Patents

Literature

93results about How to "Reduce color variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

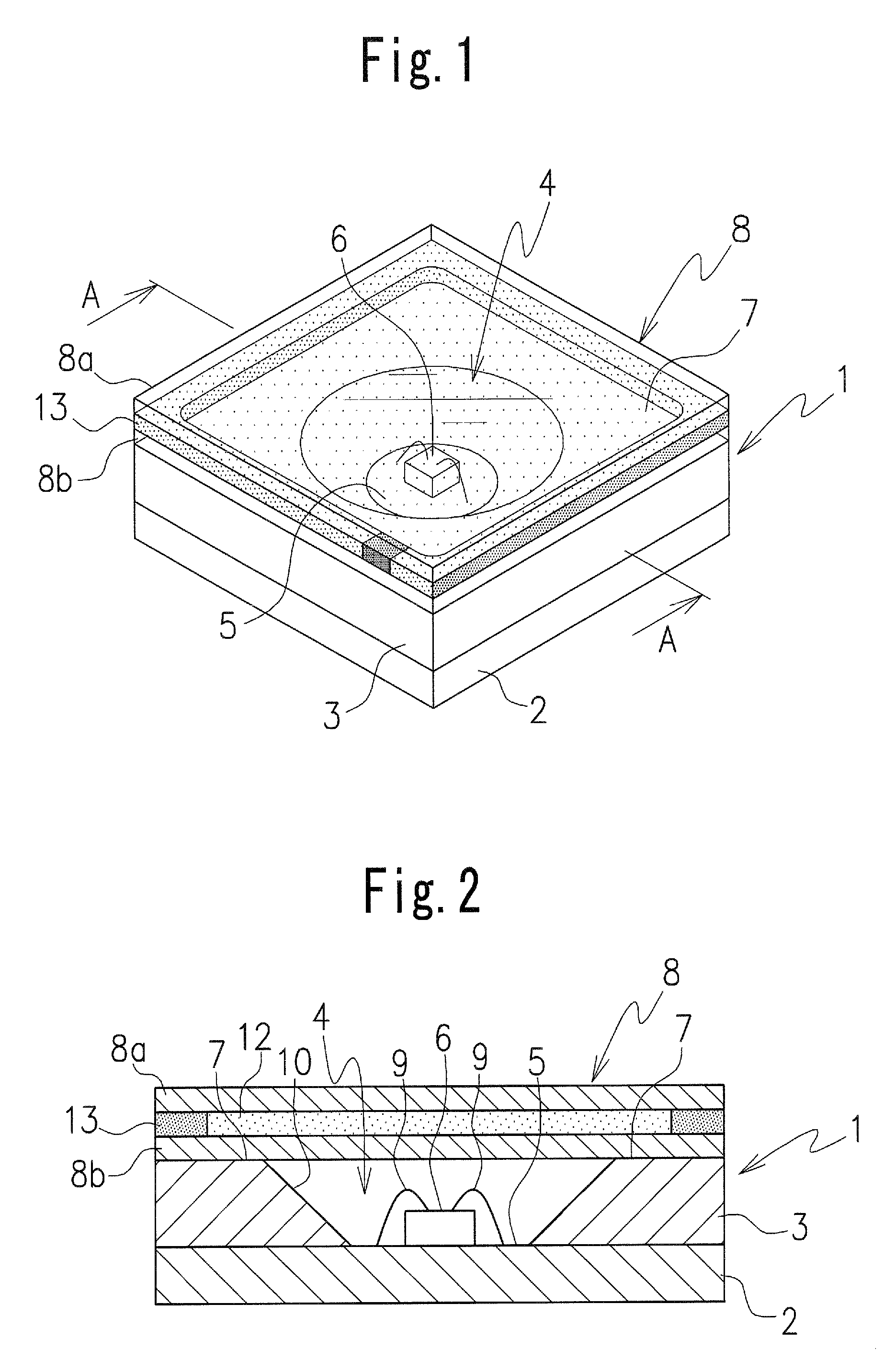

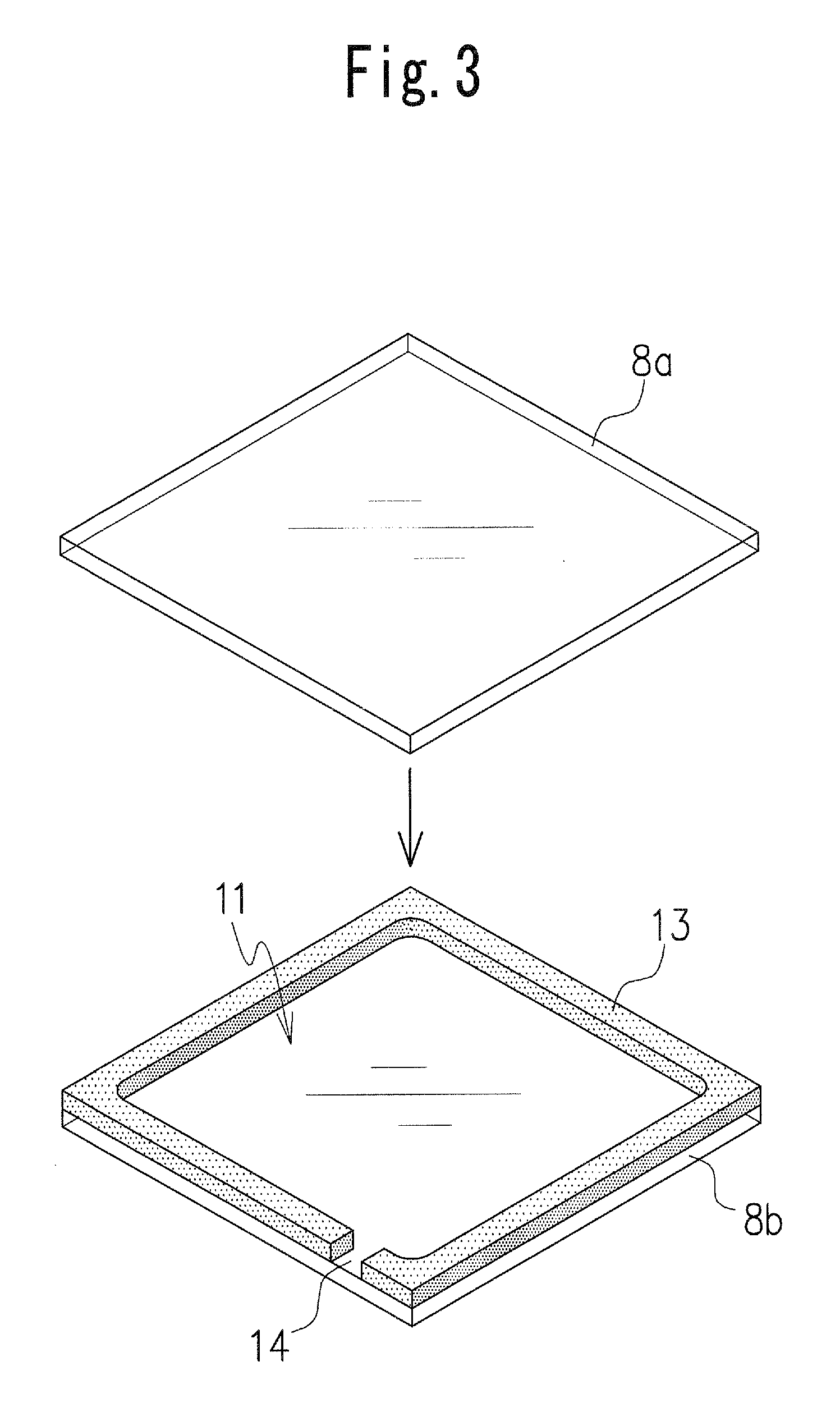

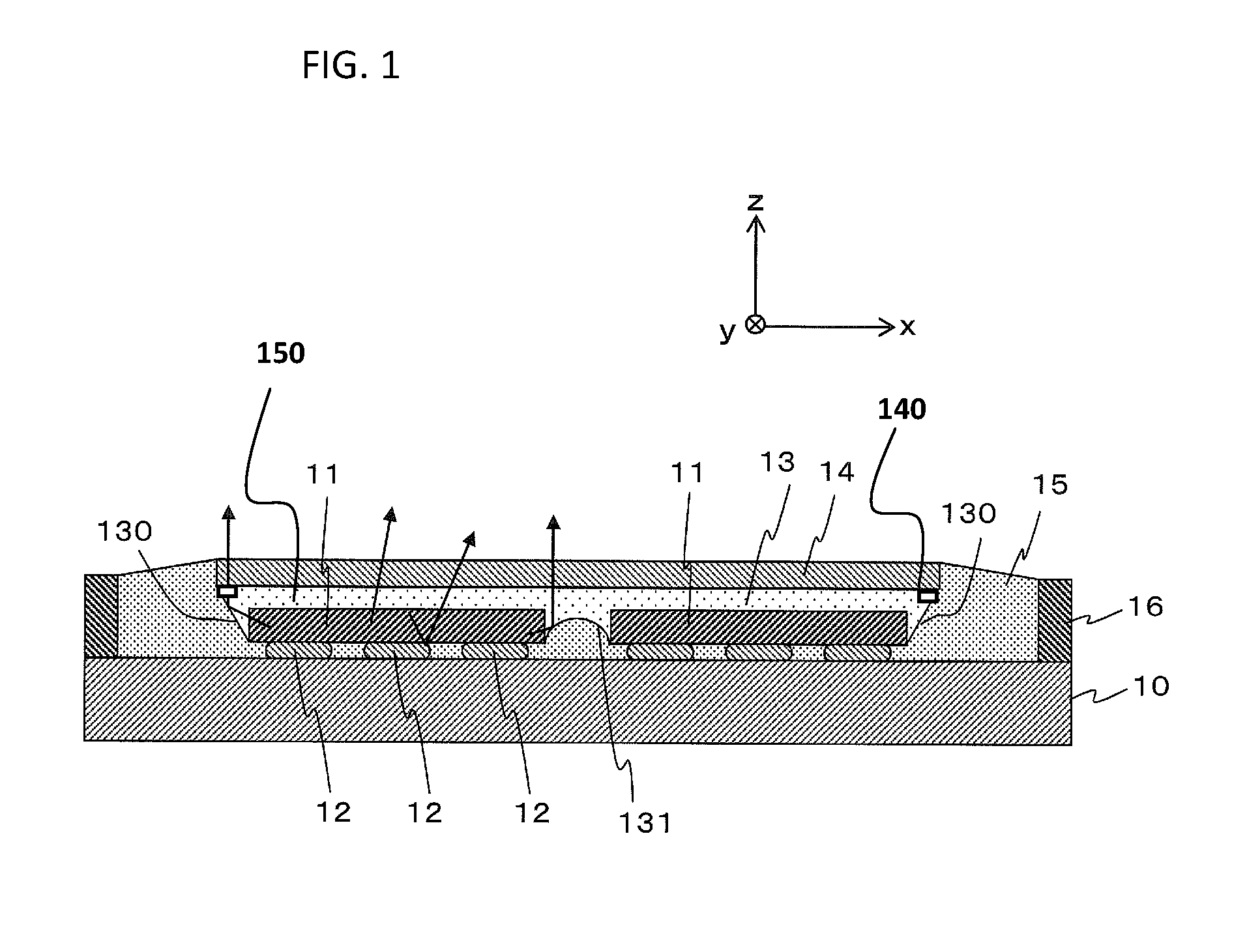

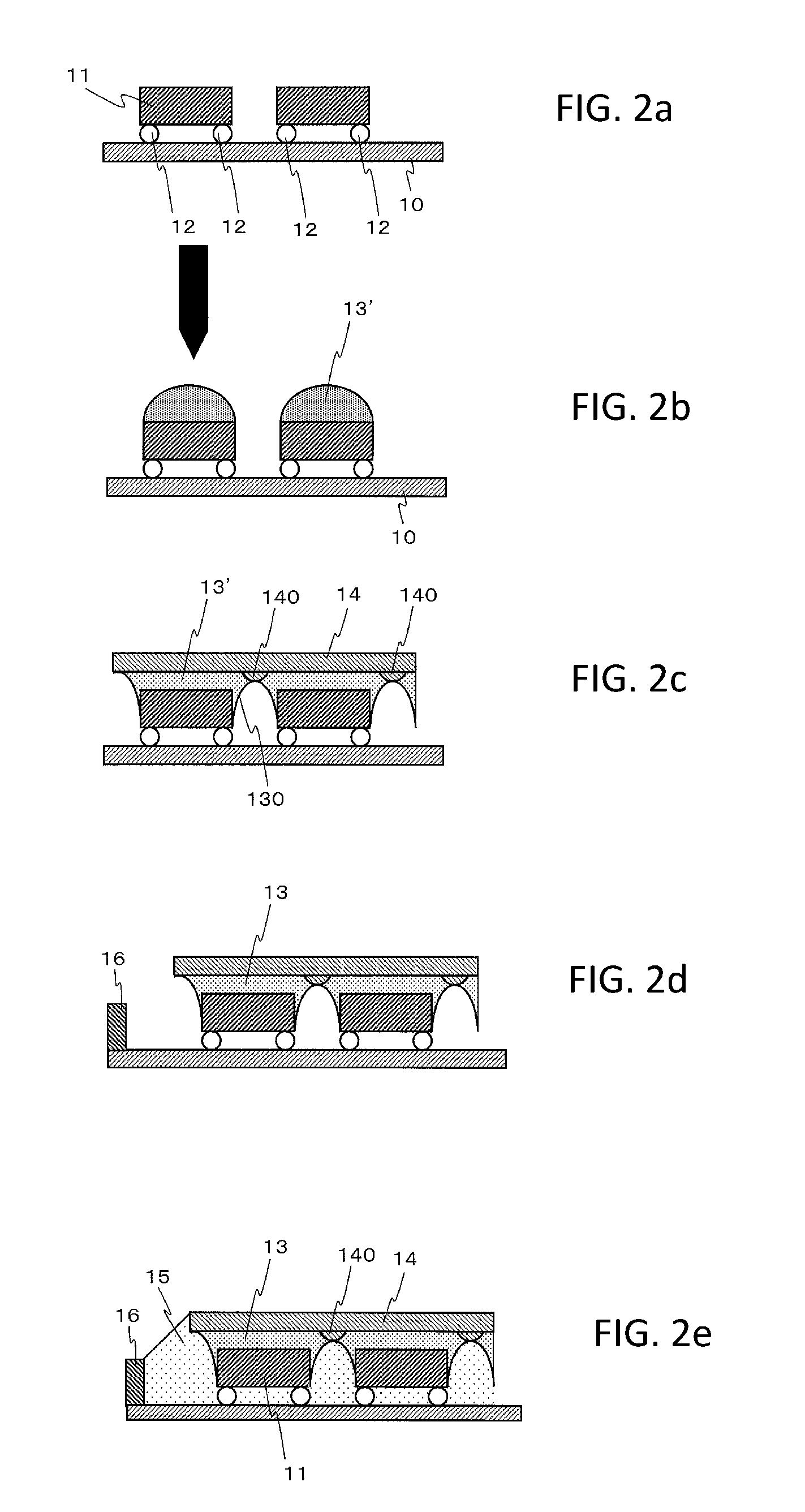

Semiconductor light emitting device and manufacturing method

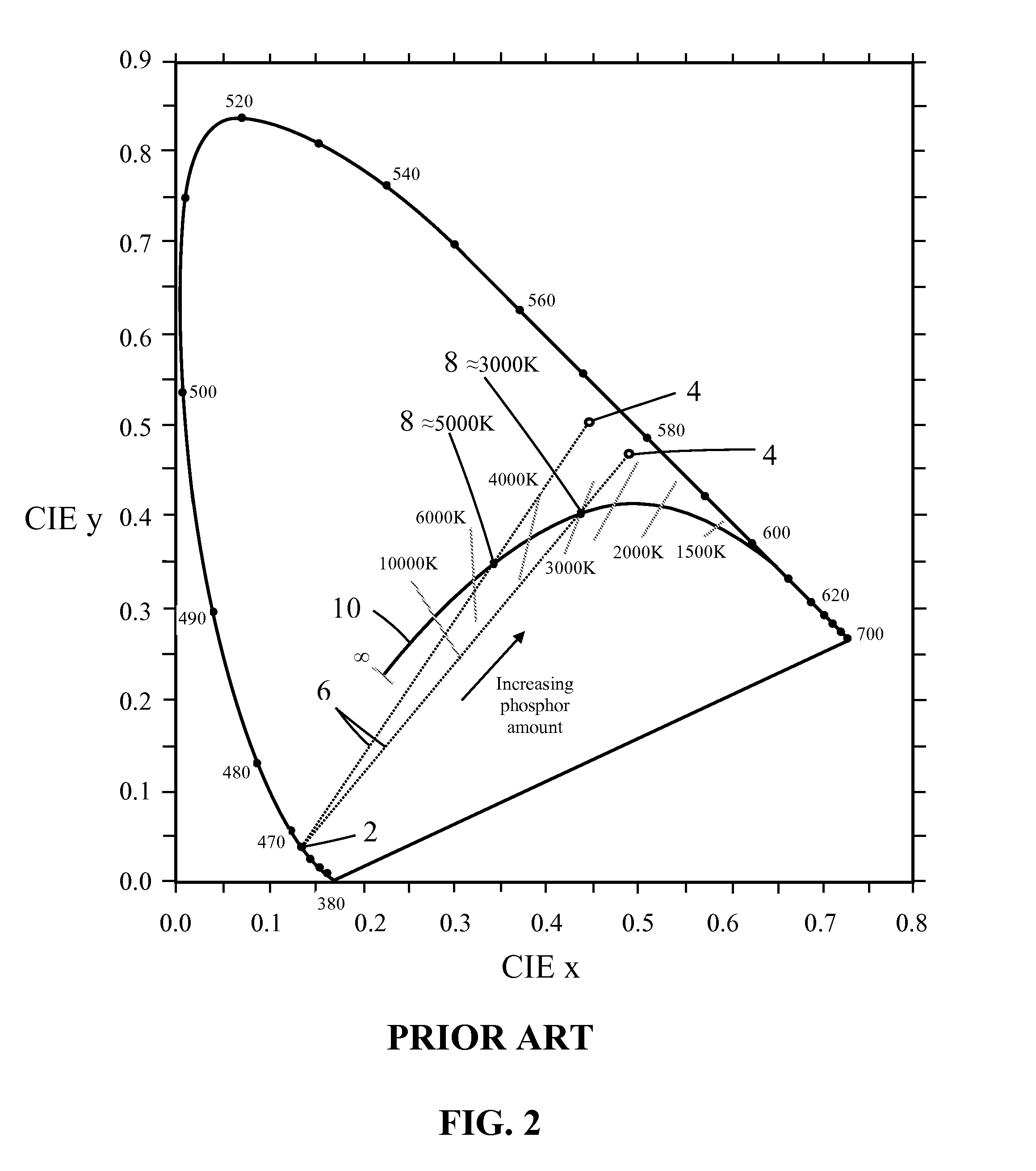

InactiveUS20120236582A1Improve light emission efficiencyUniform toneLighting heating/cooling arrangementsSolid-state devicesLength waveColored light

A semiconductor light-emitting device and a method for manufacturing the same can include a wavelength converting layer in order to emit various colored lights including white light. The device can include a board, a frame located on the board, at least one light-emitting chip mounted on the board, the wavelength converting layer located between an optical plate and an outside surface of the chips so that a density of a peripheral region is lower than that of a middle region, and a reflective material layer disposed at least between the frame and a side surface of the wavelength-converting layer. The device can have the reflective material layer form each reflector and can use a wavelength converting layer having different densities, and therefore can emit a wavelength-converted light having a high light-emitting efficiency and a uniform color tone from various small light-emitting surfaces.

Owner:STANLEY ELECTRIC CO LTD

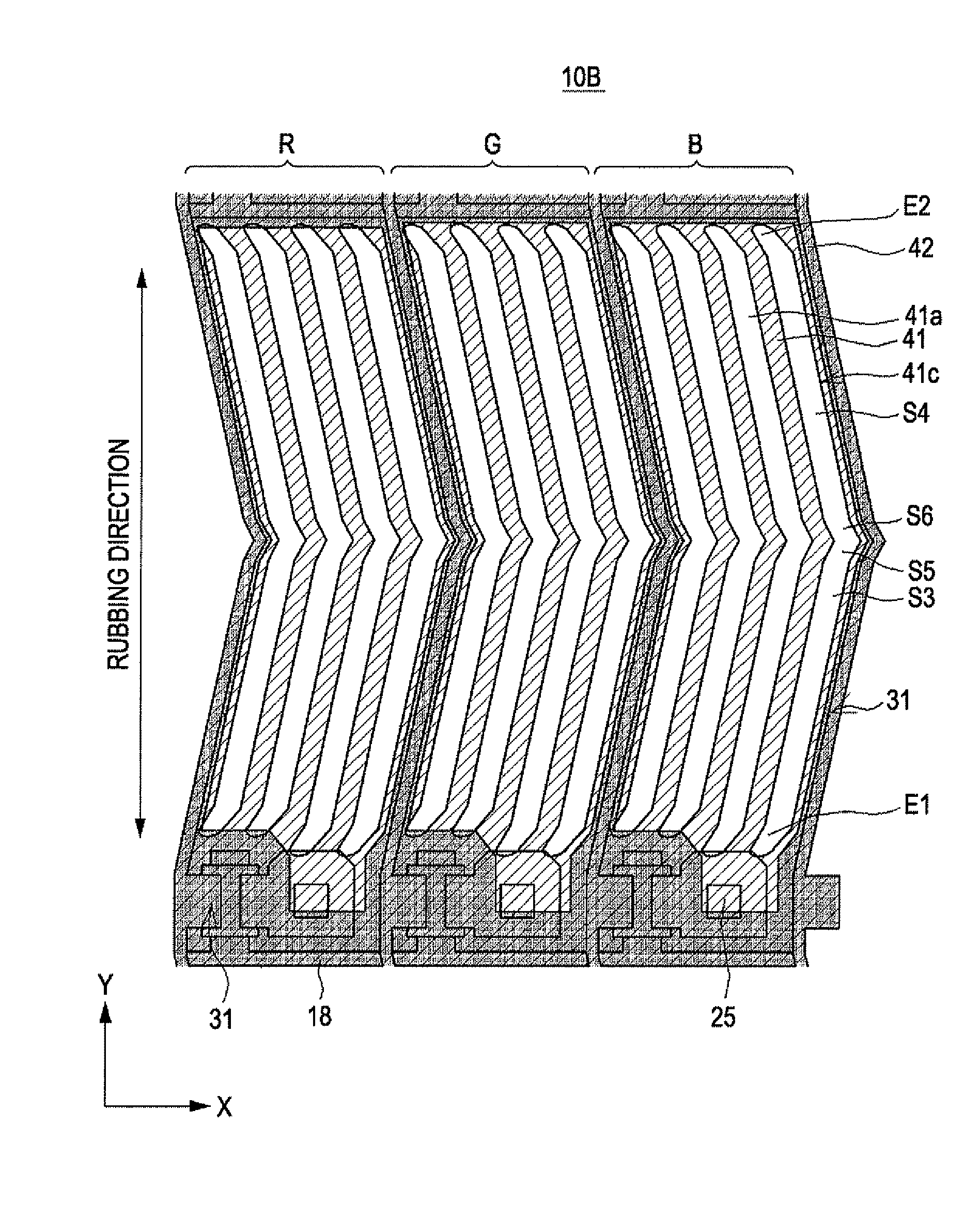

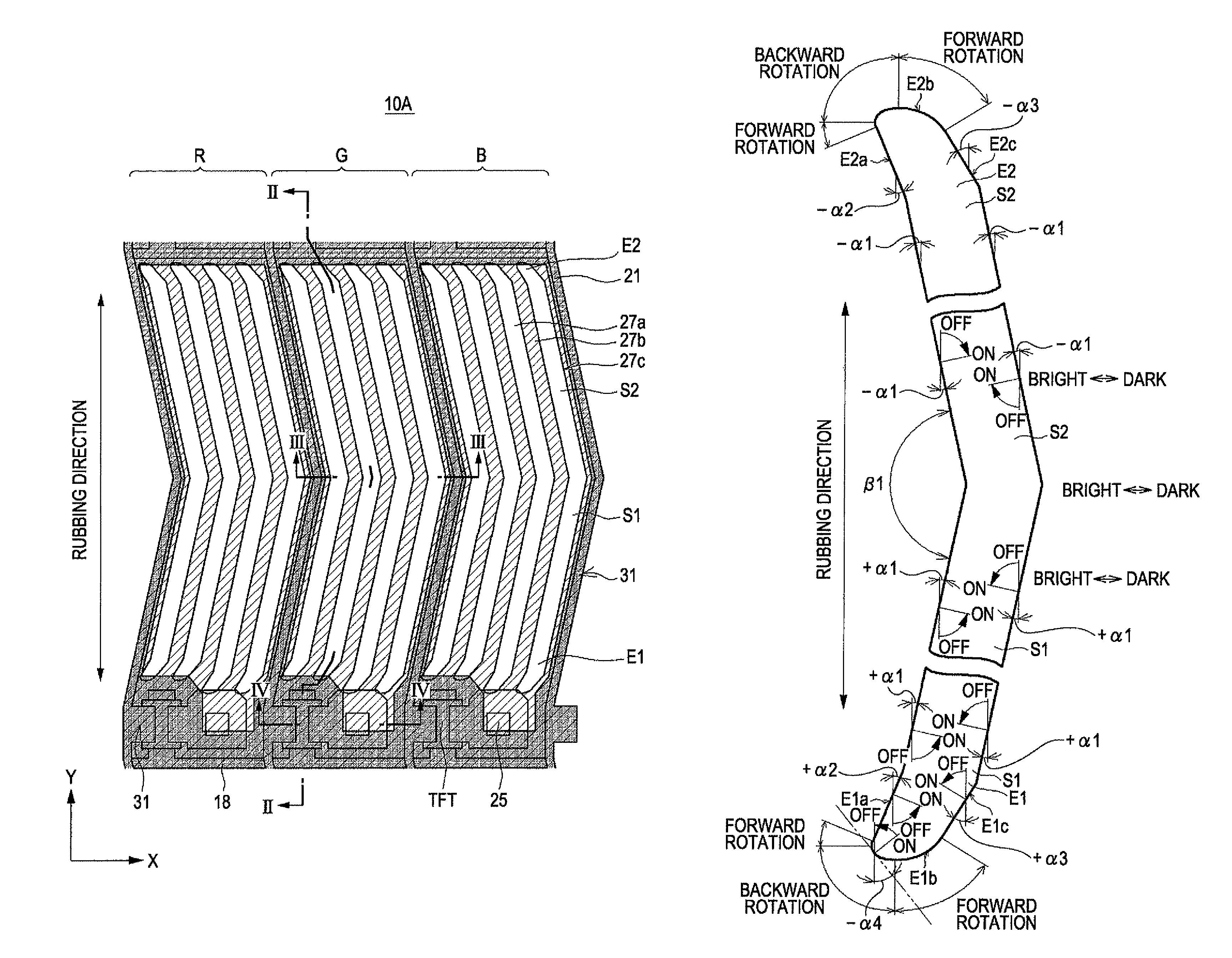

Liquid crystal display panel

ActiveUS20100079712A1Efficiently obtainedDisplay brightNon-linear opticsLiquid-crystal displayLiquid crystal

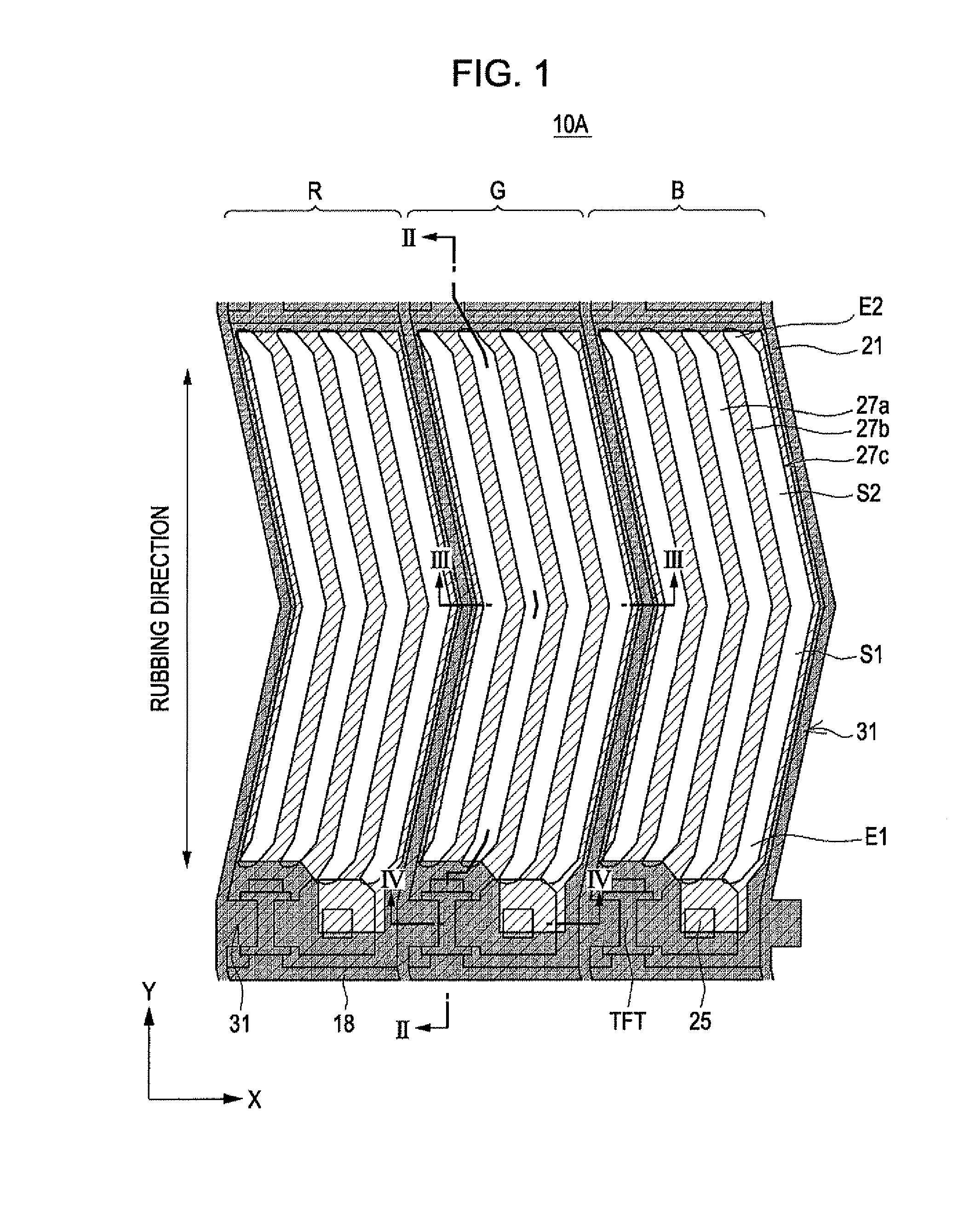

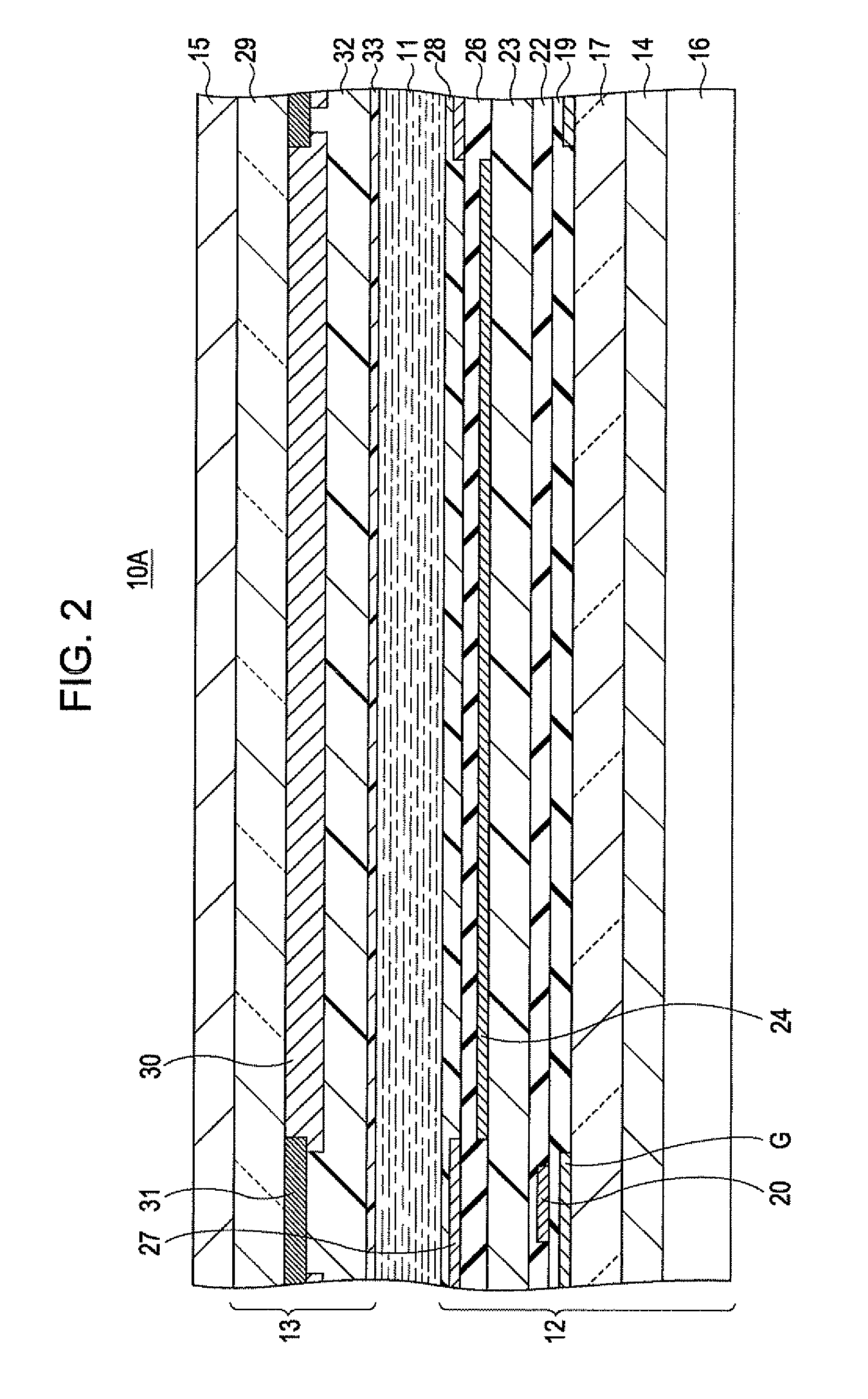

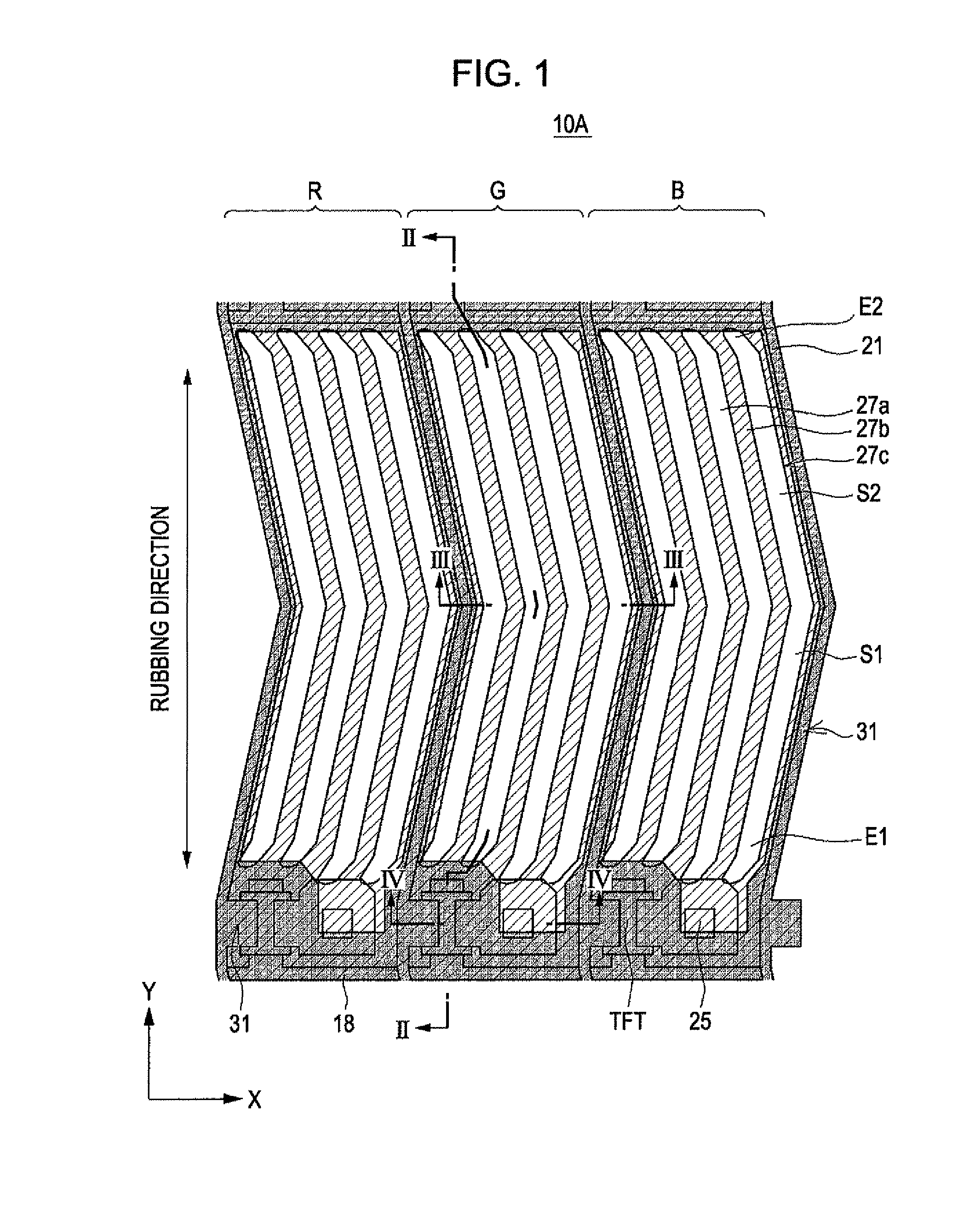

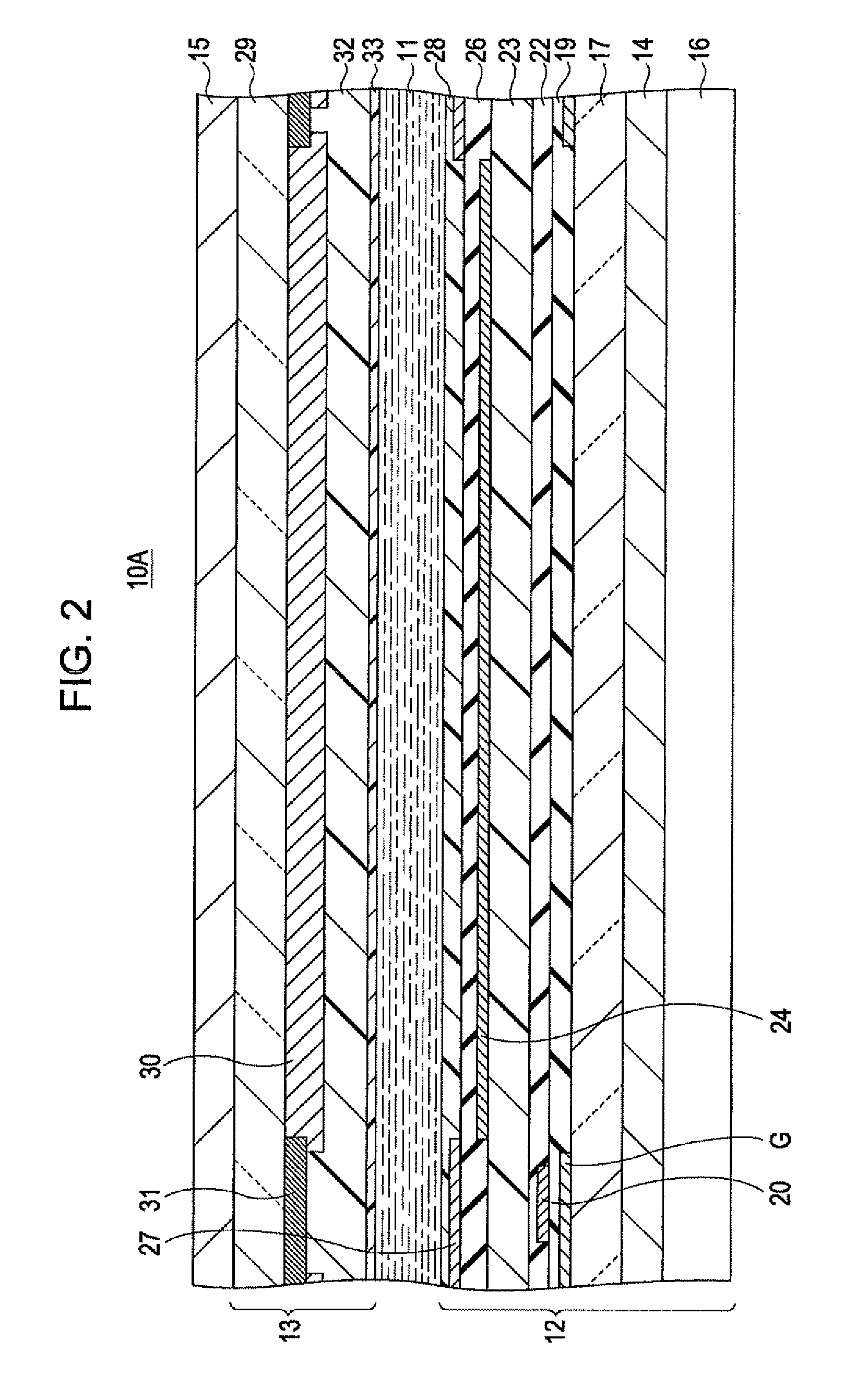

A liquid crystal display panel includes: a pair of substrates which are opposed to each other; and a liquid crystal layer which is interposed between the pair of substrates, wherein one of the pair of substrates is provided with a plurality of scanning lines and a plurality of signal lines which are arranged in a matrix shape in a display area, lower electrodes which are each formed in each of sub-pixel areas partitioned by the plurality of scanning lines and the plurality of signal lines, an insulating film which is formed in the display area so as to cover the lower electrodes, upper electrodes which are formed in the display area through the insulating film and each have a plurality of slits in each of the sub-pixel area, and an alignment film which is formed on the upper electrodes and slit-shaped openings close to the liquid crystal layer, wherein the other of the pair of substrates is provided with light-shielding films which are formed at locations overlapping with the scanning lines and the signal lines in plan view, wherein each of the upper electrodes overlaps with each of the light-shielding films in at least a partial portion in plan view, wherein each of the slit-shaped openings extends along any one of the signal line or the scanning line and has a main portion extending in an direction inclined at a predetermined angle with respect to a rubbing direction of the alignment film and a front end portion, and wherein an edge of the circumference of at least one of the slit-shaped openings formed on both sides of the light-shielding film so as to dispose the light-shielding film therebetween in plan view does not overlap with the light-shielding film disposed between the slit-shaped openings in plan view.

