Full-automatic wire stripping machine

A wire stripping machine, fully automatic technology, used in cable installation devices, electrical components, equipment for dismantling/armoring cables, etc., can solve the problems of high labor intensity, high production cost, low wire stripping efficiency, etc. Low labor and cost, and the effect of improving wire stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

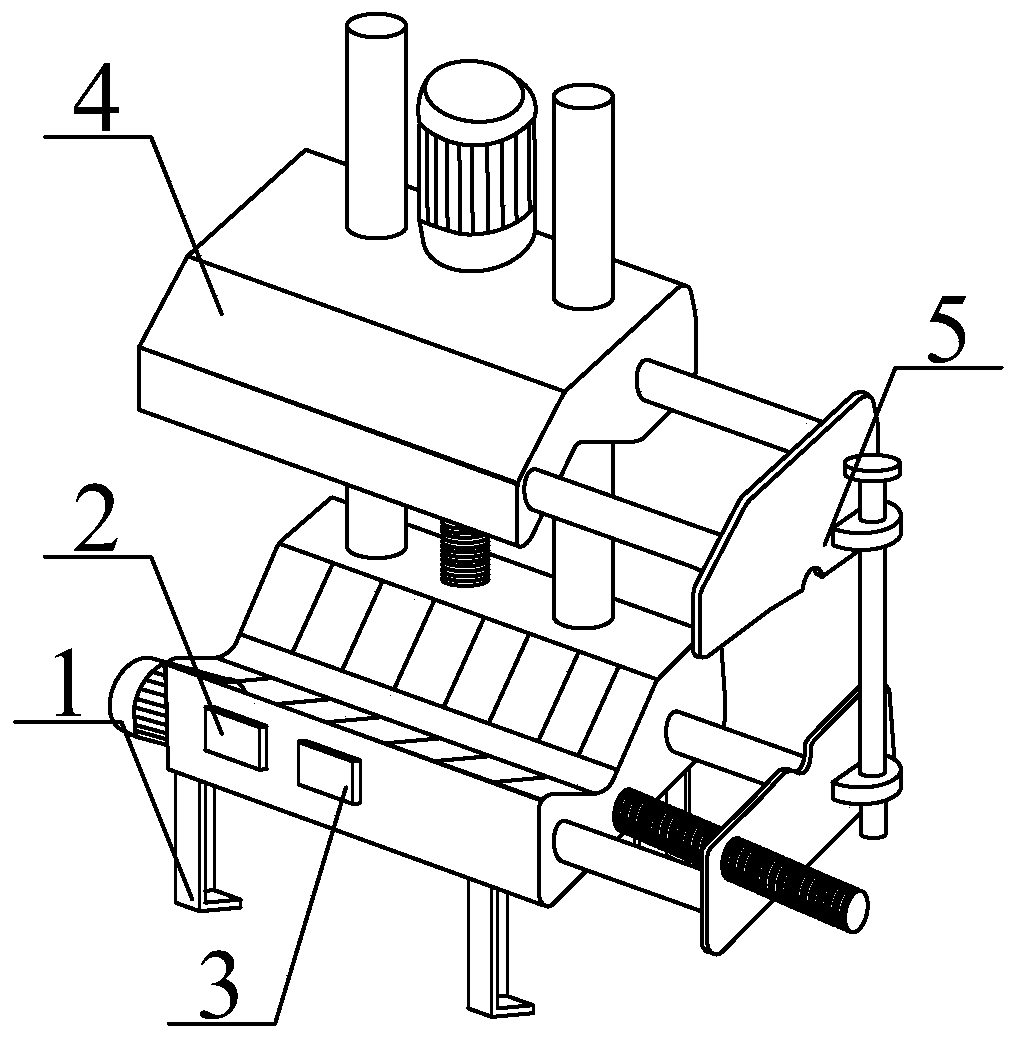

[0019] Such as Figure 1-3 As shown, the present invention provides a technical solution: a fully automatic wire stripping machine, including a leg 1, a first controller 2, a second controller 3, a cable clamping device 4 and a wire stripping mechanism 5, the described There are 4 supporting legs 1, which are respectively welded to the four corners of the bottom of the bottom clamp seat 41; the first controller 2 and the second controller 3 are installed on one side of the bottom clamp seat 41 by screws, and are connected to the 36V battery connection; the stripping mechanism 5 is detachably connected to the cable clamping device 4 .

