Method for calculating temperature rise in double-frequency quenching machining transition process

A technology of transition process and calculation method, which is applied in the direction of program control, instrumentation, electrical test/monitoring, etc., can solve the problem that the fault cannot be detected by the sensor cost, etc., to increase the cost of installation and monitoring, accurately detect faults, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

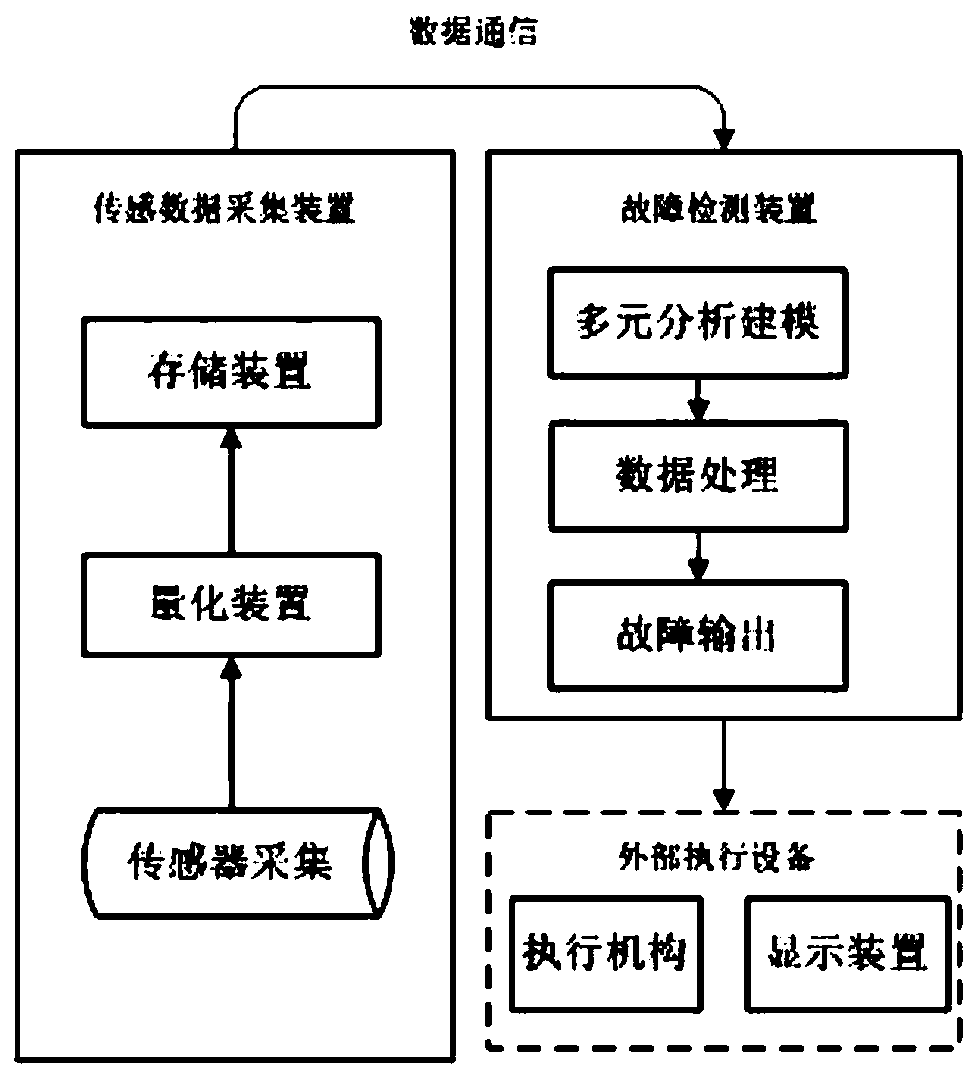

[0105] see figure 1 – Figure 8 , a method for calculating the temperature rise in the transition process of dual-frequency quenching, said method comprising: data collection and storage, data processing and analysis, and data diagnosis and alarm in three steps:

[0106] The first step, data collection and storage: use the sensor on the submersible pump to collect the state parameters of the main pump motor operating current, hydraulic system pressure, submersible pump outlet pressure, submersible pump outlet flow, hydraulic system temperature and STC valve pressure, and then The above six state parameters are transmitted to the quantization device in real time for quantization processing, and finally the parameters after the quantization processing are respectively transmitted to the storage device and the diagnosis device, and the storage device stores the collected data for future use;

