Cutting and canning device for canned yellow peach

A technology of canning and dicing yellow peach, applied in metal processing and other directions, can solve the problems of reduced work efficiency and labor consumption, and achieve the effects of improving work efficiency, protecting equipment, and slowing down the reset time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

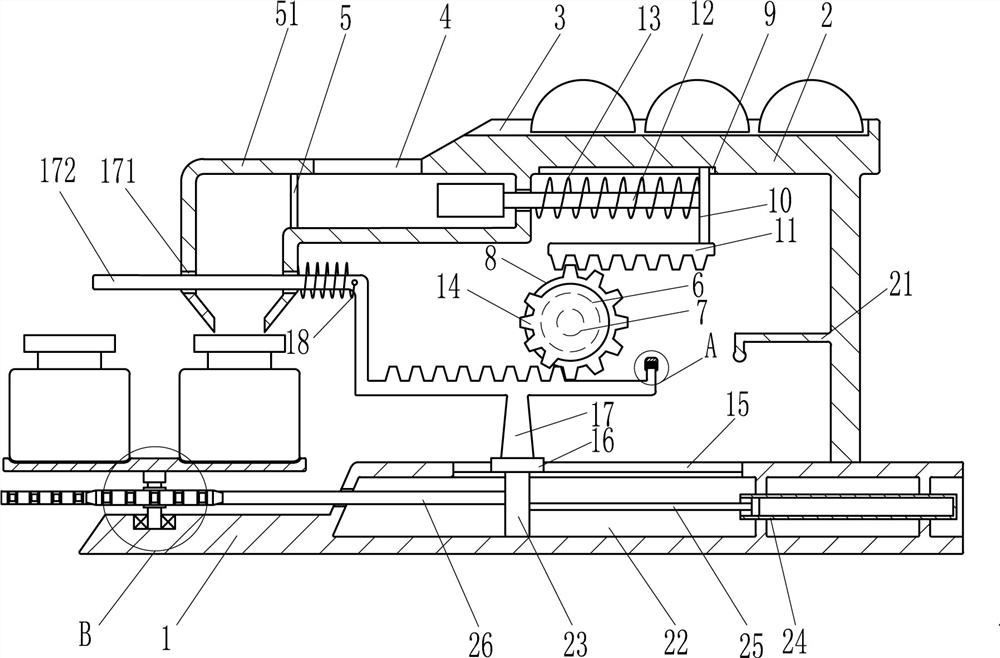

[0018] A kind of dicing and canning device for canned yellow peach, such as figure 1 As shown, it includes a base 1, a special-shaped frame 2, a material inlet 4, a knife net 5, a discharge pipe 51, a cutting assembly and a discharge part, and the right side of the top of the base 1 is provided with a special-shaped frame 2, and the special-shaped frame 2 There is a sliding groove 3 on the right side of the top, a feed inlet 4 is opened on the left side of the top of the special-shaped frame 2, a knife net 5 is provided on the left side of the inner wall of the special-shaped frame 2, and a discharge pipe 51 is provided on the left side of the special-shaped frame 2. The special-shaped frame 2 inwall is provided with the dicing assembly that yellow peach is cut into pieces by sliding mode, and the base 1 top is provided with a discharge part, and the discharge part cooperates with the discharge pipe 51.

[0019] Such as figure 1 As shown, the cutting block assembly includes a...