Embodiment 2

[0021] A fully automatic wire stripping machine, comprising a leg 1, a first controller 2, a second controller 3, a cable clamping device 4 and a wire stripping mechanism 5, the four legs 1 are welded on the bottom At the four corners of the bottom of the clamp base 41; the first controller 2 and the second controller 3 are installed on one side of the bottom clamp base 41 by screws, and are connected with the 36V battery; the stripping mechanism 5 is connected with the cable The clamping device 4 is detachably connected.

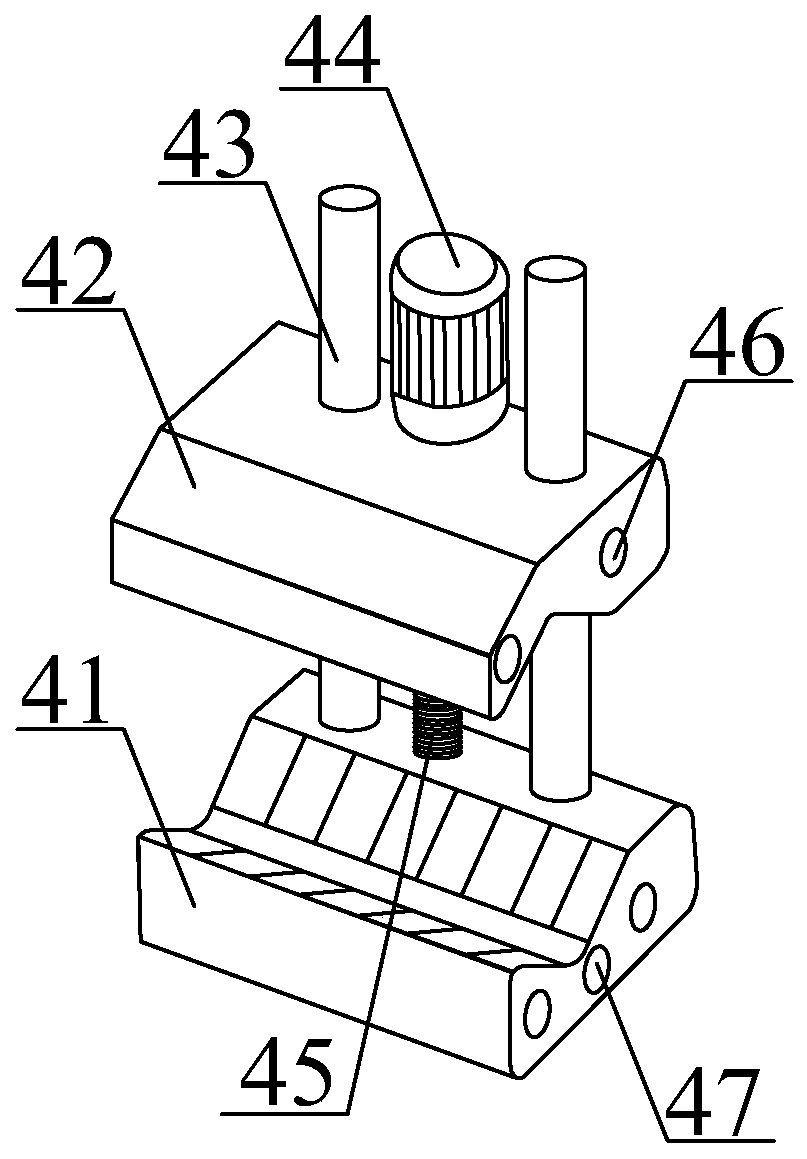

[0022] Preferably, the cable clamping device 4 includes a bottom clamp seat 41, an upper clamp seat 42, a guide rod 43, a first motor 44, a first screw rod 45, a guide hole 46 and a through hole 47, and the bottom clamp seat 41 Both the upper end and the lower end of the upper clamping seat 42 are provided with V-shaped grooves; the upper clamping seat 42 is sleeved on the guide rod 43; two guide rods 43 are used and welded on one side of the upper end of t...

