Dust removal device for motorcycle spare part production

A technology for dust removal devices and motorcycles, used in maintenance and safety accessories, metal processing machinery parts, parts of boring machines/drilling machines, etc. The effect of personnel health, low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] The following is a further detailed description through specific implementations:

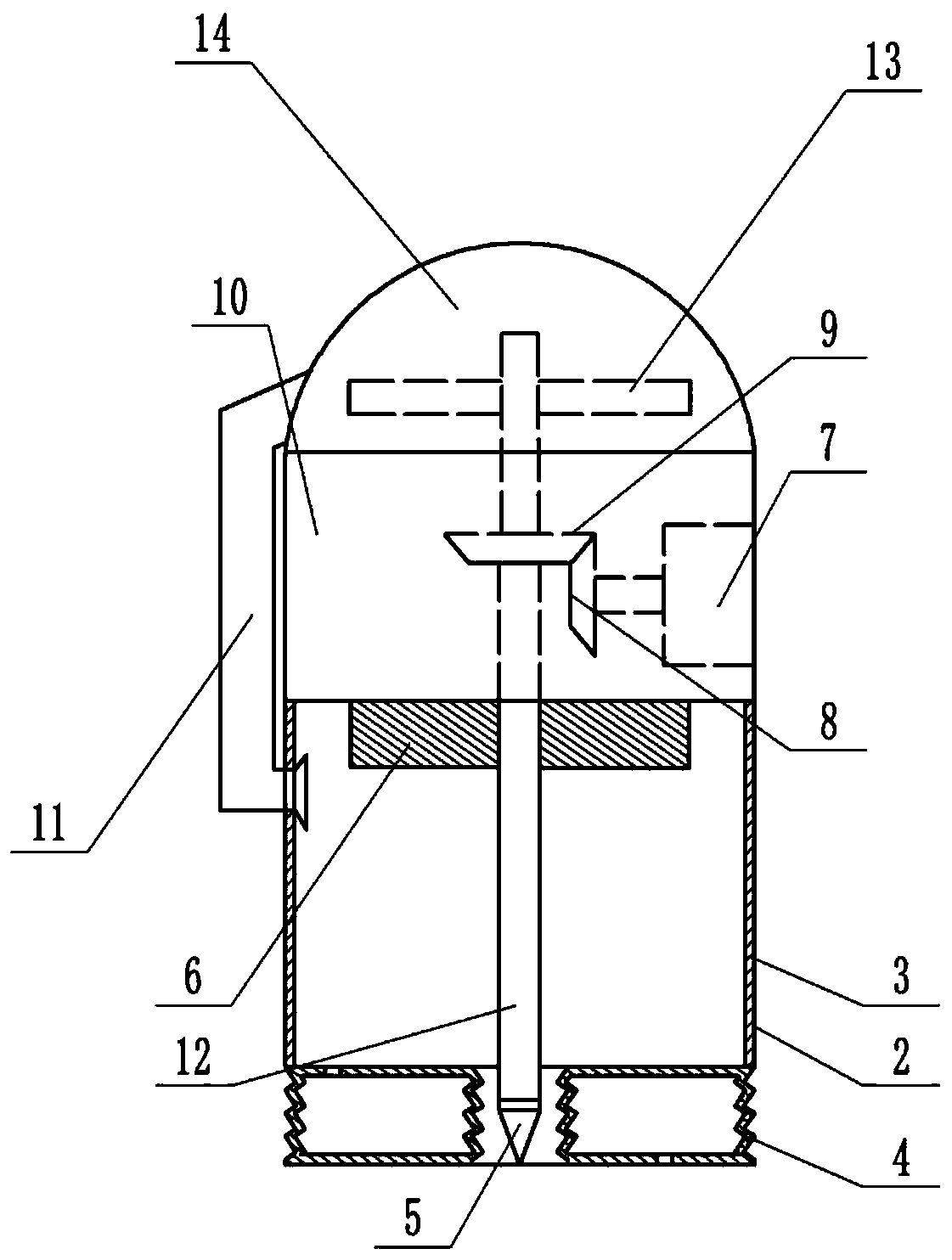

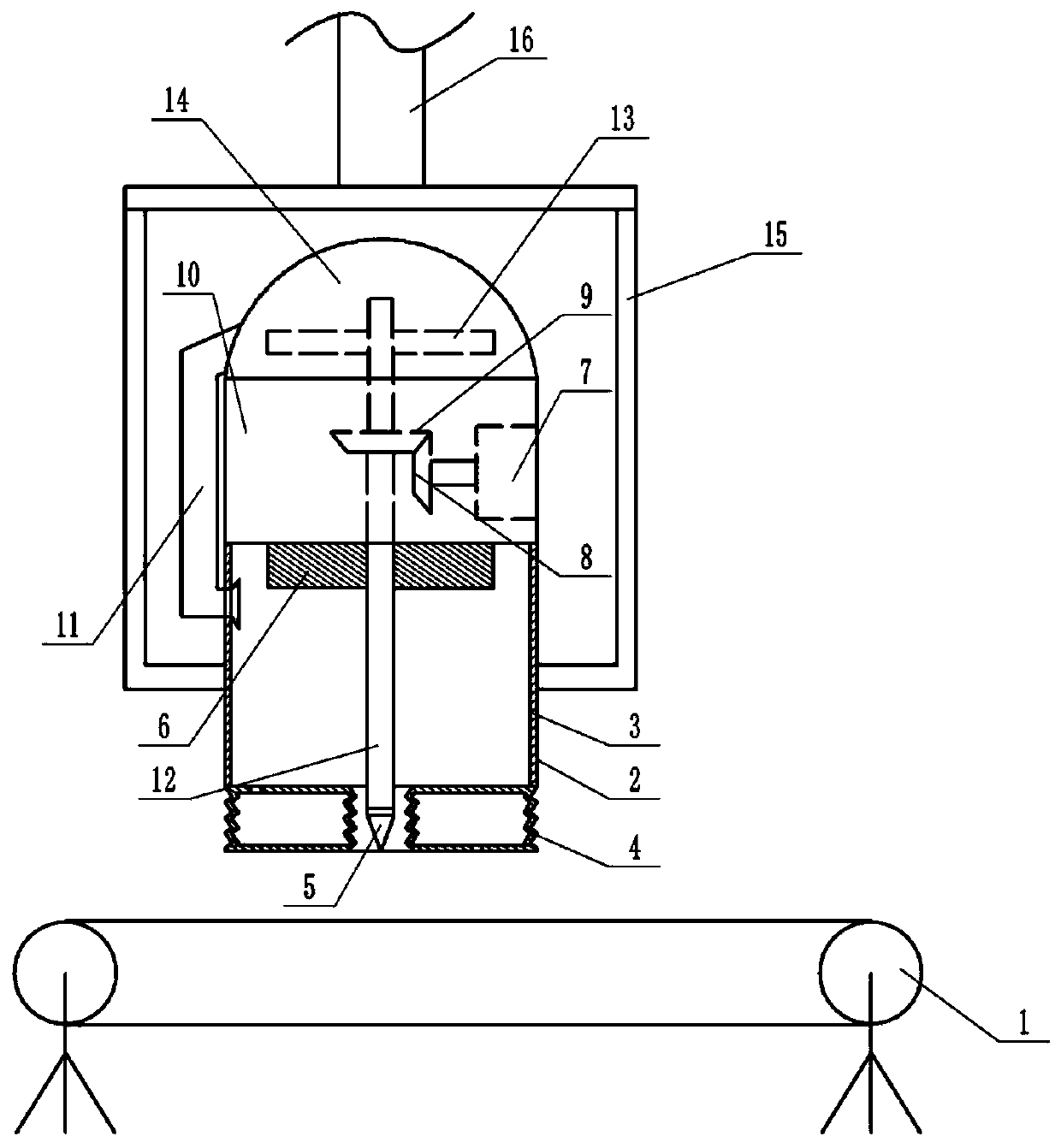