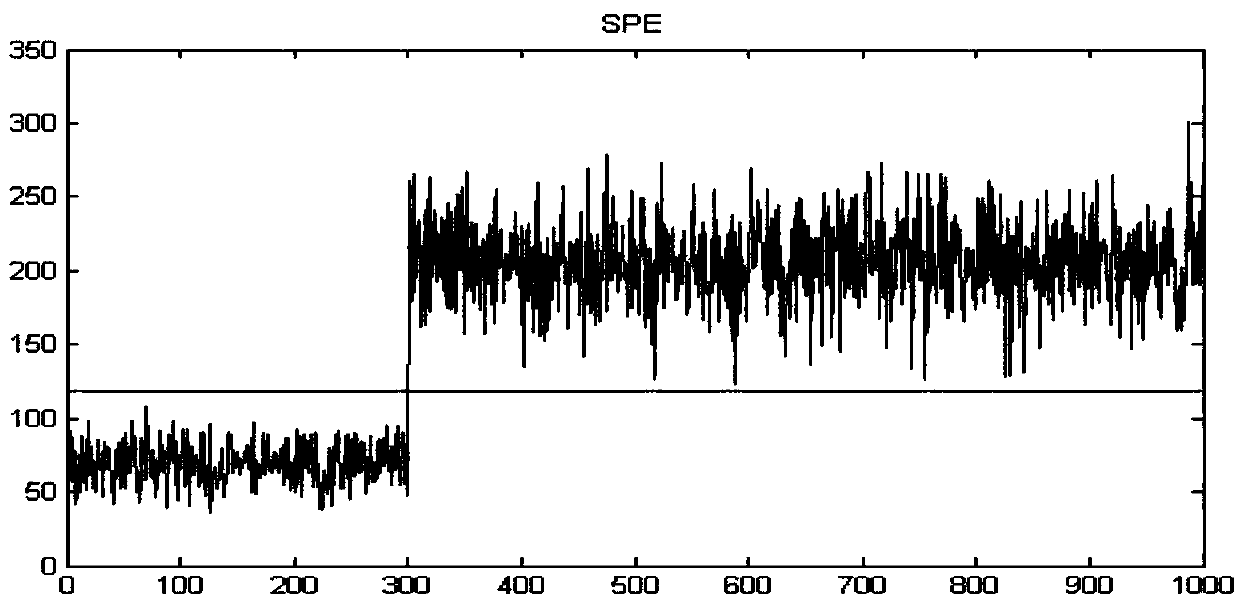

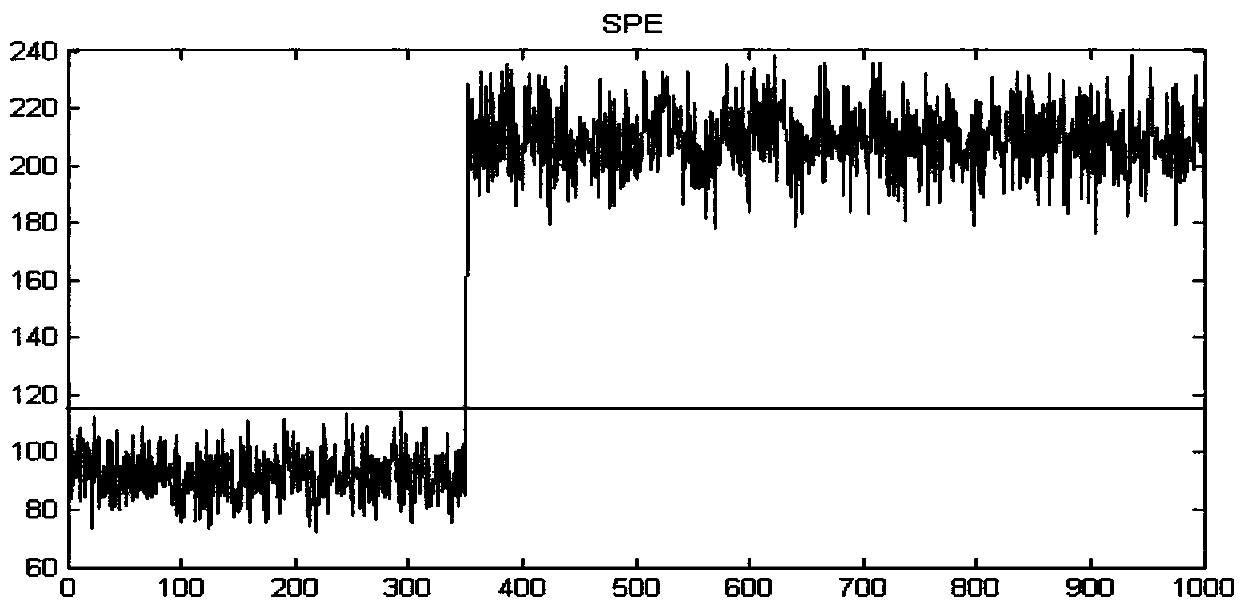

[0107] The second step, data processing and analysis: the diagnostic device establishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com