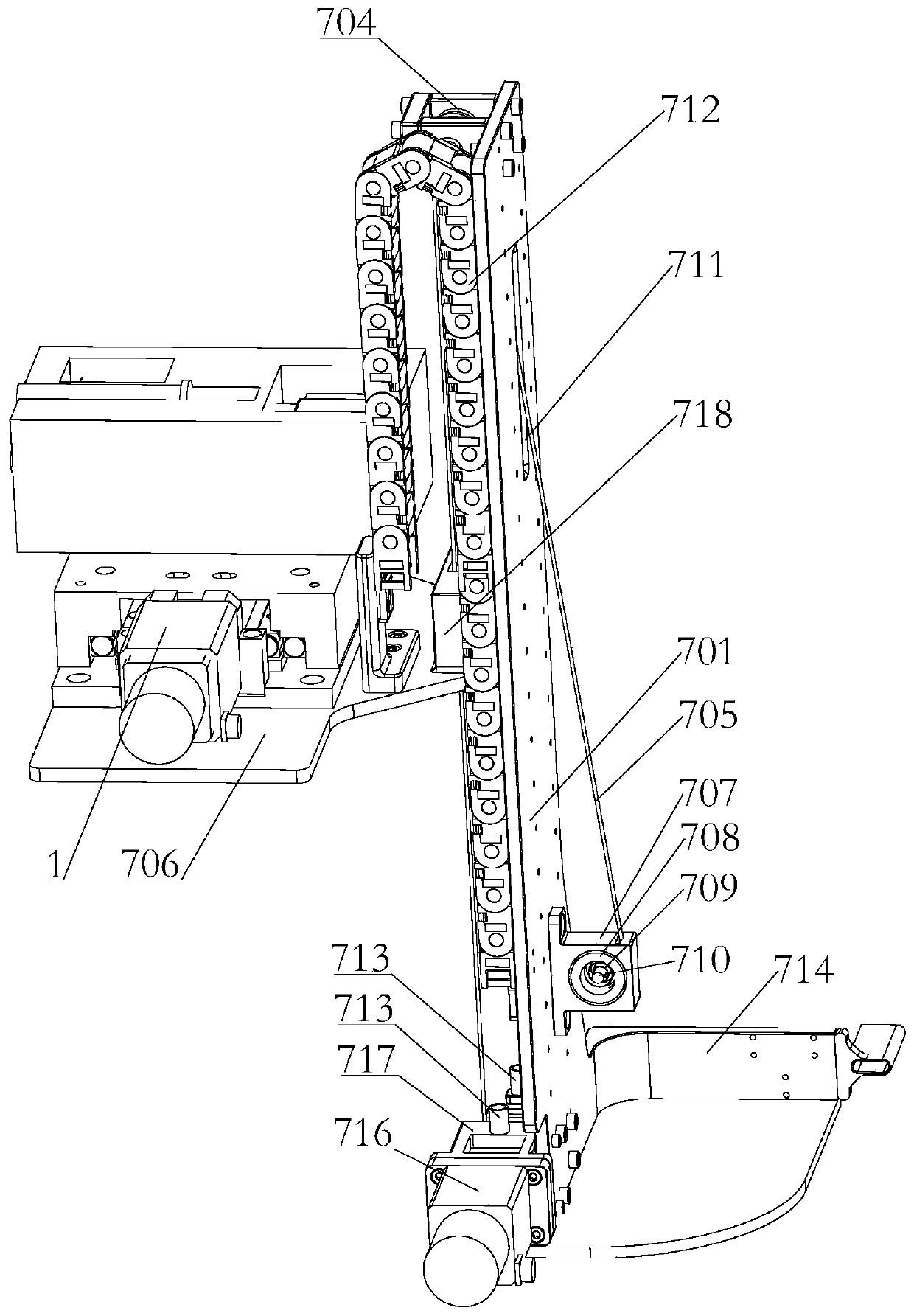

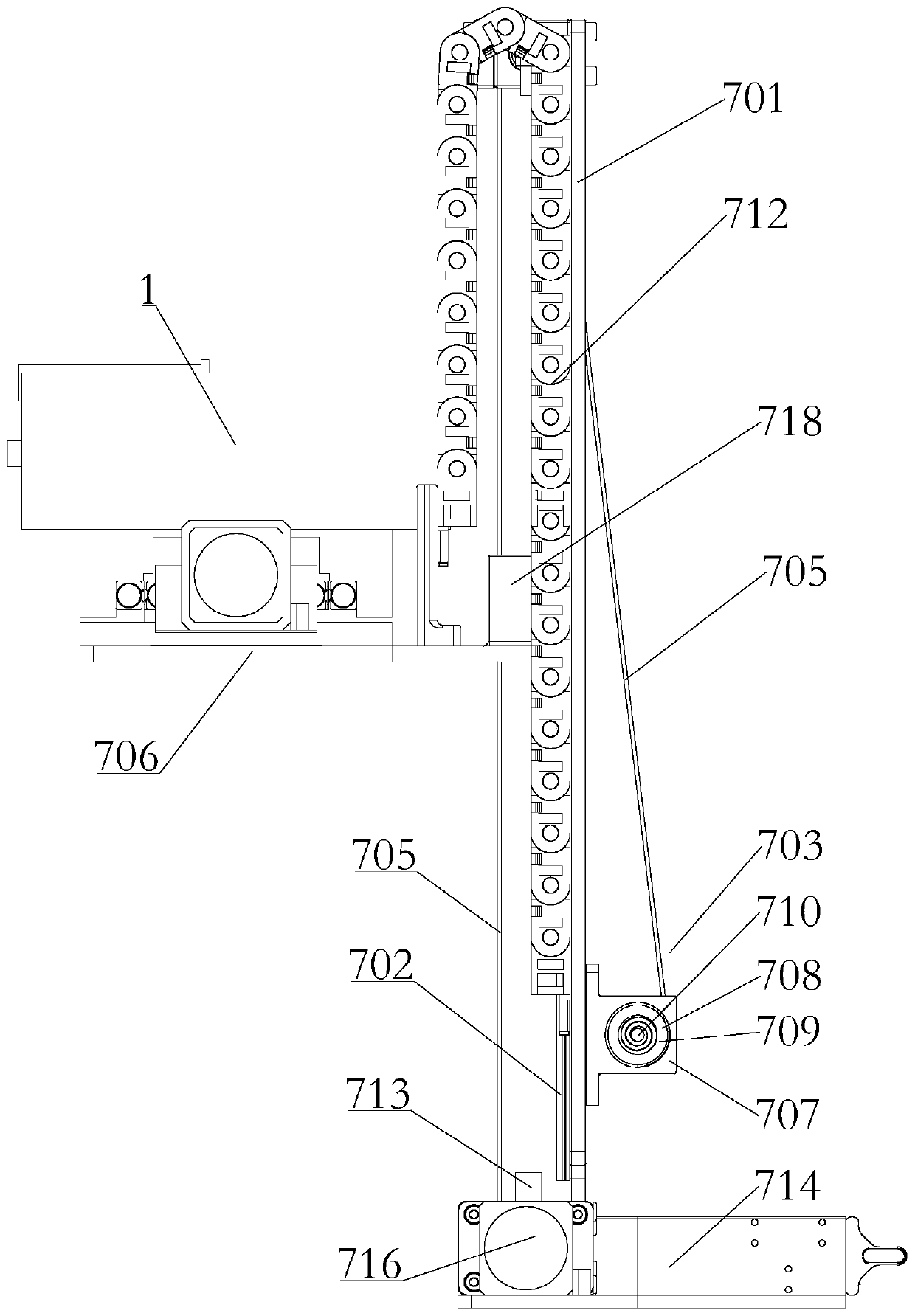

[0063] Such as Figure 1-Figure 4 As shown, a wire rope driving mechanism 700 for optical inspection of materials outside the cabin in this embodiment includes:

[0064] Bracket 701;

[0065] The guide rail 702 is installed on one side of the bracket 701, and is used for bearing and guiding the wire rope driving mechanism, supporting the reciprocating linear motion of the slider and the inspection mechanism;

[0066] The wire rope tightening device 703 is installed on the other side of the bracket 701, and moves along with the active wire rope winding wheel 715 to wind or release the wire rope 705 to ensure that the length of the wire rope 705 is normal and always in a pre-tightened state, so as to avoid transmission failure of the wire rope 705;

[0067] The driving device 716 is installed on the bottom of one side of the support 701, and its driving end is connected with an active wire rope winding wheel 715; the driving device 716 can use a motor as a power source to reali...

Embodiment 2

[0088]A material outdoor exposure platform in this embodiment includes a test box, an optical inspection module 1, an installation platform, and the wire rope drive mechanism 700, the test box is installed on the installation platform, and the test box The exposed surface after opening is arranged towards the surroundings of the installation platform, and the bottom of the bracket 701 is provided with a connecting plate 714 arranged vertically thereto, and the connecting plate 714 is installed on the peripheral side of the installation platform, and the optical inspection module 1 is installed on the bearing plate 706, and is driven by the wire rope 705 to reciprocate in a direction perpendicular to the installation platform, so as to inspect the exposed surface.

[0089] Wherein, the installation platform is square, the connecting plate 714 is installed on one side of the installation platform, and the bearing plate 706 is driven by the wire rope 706 to move in a direction per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com