Owner:JAPAN DISPLAY WEST

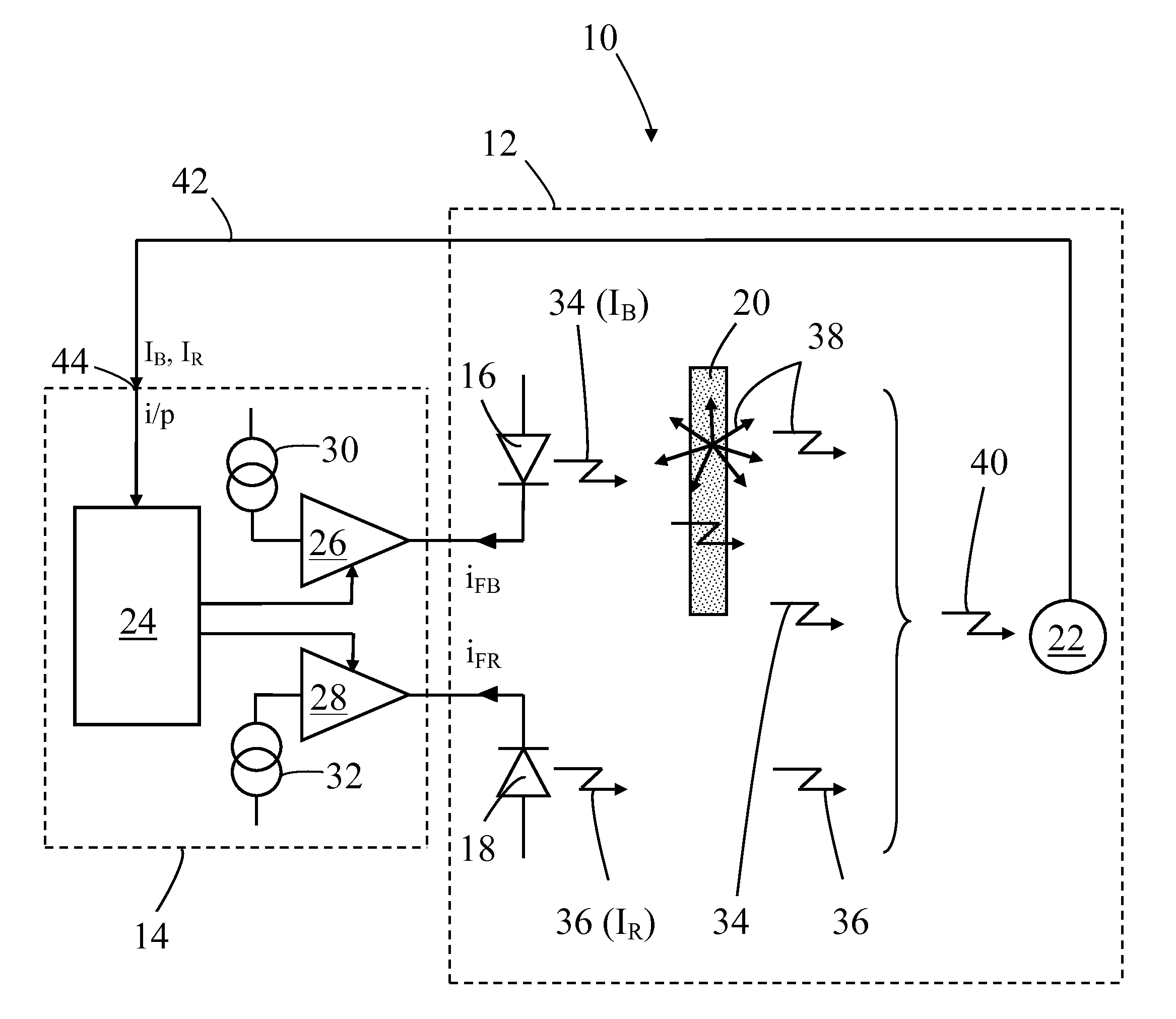

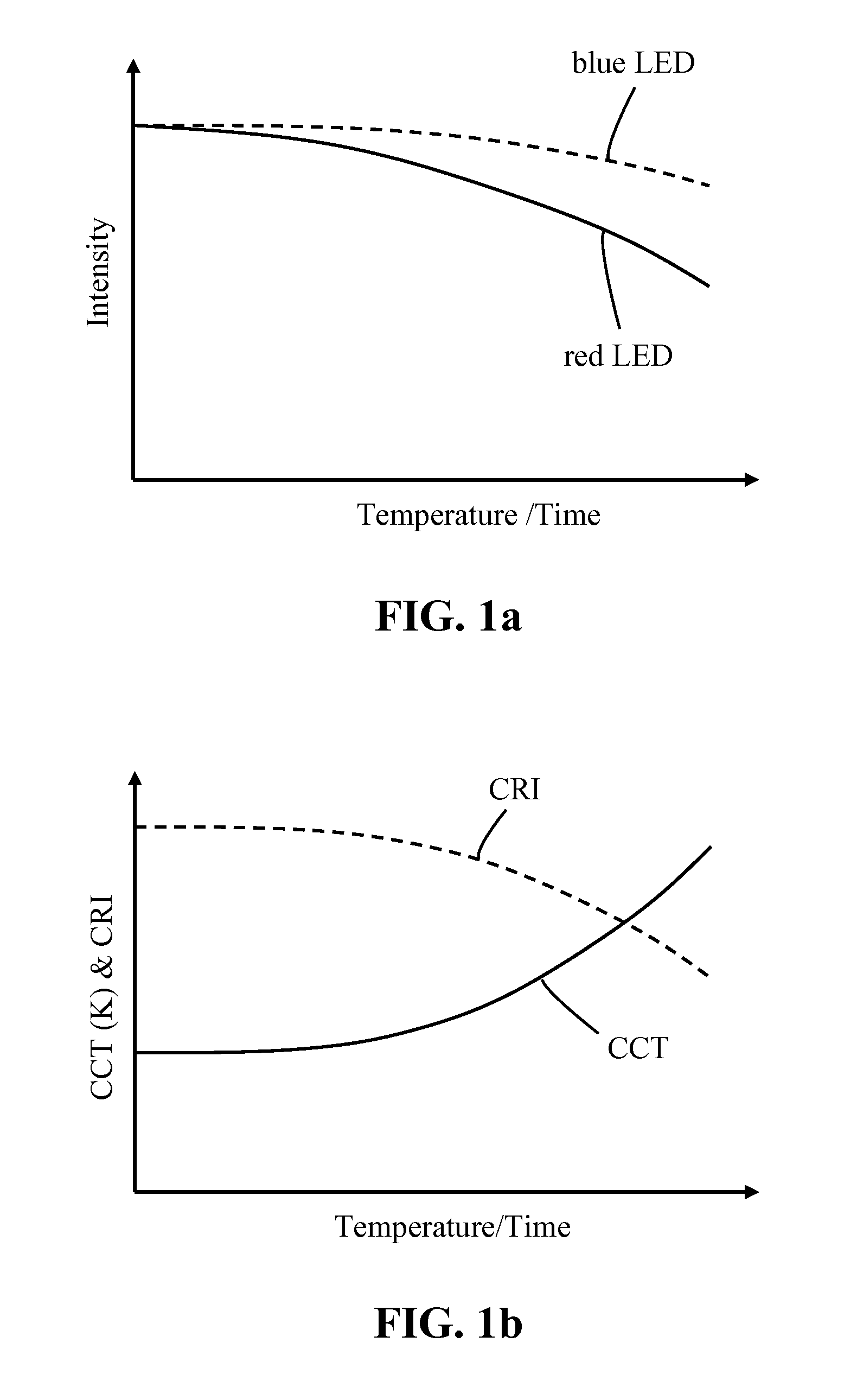

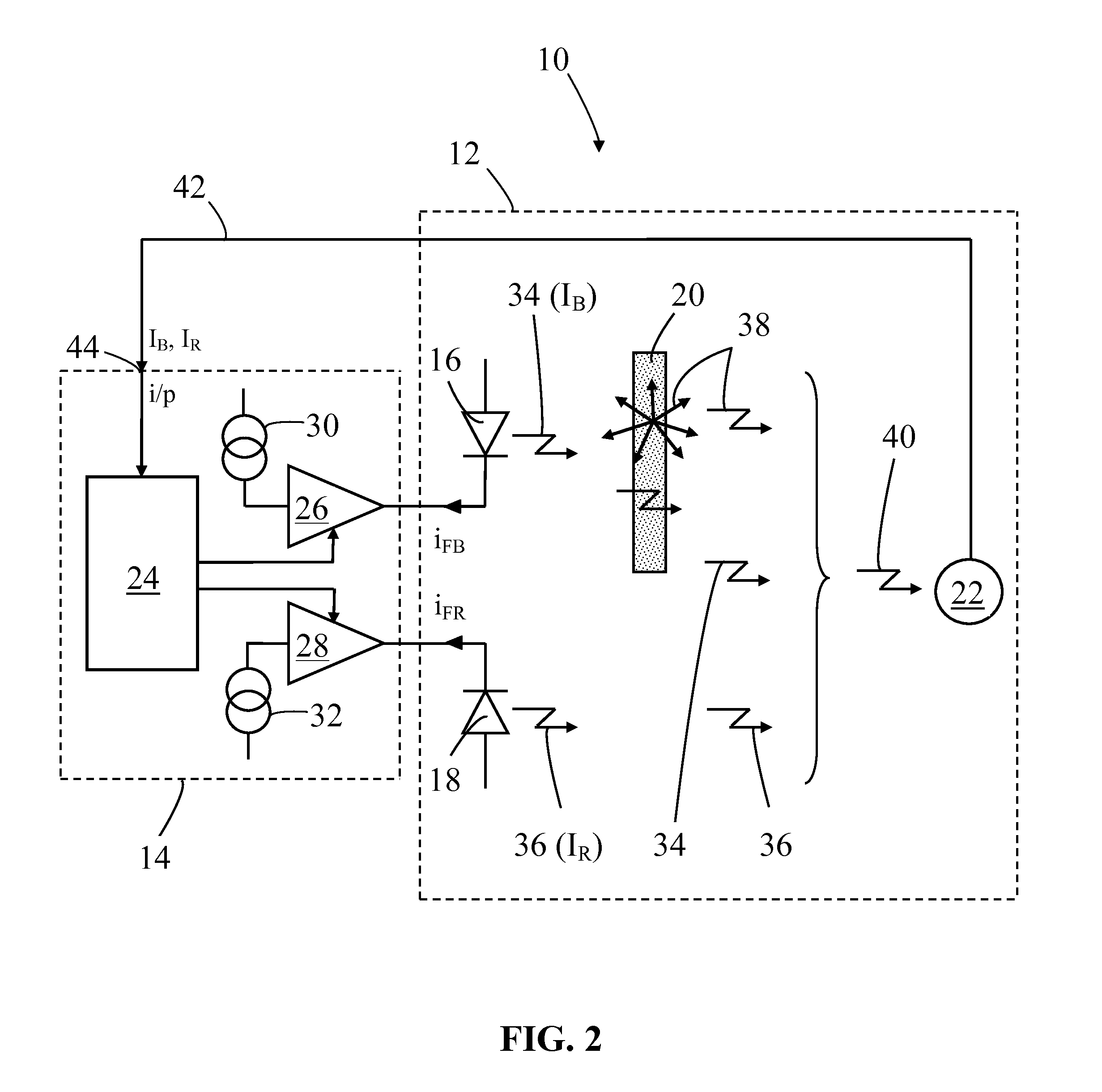

Led-based light emitting systems and devices

InactiveUS20120155076A1Reduce thermal degradationMore colorPlanar light sourcesLight source combinationsElectricityDriving current

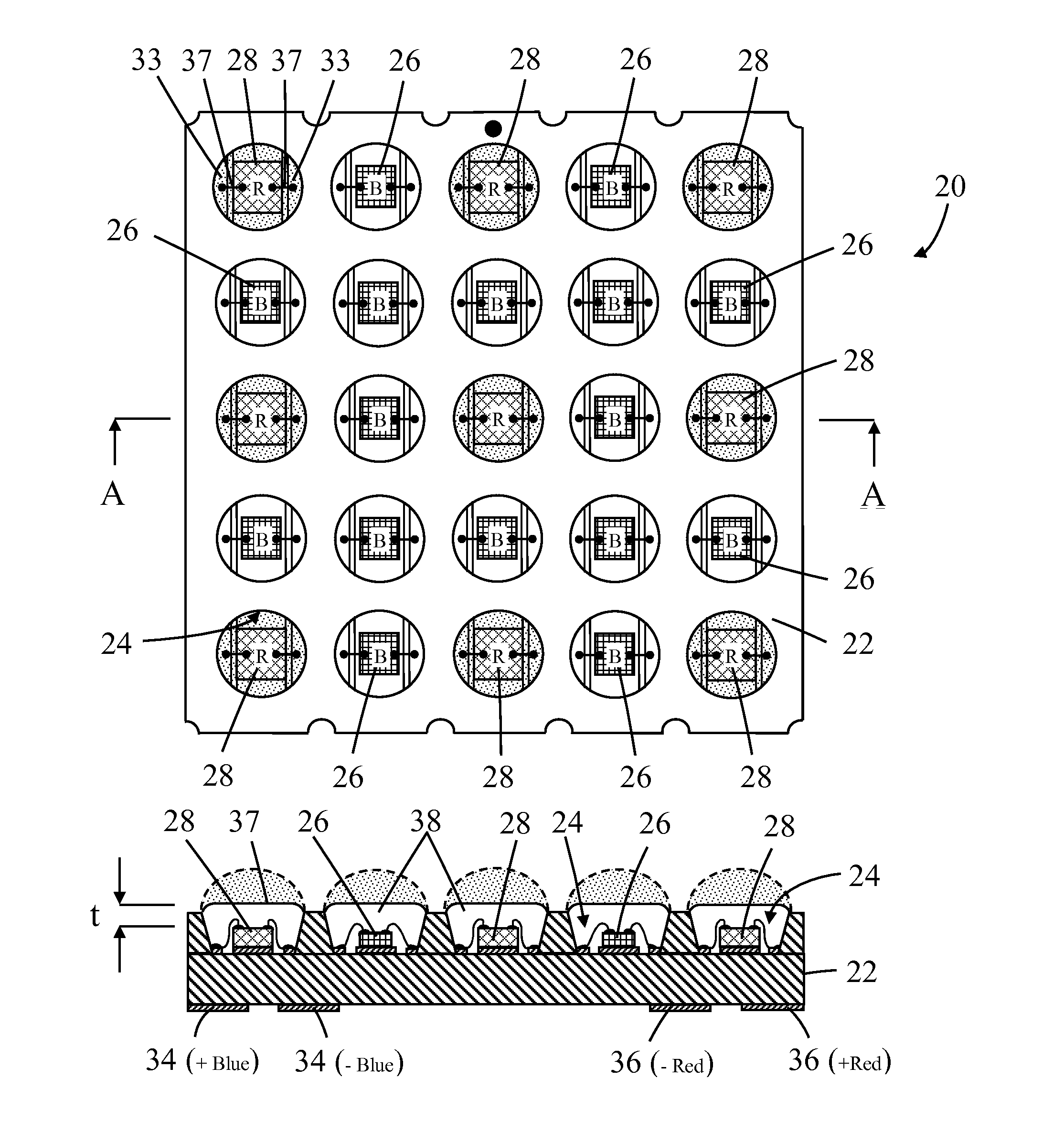

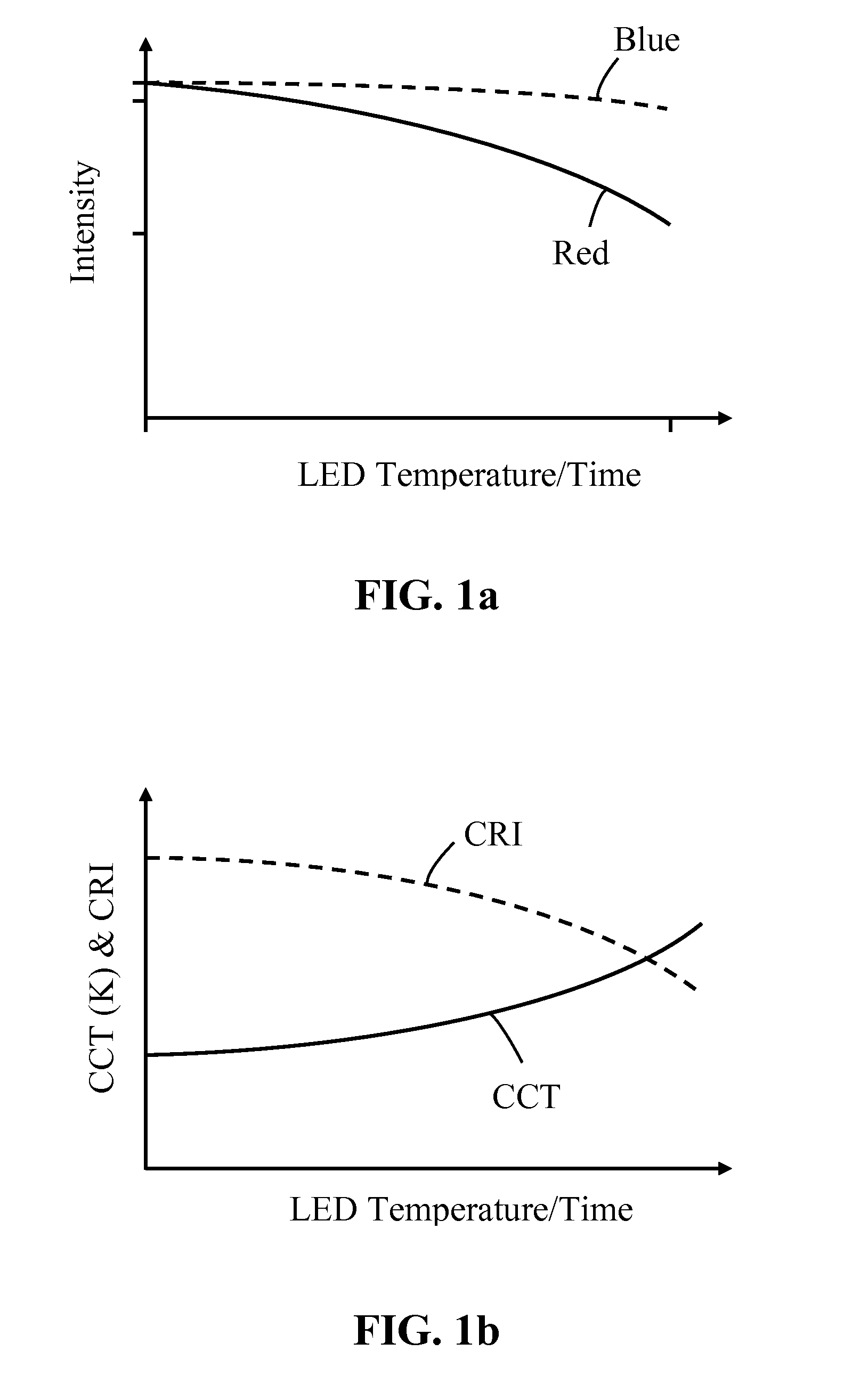

A light emitting device comprises: a package; at least one red LED housed in the package and operable to emit red light; at least one blue LED housed in the package and operable to emit blue light wherein the emission product of the device comprises the combination of light emitted by the red and blue LEDs; and a light transmissive material encapsulating the LEDs. Preferably, the package further comprises electrical contacts that are configured such that the drive current of the blue and red LEDs is independently controllable. Devices and / or light emitting systems further comprise a driver operable to control a drive current of the red and / or blue LEDs in response the measured emission intensities of the LEDs such as to maintain a substantially constant ratio of the blue to red light in the emission product.

