Method for judging granulation selectivity strength among different iron ore powder particles

An iron ore powder, selective technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve problems such as the influence of the sintering process, and achieve the effect of strong operability and strong guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for judging the granulation selectivity strength between different iron ore powder particles of the present invention comprises the following steps:

[0047] 1) Take 1kg of iron ore powder A and 2kg of iron ore powder B. Iron ore powder A is Canadian fine ore in the specularite category, and iron ore powder B is Caragas fine ore in the hematite category , after drying in an oven above 100°C, use a standard sieve to screen out different particle sizes, and take the particles with a particle size of 0A = 0.25mm and D B =4mm, for use.

[0048] 2) The selected iron ore powder A with a particle size of 0 A =0.0061mm, DM A = 0.0712mm and DF B =0.0149mm, DM B = 0.0873 mm.

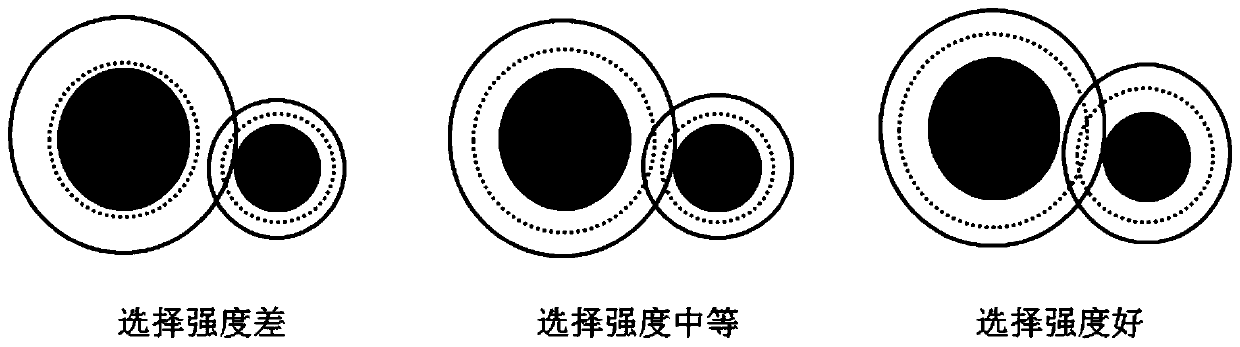

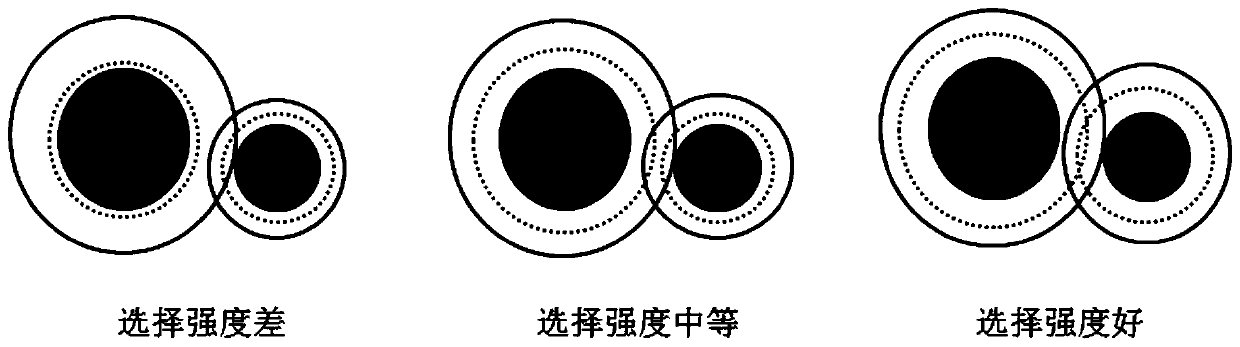

[0049] 3) Judging the quality of the selectivity strength when the particles with a particle size of 0

[0050] According to the a...

Embodiment 2

[0056] A method for judging the granulation selectivity strength between different iron ore powder particles of the present invention comprises the following steps:

[0057] 1) Get the iron ore powder A of 1.5kg and the iron ore powder B of 1kg, the iron ore powder A is the Canadian powder ore in the specularite category, and the iron ore powder B is the king's powder ore in the limonite category, After drying in an oven above 100°C, use a standard set of sieves to screen out different particle sizes, and take the particles of 0A = 0.25mm and D B =0.25mm, for use.

[0058] 2) The selected particles of iron ore powder A with a particle size of 0A =0.0061mm, DM A = 0.0712mm and DF B =0.0254mm, DM B = 0.0849mm.

[0059] 3) Judging whether the particles of iron ore powder A with a particle size of 0<particle size≤0.5mm and the particles of iron ore powder B with a particle size of 0<particle size≤0.5mm are good or bad when they are used as adhesive particles at the same time:

...

Embodiment 3

[0066] A method for judging the granulation selectivity strength between different iron ore powder particles of the present invention comprises the following steps:

[0067] 1) get the iron ore powder A of 2kg and the iron ore powder B of 3kg, the iron ore powder A is the Yangdi powder ore in the limonite category, and the iron ore powder B is the king's powder ore in the limonite category, After drying in an oven above 100°C, use a standard set of sieves to screen out different particle sizes, and take the particles of 0A = 0.25mm and D B =0.25mm, for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com