Embodiment 3

[0024] A fully automatic wire stripping machine, comprising a leg 1, a first controller 2, a second controller 3, a cable clamping device 4 and a wire stripping mechanism 5, the four legs 1 are welded on the bottom At the four corners of the bottom of the clamp base 41; the first controller 2 and the second controller 3 are installed on one side of the bottom clamp base 41 by screws, and are connected with the 36V battery; the stripping mechanism 5 is connected with the cable The clamping device 4 is detachably connected.

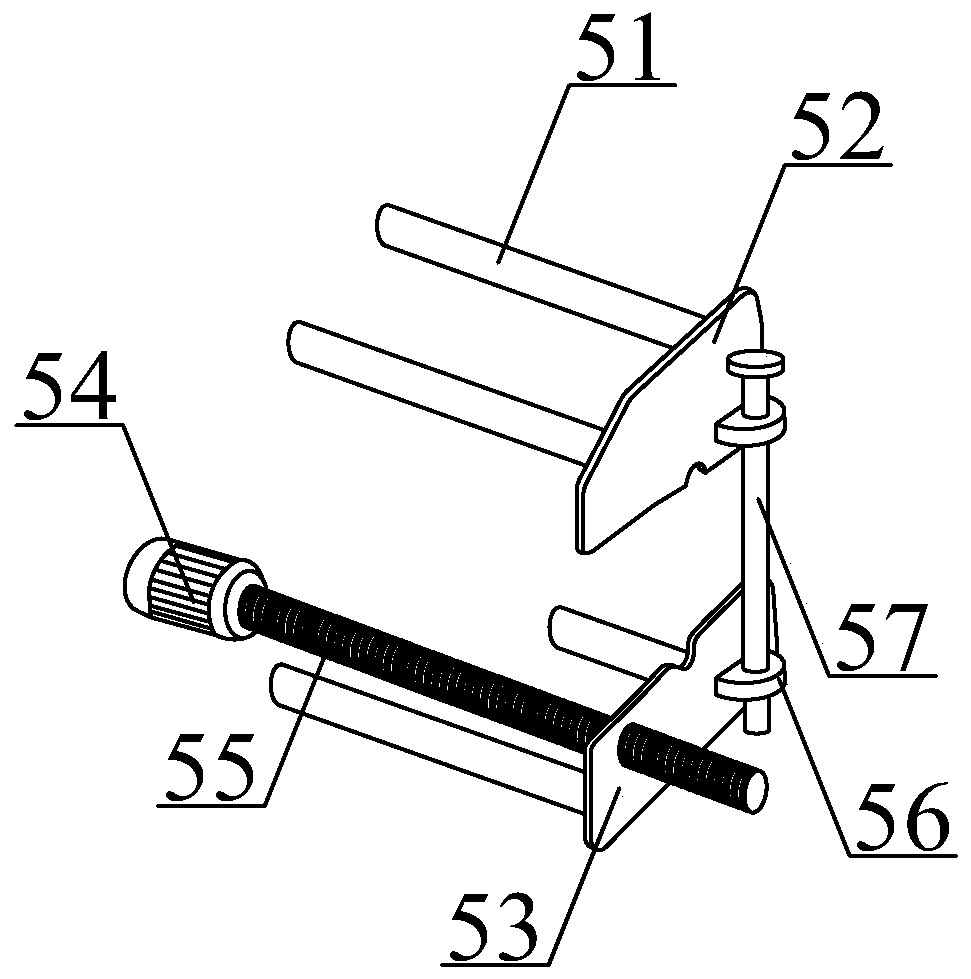

[0025] Preferably, the stripping mechanism 5 includes a slide bar 51, an upper splint 52, a lower splint 53, a second motor 54, a second screw 55, a linkage ear 56 and a T-bar 57, and the slide bar 51 adopts four , 2 as a group, respectively vertically welded with the upper splint 52 and the lower splint 53; the second motor 54 is installed on the left side of the bottom clamp seat 41 through bolts; the left end of the second screw 55 is passed through a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com