Owner:INTEMATIX

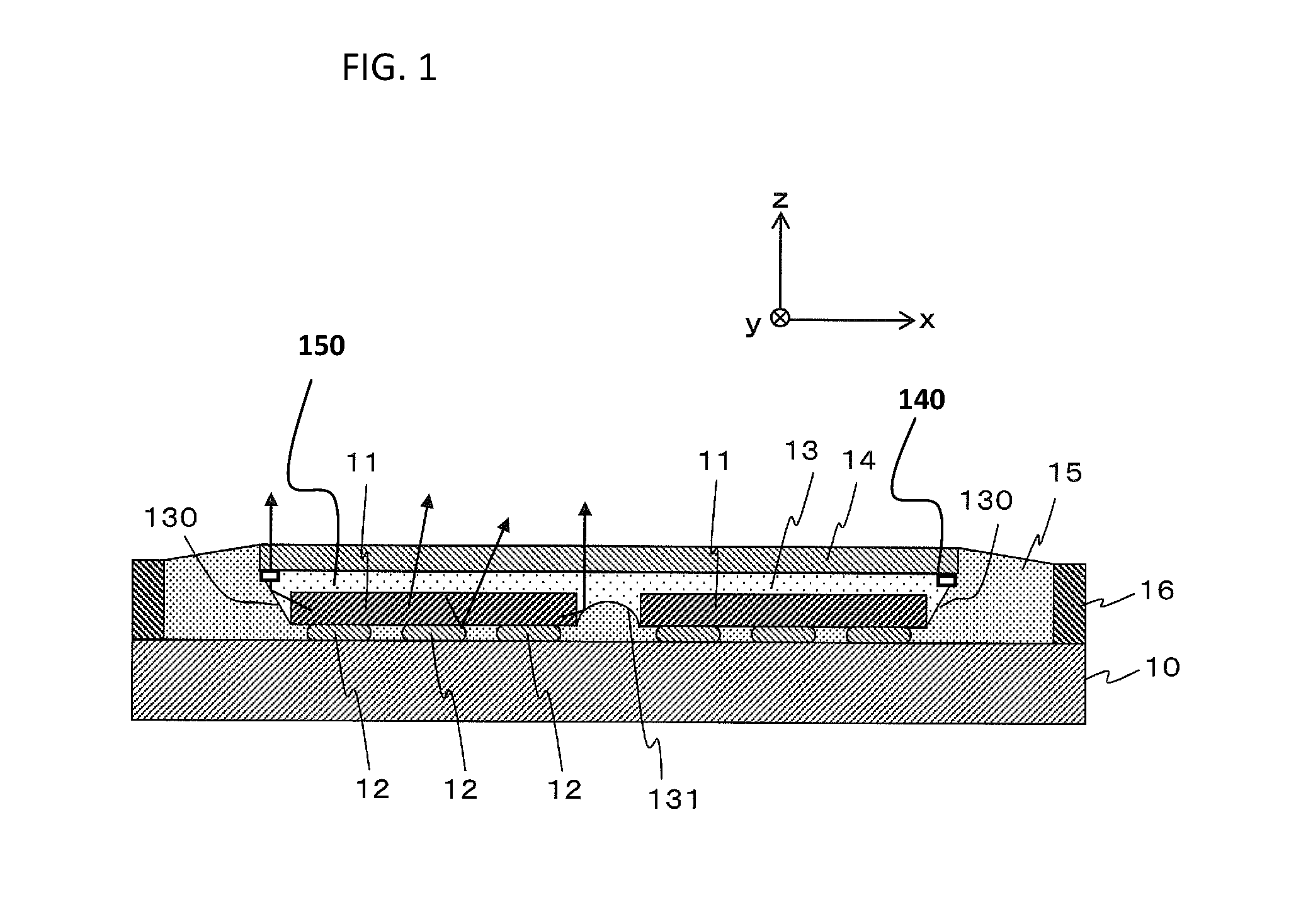

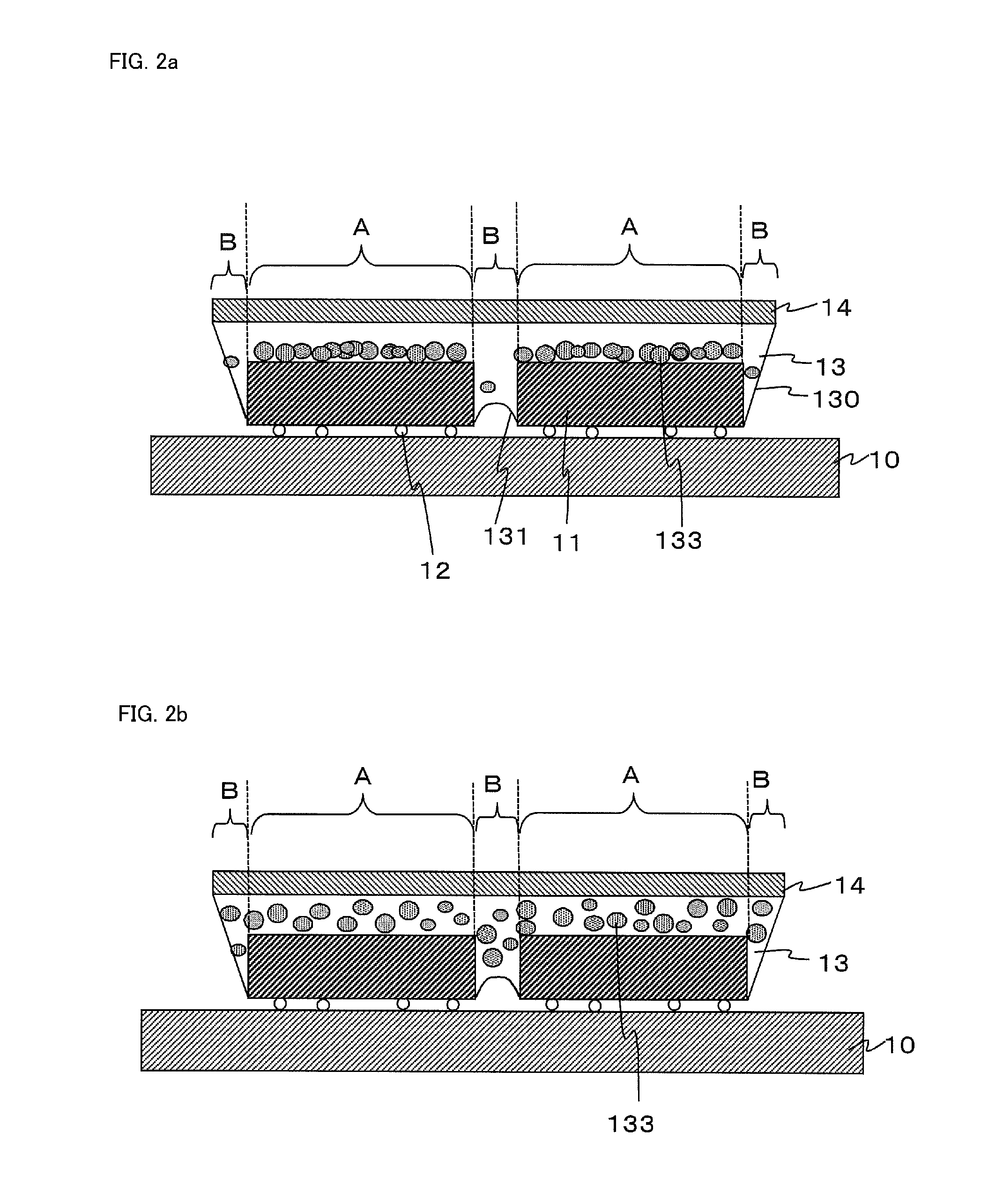

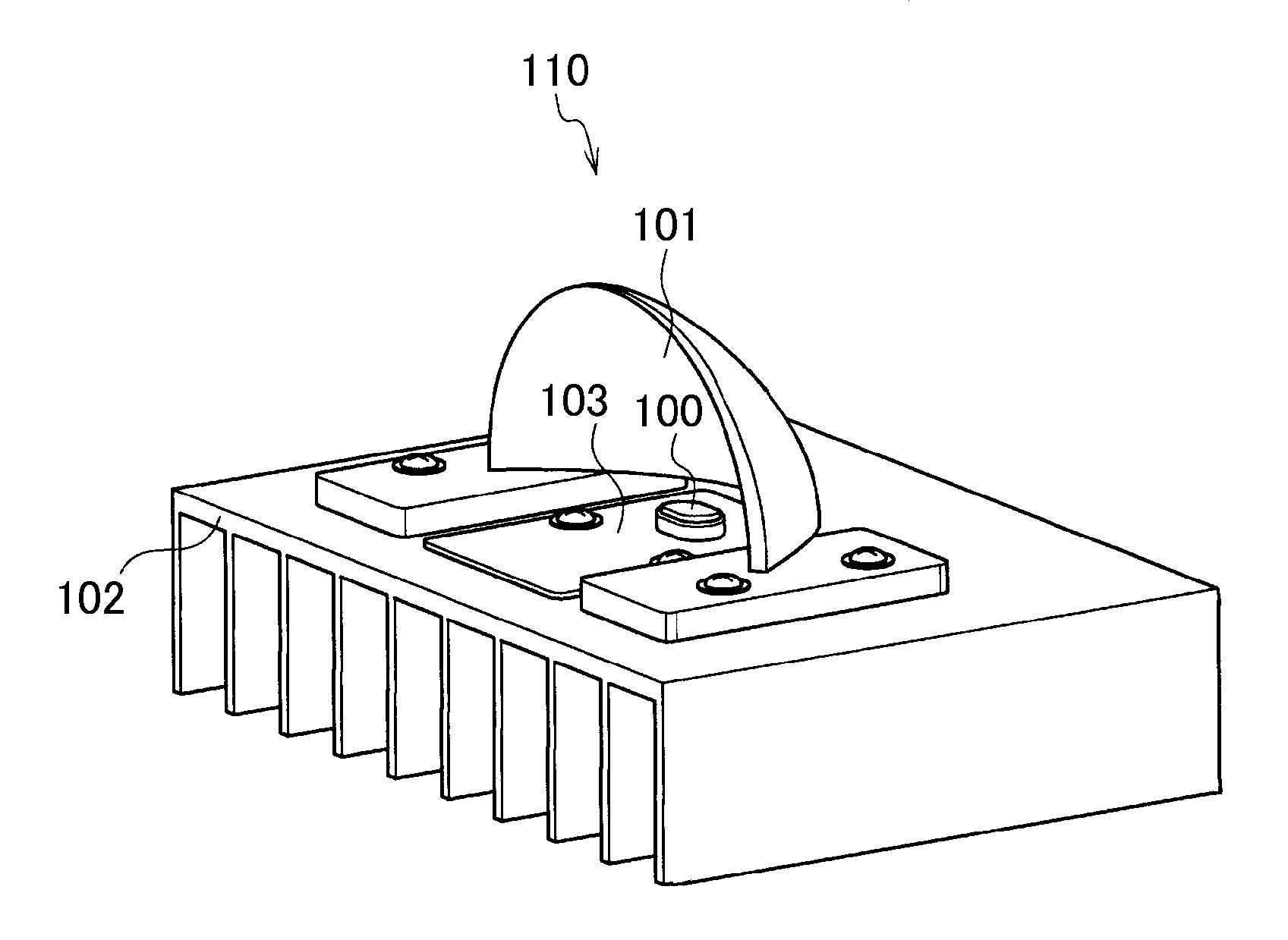

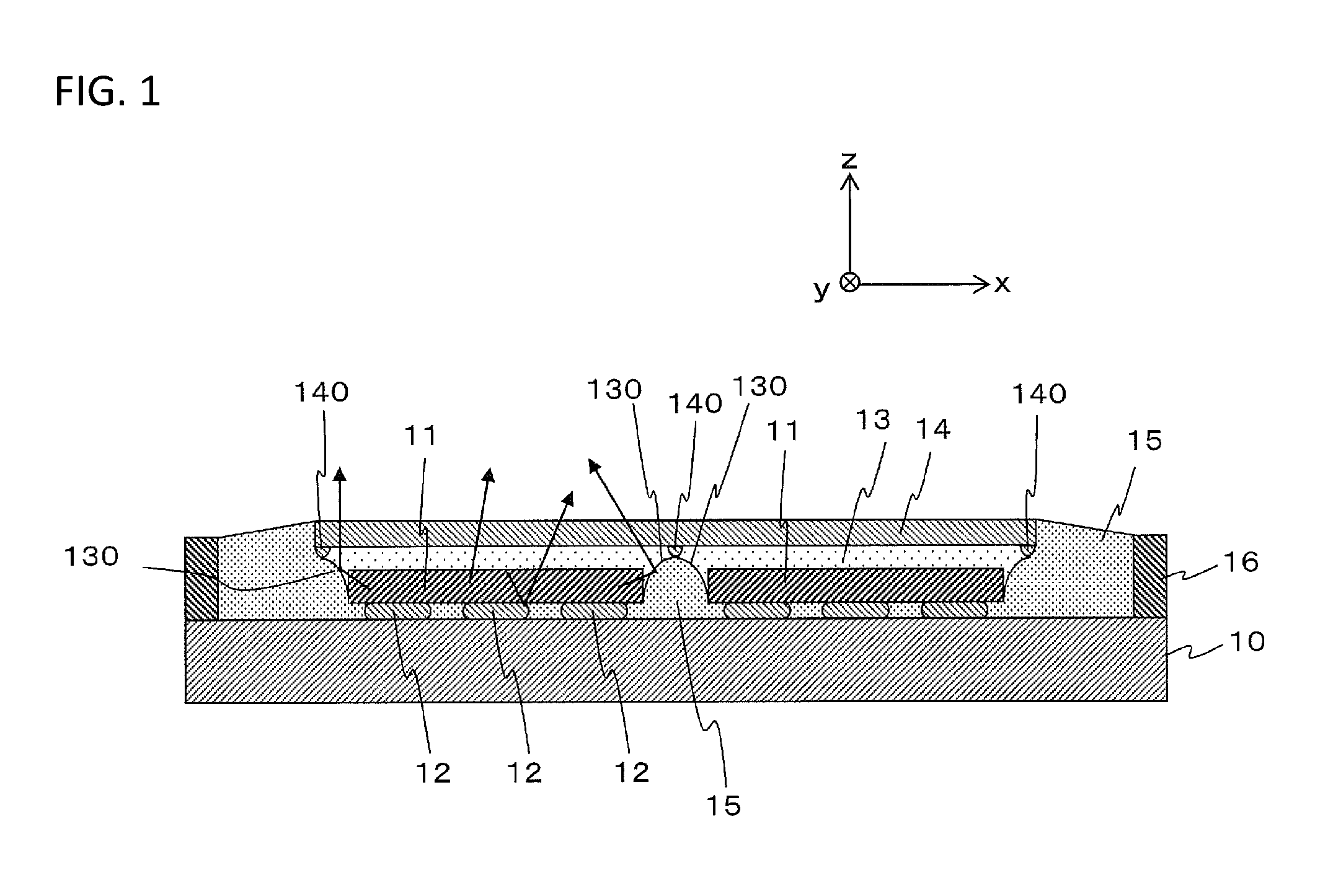

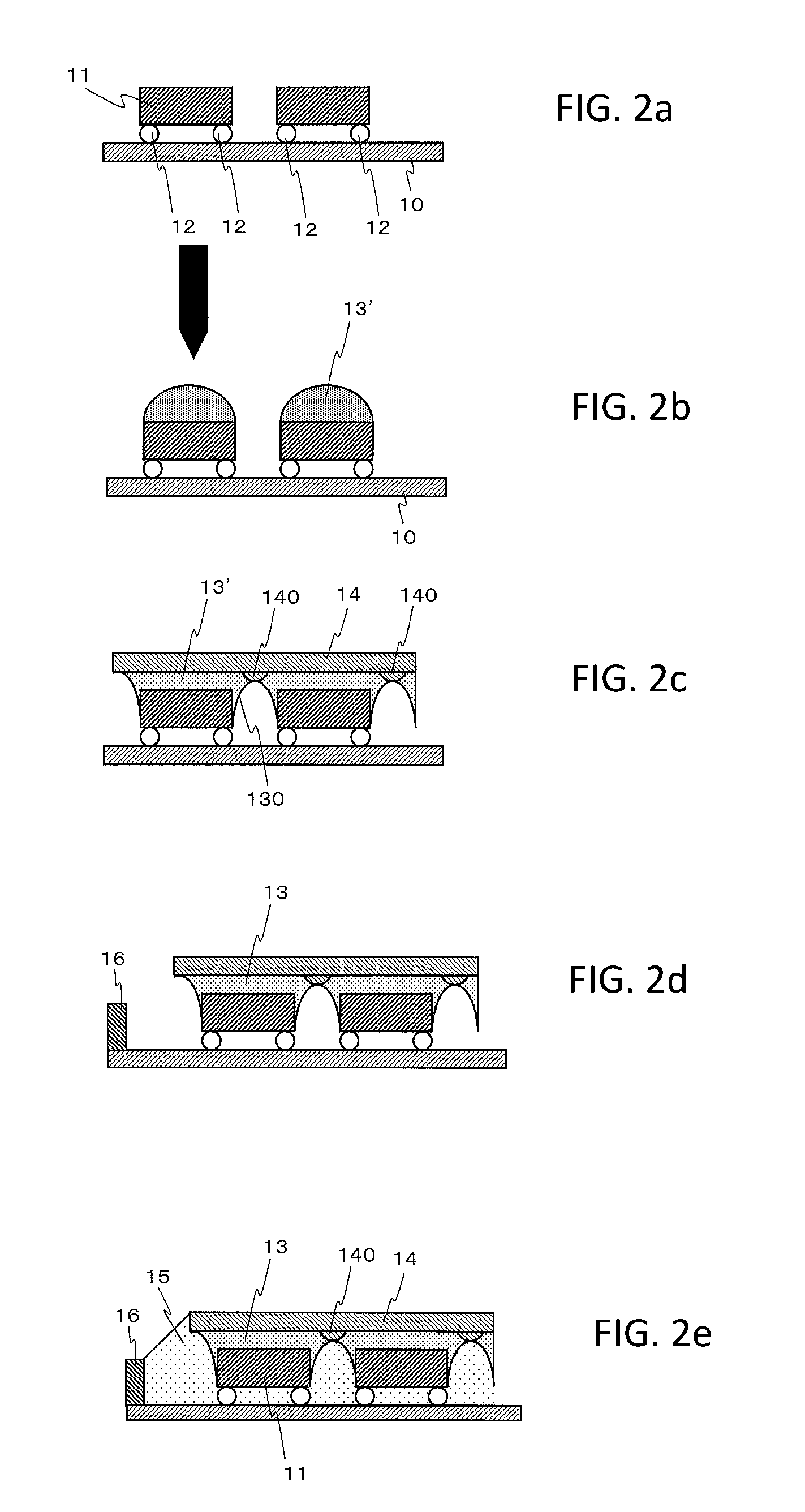

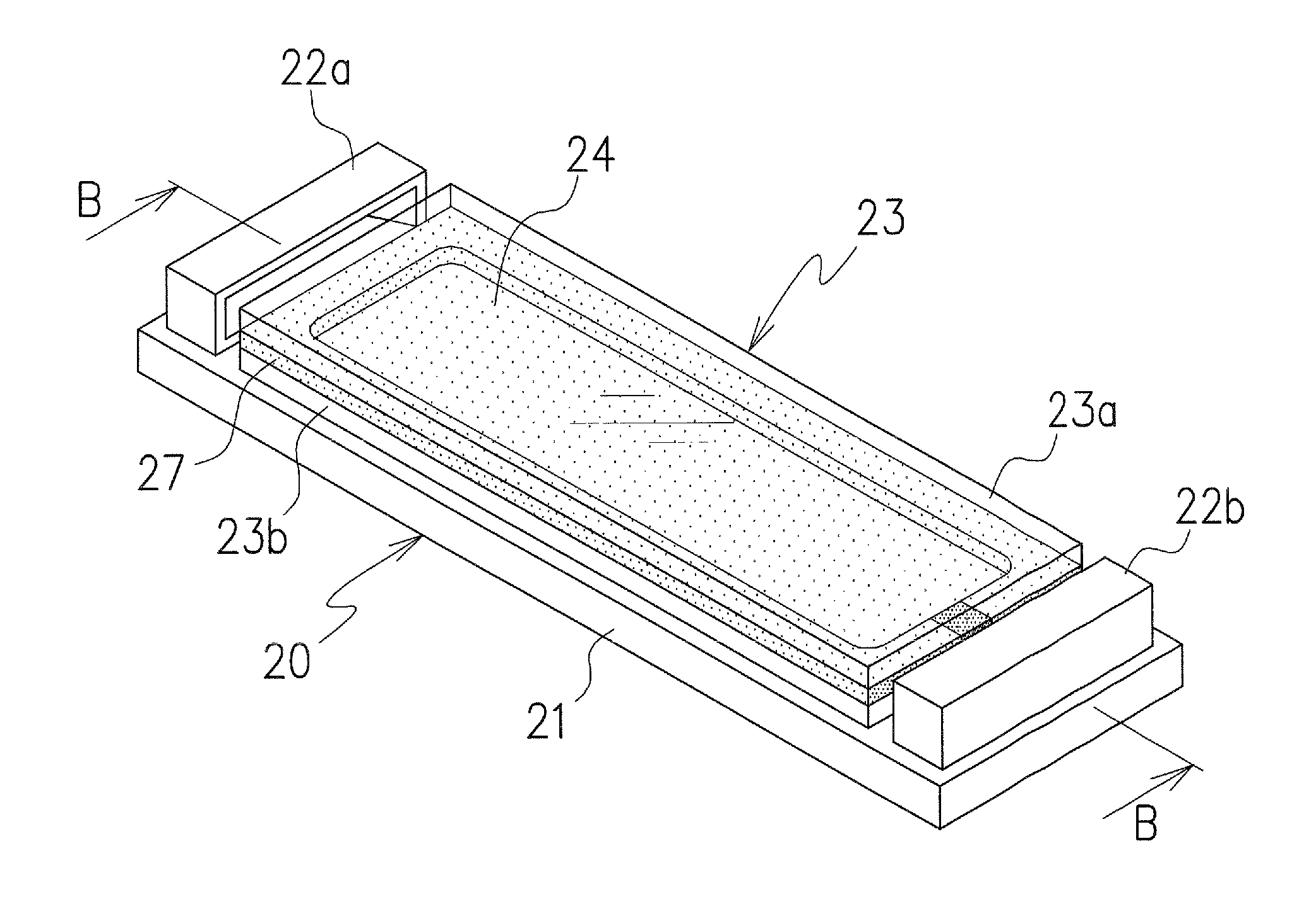

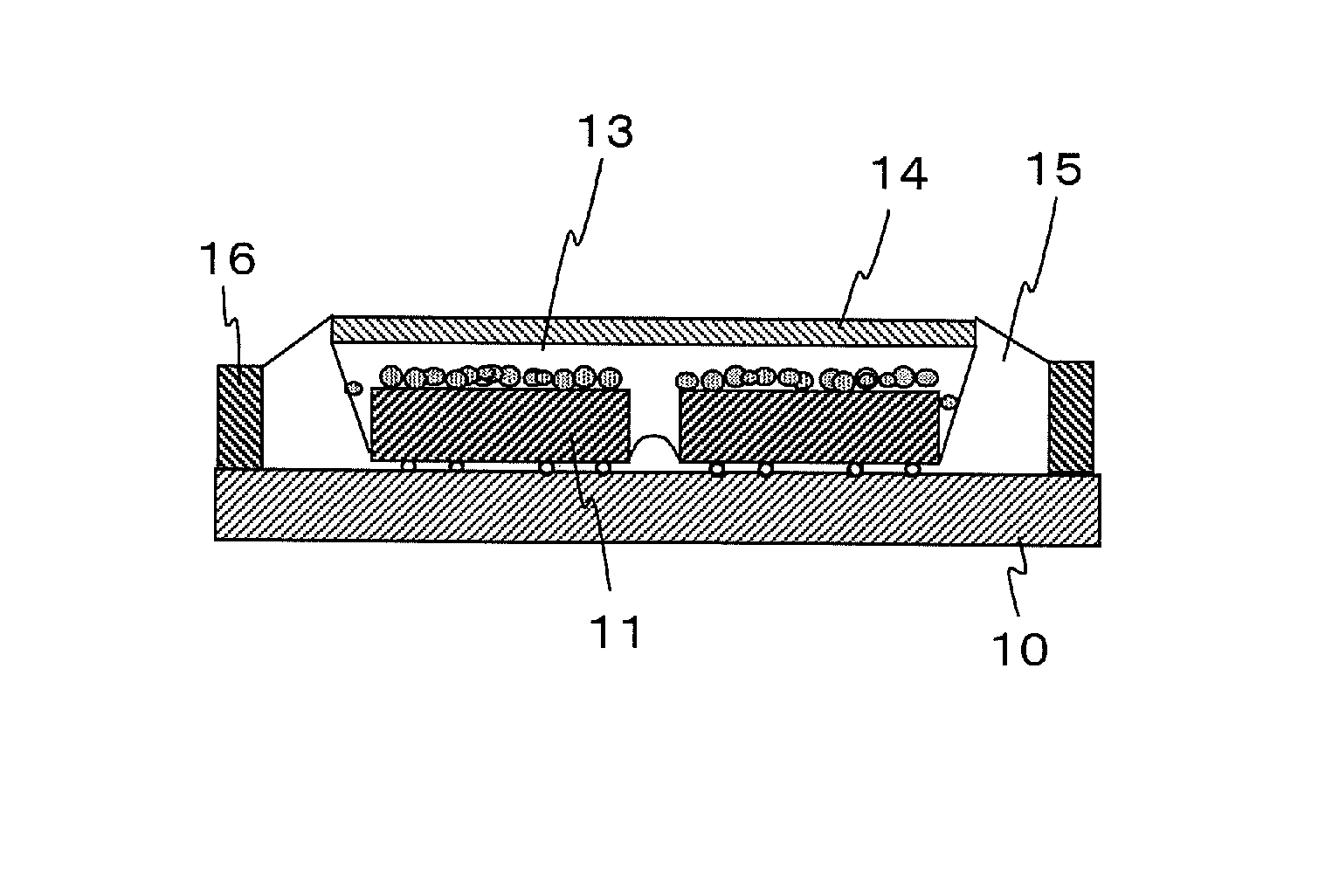

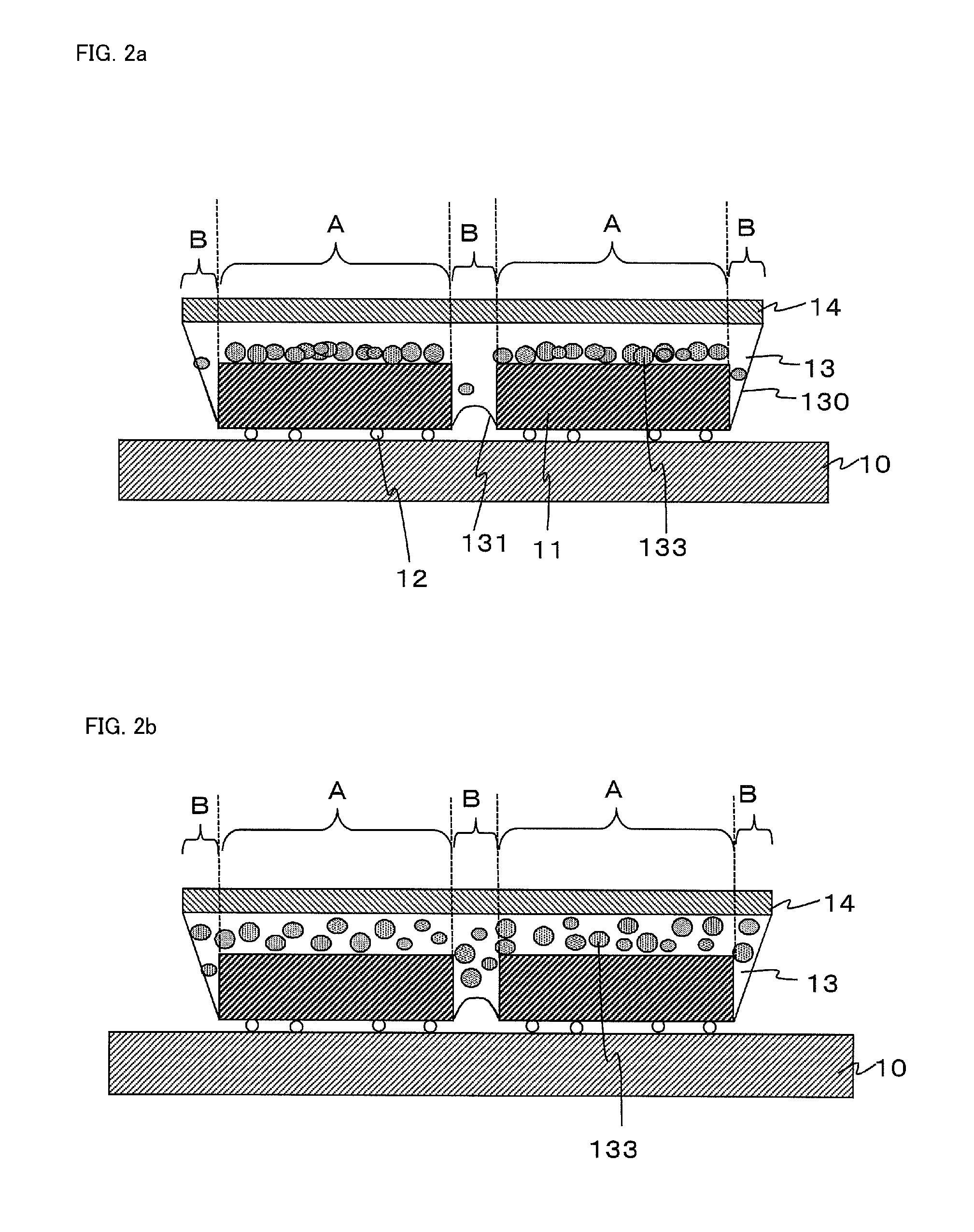

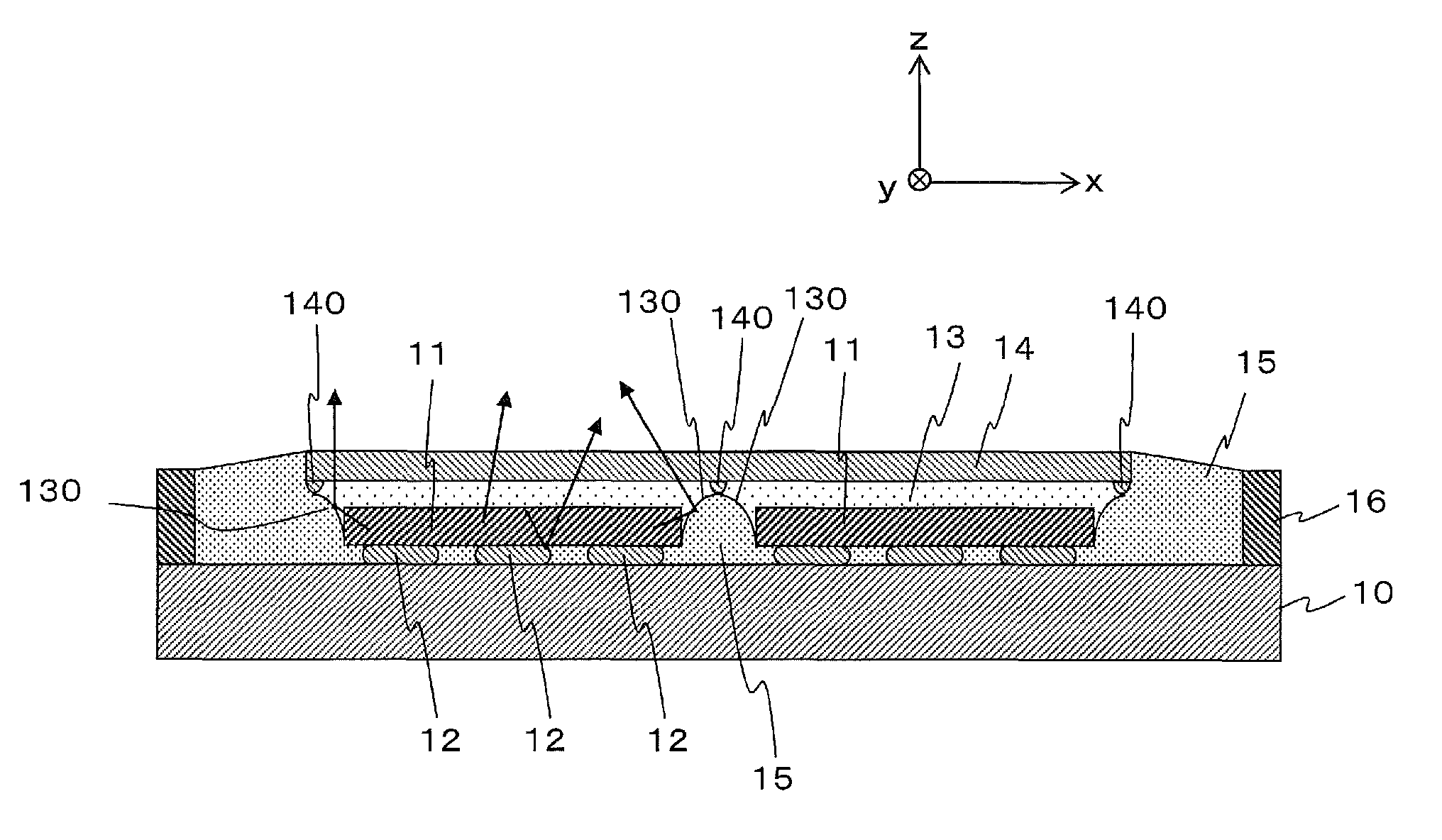

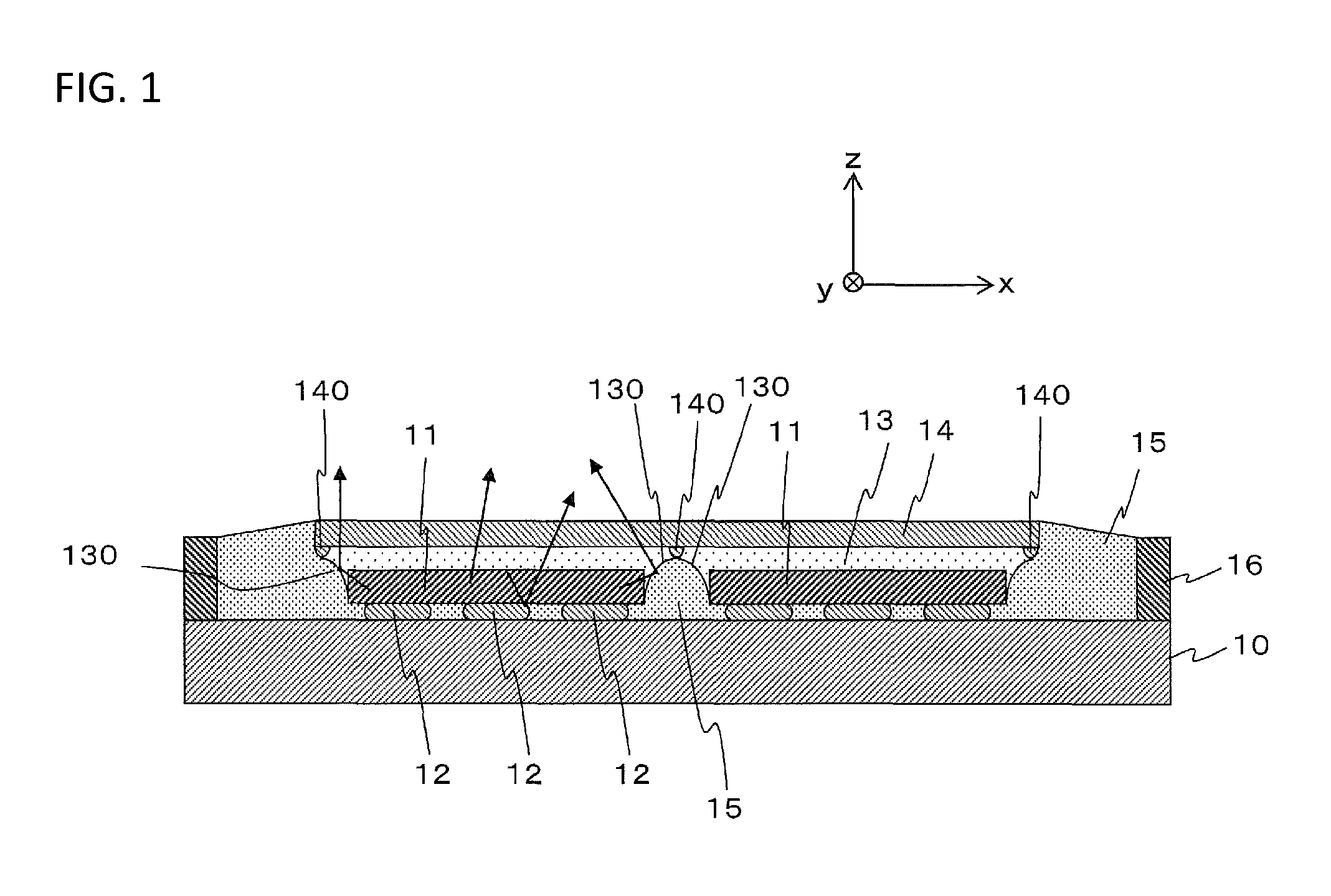

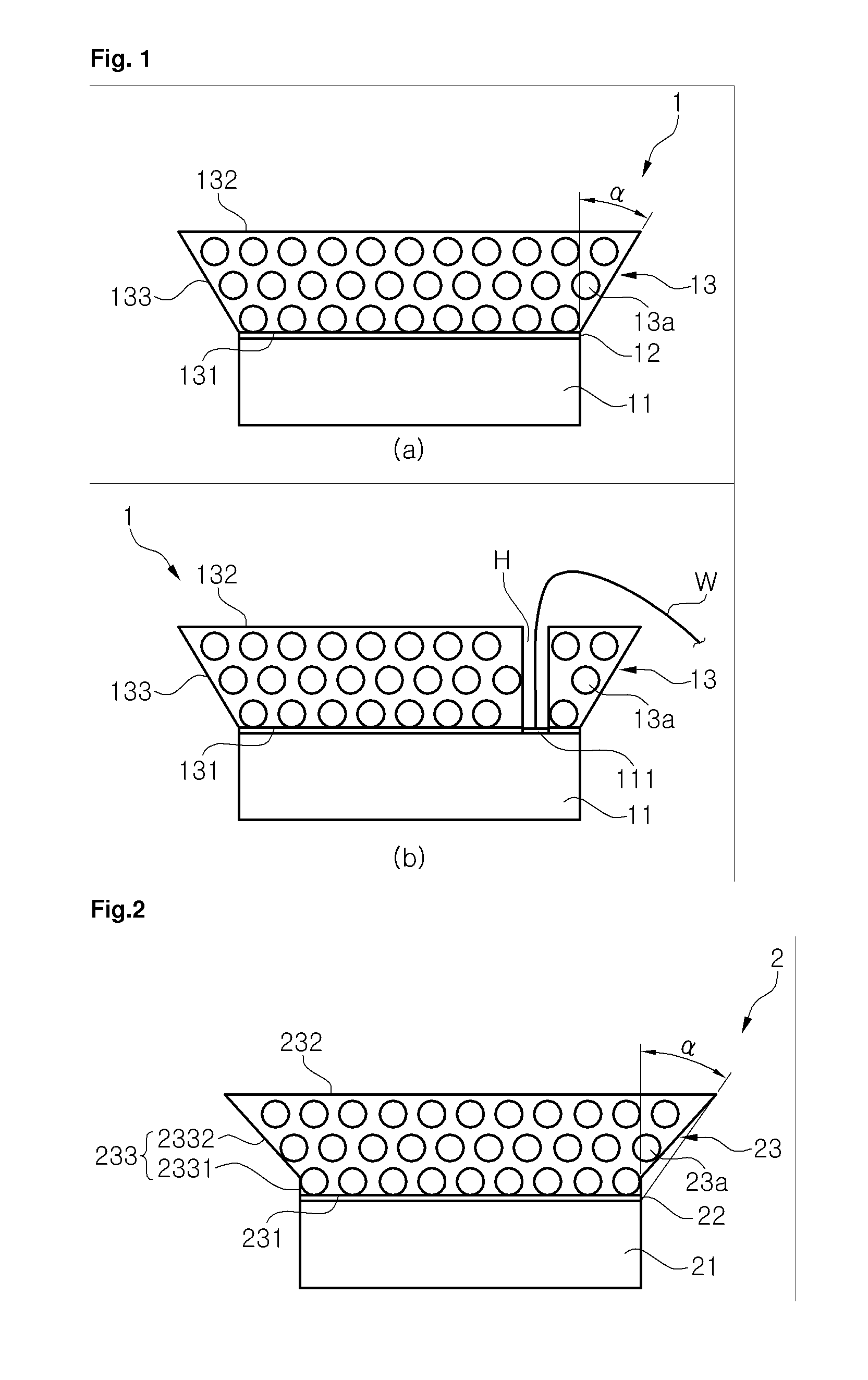

Semiconductor light emitting device and manufacturing method

ActiveUS20120140506A1Improve light emission efficiencyReduce color variationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLength wave

A semiconductor light-emitting device and a method for manufacturing the same can include a wavelength converting layer in order to emit various colored lights including white light. The semiconductor light-emitting device can include a base board, a frame located on the base board, at least one light-emitting chip mounted on the base board, the wavelength converting layer located between an optical plate and each outside surface of the chips so as to extend toward the optical plate using a meniscus control structure, and a reflective material layer disposed at least between the frame and both side surfaces of the wavelength converting layer and the optical plate. The semiconductor light-emitting device can be configured to improve light-emitting efficiency and color variability between the light-emitting chips by using the reflective material layer as each reflector, and therefore can emit a wavelength-converted light having a high light-emitting efficiency from various small light-emitting surfaces.

Owner:STANLEY ELECTRIC CO LTD

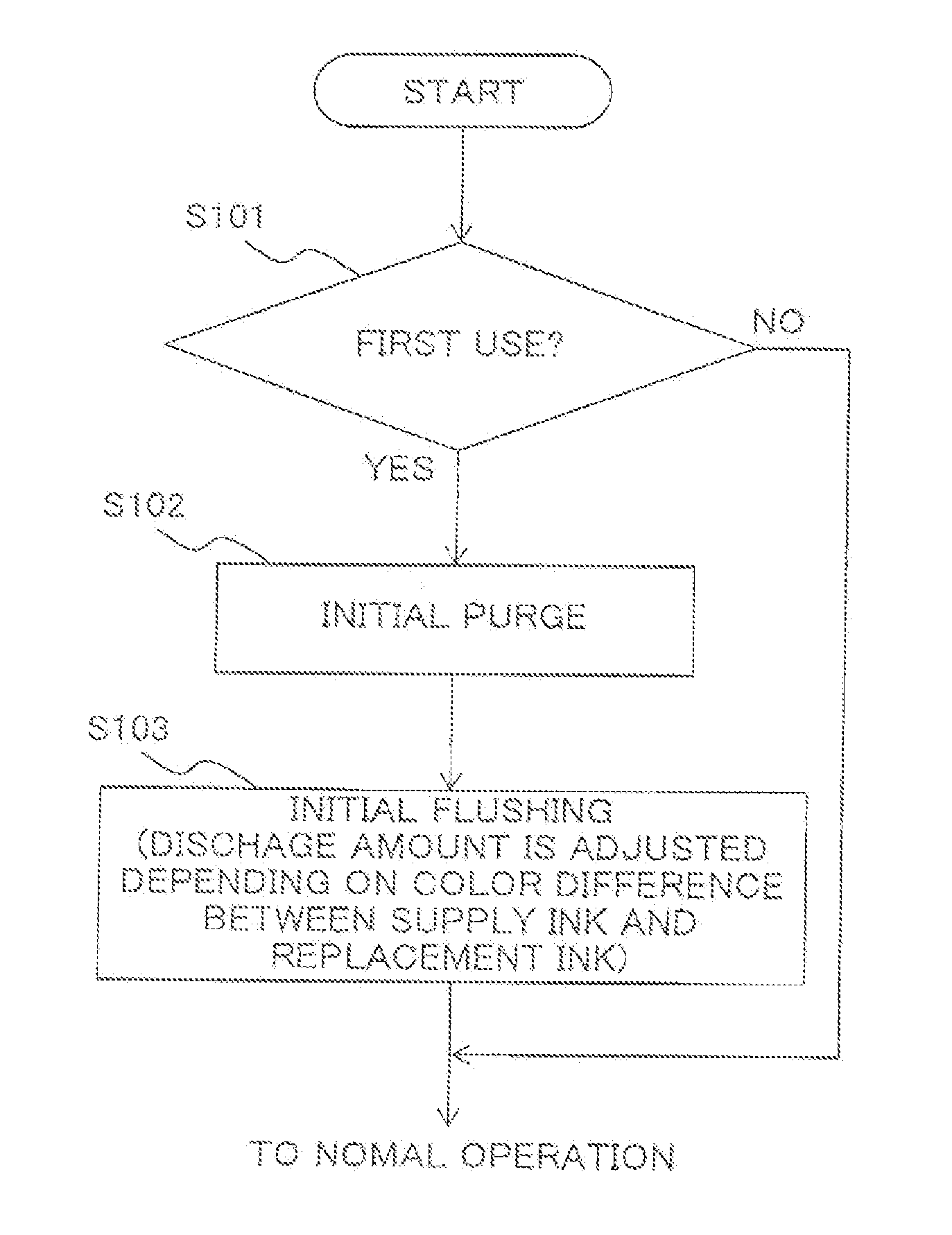

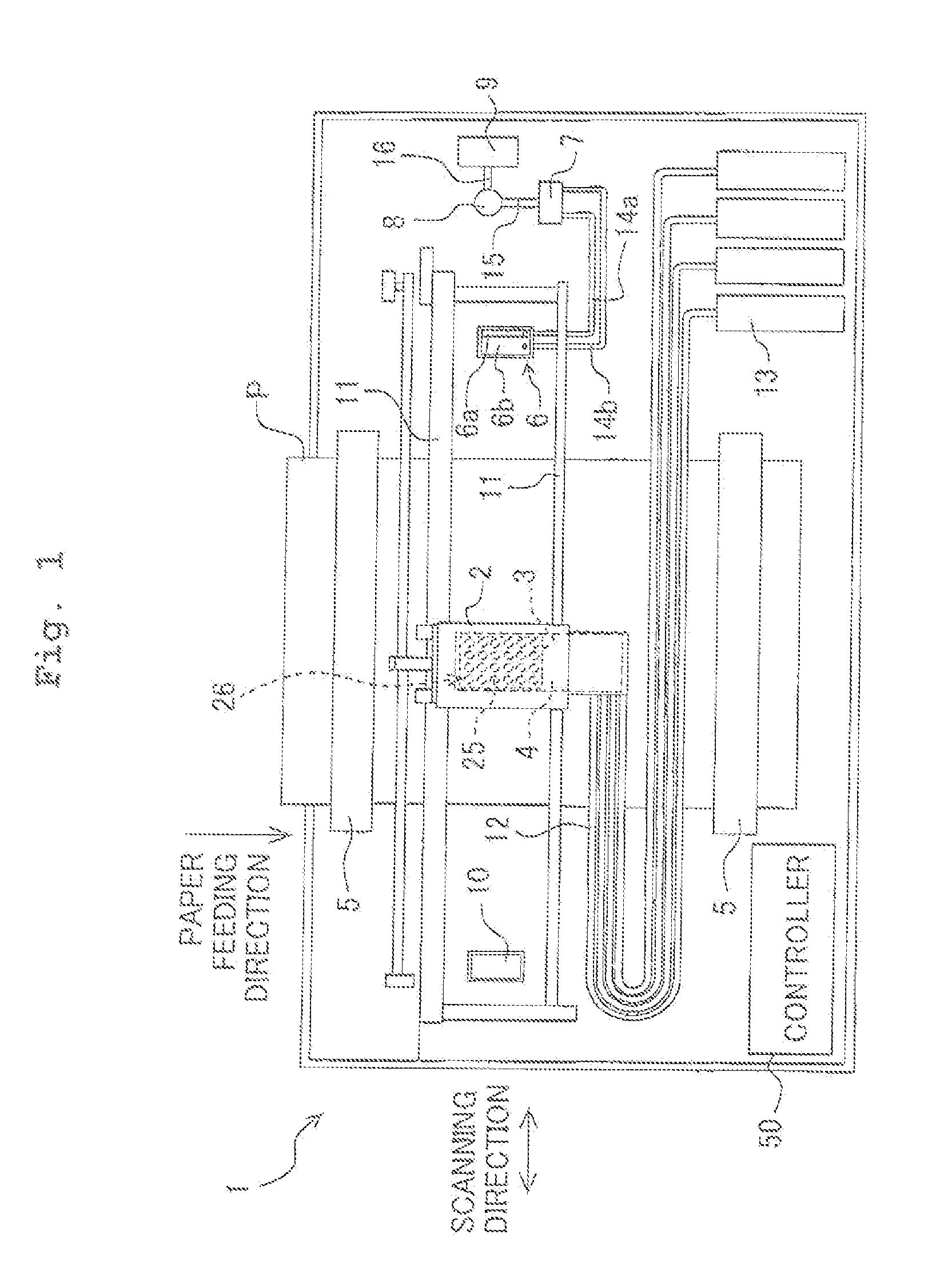

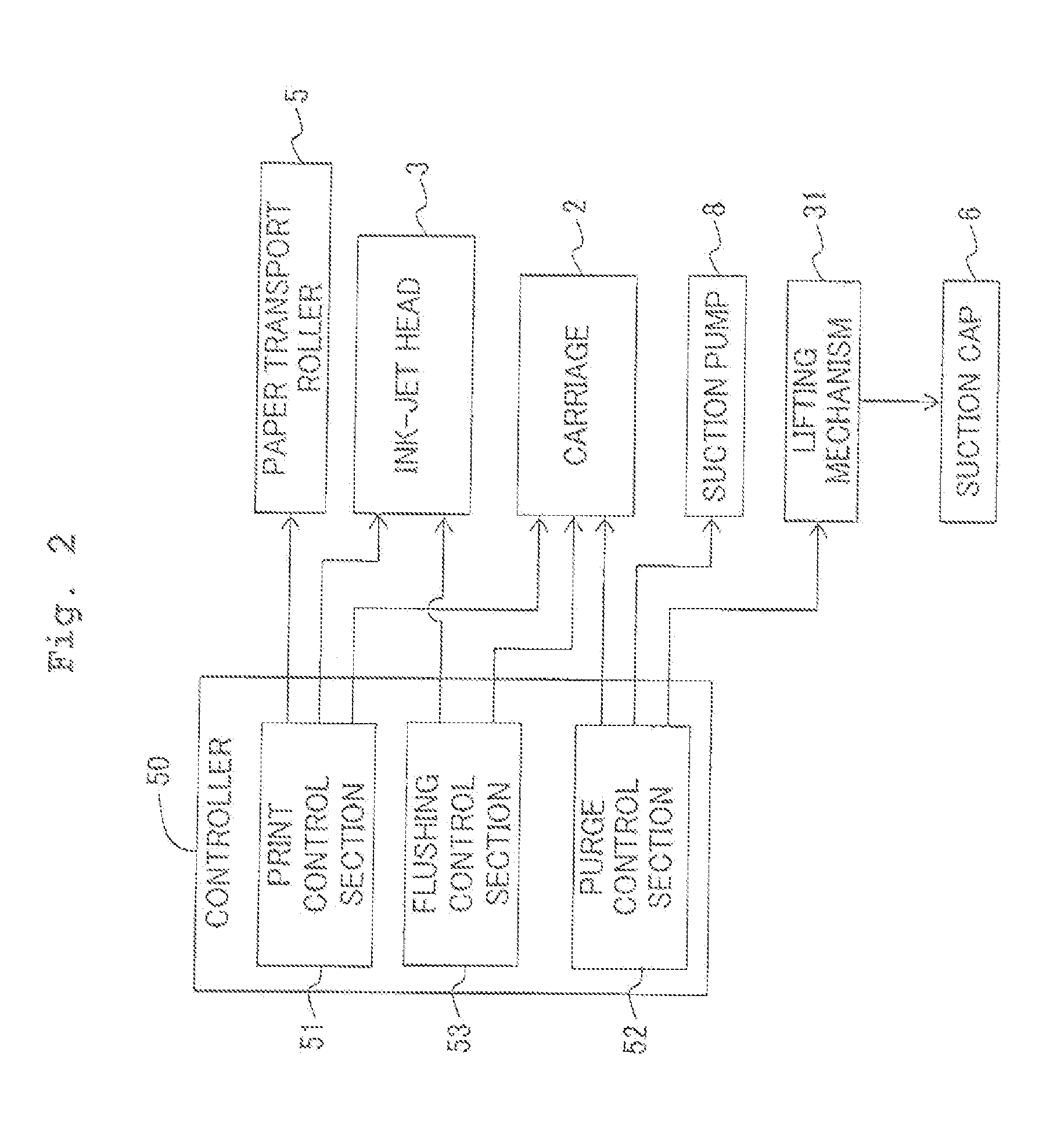

Ink-jet printer and method for replacing filling liquid in ink-jet head

ActiveUS20120075364A1Ensure printing qualityReduce color changeOther printing apparatusColor differenceEngineering

There is provided an ink-jet printer including: an ink supply source; an ink-jet head in which a plurality of nozzle groups corresponding to a plurality of color inks are formed; a maintenance mechanism; a controller which controls the ink-jet head and the maintenance mechanism; and a filling liquid filled in the ink jet head in a state before the ink-jet printer is used for the first time, wherein, in the state before the ink-jet primer is used for the first time, the controller controls the maintenance mechanism and the ink-jet head to perform an initial discharge operation; and an amount of a liquid discharged from the ink-jet head during the initial discharge operation is adjusted based on a color difference between one of the plurality of color inks and a replaced-ink.

Owner:BROTHER KOGYO KK

Led-based light emitting systems and devices with color compensation

ActiveUS20120032600A1Easy to controlReduce color variationElectrical apparatusElectroluminescent light sourcesColor compensationLight emitting device

A light emitting system comprises an LED-based light emitting device and a controller for controlling operation of the device. The device comprises at least two LEDs that are operable to generate light of different colors that contribute to the emission product of the device. The controller is operable to control light emission from the LEDs in response to the measured intensity of the first and second color light contributions in the emission product. To measure the individual light contributions the controller is operable to interrupt, or at least change, light emission from one LED for a selected time period and during this time period to measure the intensity of the emission product of the device. The intensity of light of the first and second color can be determined by comparing the measured intensity with the measured intensity when the light emission from the other LED is interrupted or changed.

