Flexographic printed wide color gamut printing method, system and device

A printing method and technology of printing system, applied in printing device, printing and other directions, can solve the problems of waste of ink, printing cost, color distortion, etc., and achieve the effect of reducing washing machine waste, increasing utilization rate, and reducing color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

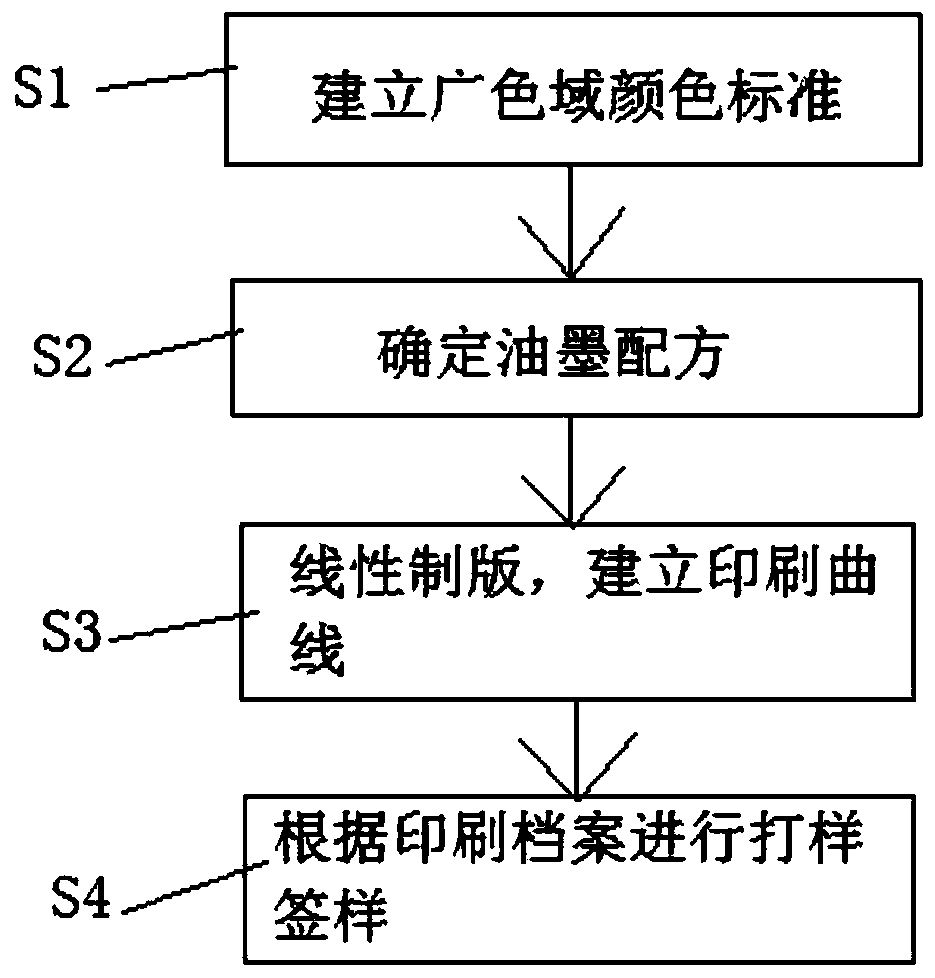

[0032] This embodiment proposes a flexographic wide color gamut printing method, refer to figure 1 , including the following steps:

[0033] S1. Establish a wide color gamut color standard, specifically including:

[0034] Extend the CMYK four-color gamut to a seven-color gamut, and the seven-color gamut includes the CMYK four-color gamut + orange + green + purple. Extend the original CMYK four-color gamut to CMYK+O (orange)+G (green)+V (purple) seven-color gamut to solve the problem of limited color gamut of pre-press design due to printing subtractive color method.

[0035] S2. Determine the ink formula, specifically including: determine the ink formula by performing ink IDD tests according to the ink standard, where the ink standard includes the setting standard of the ink detection color difference meter: D50 light source / 2° viewing angle, ΔE2000 detection standard; ink color difference standard: 100% on-site ΔE≤2.0, 50% dots ΔE≤3.0; for the Lab value standard of ink CMY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com