Embodiment 2

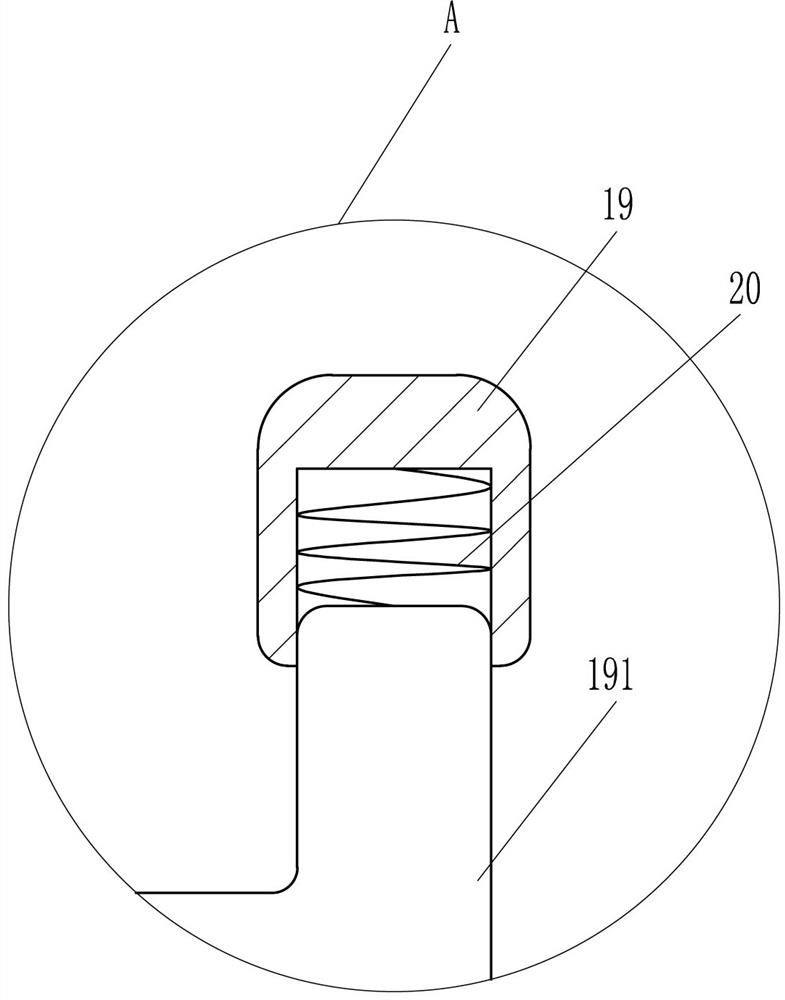

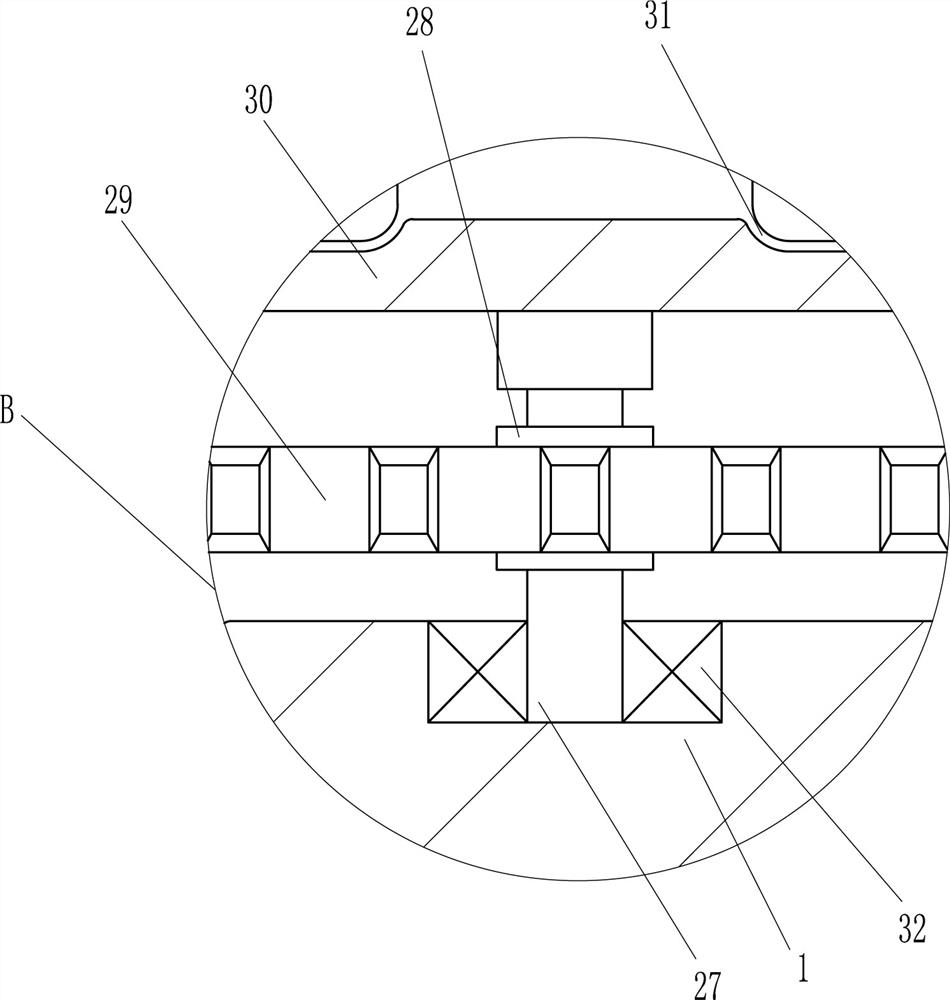

[0025] Such as figure 2 with 3 As shown, on the basis of Embodiment 1, in order to use the device better, it also includes a sliding sleeve 19, a third spring 20, a clamping rod 21, a second sliding rod 23, a cylinder body 24, a piston 25, a second Rack 26, second rotating shaft 27, overrunning clutch 28, full gear 29, placement plate 30 and one-way bearing seat 32, protruding block 191 is welded on the right side of special-shaped rack 17, and sliding type is provided with sliding sleeve on protruding block 191 19, the third spring 20 is connected between the sliding sleeve 19 and the bump 191, the left side of the right wall of the special-shaped frame 2 is provided with a clamping rod 21, the clamping rod 21 cooperates with the sliding sleeve 19, and there is a working groove 22 in the base 1 , the working groove 22 communicates with the second chute 15, the bottom of the sliding block 16 is provided with a second slide bar 23, the right part of the working groove 22 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com