Owner:INTEMATIX

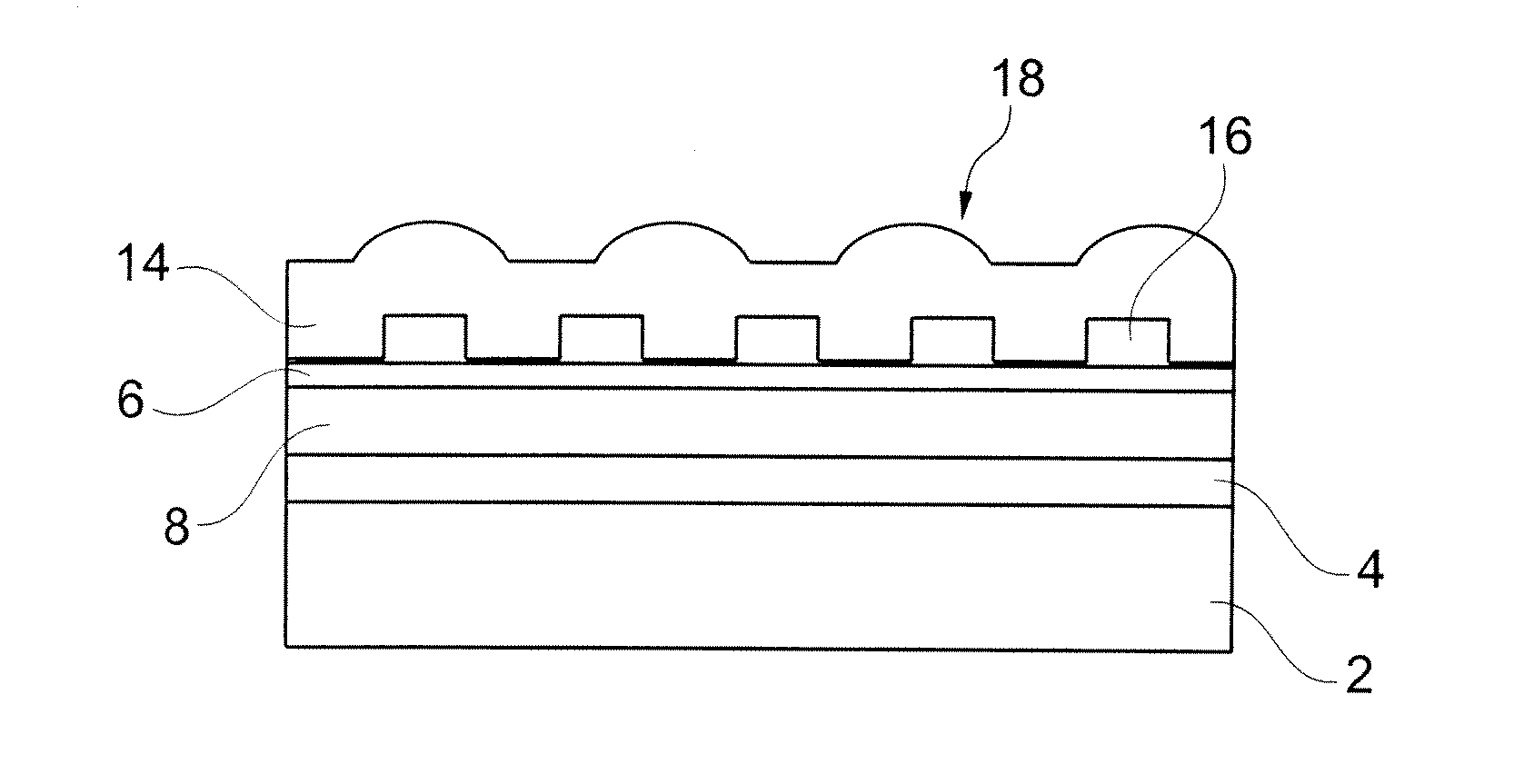

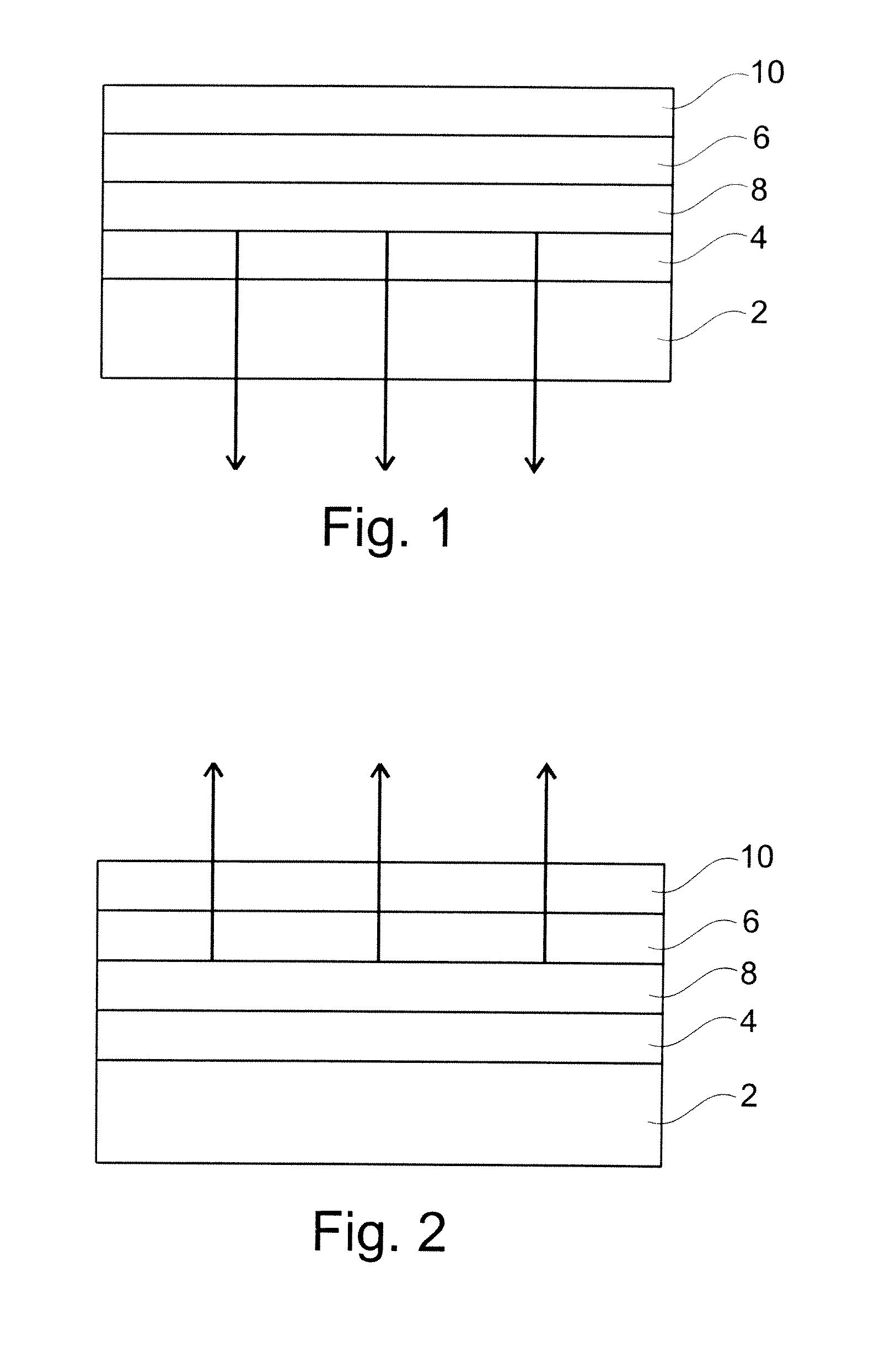

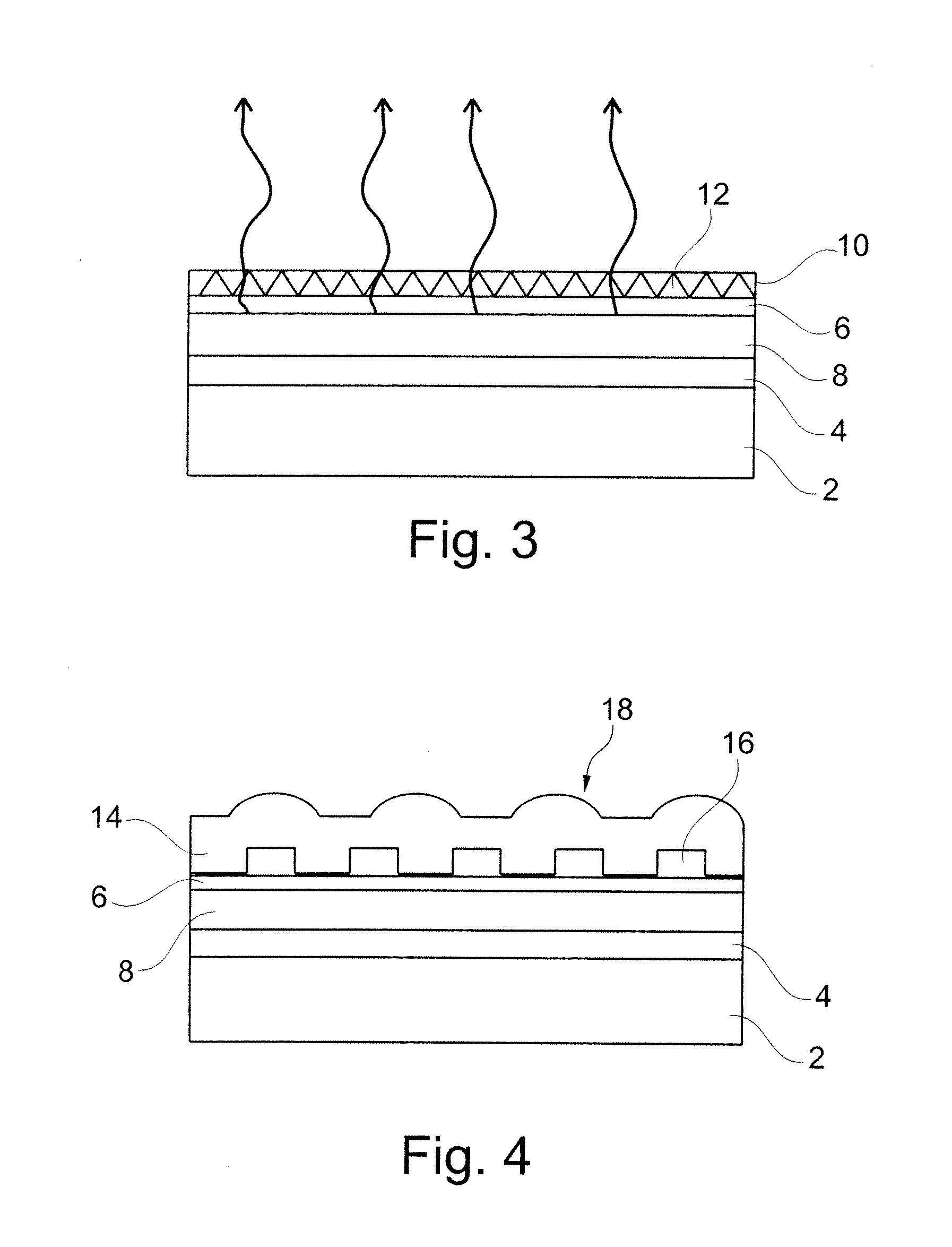

Organic Electroluminescent Device

InactiveUS20110241051A1Reducing angular colour variationReduce color variationStatic indicating devicesElectroluminescent light sourcesOrganic electroluminescenceSealant

An organic electroluminescent device comprising: a substrate; a first electrode disposed over the substrate for injecting charge of a first polarity; a second electrode disposed over the first electrode for injecting charge of a second polarity opposite to said first polarity; an organic light emitting layer disposed between the first and the second electrode, the second electrode being transparent to light emitted by the light emitting layer; and a transparent encapsulant disposed over the second electrode, wherein the transparent encapsulant comprises a microlens array formed by a top surface of the transparent encapsulant and a diffraction grating formed by a bottom surface of the transparent encapsulant.

Owner:CAMBRIDGE DISPLAY TECH LTD

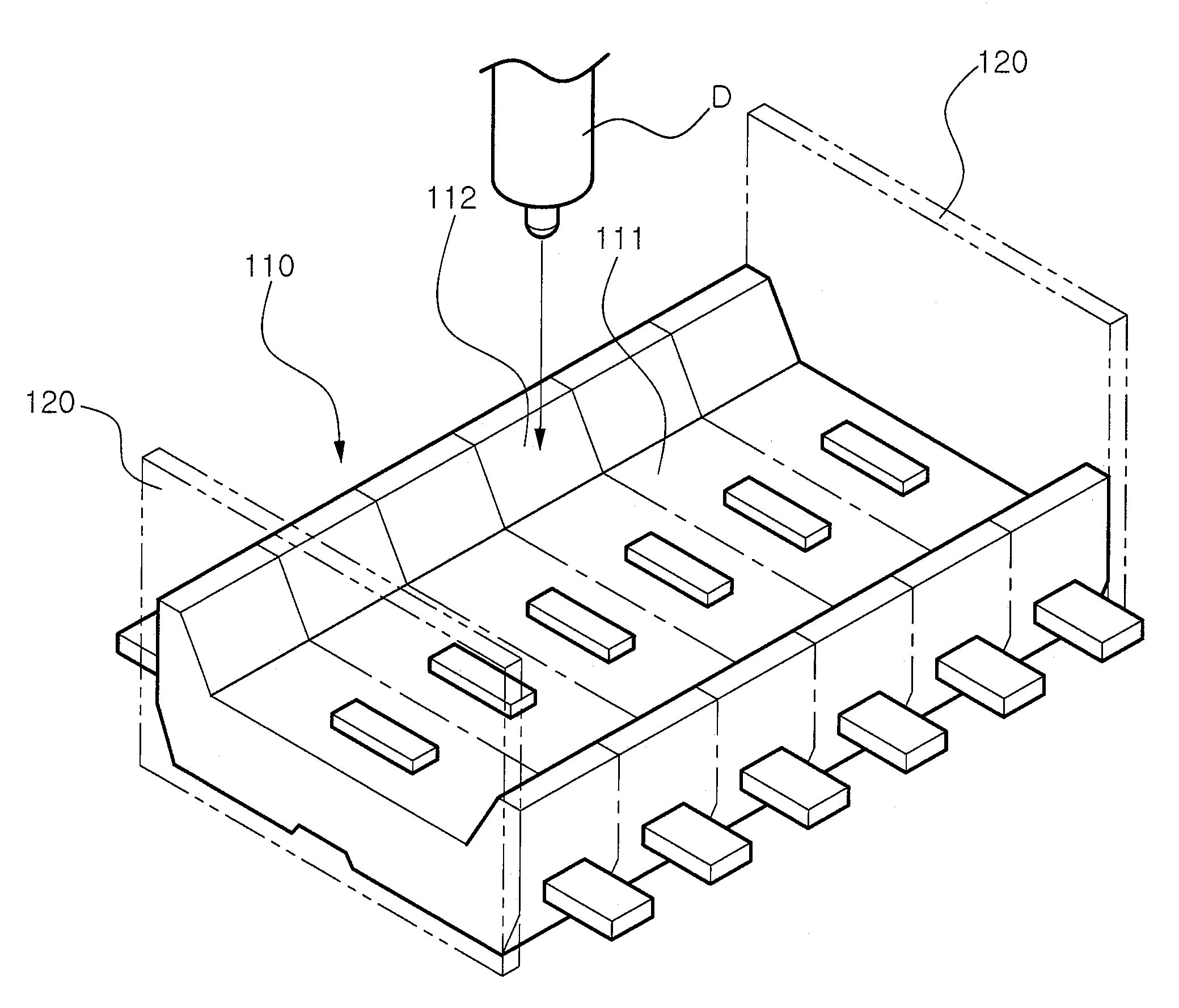

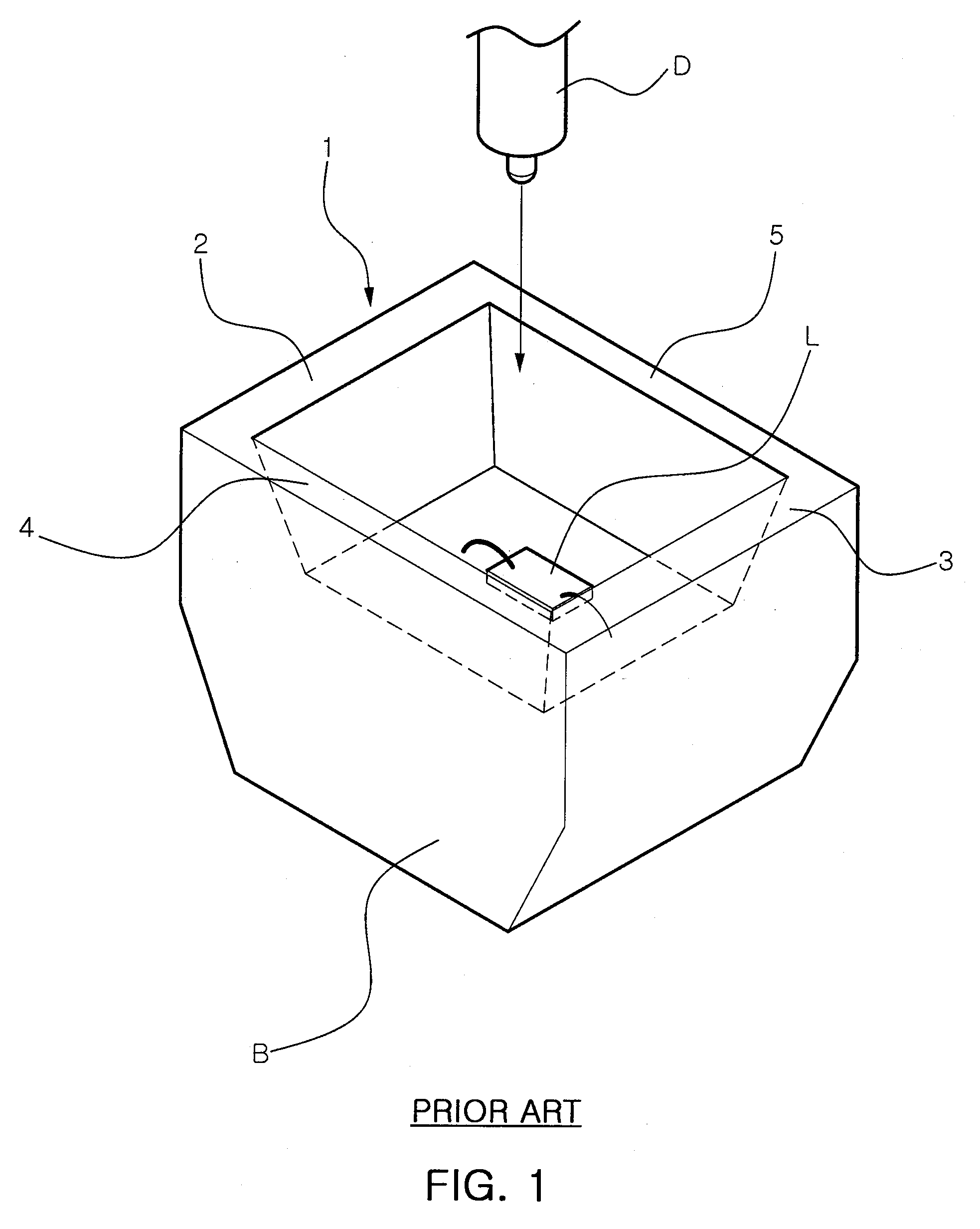

LED package and method of manufacturing the same

InactiveUS20090230410A1Reduce color variationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The present invention relates to light emitting diode (LED) packages and methods of manufacturing the same, and more particularly, to an LED package and a method of manufacturing the same that can reduce a variation of color coordinates of mass-produced LED packages.

Owner:SAMSUNG LED CO LTD

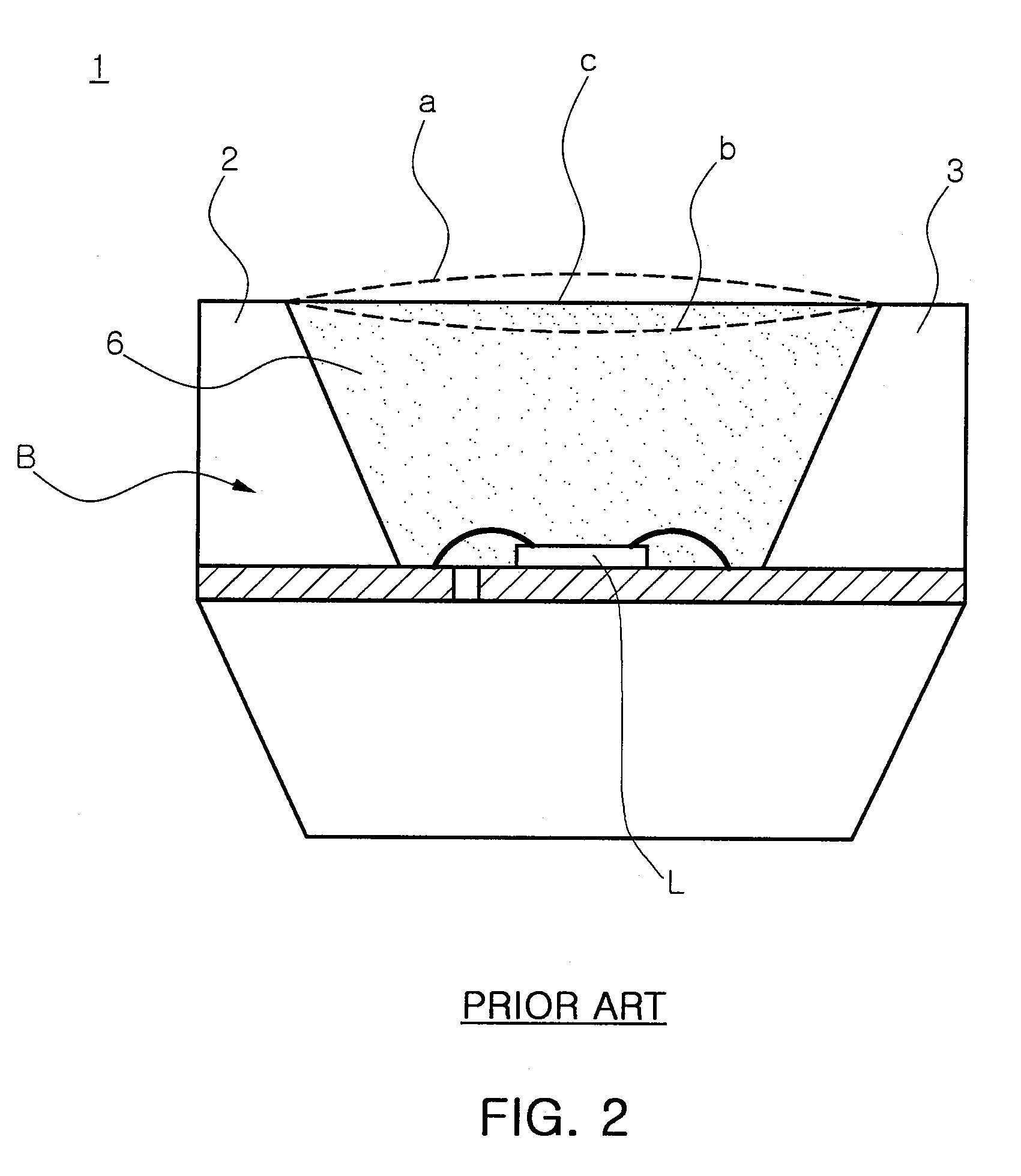

Light Emitting Diode and Method of Fabricating the Same

ActiveUS20080217637A1Reduce color variationEnhance luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceDiode

The present invention relates to a light emitting diode and a method of fabricating the same, wherein the distance between a fluorescent substance and a light emitting diode chip is uniformly maintained to enhance luminous efficiency. To this end, there is provided a light emitting diode comprising at least one light emitting diode chip, lead terminals for use in applying electric power to the light emitting diode chip, and a frame that is used for mounting the light emitting diode chip thereon and is formed to have a predetermined height and a shape corresponding to that of the light emitting diode chip.

Owner:SEOUL SEMICONDUCTOR

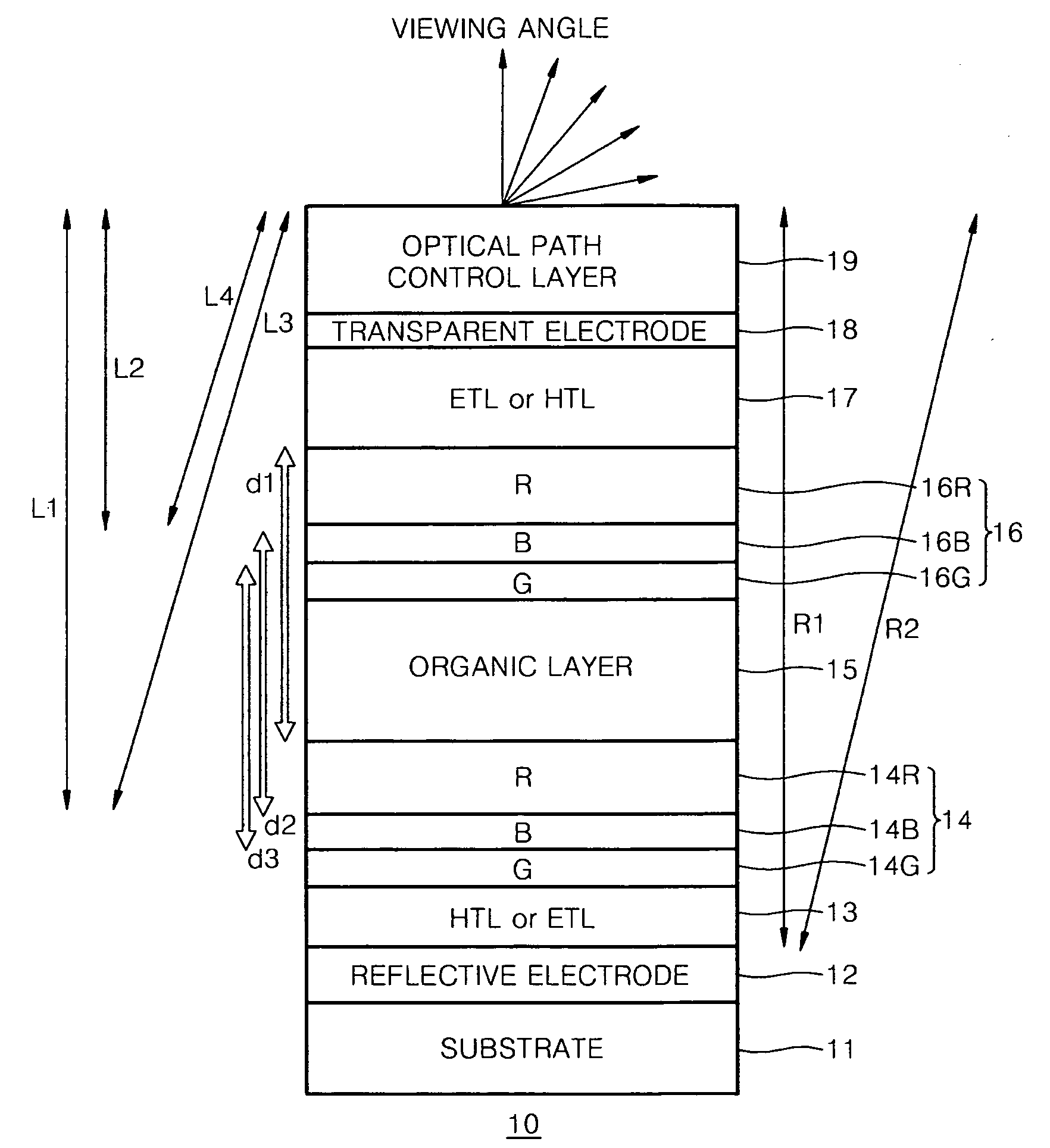

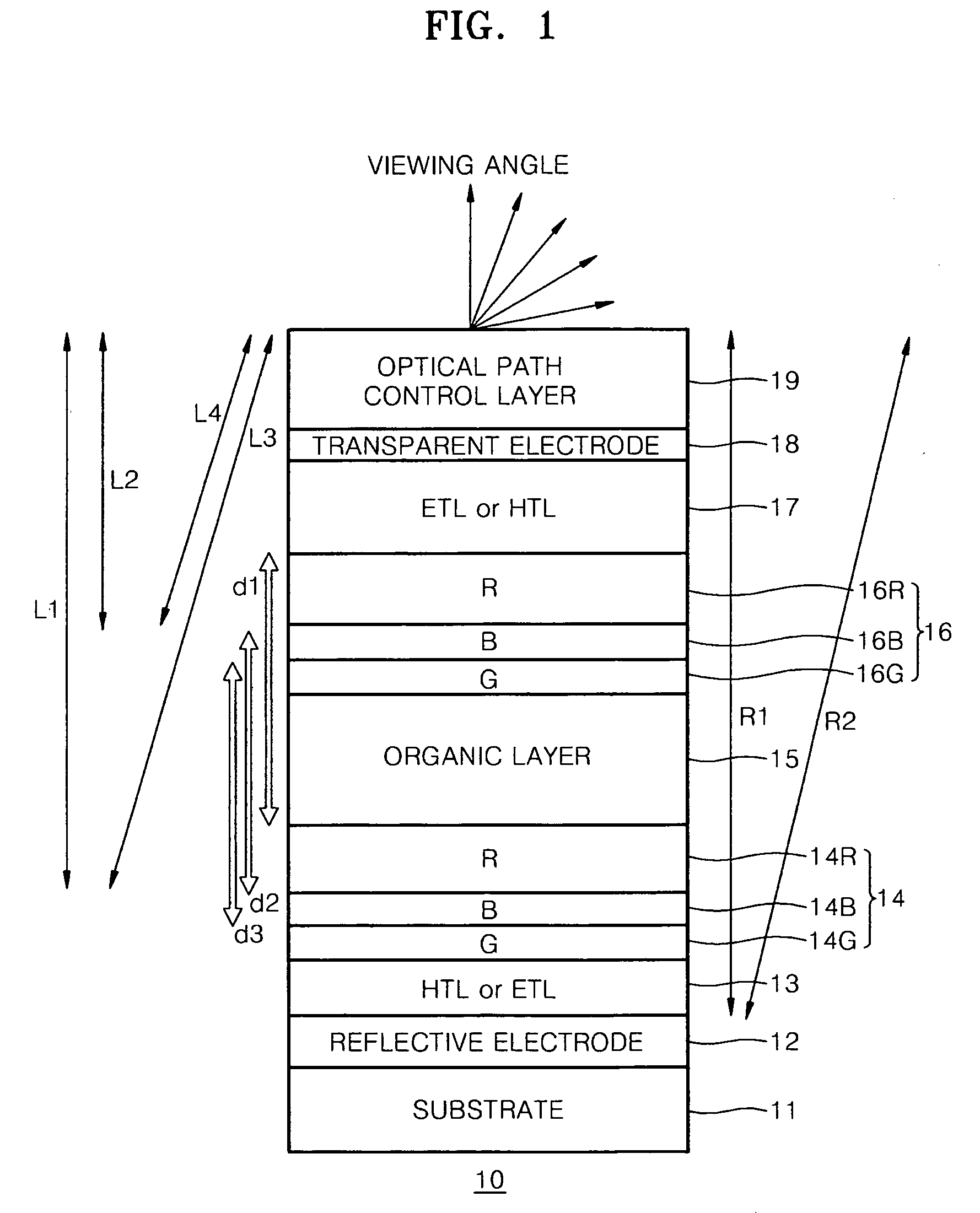

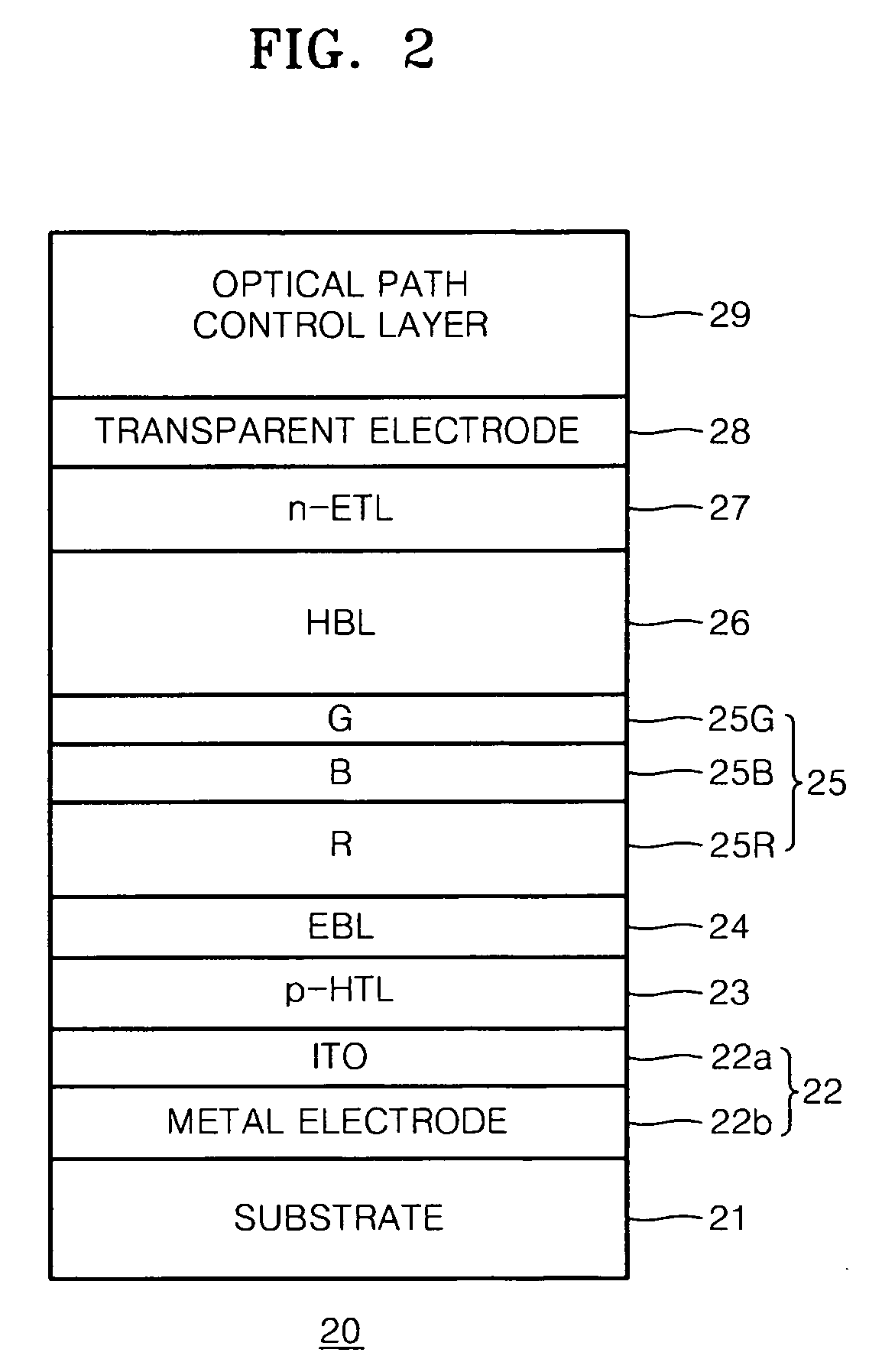

Organic light emitting device and color display apparatus using the same

ActiveUS20090102362A1Improved top-emissionReduce color variationDischarge tube luminescnet screensElectroluminescent light sourcesControl layerGamut

A top-emitting or bottom-emitting OLED has a wide color gamut and reduces a variation in color with a viewing angle. The OLED includes a reflective electrode and a transmissive or semi-transmissive electrode disposed opposite each other; at least two organic emission layers (EMLs) interposed between the reflective electrode and the transmissive or semi-transmissive electrode; and an optical path control layer disposed on an outer surface of the transmissive or semi-transmissive electrode. A resonator is formed between the reflective electrode and the optical path control layer so a resonance mode of light extracted from the optical path control layer is a multi-resonance mode having at least two modes in a visible light region. A distance between the organic EMLs satisfies the condition of constructive interference between light beams emitted by the respective organic EMLs. A color display apparatus using the OLED are taught.

