Electric control device and electric control system of simple independent cutting box

A technology of electric control system and electric control device, applied in general control system, control/adjustment system, electrical program control, etc., can solve the problems of semi-finished products occupying a large space, low consistency, waste of labor costs, etc., to achieve The consistency of product batches is high, the equipment automation is realized, and the equipment cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

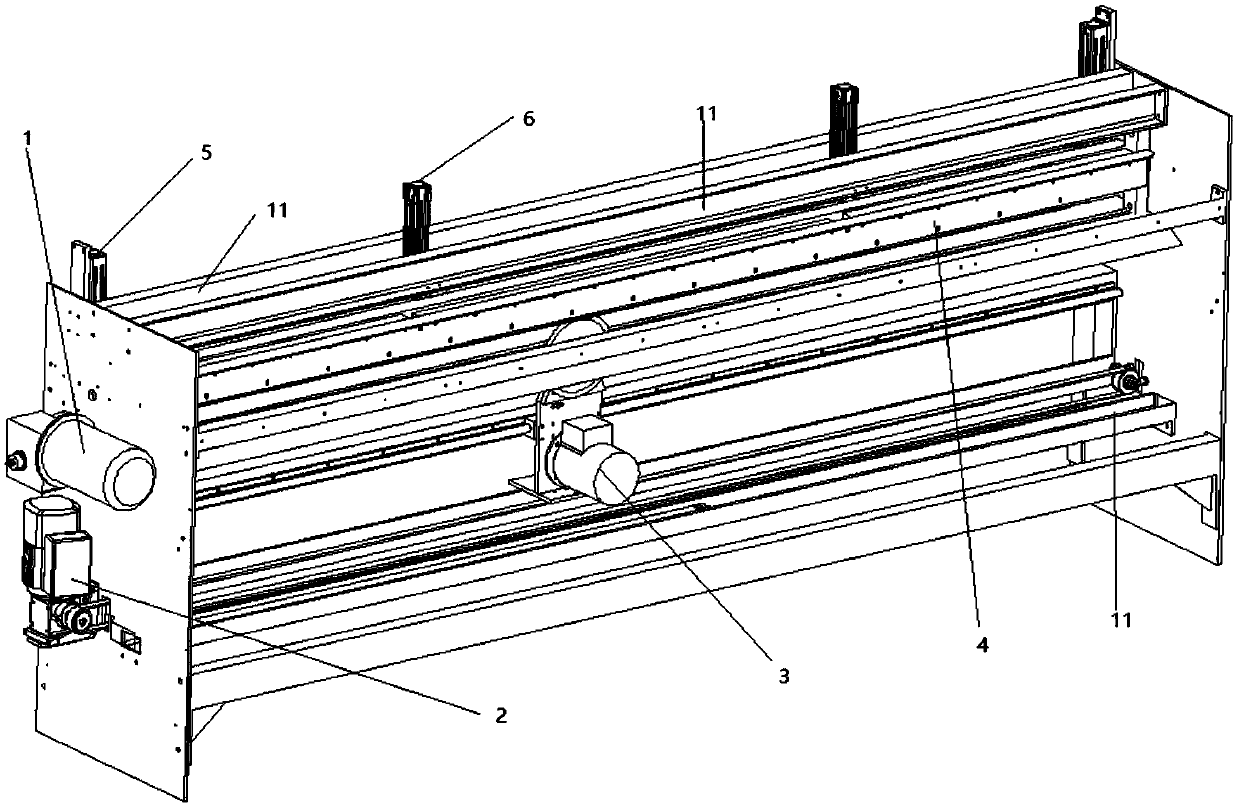

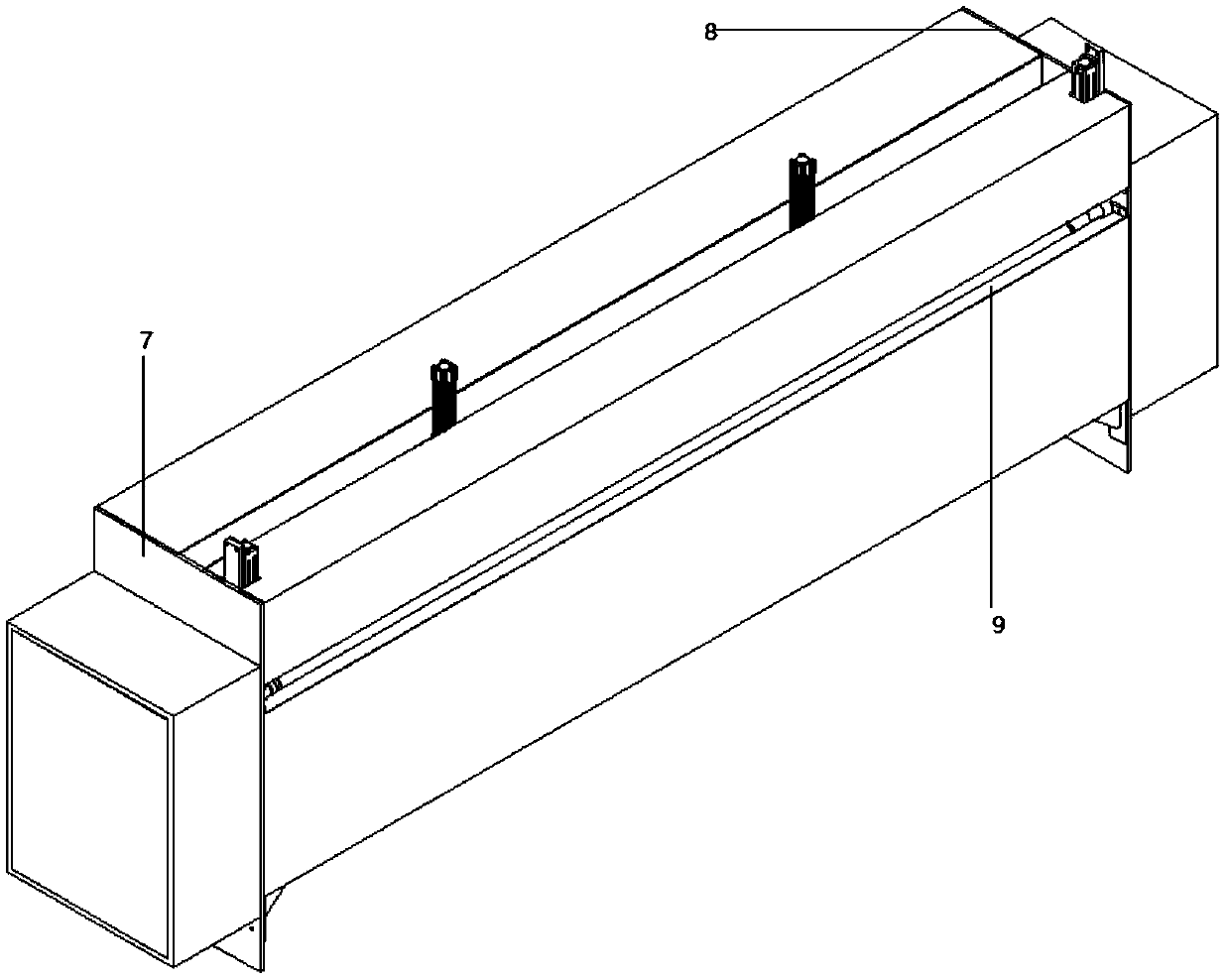

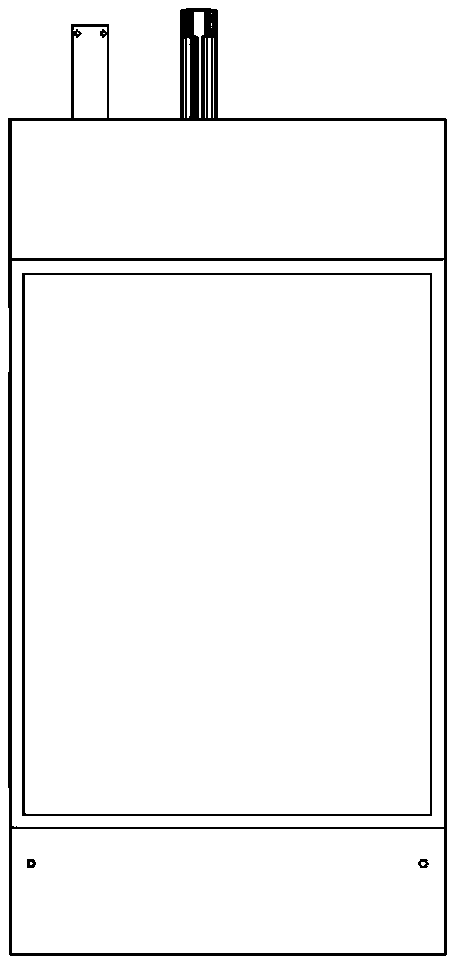

[0029] A simple electric control device and an electric control system for an independent cutting box, wherein the electric control device part mainly includes: a material pulling component (1), a cross-cutting moving component (2), a cross-cutting component (3), a cutting Material pressure bar (4), pull material pressure roller (5), pressure bar cylinder (6), left vertical plate (7), right vertical plate (8), upper beam (9), lower beam (10), reinforcement beam (11).

[0030] The pulling assembly (1) is a three-phase asynchronous motor equipped with a worm gear reducer. The flange of the reducer is installed on the left vertical plate,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap