Simple bridge expansion joint structure

A technology for expansion joints and bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of peeling of expansion joint components and bridge beam structure, reducing bonding strength, easy to jump, etc., achieving soft texture and saving steel , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

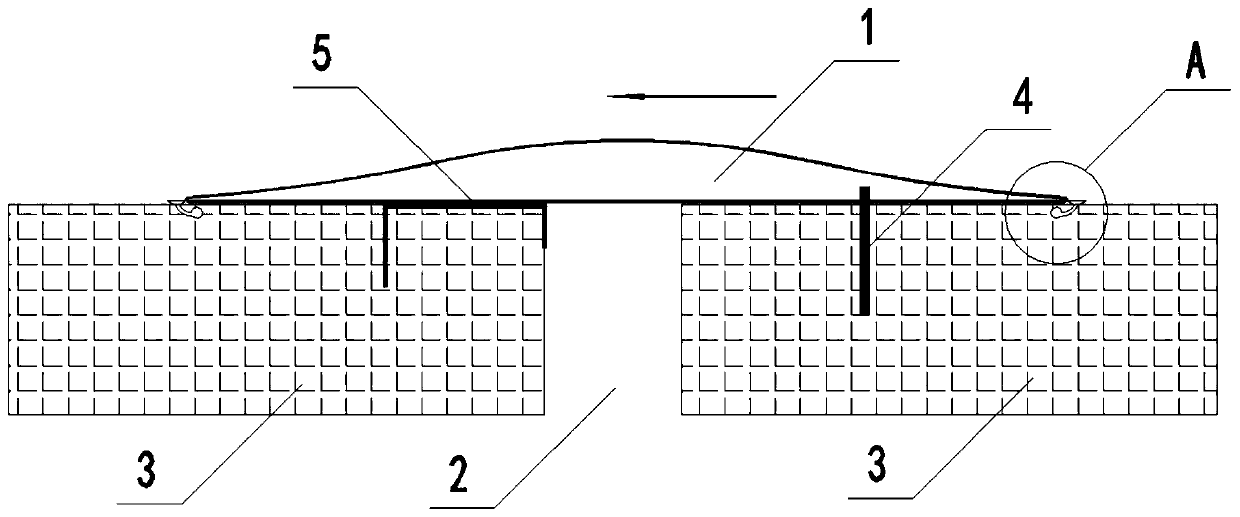

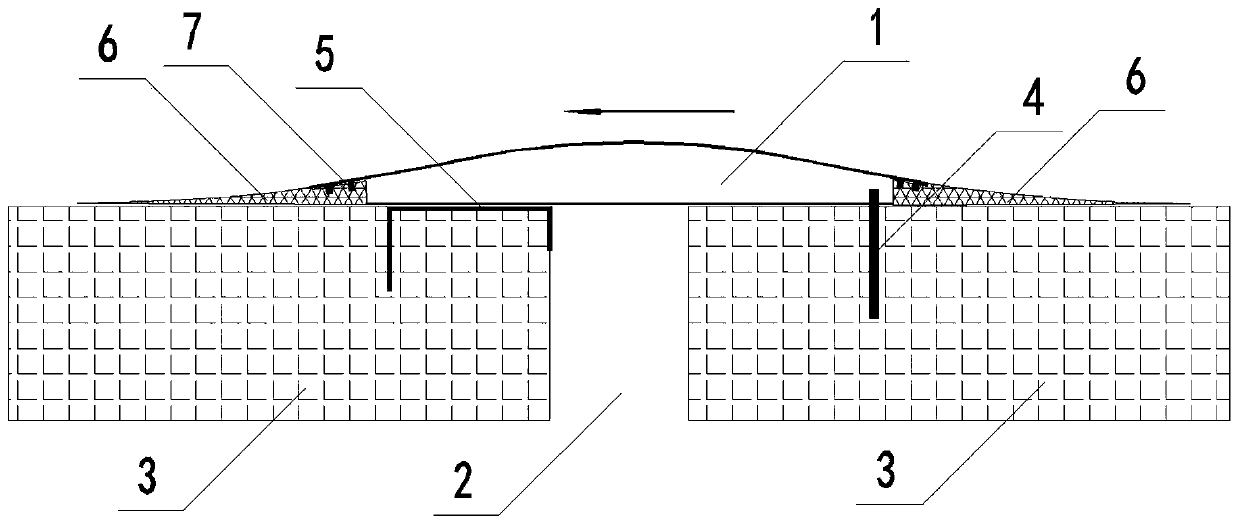

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

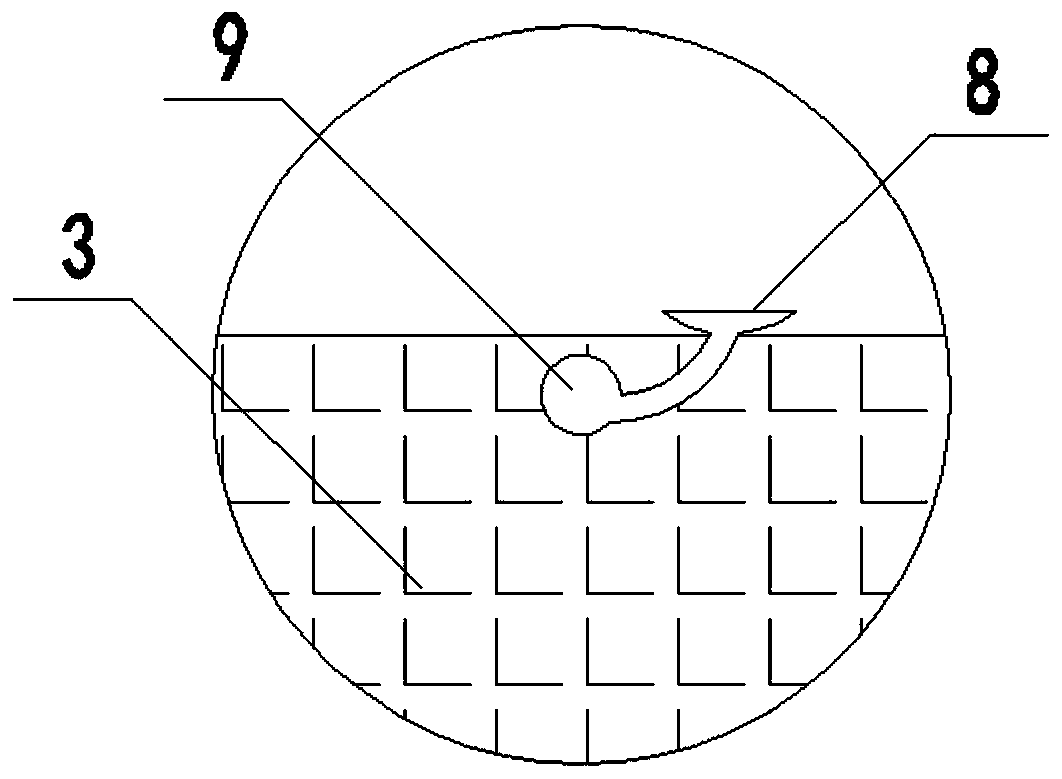

[0034]It should be noted that, in the embodiment of the present invention, the beam structure 3 includes a beam body and a surface paving layer (generally 10 cm in thickness) arranged on the surface of the beam body. The surface of the beam structure 3 referred to in the embodiment of the present invention usually refers to the surface of the pavement layer, but not all only stay on the surface pavement layer, for some parts (such as the fixed column 4 and the fixed steel plate 5, etc.) , need to extend into the corresponding beam body.

[0035] Such as figure 1 and figure 2 As shown, a simple bridge expansion joint structure includes a steel plate body 1 with a convex middle part, an arc-shaped surface and an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com