Owner:SAMSUNG DISPLAY CO LTD

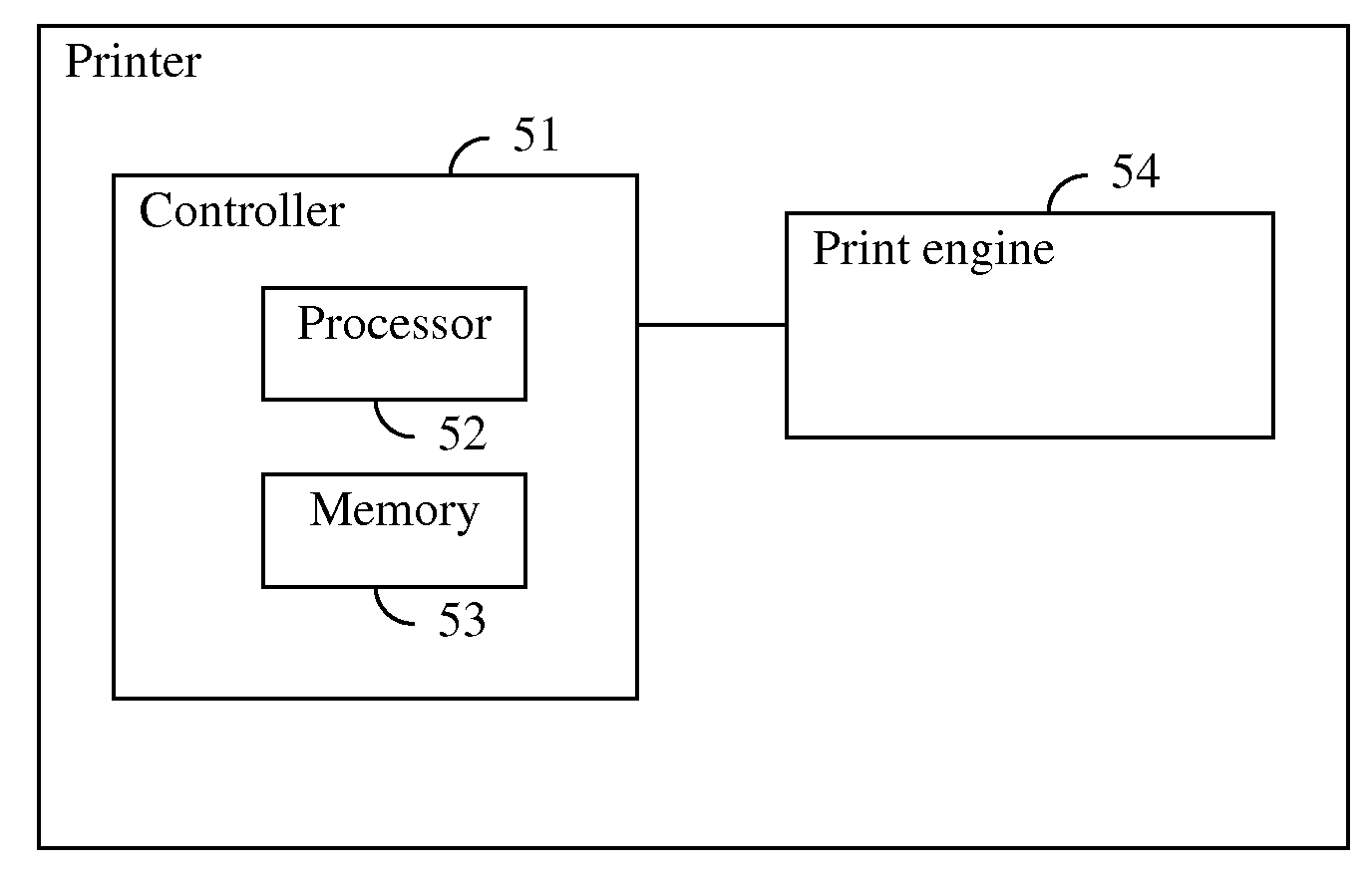

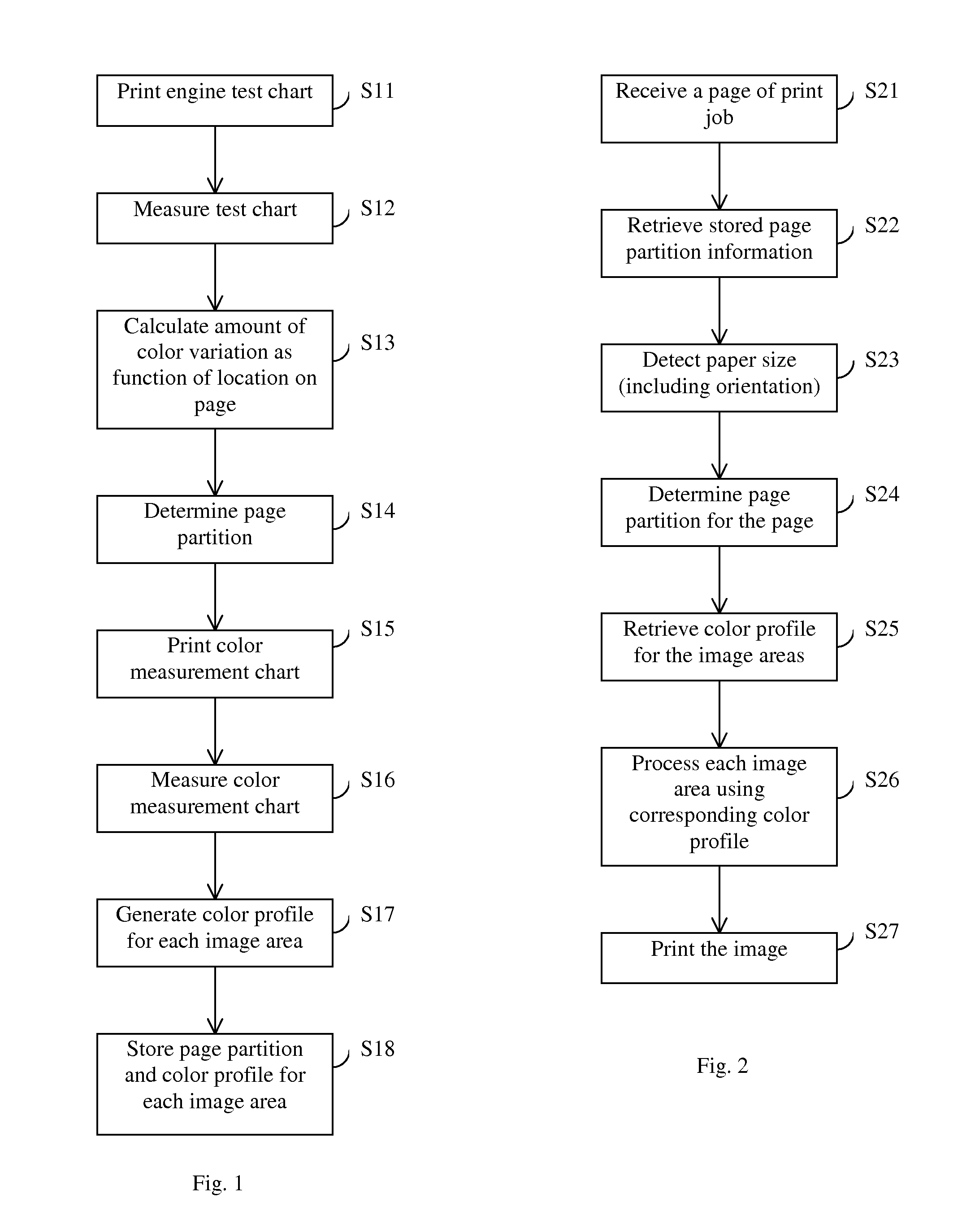

Method for compensating for color variations across a printed page using multiple color profiles

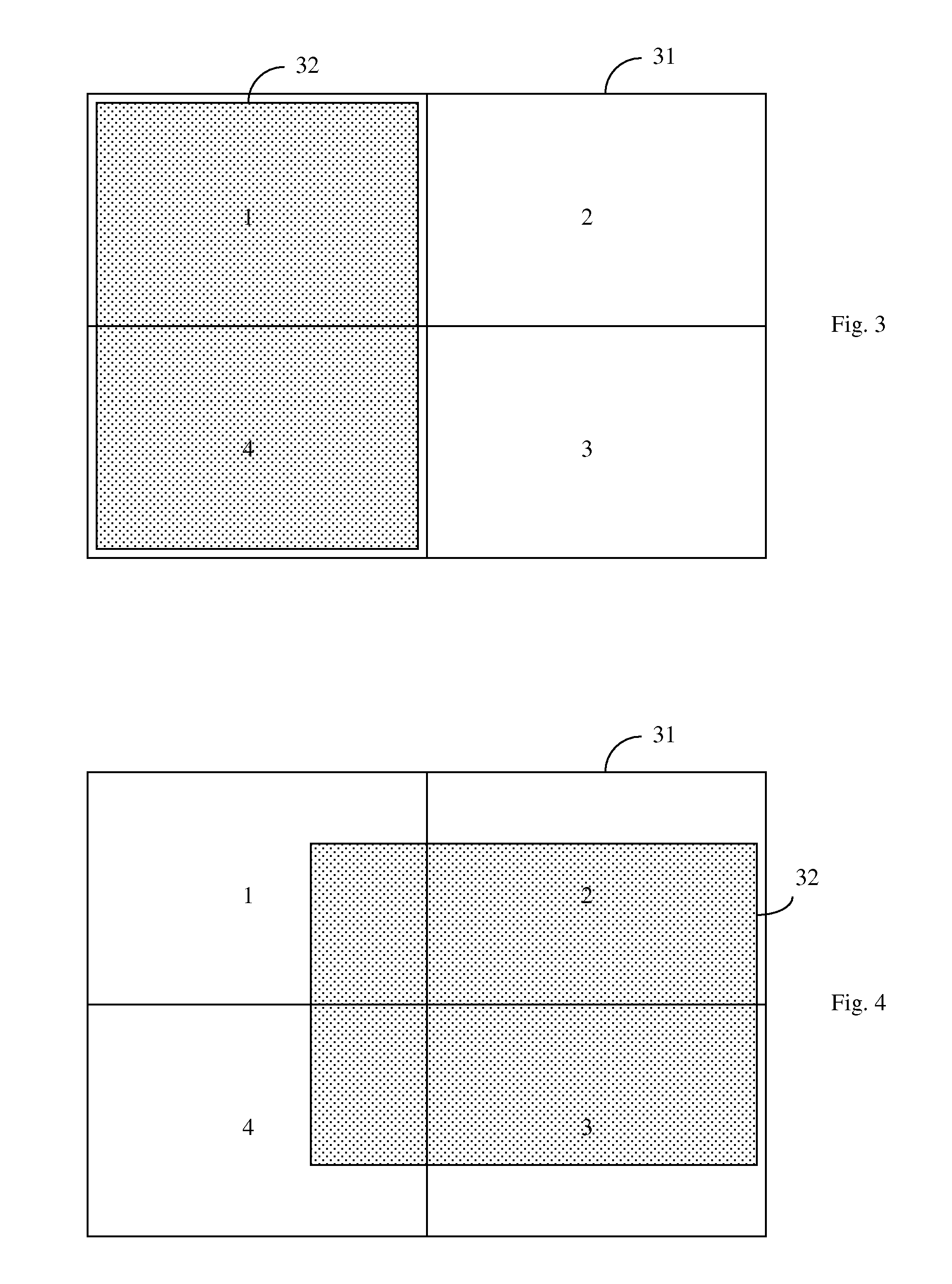

ActiveUS20090086290A1Reduce color variationImage enhancementDigitally marking record carriersComputer printingDigital image

A method for compensating for color variations introduced by printer hardware limitations and other factors is described. First, the extent of color variation throughout a printed page is determined. Based on this determination, each page is partitioned into a plurality of image areas. A color profile is generated for each image area. The partition and the multiple color profiles are stored in the printer. In an actual printing process, the page of image to be printed is divided into a plurality of image areas based on the paper size and the stored partition, and the respective stored color profiles for the image areas are retrieved and used to process the digital image for printing.

Owner:KONICA MINOLTA LAB U S A INC

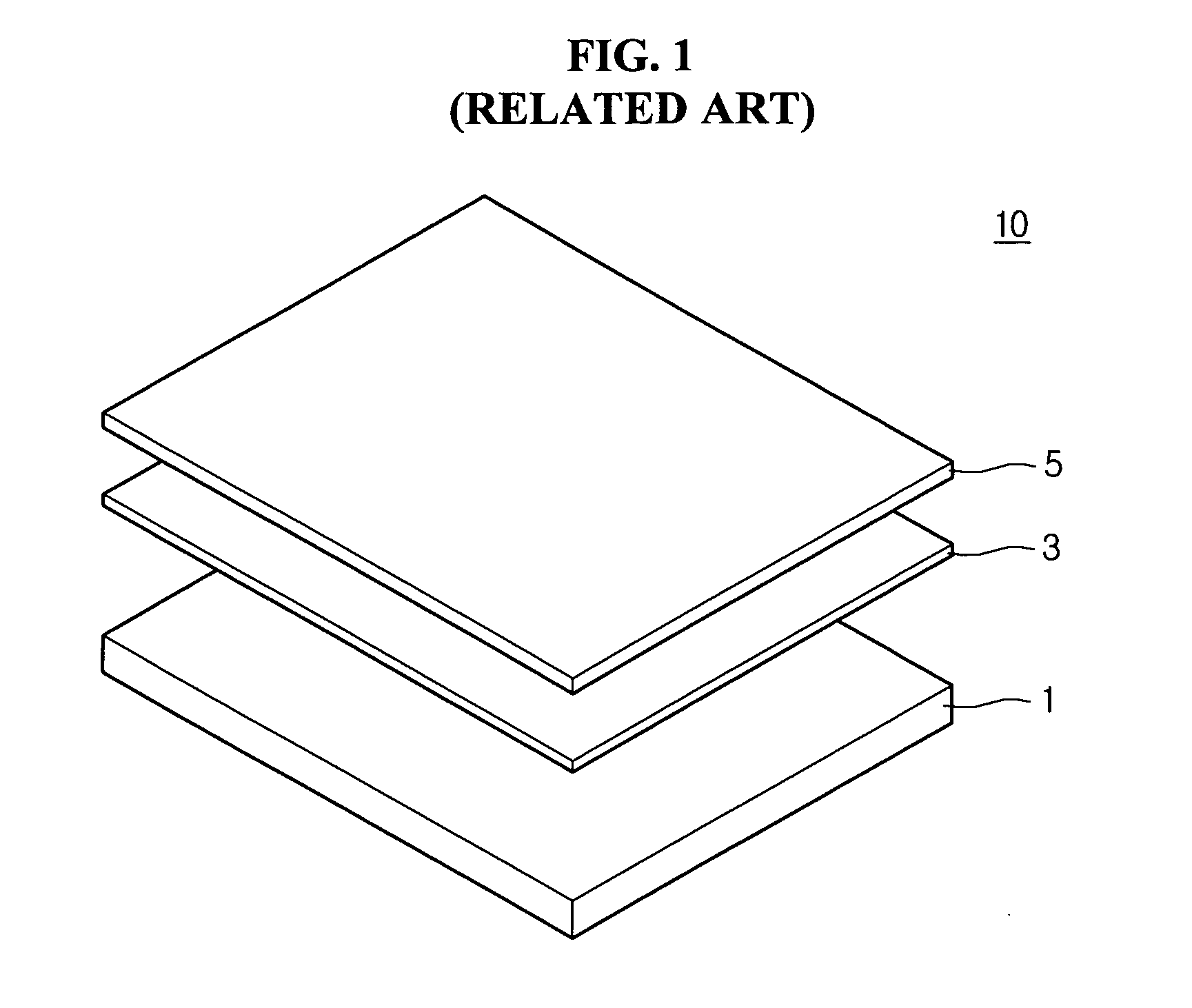

Translucent laminate sheet and light-emitting device using the translucent laminate sheet

InactiveUS7839072B2High color reproducibility and chromaticnessInhibit deteriorationDischarge tube luminescnet screensPoint-like light sourcePhosphorEngineering

Owner:CITIZEN ELECTRONICS CO LTD

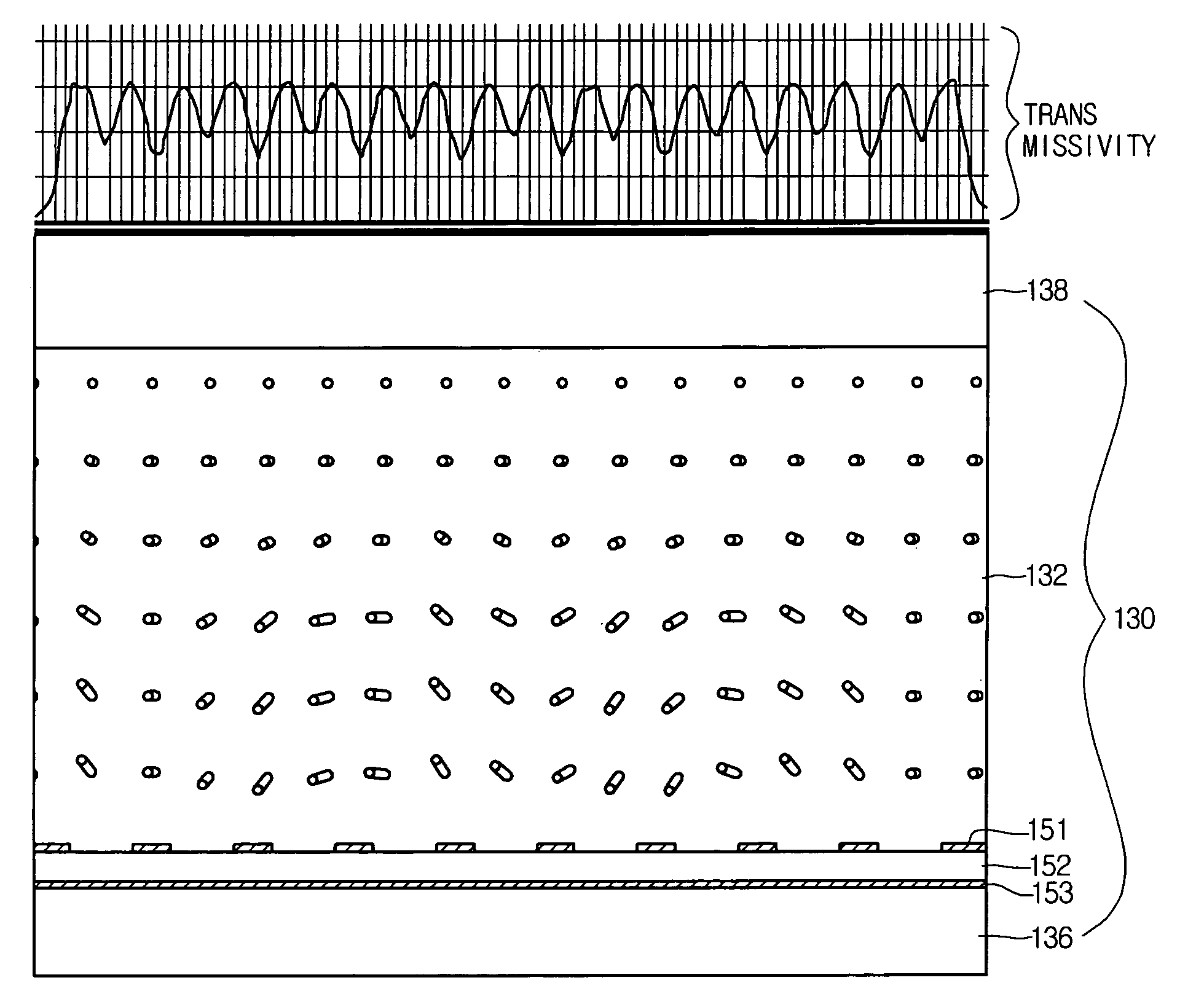

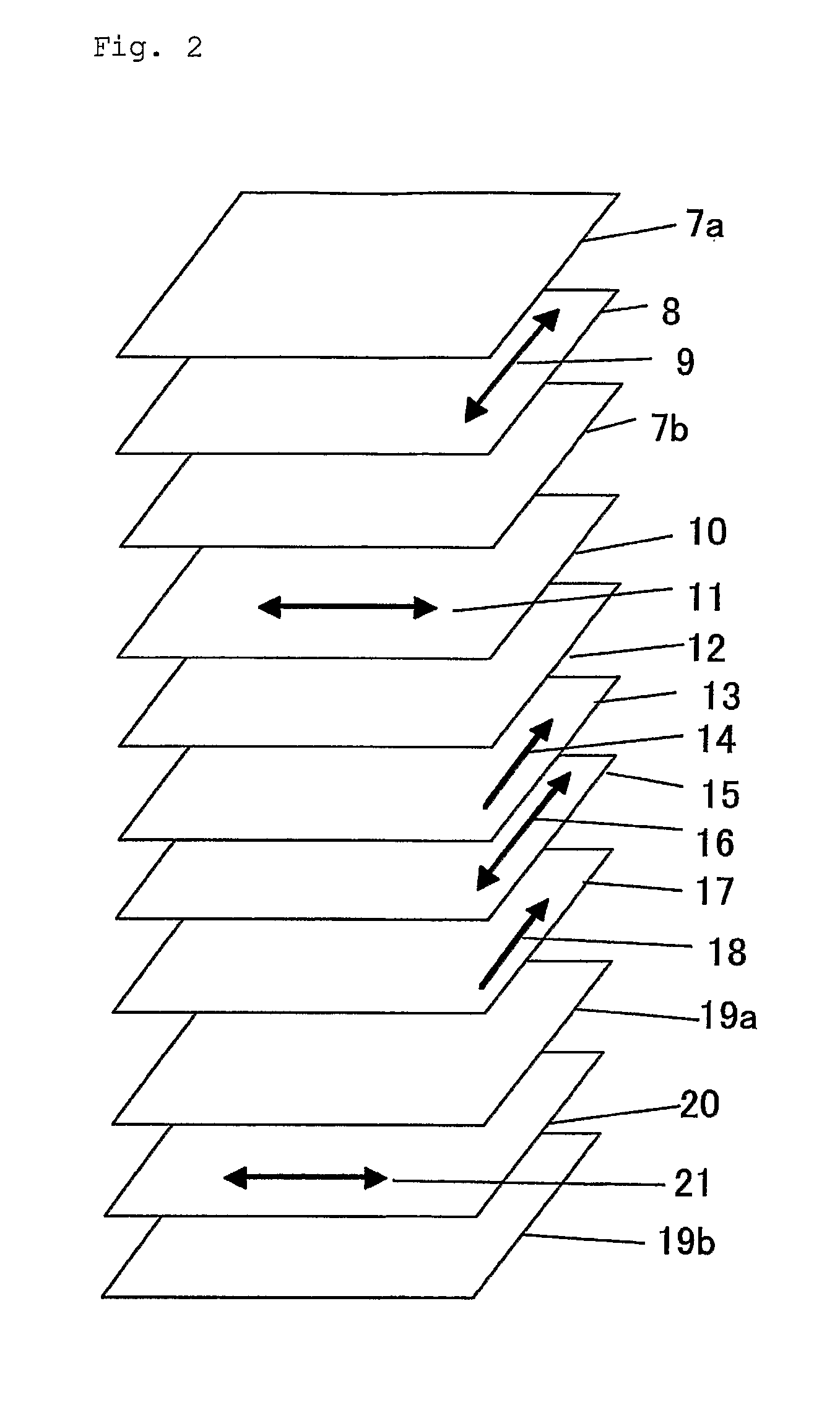

Optical sheet and surface light source apparatus

InactiveCN104508517AImprove light extraction efficiencyReduce color variationDiffusing elementsElectroluminescent light sourcesLight sourceOptoelectronics

An optical sheet comprising: a transparent substrate; a light diffusion layer having a surface roughness structure which is provided on one surface of the transparent substrate; and a light diffusion adhesive layer provided on the other surface of the transparent substrate, wherein the light diffusion layer comprises a resin and first diffusion particles having a number-average particle size of 1.7 mum or above, the light diffusion adhesive layer comprises a binder, highly refractive nanoparticles and second diffusion particles, and the relationship x1 > x2 is satisfied, where the haze of the light diffusion layer is x1 (%) and the haze of the light diffusion adhesive layer is x2 (%); and a surface light source apparatus provided with said optical sheet and an organic electroluminescent light-emitting element.

Owner:ZEON CORP

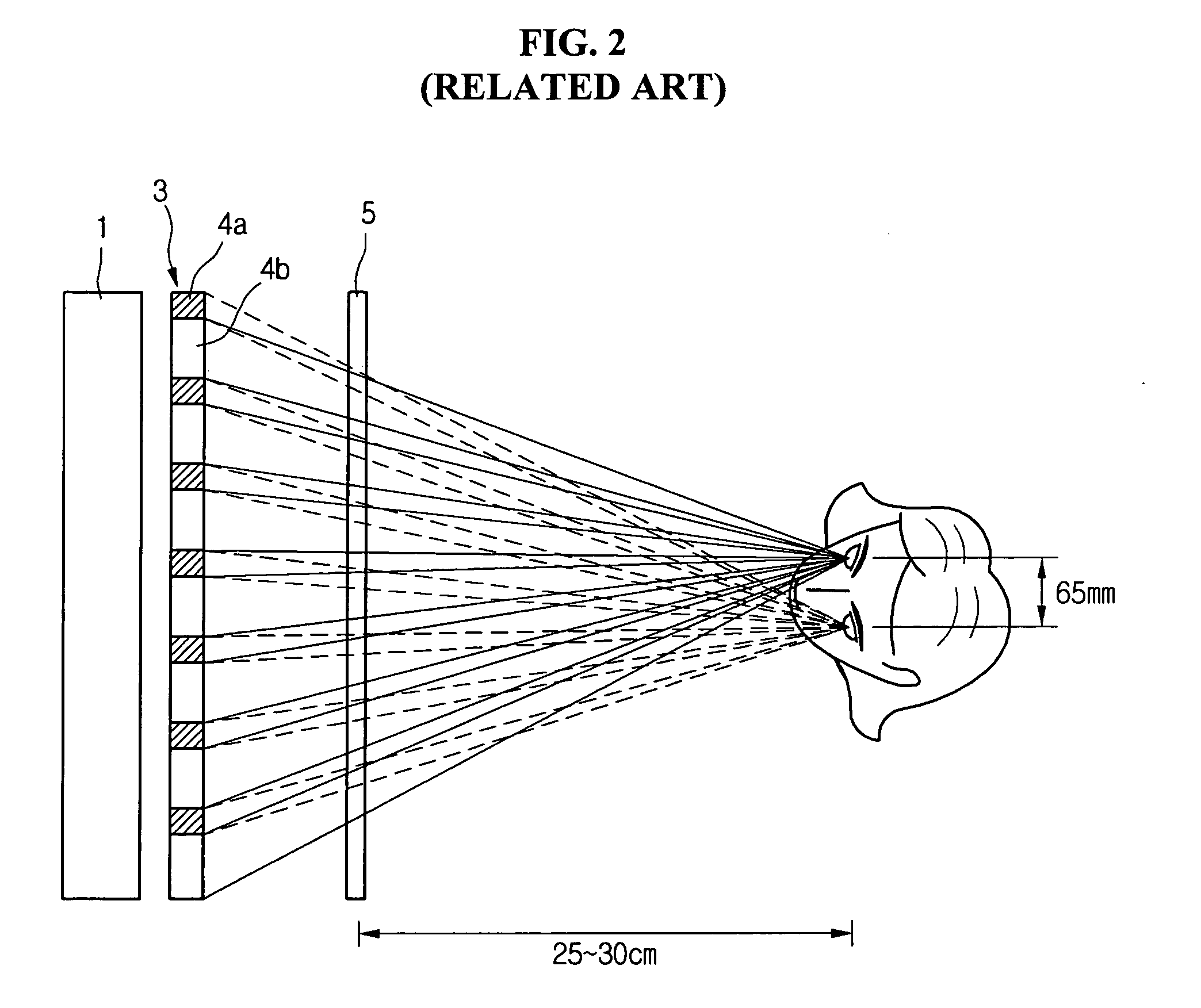

2-Dimensional and 3-dimensional image display device and method of manufacturing the same

ActiveUS20070152998A1Reduce color variationSteroscopic systemsNon-linear opticsDisplay deviceComputer science

Provided are a 2-dimensional and 3-dimensional image display device and a method of manufacturing the same. The display device includes: an image display panel including first and second substrates with a first liquid crystal layer interposed therebetween; a switching panel including third and fourth substrates with a second liquid crystal layer interposed therebetween; and a backlight unit for supplying light to the image display panel and the switching panel.

Owner:LG DISPLAY CO LTD

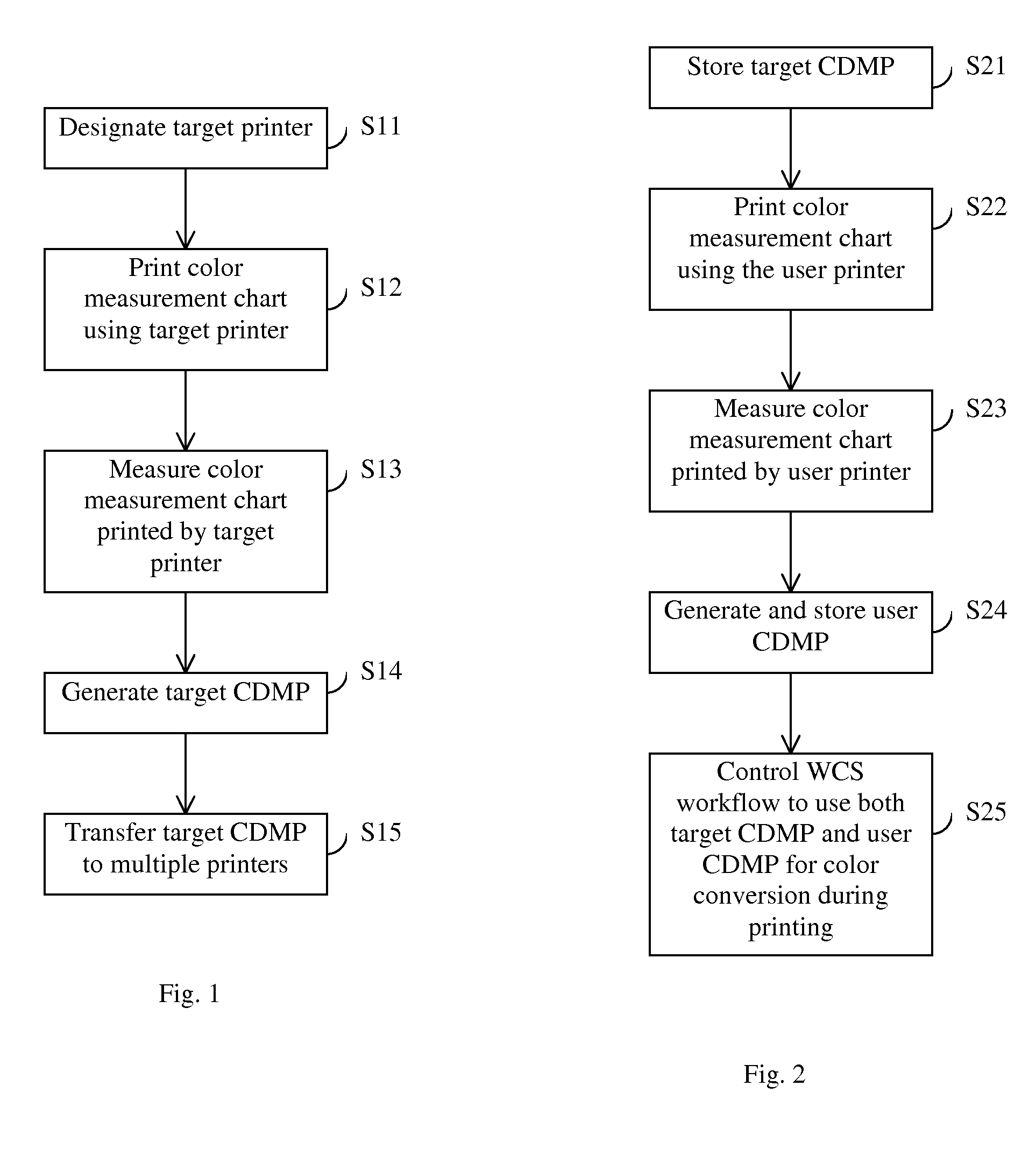

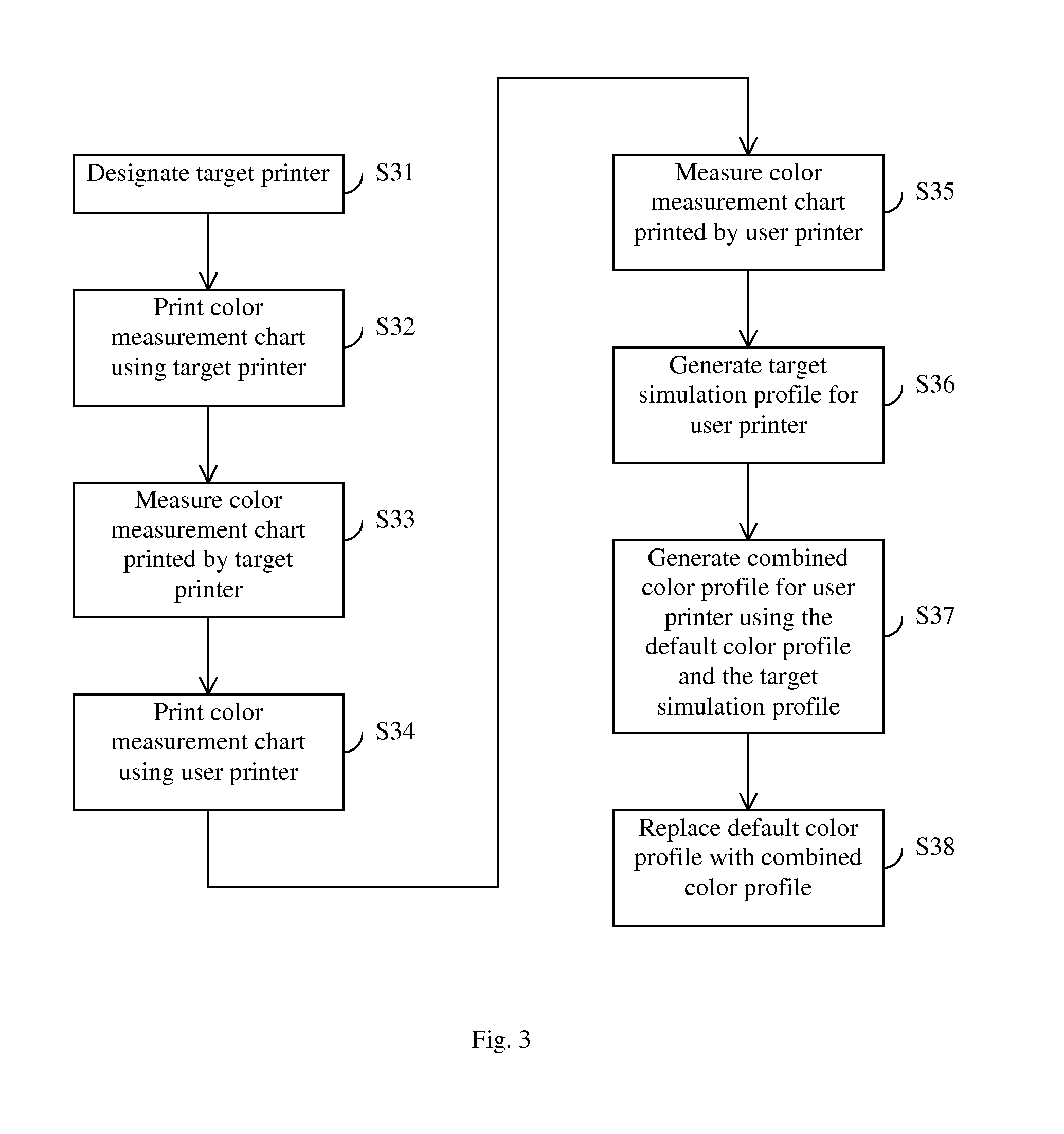

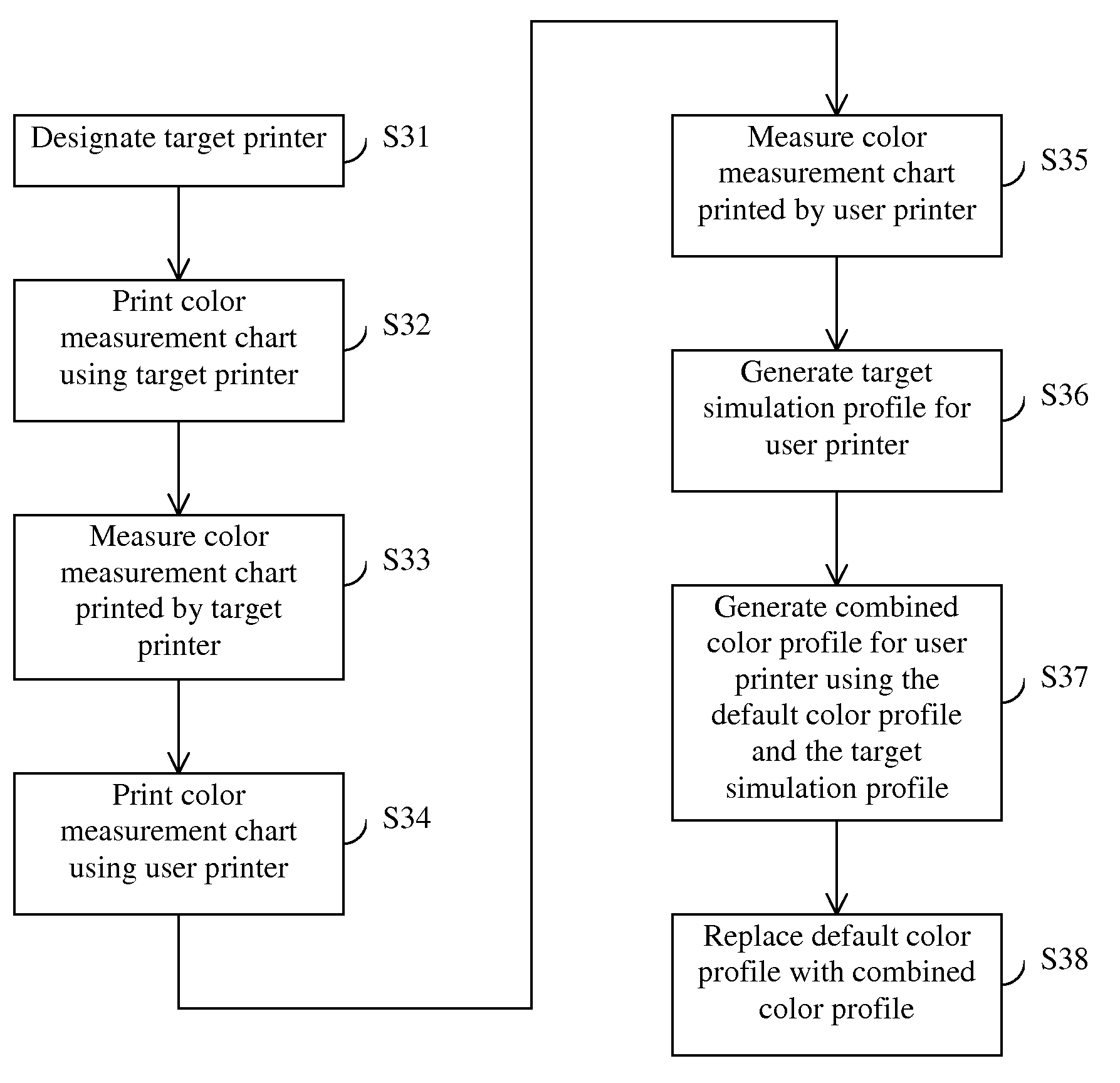

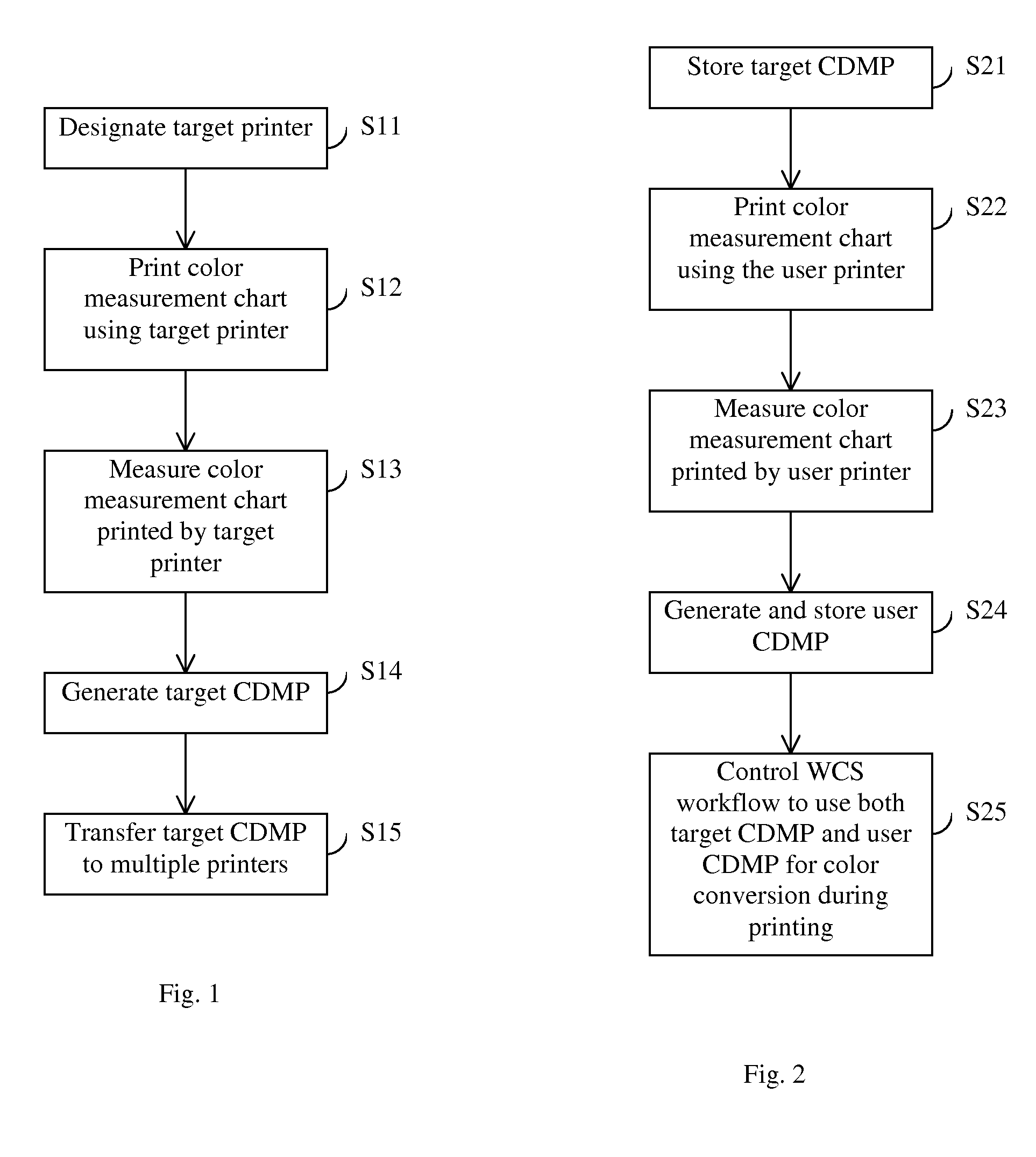

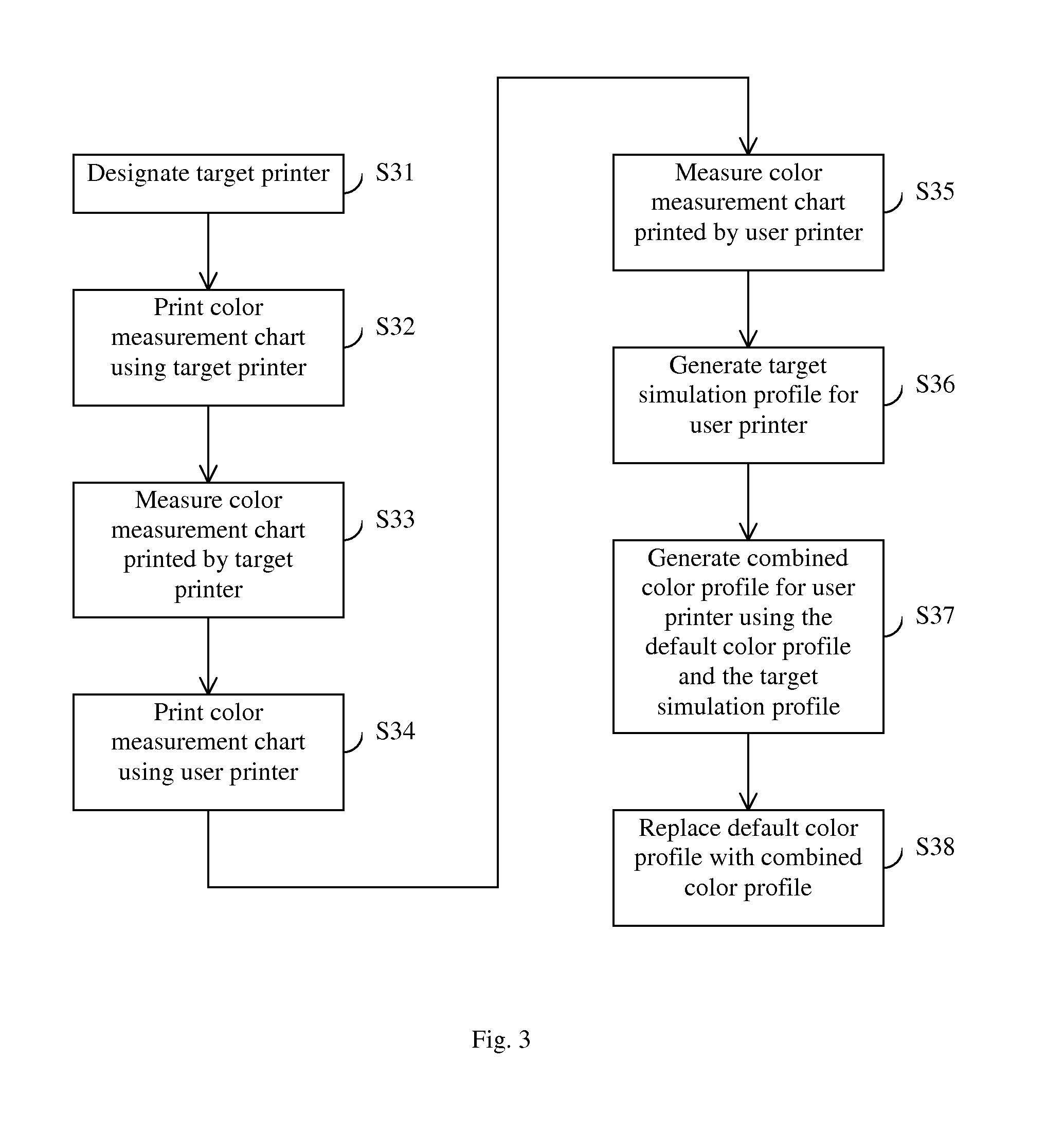

Method for compensating for color variations among multiple printers

InactiveUS7978366B2Reduce color variationDigitally marking record carriersDigital computer detailsPattern recognitionColor changes

A method for compensating for color variations among multiple user printers by providing a target simulation process in each user printer that modifies its default color characteristics so that it has the same color characteristics as a designated target printer. In a WCS implementation, a target CDMP and a user CDMP representing color characteristics of the target printer and the user printer, respectively, are stored and used by the WCS workflow to perform color conversion when printing an image on the user printer. In an ICC implementation, a color simulation profile is generated that matches the color characteristics of the user printer to those of the target printer. The color simulation profile is combined with the default color profile of the printer to generate a combined color profile which is used to perform color conversion when printing an image on the user printer.

