External pressure collapse device

A technology of extruding blocks and outer frames, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problem that blocking perforation affects experimental accuracy, ultra-high pressure fluid risks, and affects test accuracy. and other problems to achieve the effect of ensuring test accuracy, uniform pressure, and safe and reliable test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

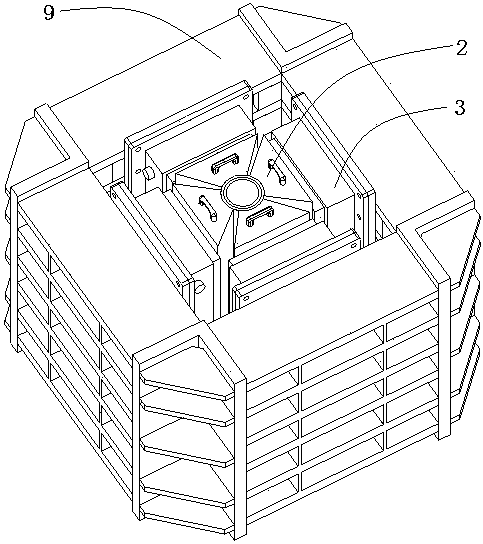

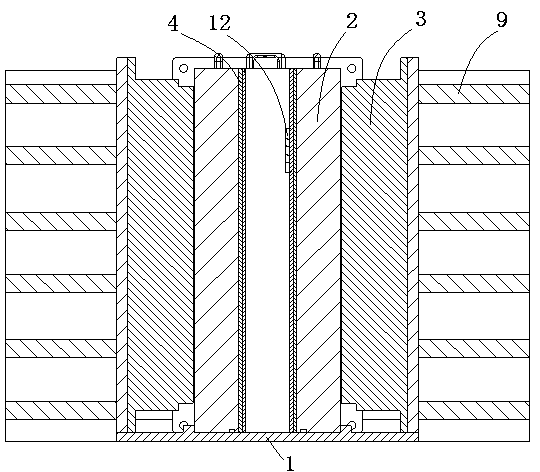

[0031] see figure 1 with figure 2 , an external pressure crushing device, including a base 1 for fixing the oil casing, and also includes an extruding block 2 and a driving member 3, the extruding block 2 is three, and the inner surface of the extruding block 2 is On the arc surface, the extruding blocks 2 are slidably arranged on the base 1 , and the extruding blocks 2 are arranged at intervals along the circumferential direction of the oil casing, and the extruding blocks 2 make linear reciprocating motions under the action of the driving member 3 .

[0032] This embodiment is the most basic implementation. There are three extruding blocks 2. The inner surface of the extruding block 2 is a circular arc surface. The extruding block 2 is slidably arranged on the base 1. Arranged at intervals in the circumferential direction, the extruding block 2 makes a linear reciprocating motion under the action of the driving member 3. Compared with the prior art that uses fluid pressure...

Embodiment 2

[0034] see figure 1 with figure 2 , an external pressure crushing device, including a base 1 for fixing the oil casing, and also includes an extrusion block 2 and a driving member 3, the number of the extrusion blocks 2 is four, and the inner surface of the extrusion block 2 is On the arc surface, the extruding blocks 2 are slidably arranged on the base 1 , and the extruding blocks 2 are arranged at intervals along the circumferential direction of the oil casing, and the extruding blocks 2 make linear reciprocating motions under the action of the driving member 3 .

[0035] The four extruding blocks 2 are arranged opposite to each other, and the extension lines of the moving tracks of the two oppositely arranged extruding blocks 2 coincide.

[0036]This embodiment is a preferred implementation mode. There are four extruding blocks 2, and the four extruding blocks 2 are arranged oppositely in pairs. The inner surface of the block 2 is set as a circular arc surface so as to a...

Embodiment 3

[0038] see figure 1 with figure 2 , an external pressure crushing device, including a base 1 for fixing the oil casing, and also includes an extrusion block 2 and a driving member 3, the number of the extrusion blocks 2 is four, and the inner surface of the extrusion block 2 is On the arc surface, the extruding blocks 2 are slidably arranged on the base 1 , and the extruding blocks 2 are arranged at intervals along the circumferential direction of the oil casing, and the extruding blocks 2 make linear reciprocating motions under the action of the driving member 3 .

[0039] The four extruding blocks 2 are arranged opposite to each other, and the extension lines of the moving tracks of the two oppositely arranged extruding blocks 2 coincide.

[0040] The distance between two adjacent extruded blocks 2 is greater than 0.05 times the inner surface diameter of the extruded blocks 2 and less than 0.2 times the inner surface diameter of the extruded blocks 2 .

[0041] This embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com