Anti-leakage detection device and tank bottom valve

A technology of detection device and tank bottom valve, applied in valve device, valve operation/release device, lift valve, etc., can solve the problems of liquid leakage of storage tank, tank bottom valve leakage, liquid cross-contamination, etc. Easy to operate, simple to install, and evenly applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

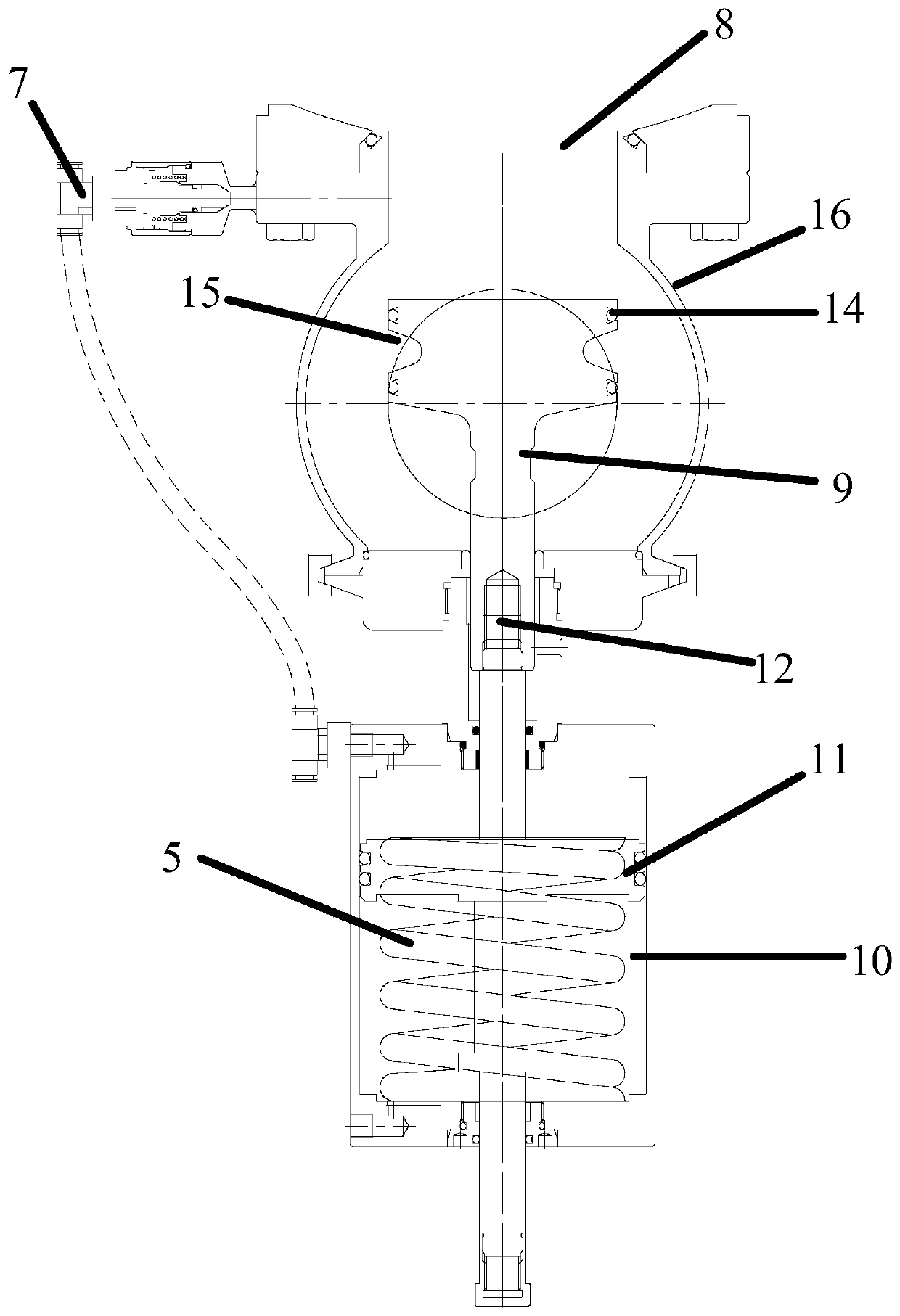

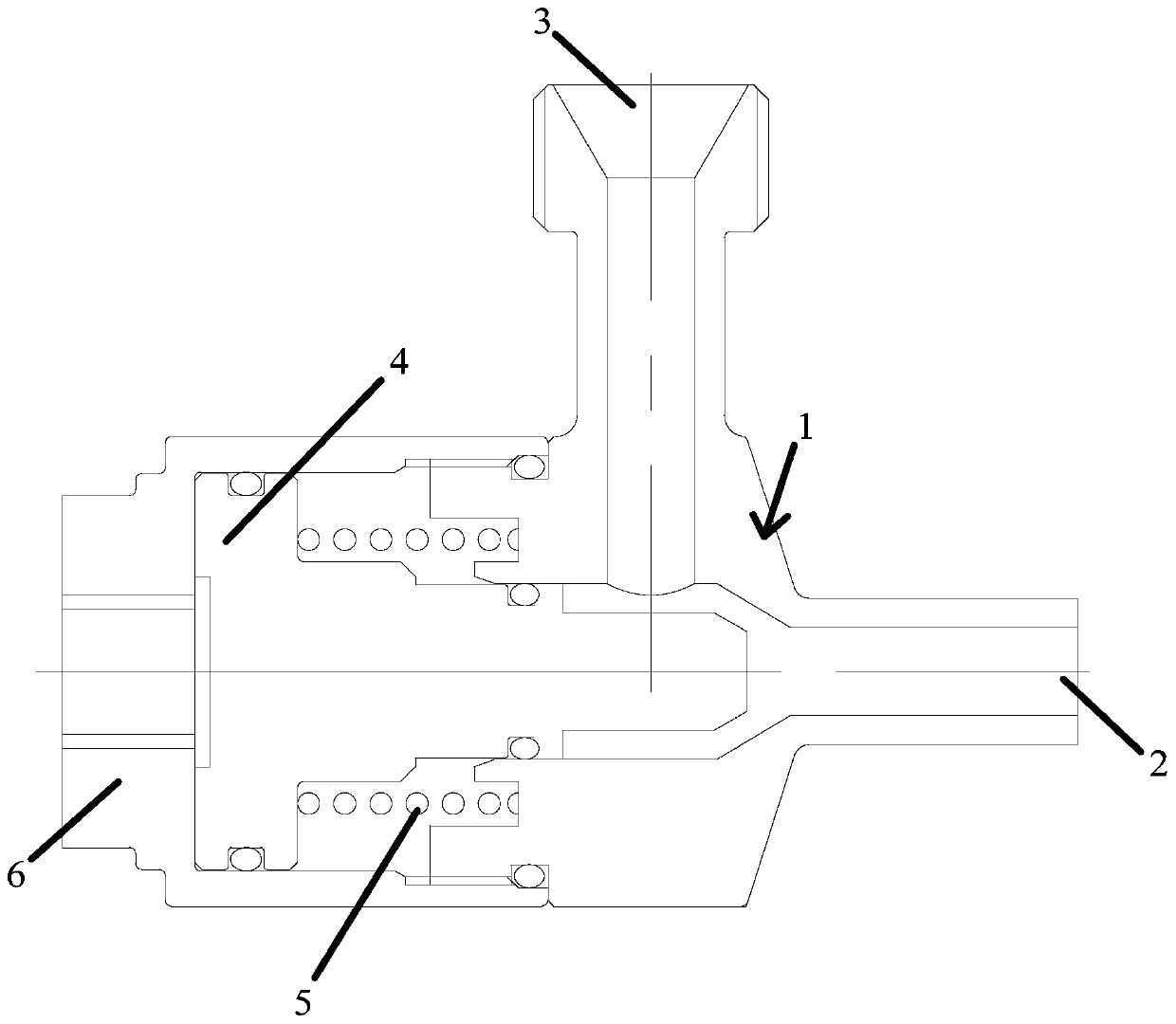

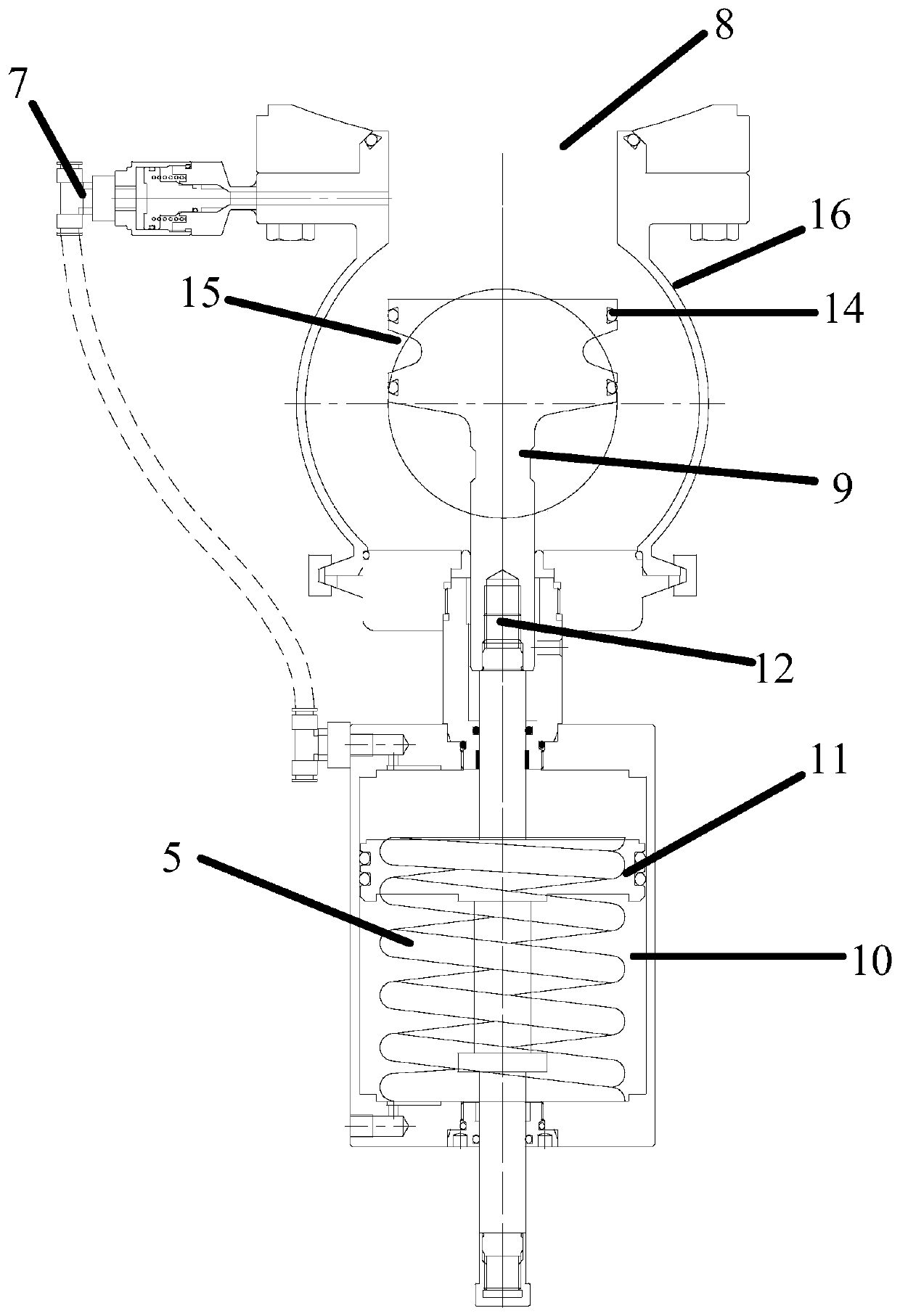

[0035] A leak-proof detection device is described, such as figure 1 , figure 2 As shown, it includes: a valve body 1; a leakage pipeline 13, which is arranged in the valve body 1, and the leakage pipeline 13 includes: a valve core 9 arranged in the circumferential direction of the tank bottom valve core of the storage tank Leakage feed port 2 connected to retention cavity 15, and leakage discharge port 3 used to detect whether there is leakage in the medium; sealing member 4 is drivenly arranged on the fluid channel of the leakage pipeline , the sealing member 4 has a closed position for blocking the fluid channel, and an open position for communicating the fluid channel; during the actual use of the tank bottom valve, the valve core repeatedly realizes the opening action of the material port 8 and the opening of the material port. 8 Closing action, if things go on like this, it will cause the wear of the sealing ring, resulting in leakage after the valve core and valve are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com