Owner:KONICA MINOLTA LAB U S A INC

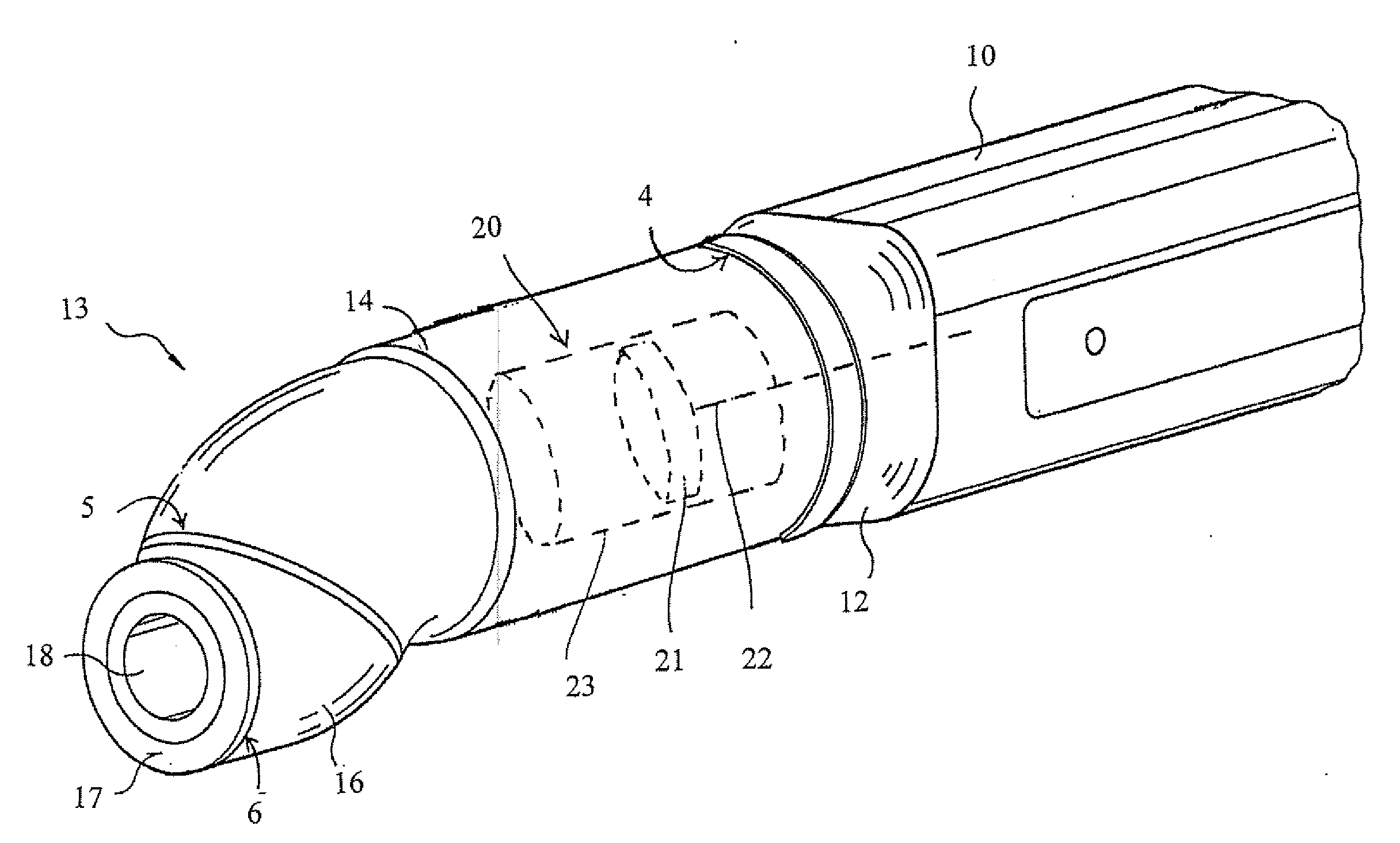

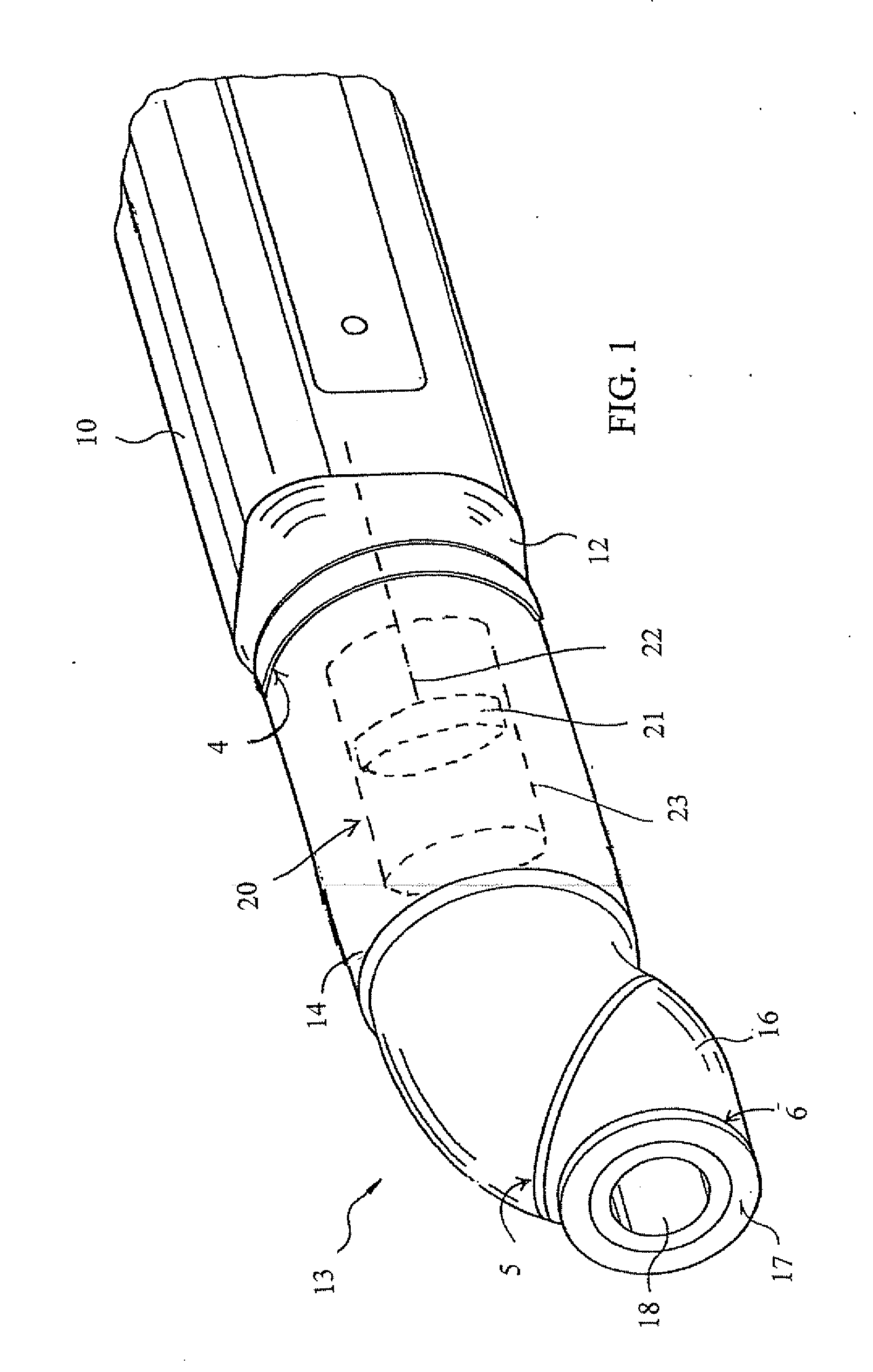

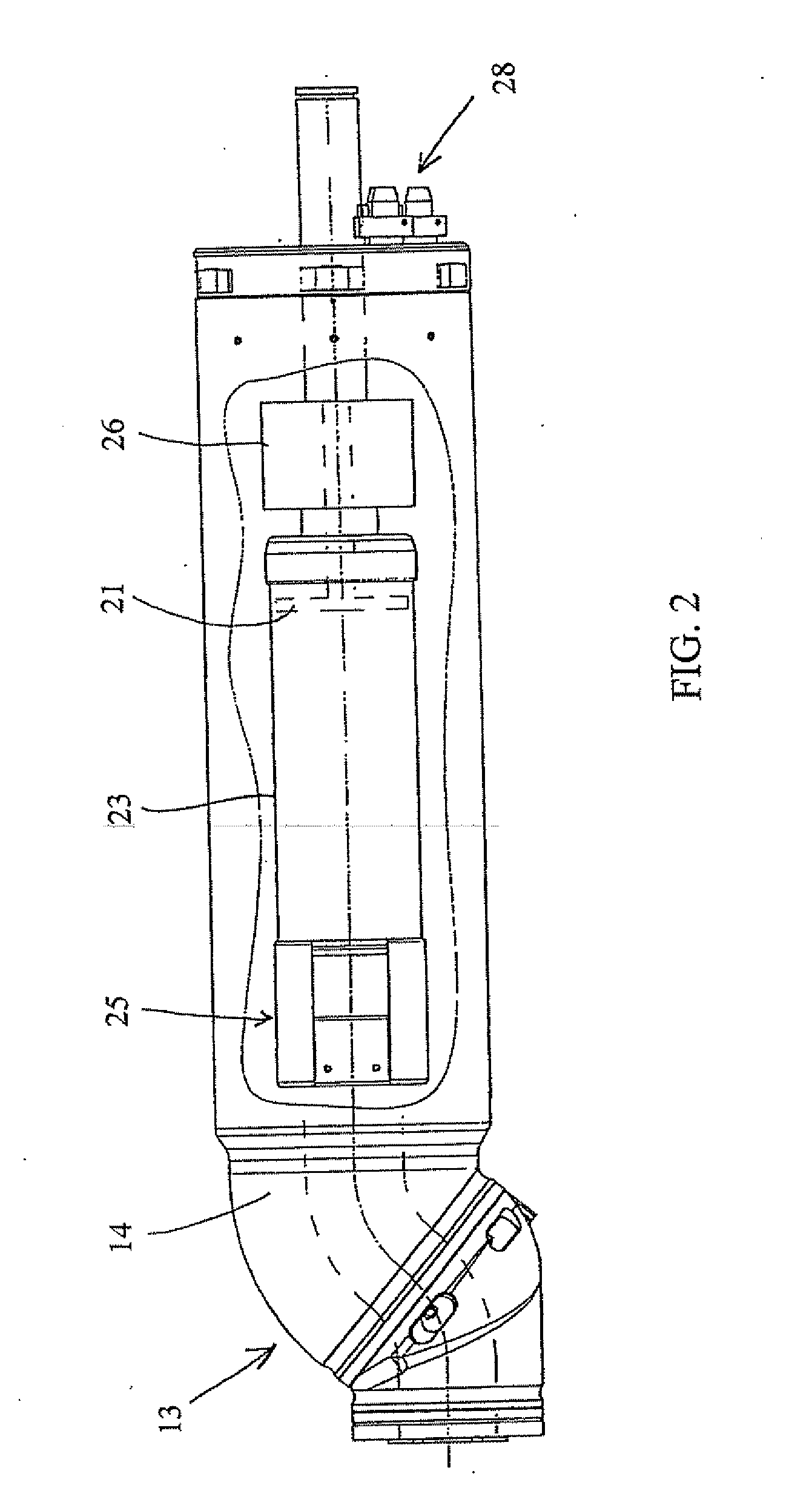

Automatically Steered Coating Machine Also A Container for The Coating Material

ActiveUS20080236484A1Reduce color changeReduce lossBurnersLiquid surface applicatorsPistonHand joint

The piston dispenser for the measured supplying of material to the atomizer of a painting robot is arranged in the hand joint of the robot. Various feasible embodiments of the dispensing cylinder of this piston dispenser are described.

Owner:DURR SYST INC

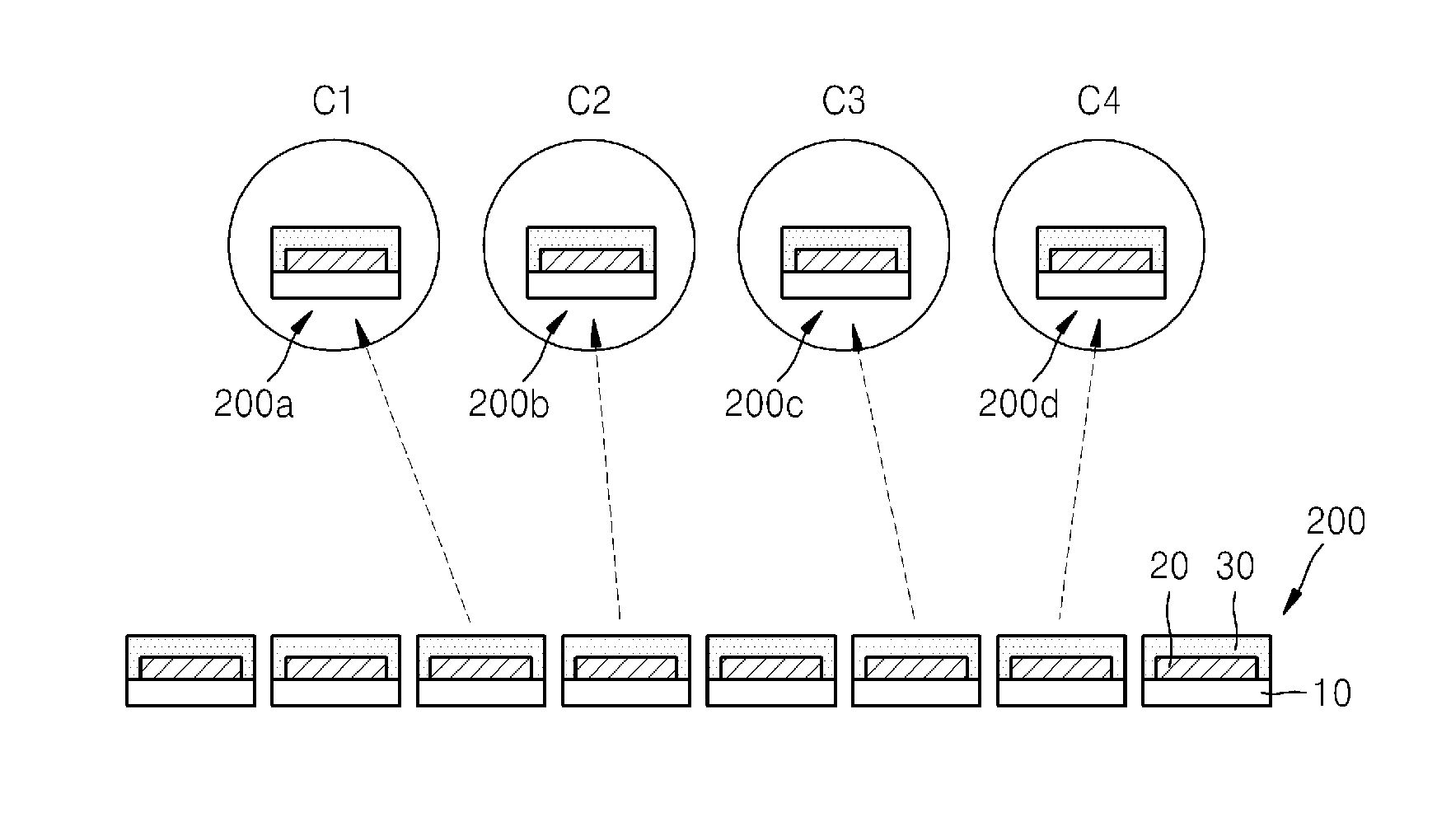

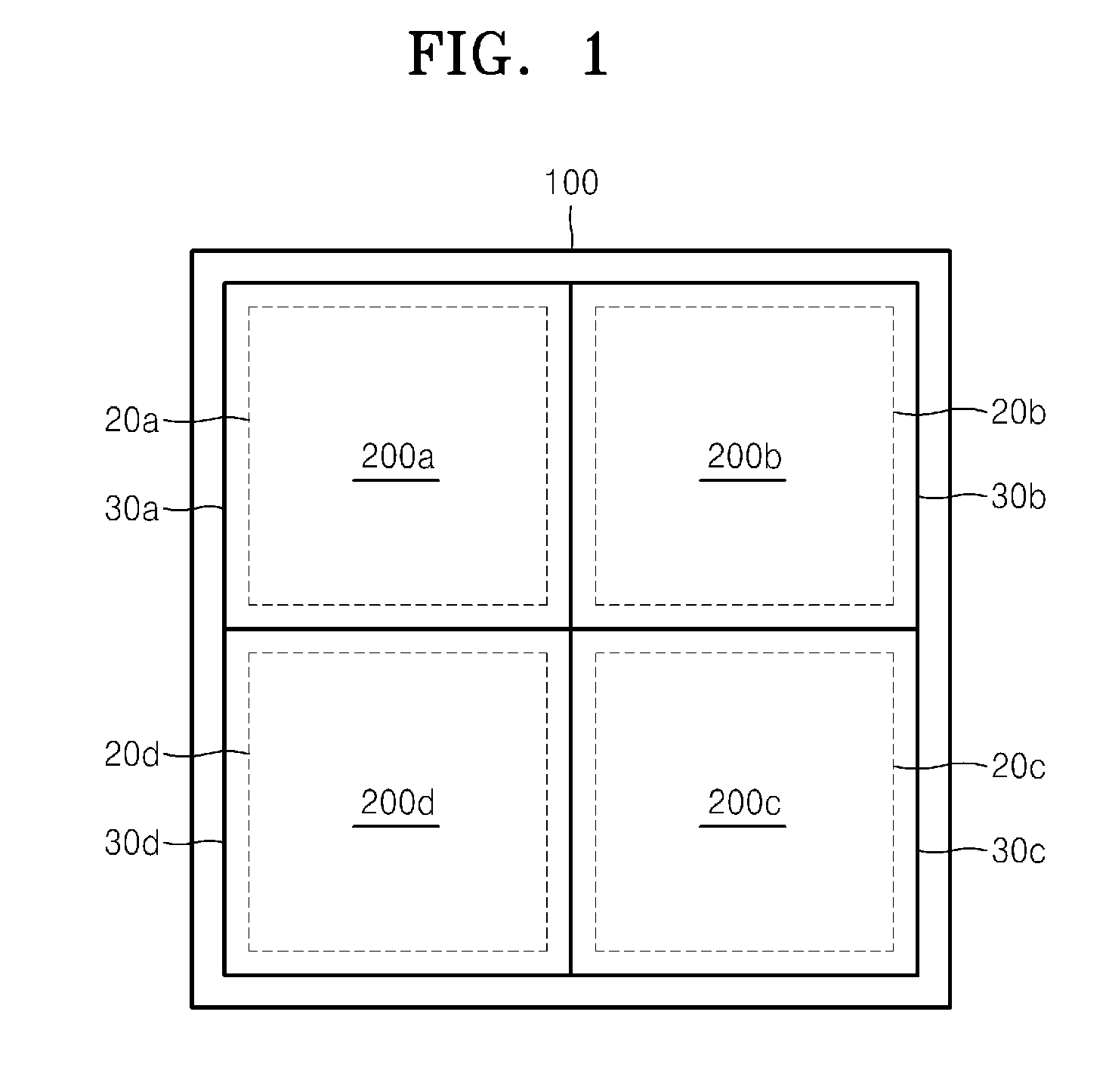

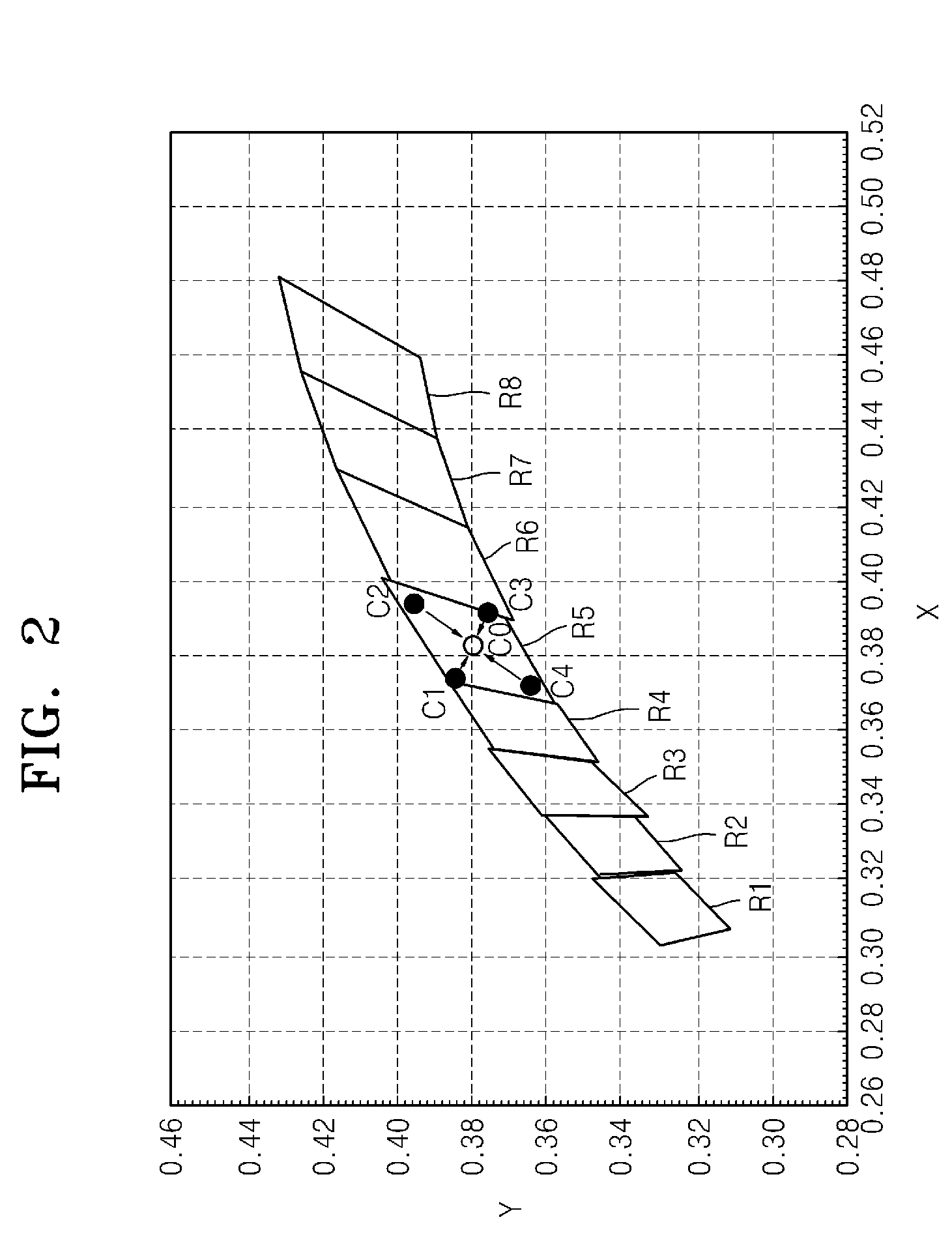

Light-emitting device package and method of manufacturing the same

ActiveUS20120161164A1Reduce color variationImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingColor temperatureEngineering

Provided are a light-emitting device package and a method of manufacturing the same. The light-emitting device package may include a plurality of light-emitting chips on one substrate (board). The plurality of light-emitting chips may produce colors around a target color. The target color may be produced by combinations of the colors of light emitted from the plurality of light-emitting chips. The colors around the target color may have the same hue as the target color and have color temperatures different from that of the target color. The plurality of light-emitting chips may have color temperatures within about ±250K of that of the target color.

Owner:SAMSUNG ELECTRONICS CO LTD

Transverse electric field mode liquid crystal display panel capable of preventing bright regions of the circumferences of slit-shaped openings of an upper electrode

A liquid crystal display panel includes a pair of substrates which are opposed to each other, and a liquid crystal layer which is interposed between the pair of substrates. One of the pair of substrates is provided with a plurality of scanning lines and a plurality of signal lines which are arranged in a matrix shape in a display area. Lower electrodes are each formed in each of sub-pixel areas partitioned by the plurality of scanning lines and the plurality of signal lines. An insulating film is formed in the display area so as to cover the lower electrodes. Upper electrodes are formed in the display area through the insulating film, and each have a plurality of slits in each of the sub-pixel area, and an alignment film which is formed on the upper electrodes and slit-shaped openings close to the liquid crystal layer.

Owner:JAPAN DISPLAY WEST

Liquid Crystal Display Device

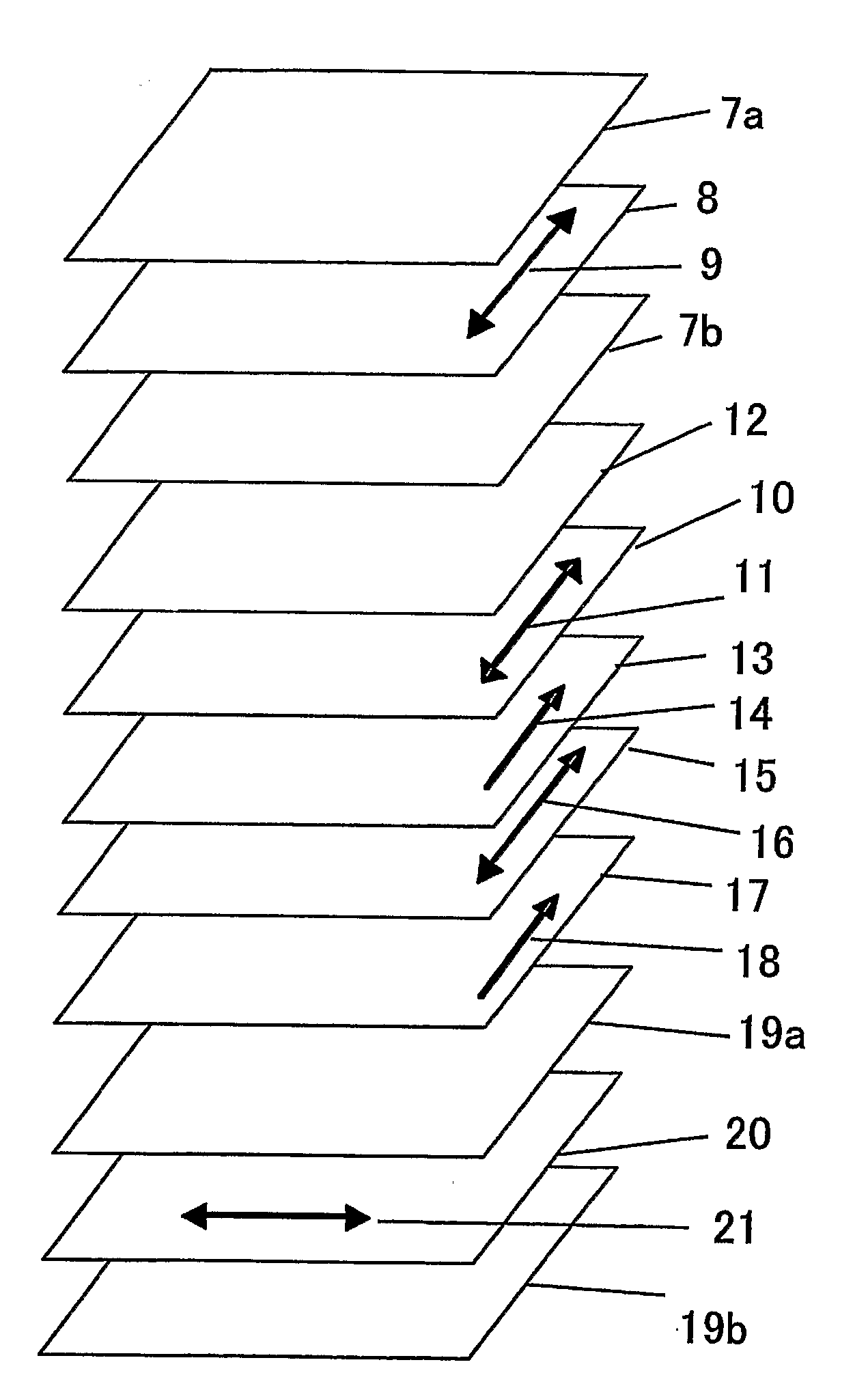

ActiveUS20080218672A1Increase contrastReduce color variationPolarising elementsNon-linear opticsEngineeringLiquid crystal cell

A novel liquid crystal display device is disclosed. The liquid crystal display device comprises a first polarizing film, a first retardation area with an Re of 70 to 330 nm and a value of Nz of not less than 0 to less than 0.5 and a slow axis perpendicular to a transmission axis of the first polarizing film; a second retardation region with an Re of not greater than 50 nm and an Rth of 10 to 140 nm; and a liquid crystal cell comprising a liquid crystal layer with a slow axis in a black state parallel to the transmission axis of the first polarizing film; and a second polarizing film in this order.

Owner:FUJIFILM CORP

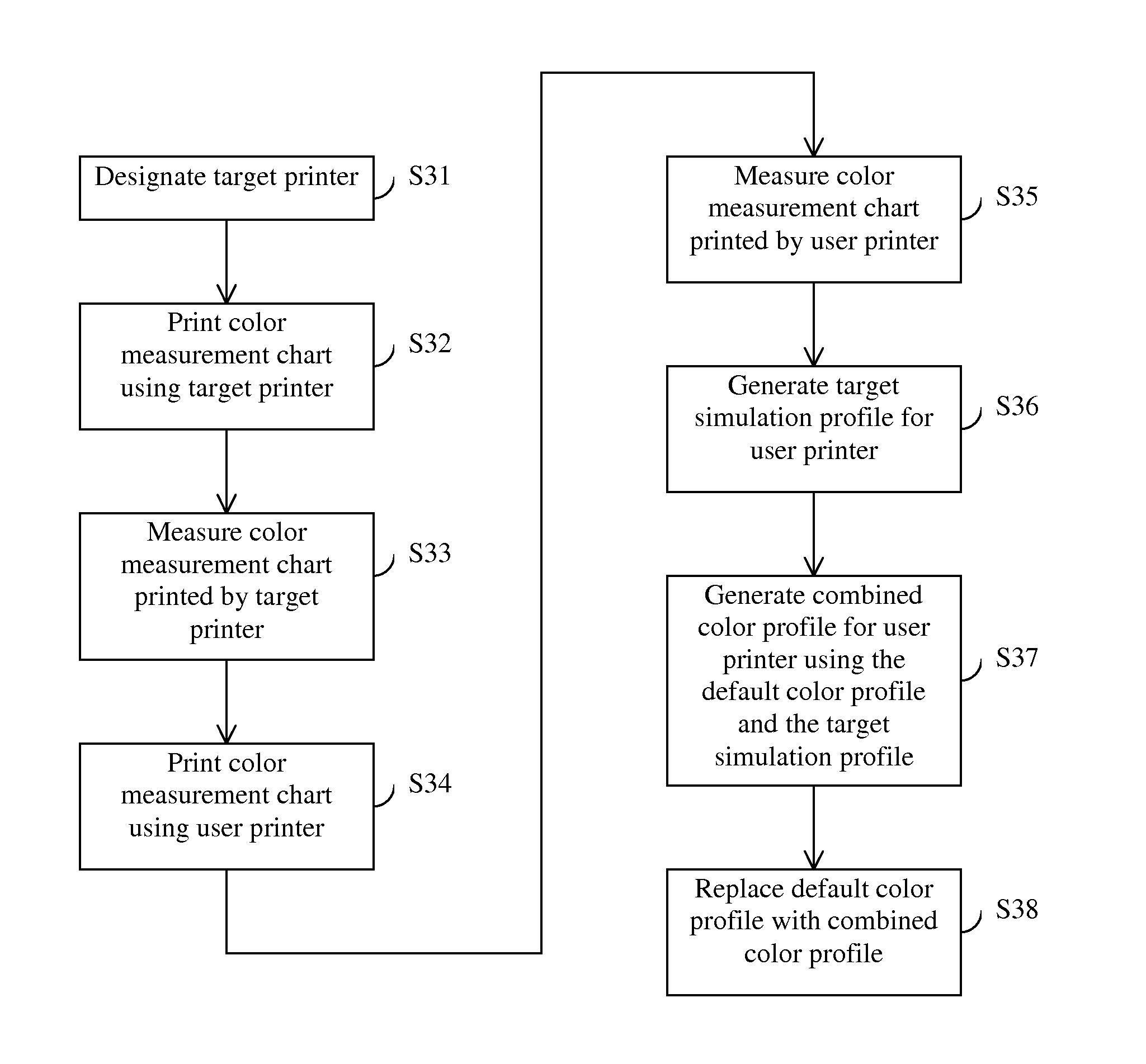

Method for compensating for color variations among multiple printers

InactiveUS20090147279A1Reduce color variationDigitally marking record carriersDigital computer detailsPattern recognitionColor transformation

A method for compensating for color variations among multiple user printers by providing a target simulation process in each user printer that modifies its default color characteristics so that it has the same color characteristics as a designated target printer. In a WCS implementation, a target CDMP and a user CDMP representing color characteristics of the target printer and the user printer, respectively, are stored and used by the WCS workflow to perform color conversion when printing an image on the user printer. In an ICC implementation, a color simulation profile is generated that matches the color characteristics of the user printer to those of the target printer. The color simulation profile is combined with the default color profile of the printer to generate a combined color profile which is used to perform color conversion when printing an image on the user printer.