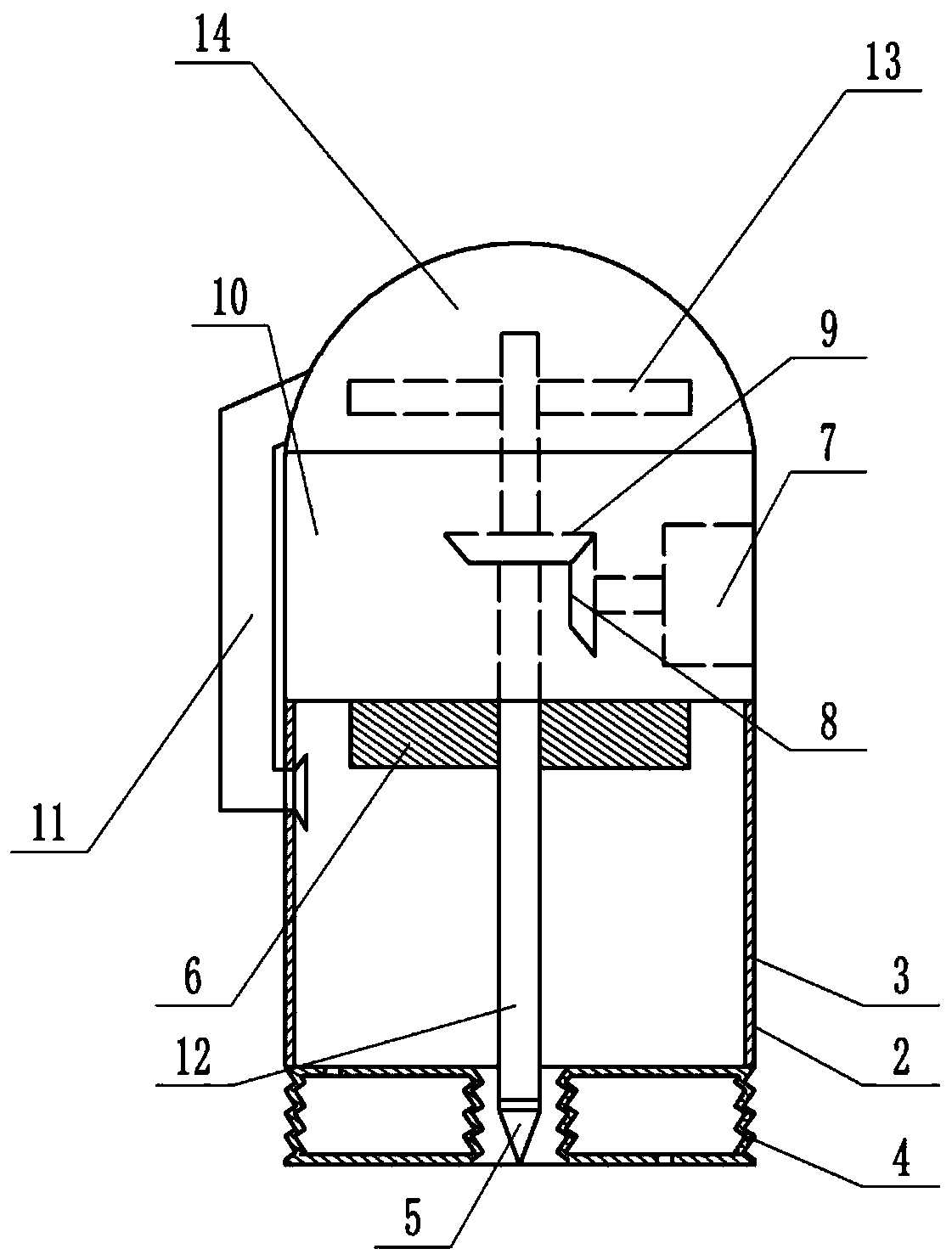

[0019] The reference signs in the drawings of the specification include: conveying mechanism 1, drilling mechanism 2, drilling box 3, annular air bag 4, drill bit 5, bearing 6, motor 7, driving bevel gear 8, driven bevel gear 9, drive box 10. Dust removal pipe 11, rotating shaft 12, negative pressure blade 13, dust removal box 14, connecting rod 15, piston rod 16.

[0020] A dust removal device used in the production of motorcycle parts, such as figure 1 with figure 2 Shown. Including a conveying mechanism for conveying the motorcycle shell 1, a drilling mechanism for drilling the motorcycle shell 2, a dust removal mechanism for absorbing metal chips generated in the drilling, and a control drilling mechanism 2 and Cylinder that moves the dust removal mechanism up and down;

[0021] The drilling mechanism 2 and the dust removal mechanism are fixedly connected to the piston rod 16 of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com