Owner:KONICA MINOLTA LAB U S A INC

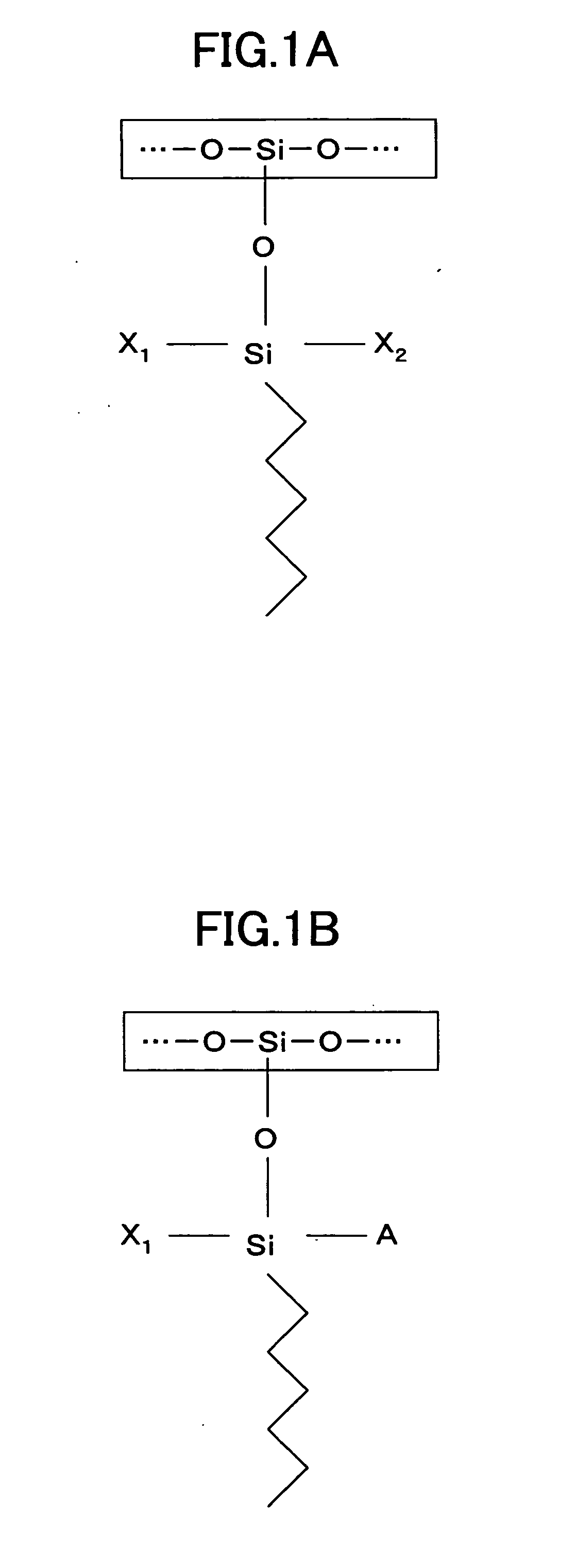

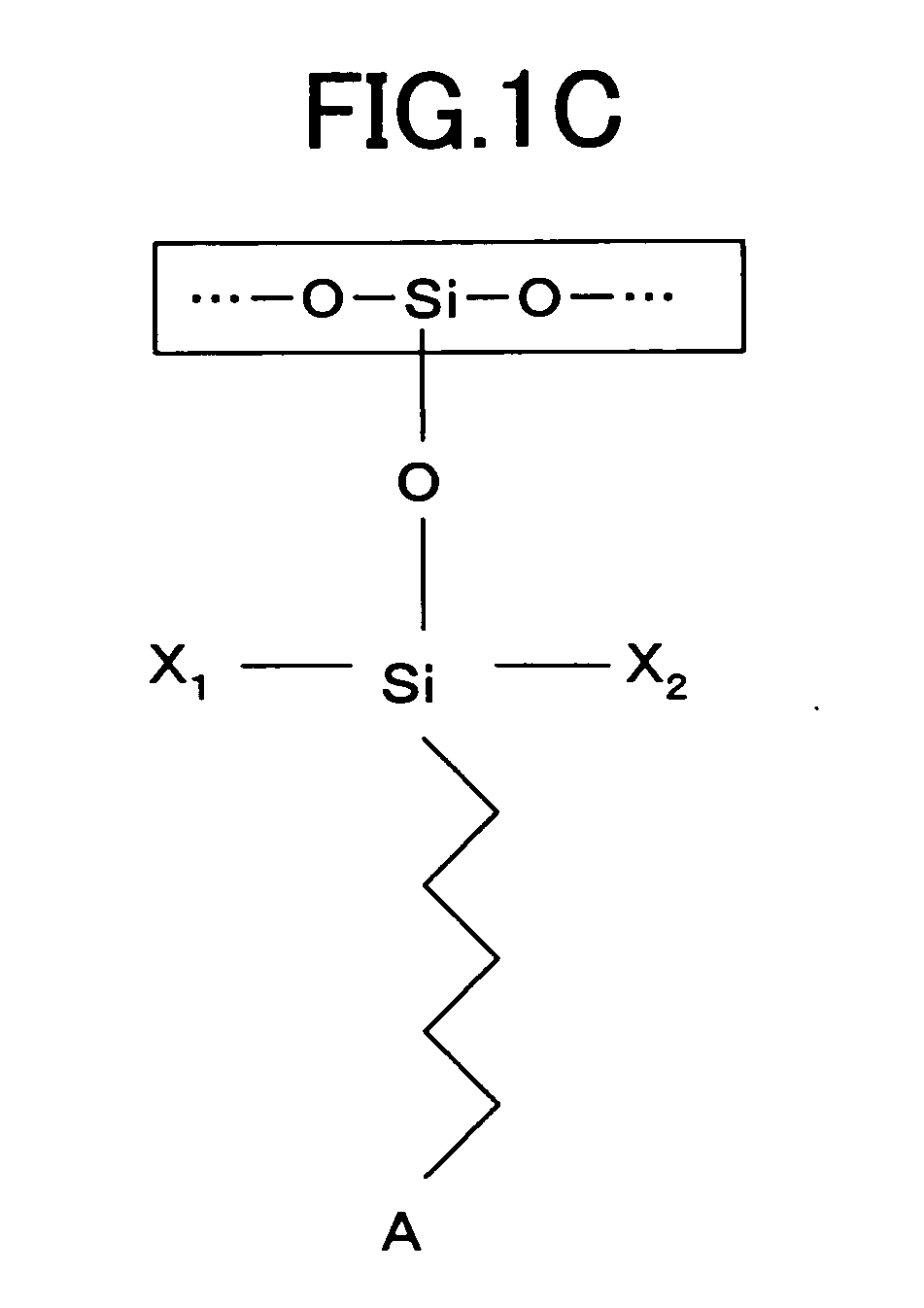

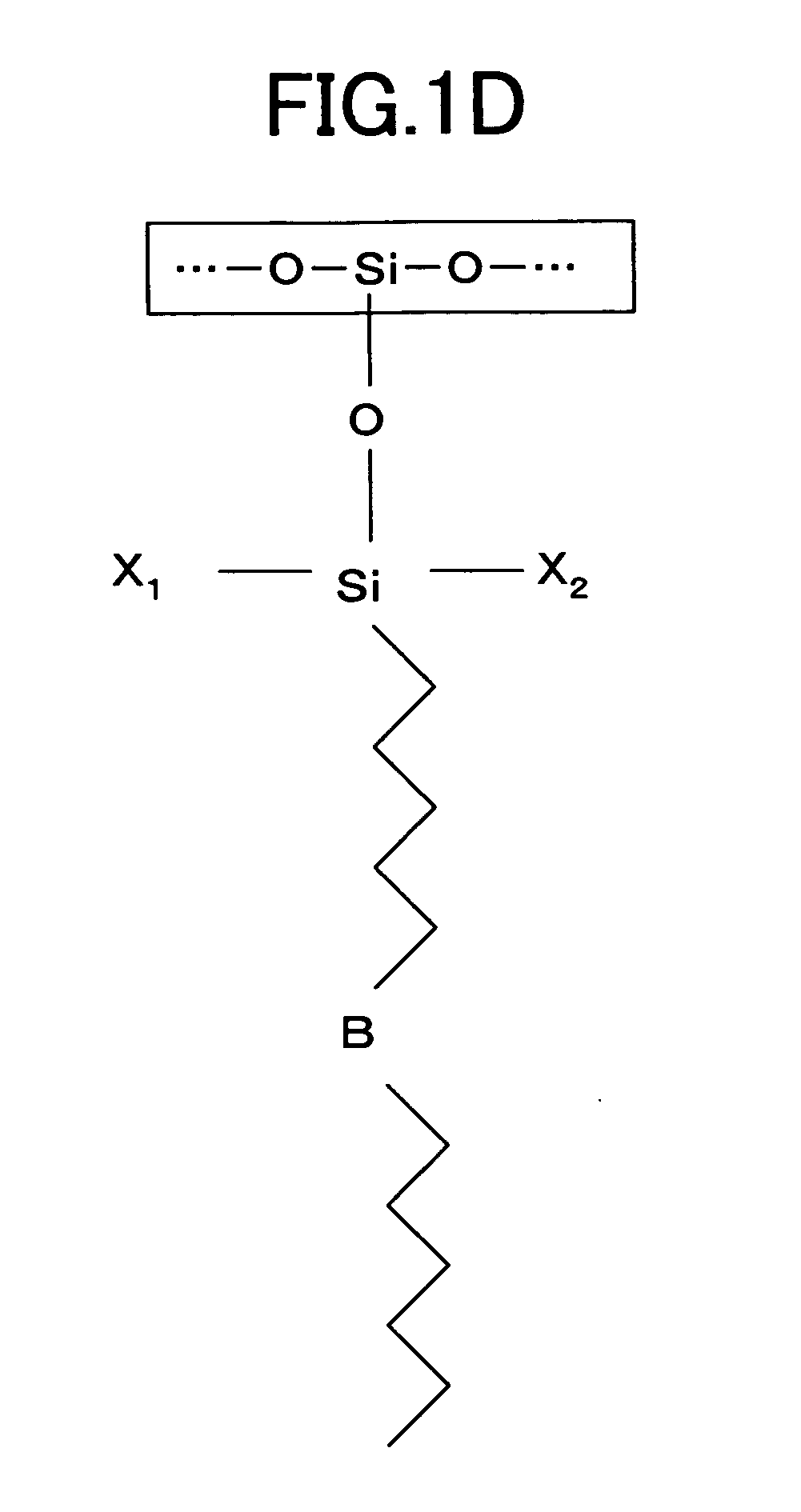

Resin composition and resin molded object

InactiveUS20070093588A1Reduce hydrolysisReduce color variationMaterial nanotechnologyPigmenting treatmentSilyleneColor changes

A resin composition which reduces hydrolysis thereof and reduces the color change thereof at the time of heating and a resin molded object which reduces hydrolysis thereof and reduces quality change of content therein are provided. The resin composition includes a resin and an organically modified layered silicate in which a substituted silyl group having a substituted or non-substituted alkyl group bonds to a layered silicate. The resin molded object is obtained by molding a resin composition including a resin and an organically modified layered silicate in which a substituted silyl group having a substituted or non-substituted alkyl group bonds to a layered silicate.

Owner:SHISEIDO CO LTD +1

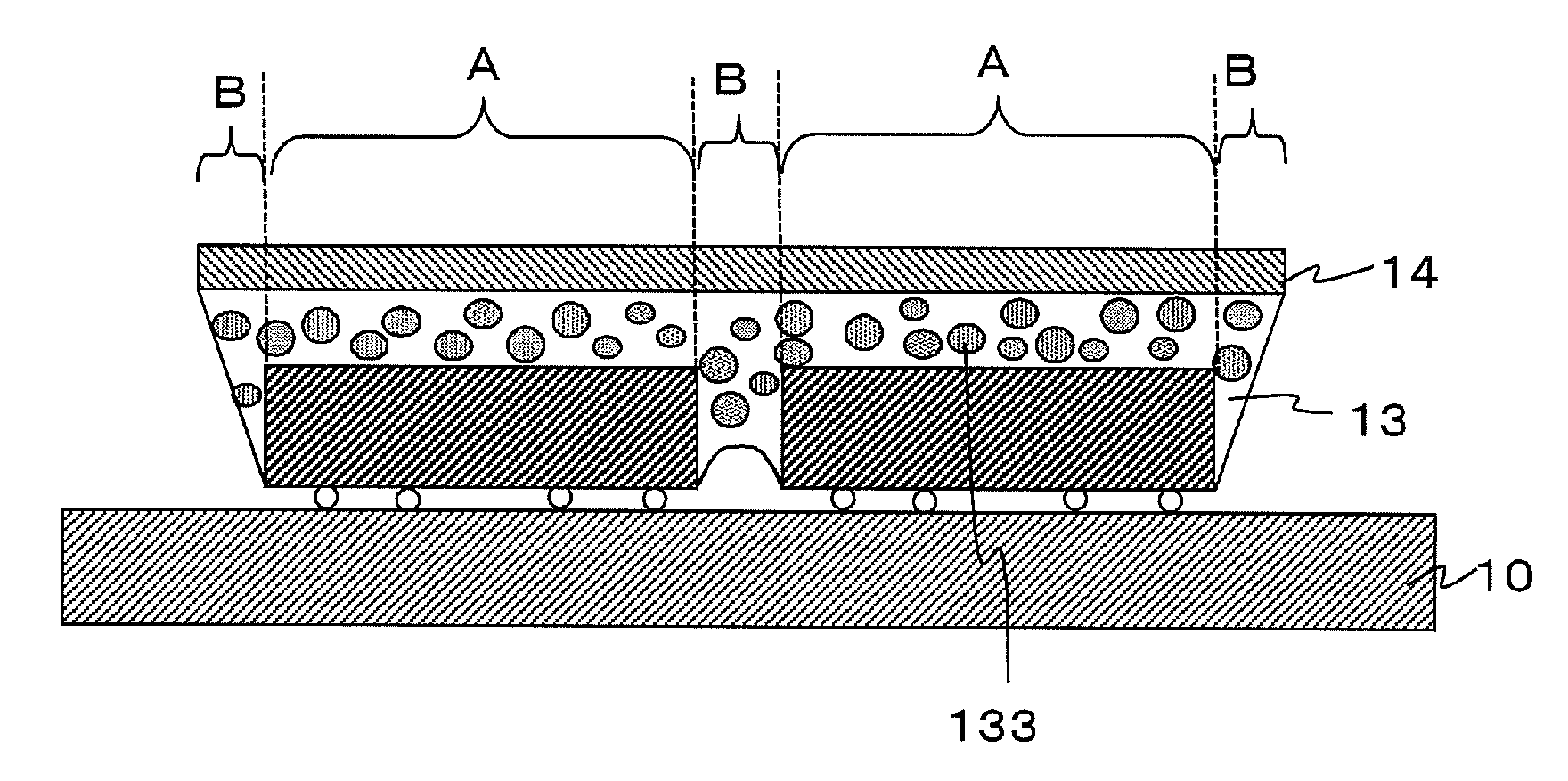

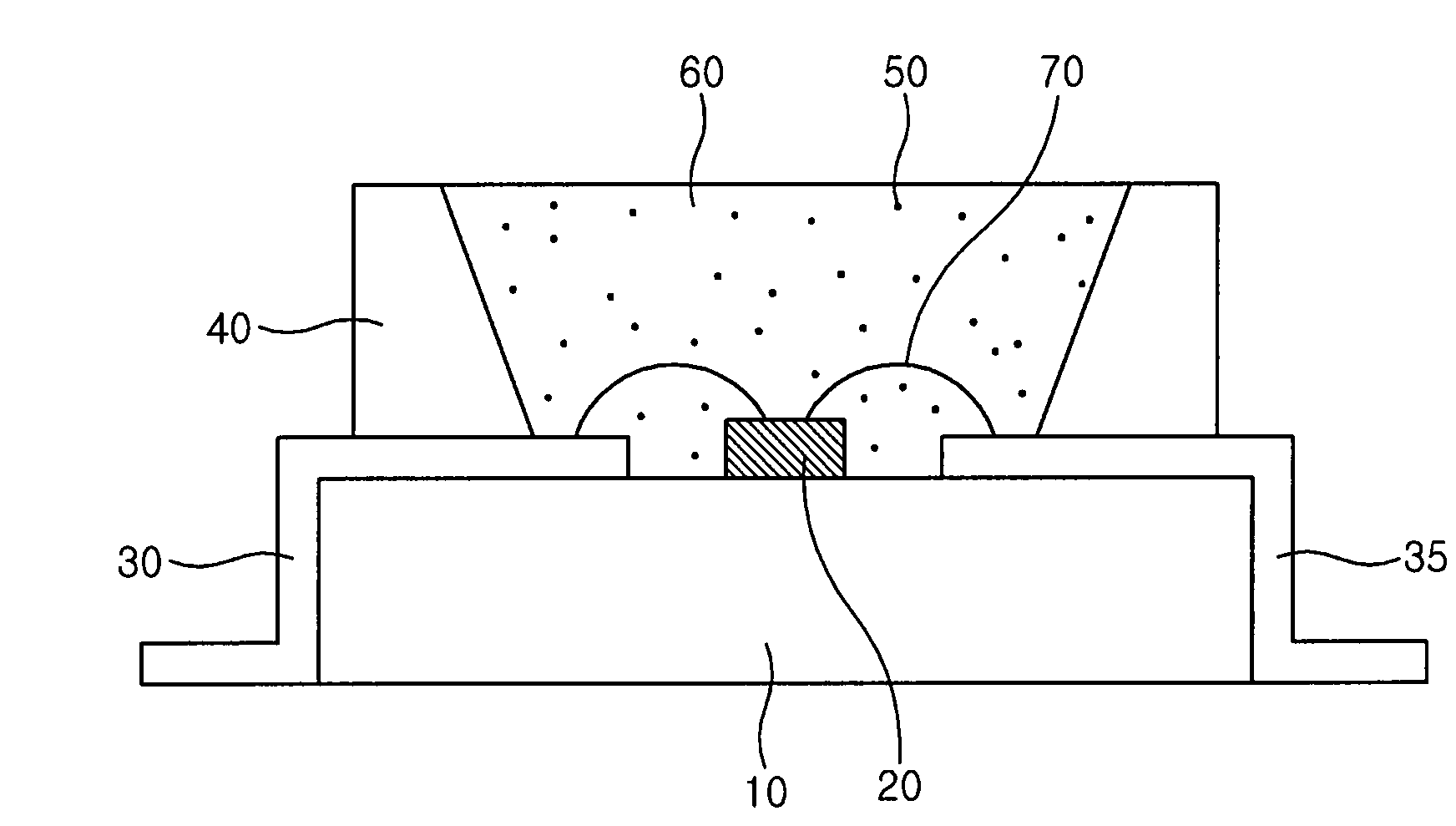

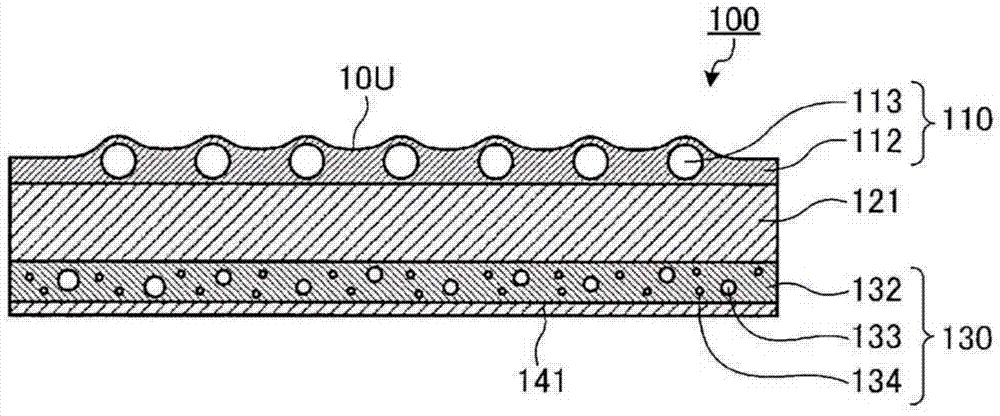

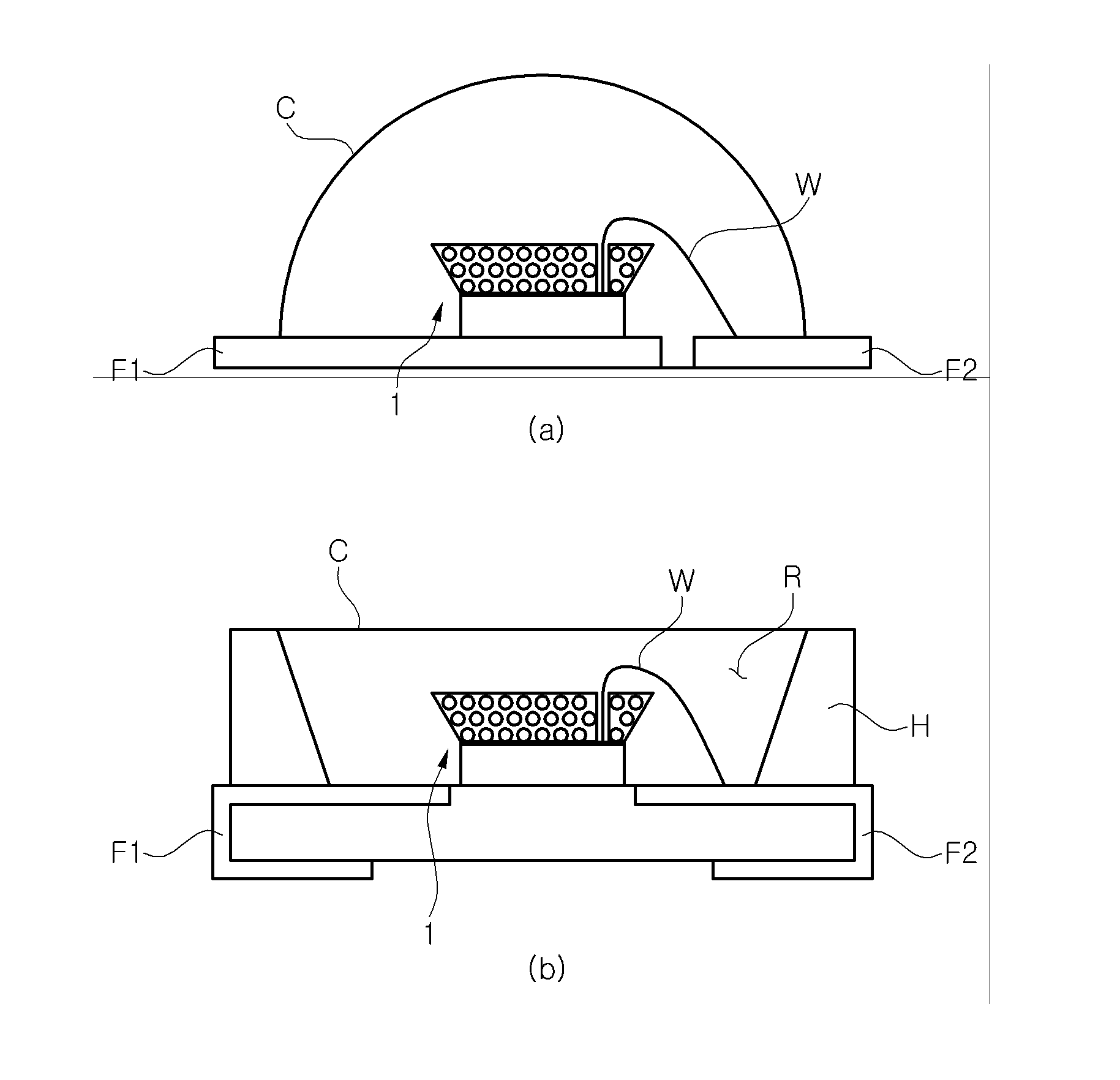

Semiconductor light emitting device having a reflective material, wavelength converting layer and optical plate with rough and plane surface regions, and method of manufacturing

InactiveUS8581287B2Reduce color variationEasy to controlDischarge tube luminescnet screensLamp detailsLength waveColored light

A semiconductor light-emitting device and a method for manufacturing the same can include a wavelength converting layer in order to emit various colored lights including white light. The device can include a board, a frame located on the board, at least one light-emitting chip mounted on the board, the wavelength converting layer located between an optical plate and an outside surface of the chips so that a density of a peripheral region is lower than that of a middle region, and a reflective material layer disposed at least between the frame and a side surface of the wavelength-converting layer. The device can have the reflective material layer form each reflector and can use a wavelength converting layer having different densities, and therefore can emit a wavelength-converted light having a high light-emitting efficiency and a uniform color tone from various small light-emitting surfaces.

Owner:STANLEY ELECTRIC CO LTD

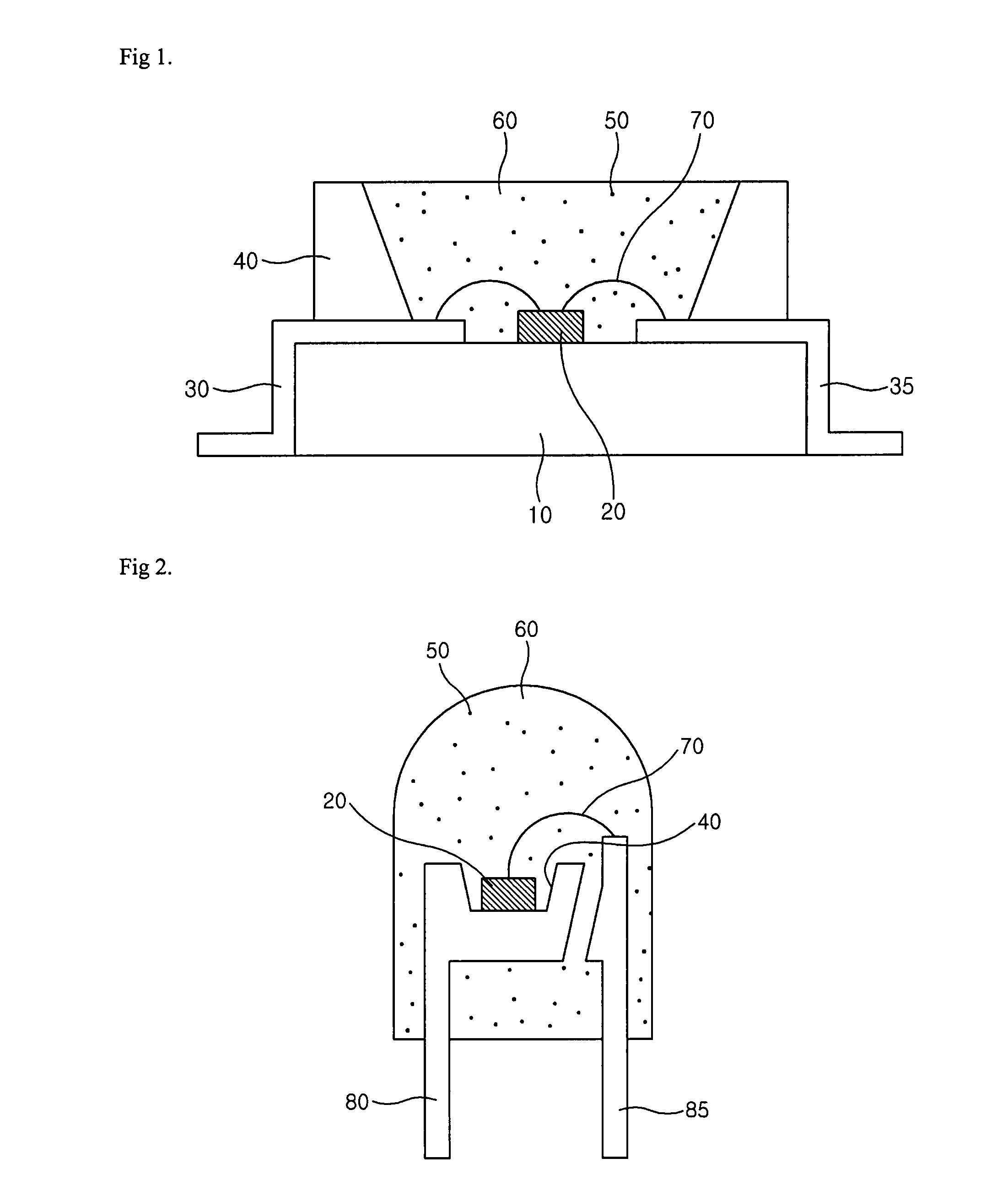

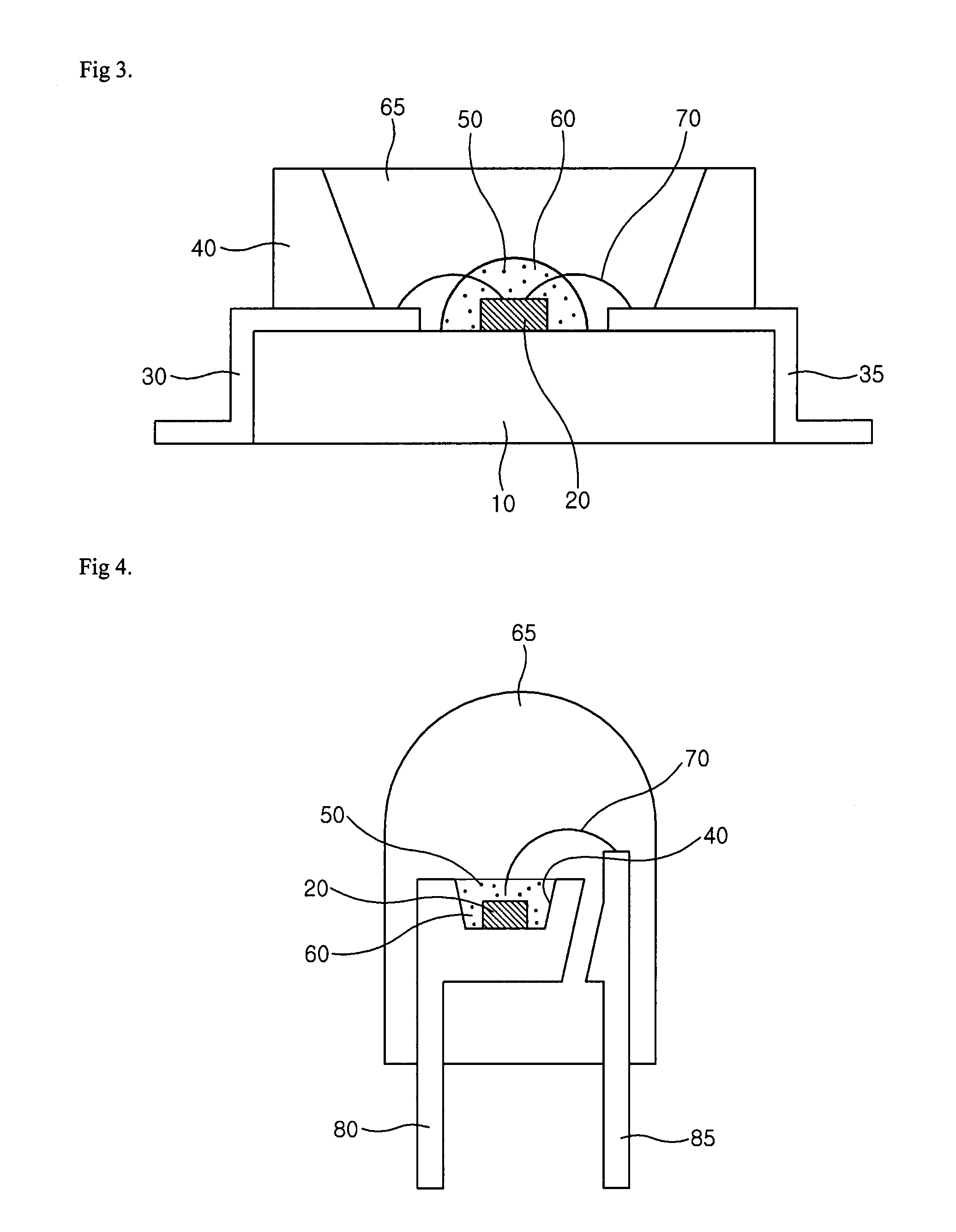

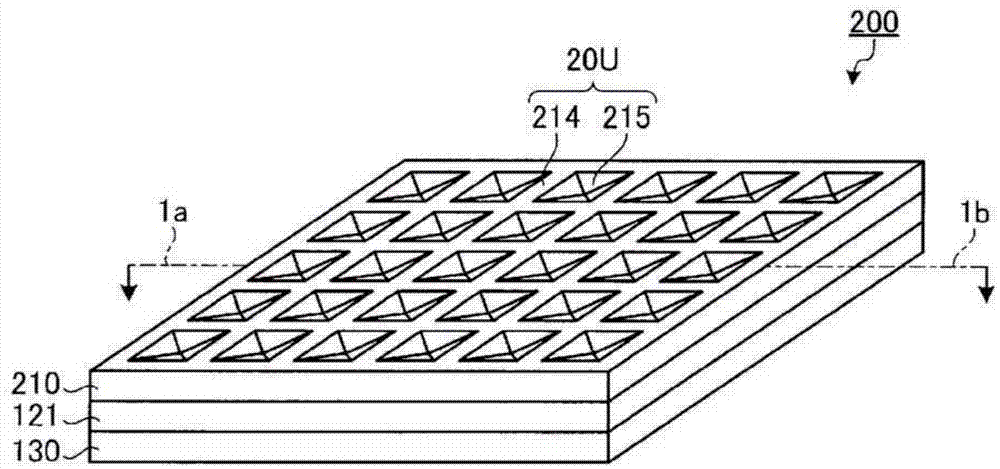

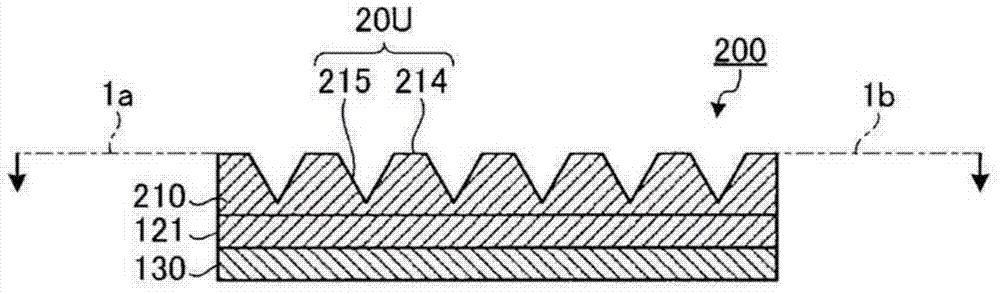

Semiconductor light emitting device having an optical plate including a meniscus control structure and method of manufacturing

ActiveUS8455907B2Reduce color variationImprove luminous efficiencyDischarge tube luminescnet screensLamp detailsEngineeringLength wave

A semiconductor light-emitting device and a method for manufacturing the same can include a wavelength converting layer in order to emit various colored lights including white light. The semiconductor light-emitting device can include a base board, a frame located on the base board, at least one light-emitting chip mounted on the base board, the wavelength converting layer located between an optical plate and each outside surface of the chips so as to extend toward the optical plate using a meniscus control structure, and a reflective material layer disposed at least between the frame and both side surfaces of the wavelength converting layer and the optical plate. The semiconductor light-emitting device can be configured to improve light-emitting efficiency and color variability between the light-emitting chips by using the reflective material layer as each reflector, and therefore can emit a wavelength-converted light having a high light-emitting efficiency from various small light-emitting surfaces.

Owner:STANLEY ELECTRIC CO LTD

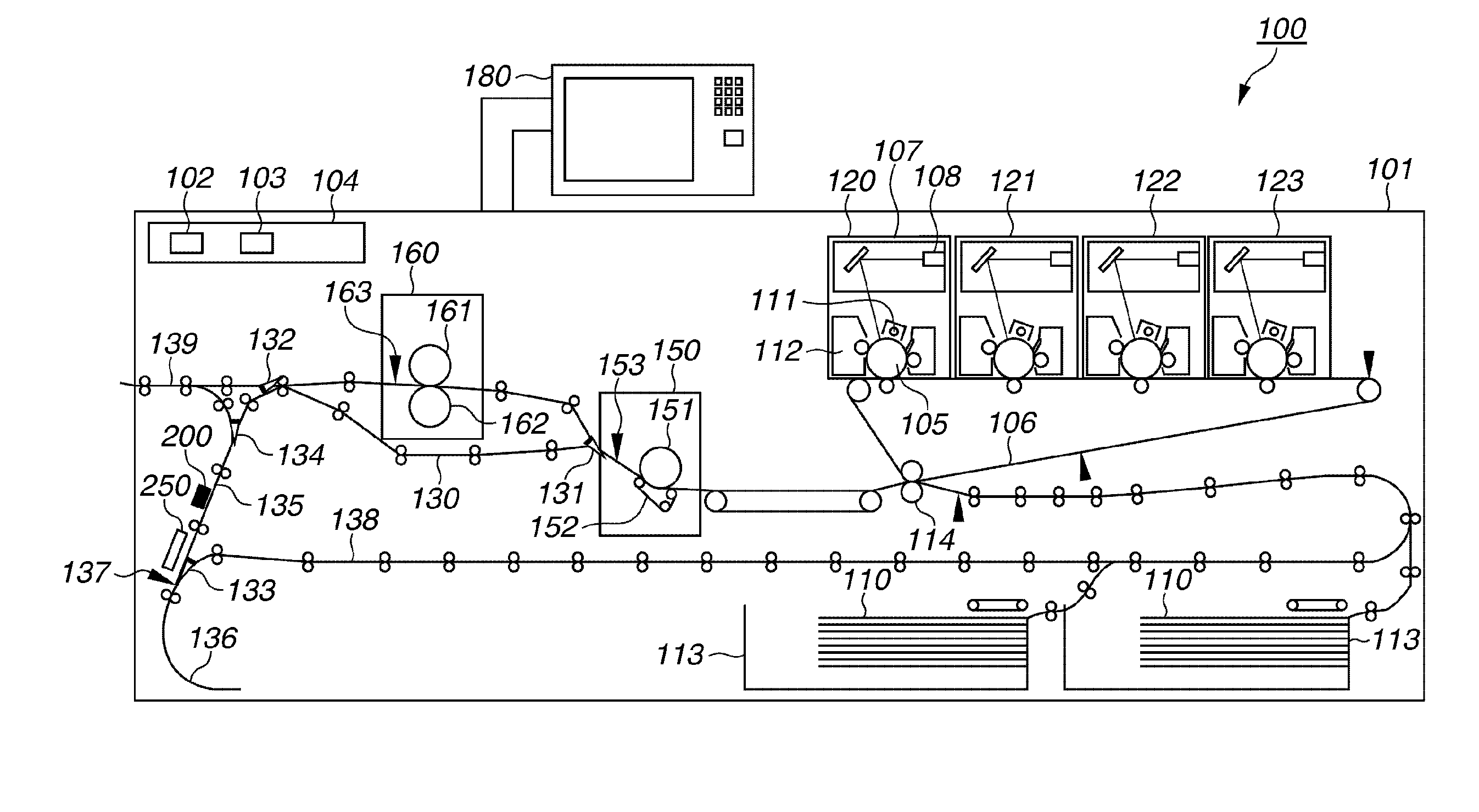

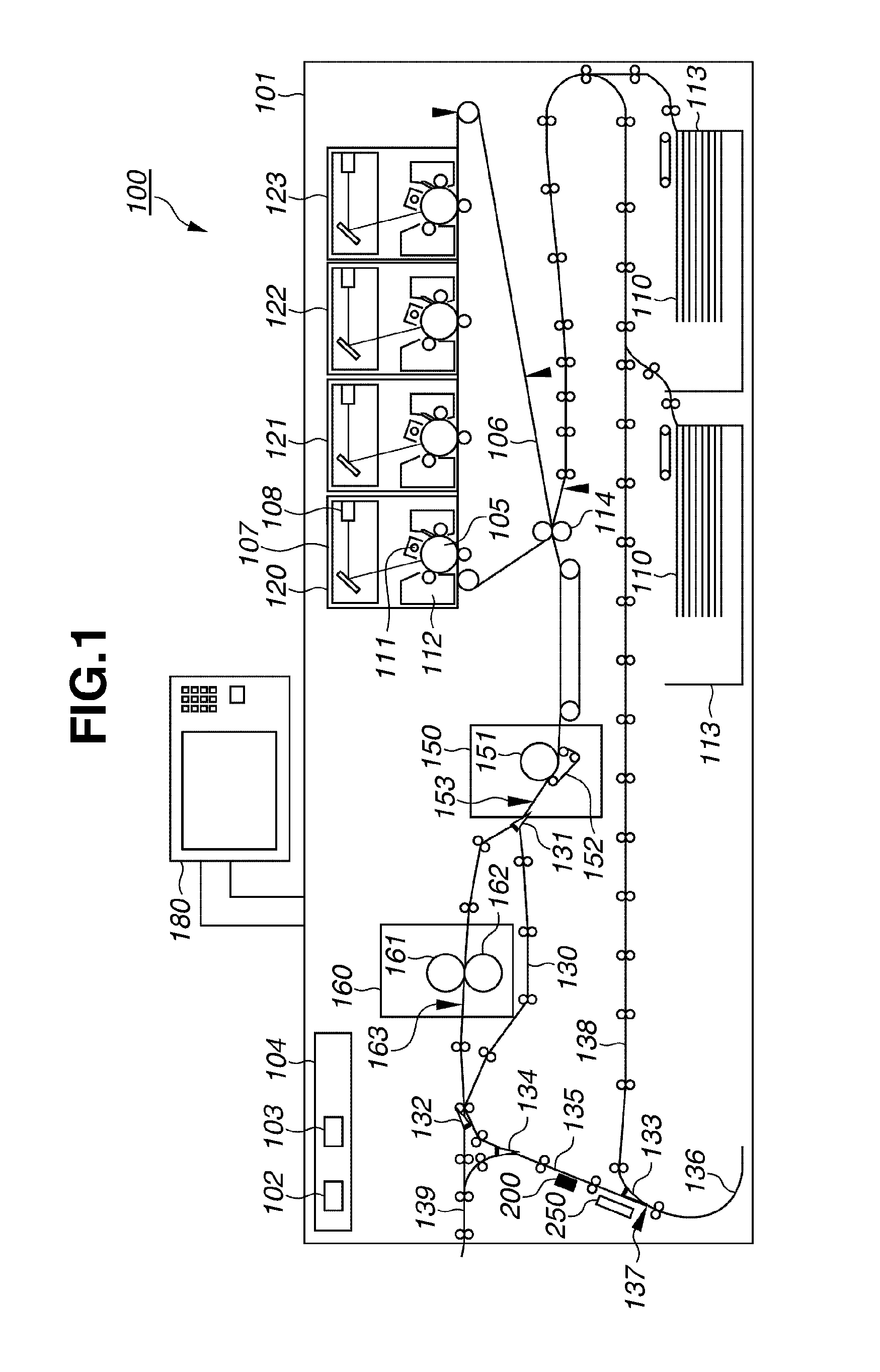

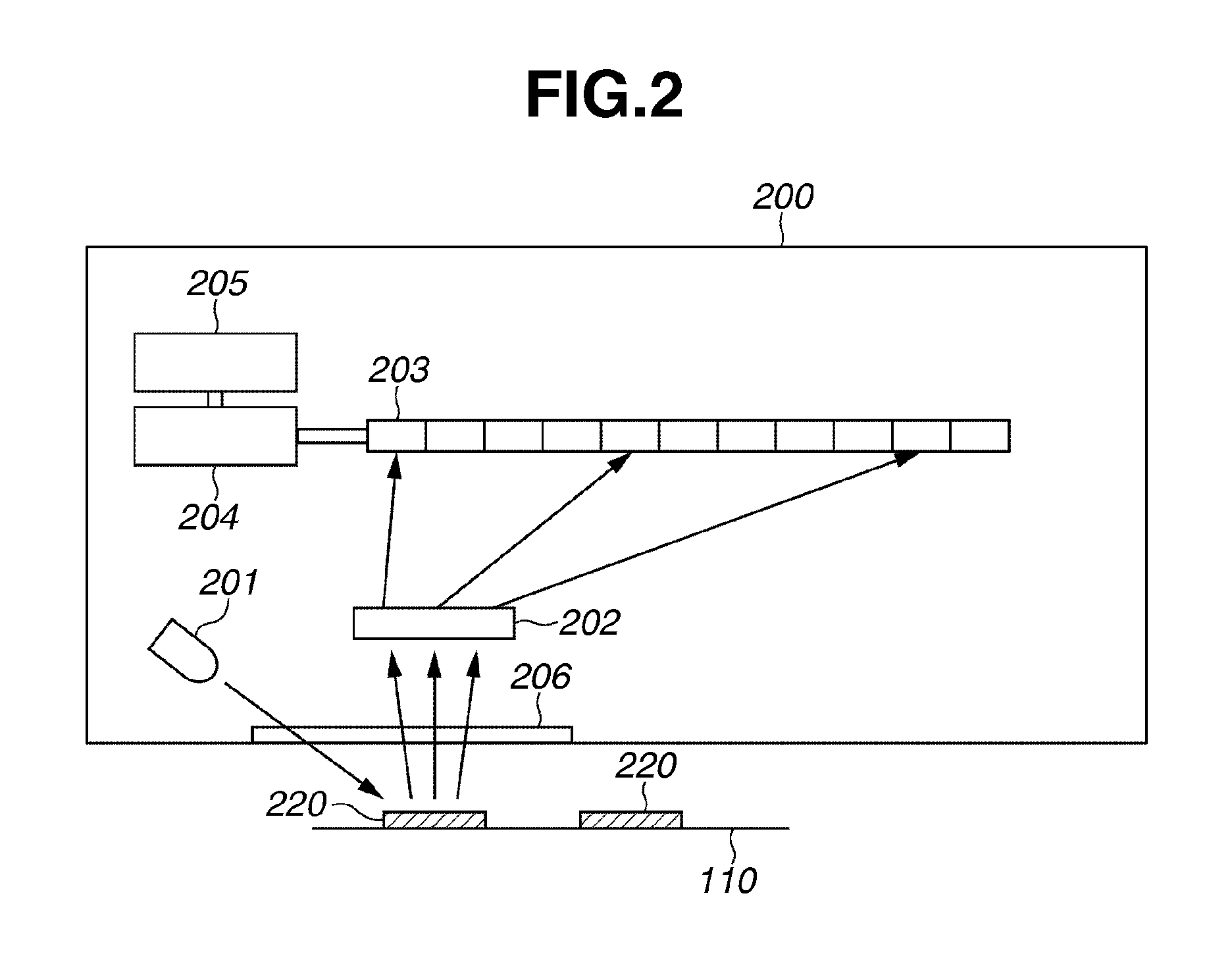

Image forming apparatus

ActiveUS20130094041A1Reducing color variationTrue colorDigitally marking record carriersDigital computer detailsCooling UnitsElectrical and Electronics engineering

An image forming apparatus includes an image forming unit configured to form a measurement image on a recording paper by using a color material, a fixing unit configured to fix a plurality of measurement images onto the recording paper by heating the measurement images, a measurement unit configured to measure the measurement images fixed onto the recording paper downstream of the fixing unit in a conveyance direction of the recording paper, a cooling unit configured to cool the recording paper heated by the fixing unit, and a control unit configured to perform control such that a cooling capacity of the cooling unit in a case where the measurement unit measures color of the measurement images is higher than a cooling capacity of the cooling unit in a case where the measurement unit measures density of the measurement images.

Owner:CANON KK

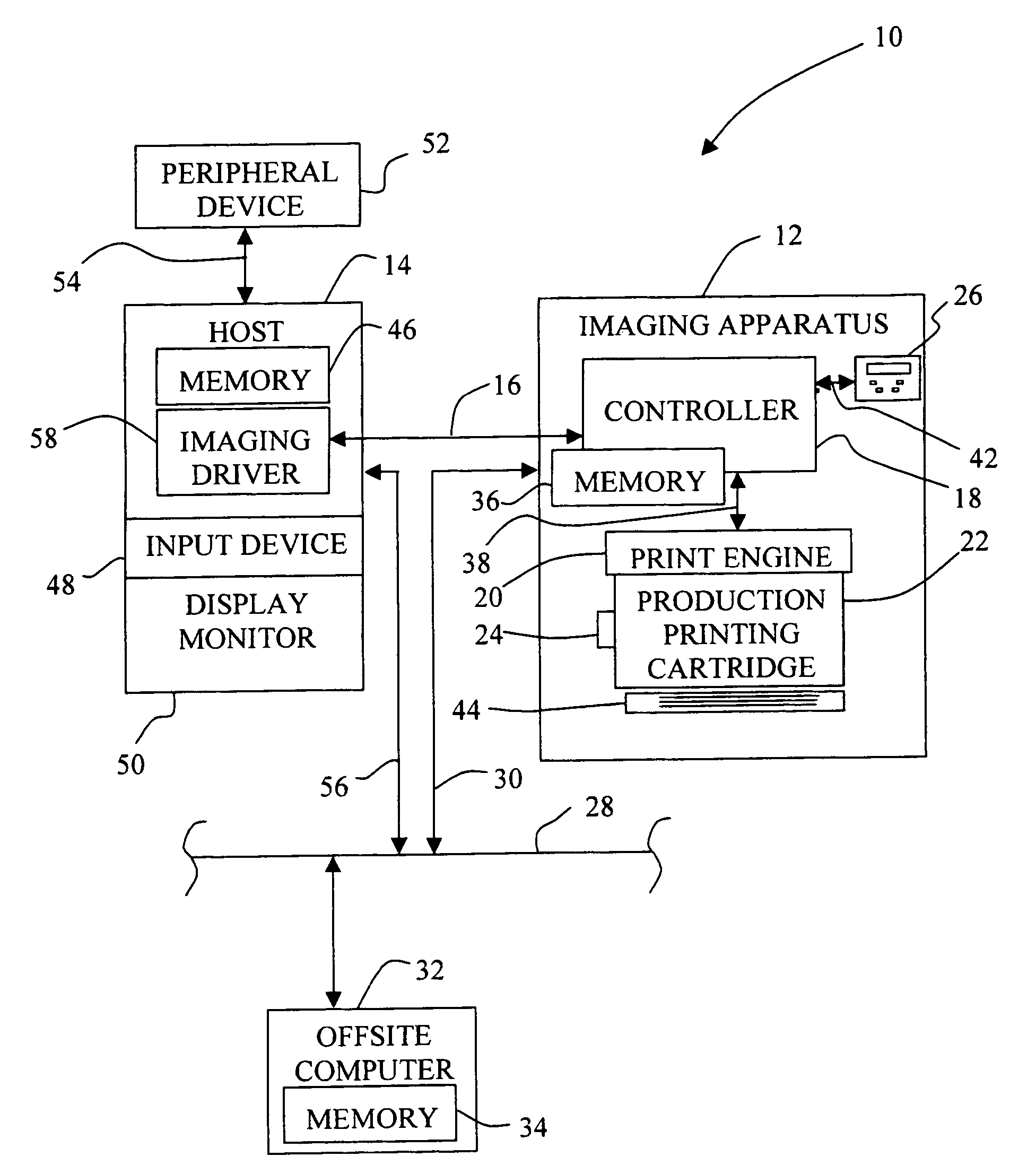

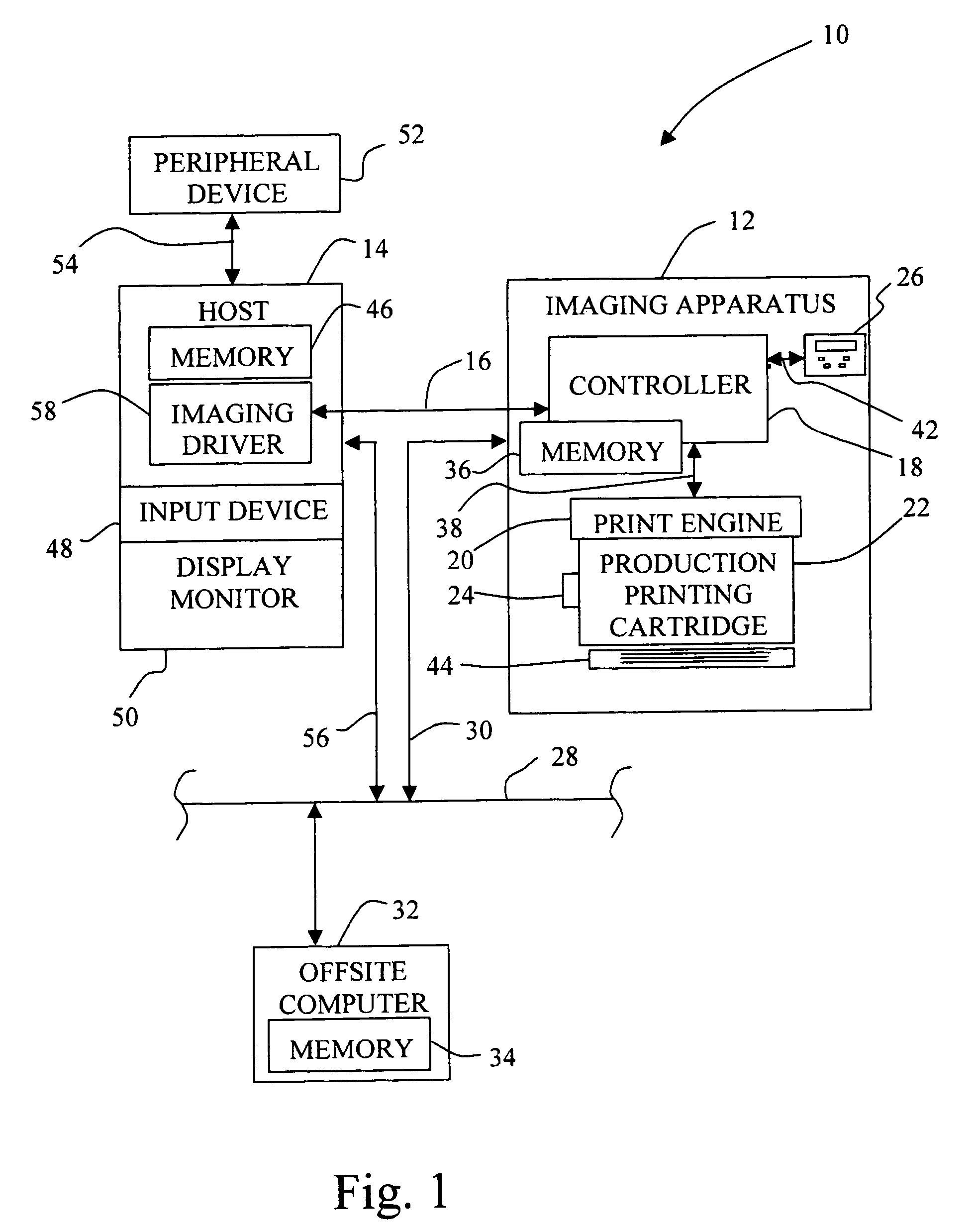

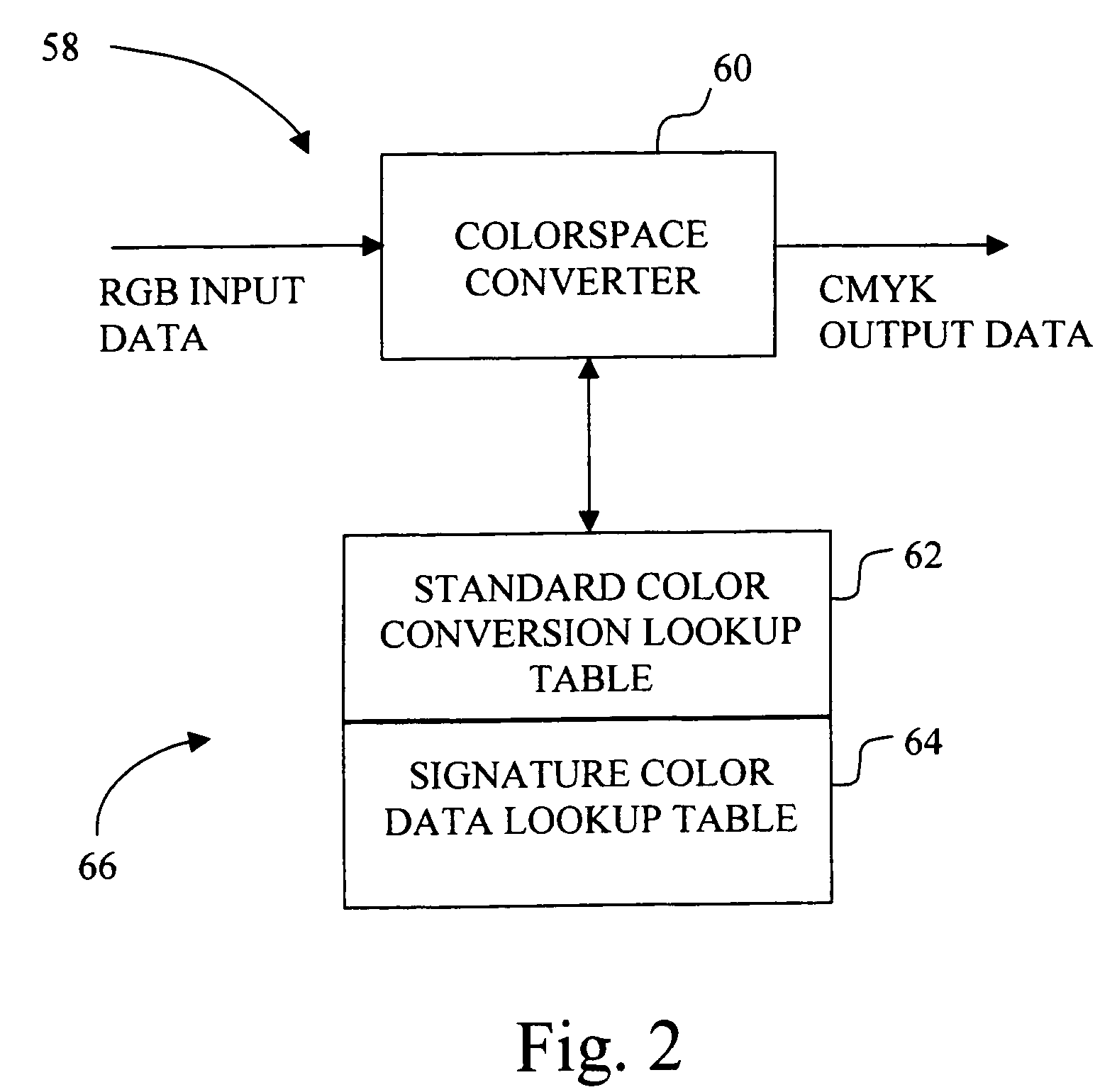

Method of correcting neutral color shifts caused by cartridge variations

InactiveUS7656554B2Neutral color variationReduce color variationDigitally marking record carriersDigital computer detailsPattern recognitionColor shift

A method for correcting neutral color shift in a production cartridge for use in an imaging system includes determining a colorant increment data based on a standard cartridge neutral variation signature color data and a standard cartridge neutral sensitivity signature color data associated with a standard cartridge, and based on a production cartridge neutral variation signature color data and a production cartridge neutral sensitivity signature color data associated with the production cartridge, and using the colorant increment data to correct the neutral color shift.

Owner:LEXMARK INT INC +1

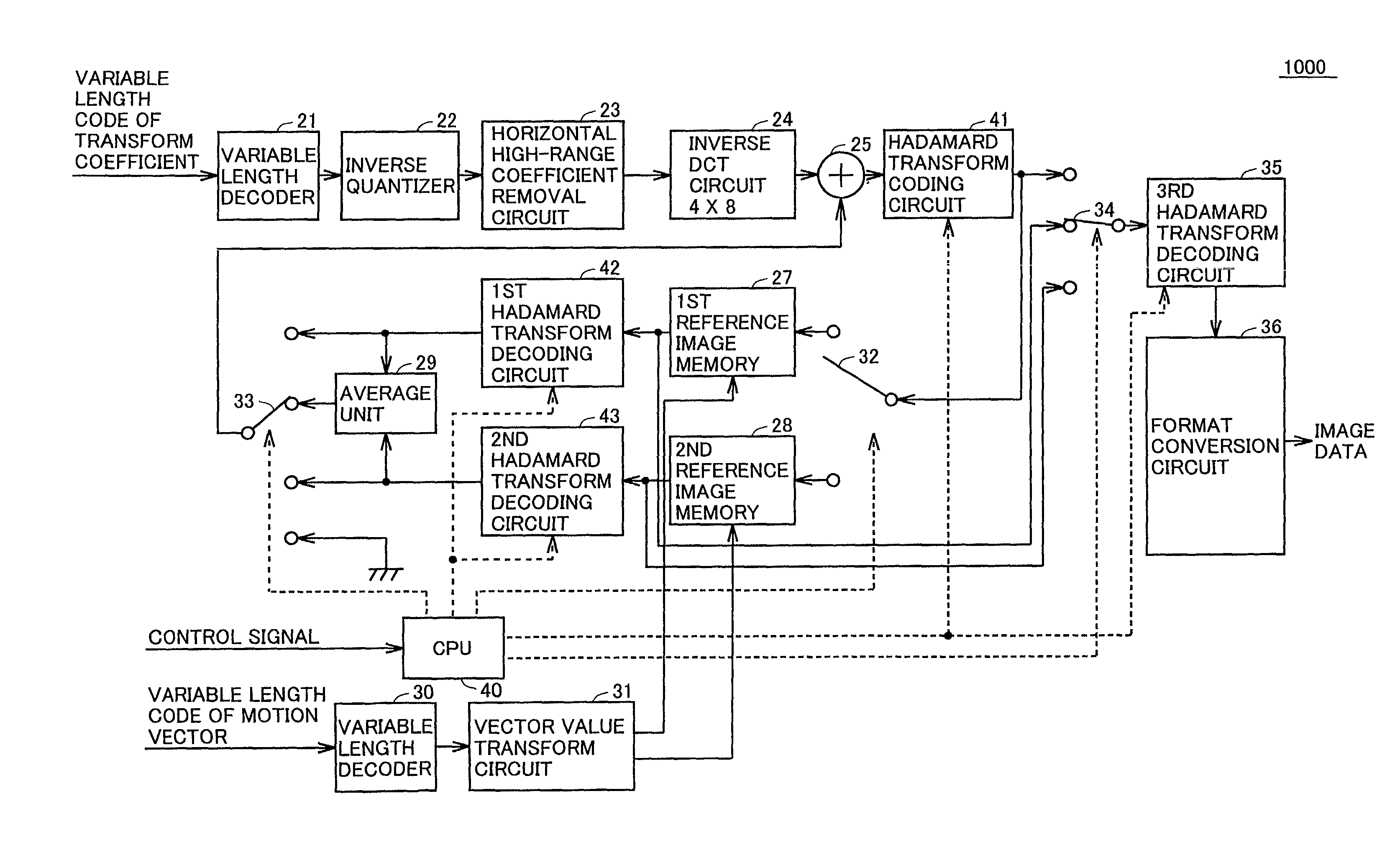

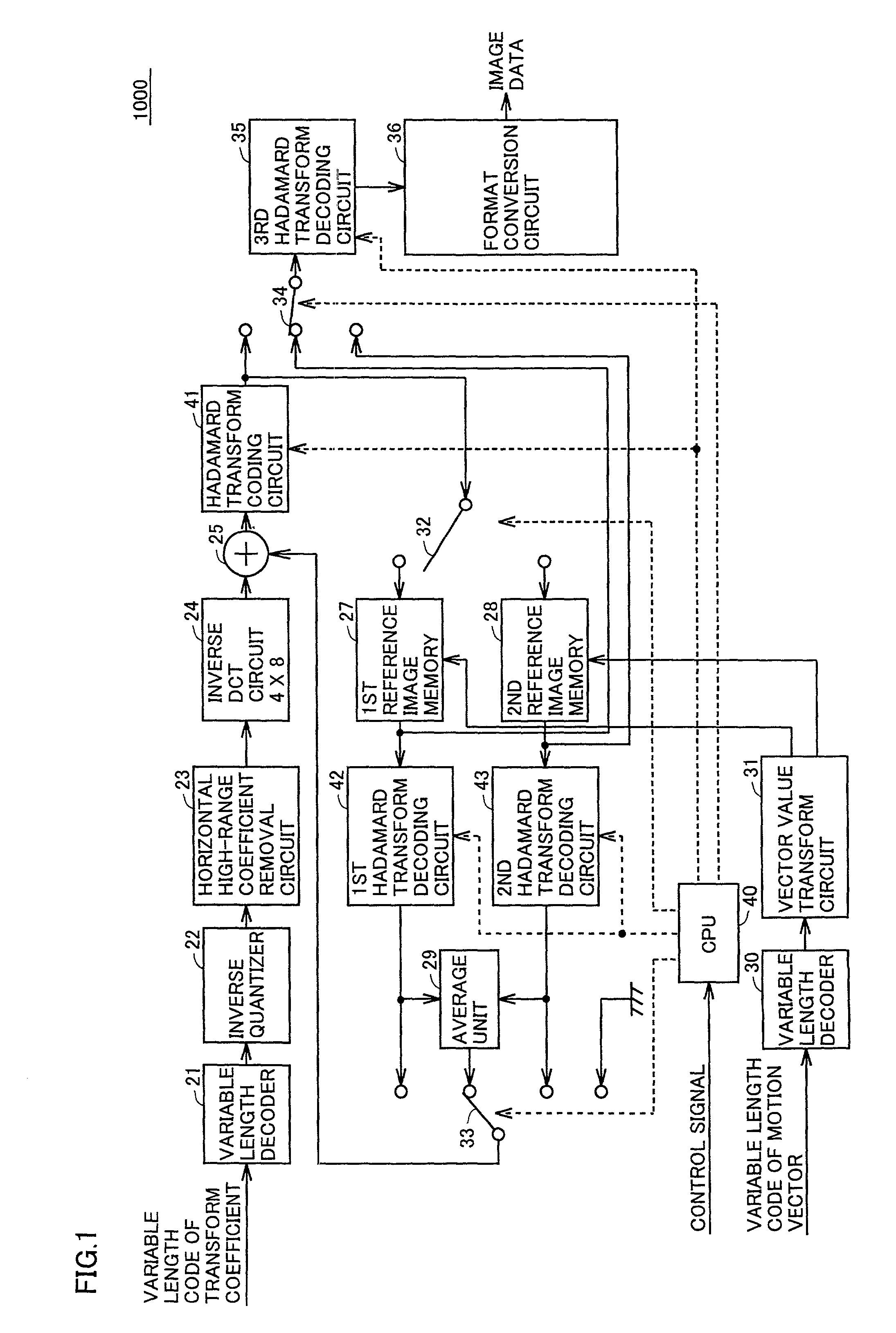

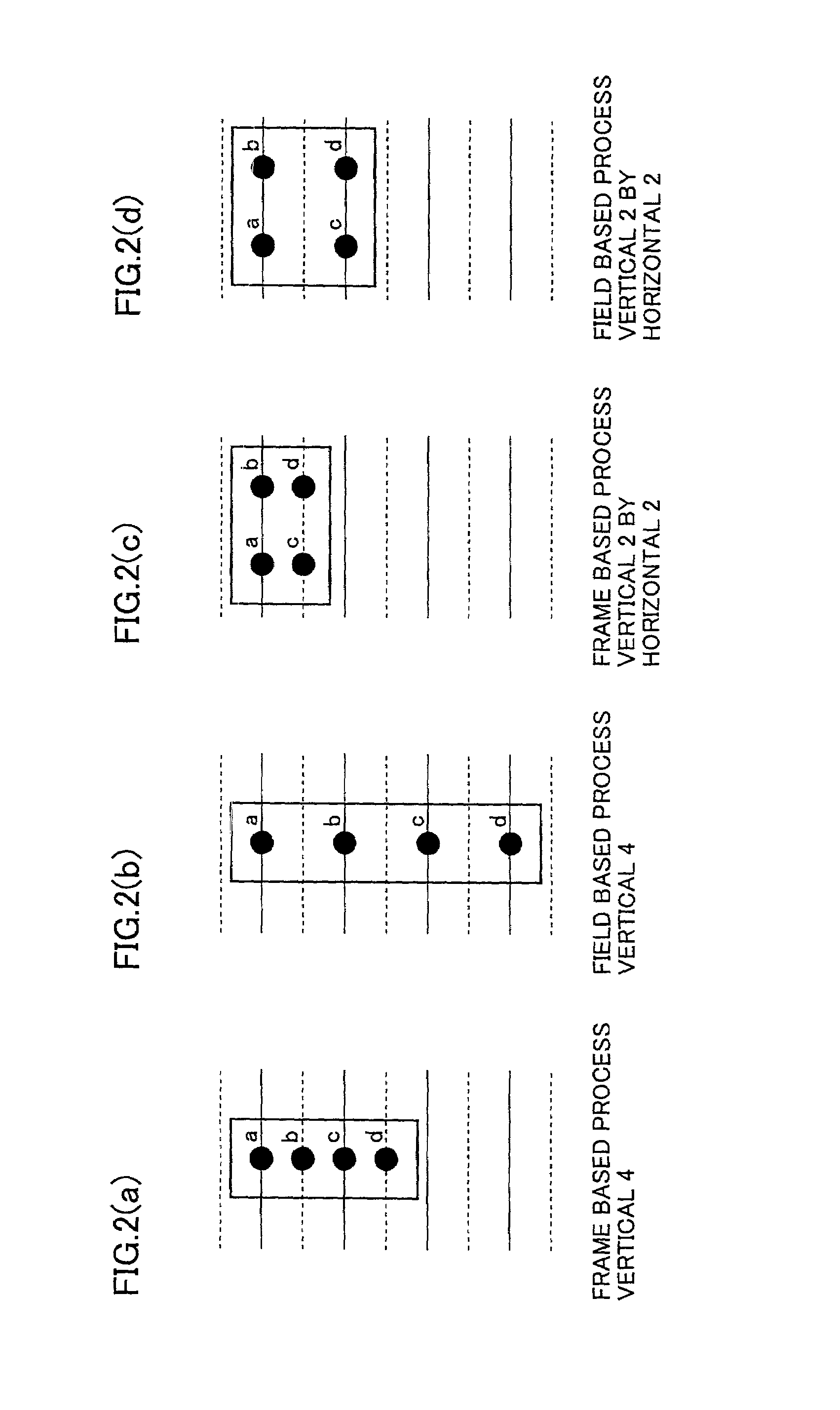

Motion image decoding apparatus and method reducing error accumulation and hence image degradation

InactiveUS7024052B2Reduce error accumulationReduce degradationPicture reproducers using cathode ray tubesCode conversionData compressionHadamard transform

An Hadamard transform coding circuit changes a rounding method for each Hadamard transform block to prevent a rounding operation from providing an error biased in one direction, as seen in a picture in its entirety, for data compression and rounding. More specifically, after Hadamard transform there exist decimal parts 0.0, 0.25, 0.5 and 0.75, and if a numerical value is simply rounded off a probability would be increased that the numerical value is biased to increase in absolute value. Accordingly for 0.5 a rounding operation to provide an integer switches for each block. Thus a motion image decoding apparatus can be provided to reduce error accumulation and suppress flickering, color variation and other similar noticeable degradations.

Owner:SANYO ELECTRIC CO LTD

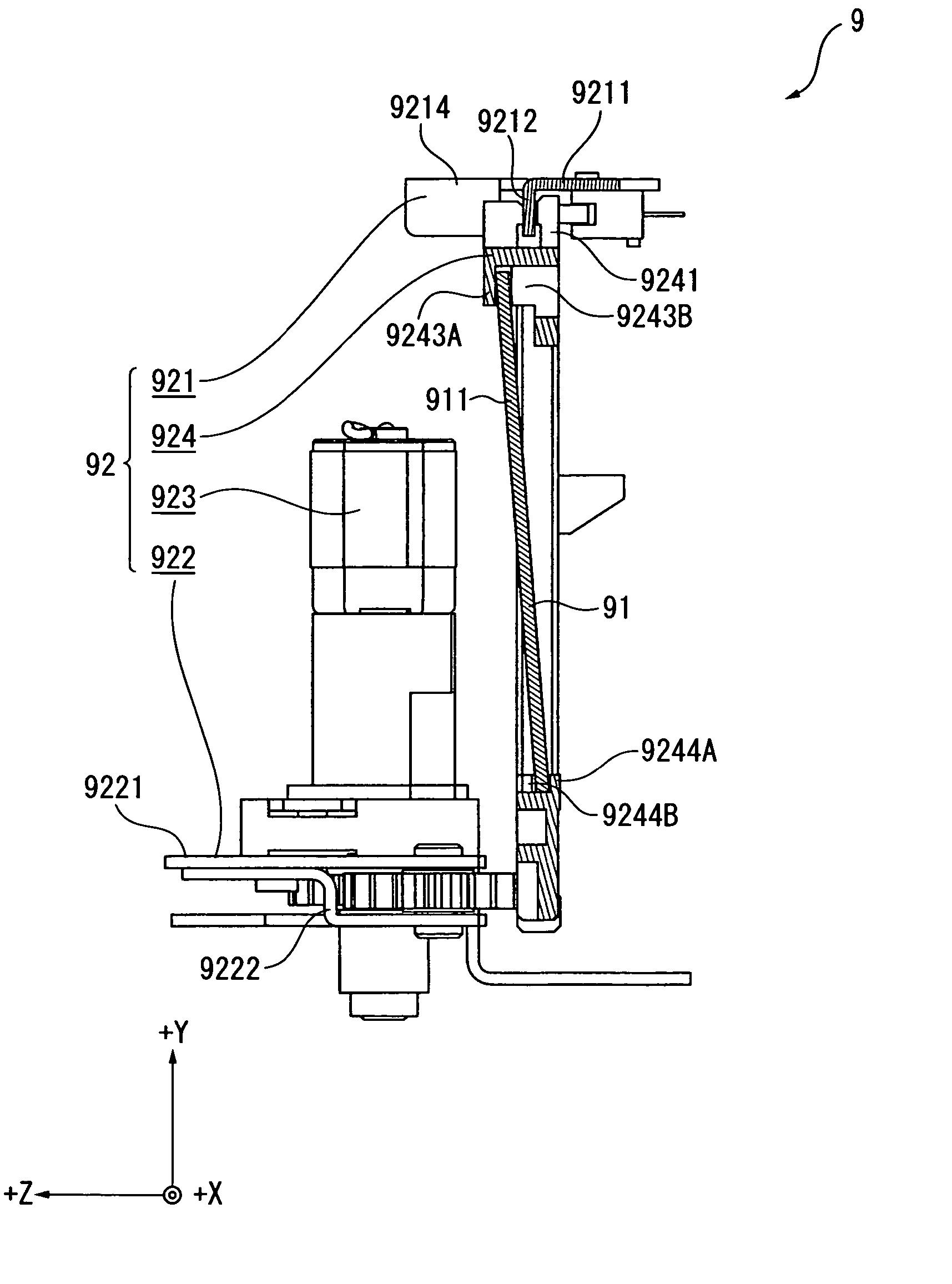

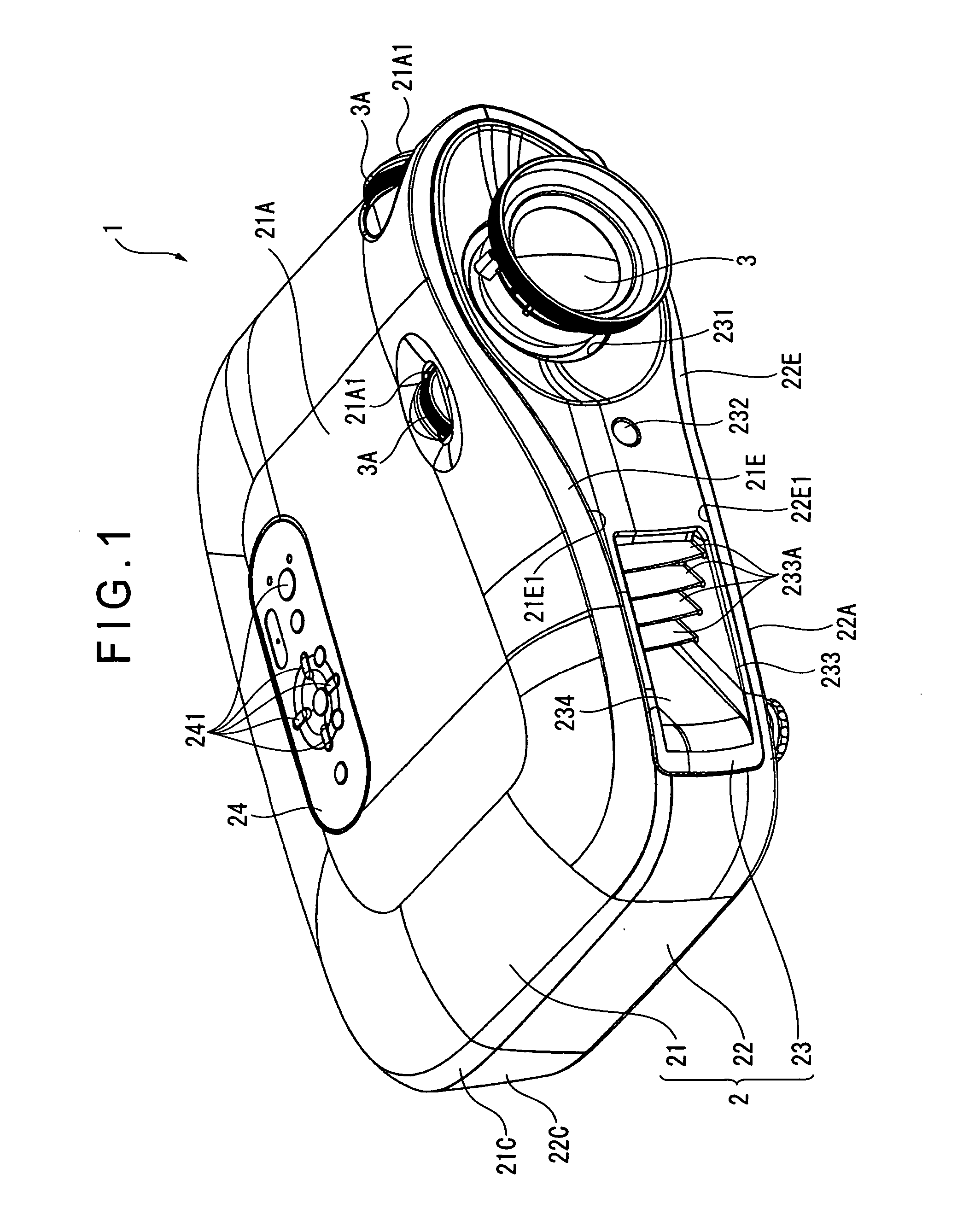

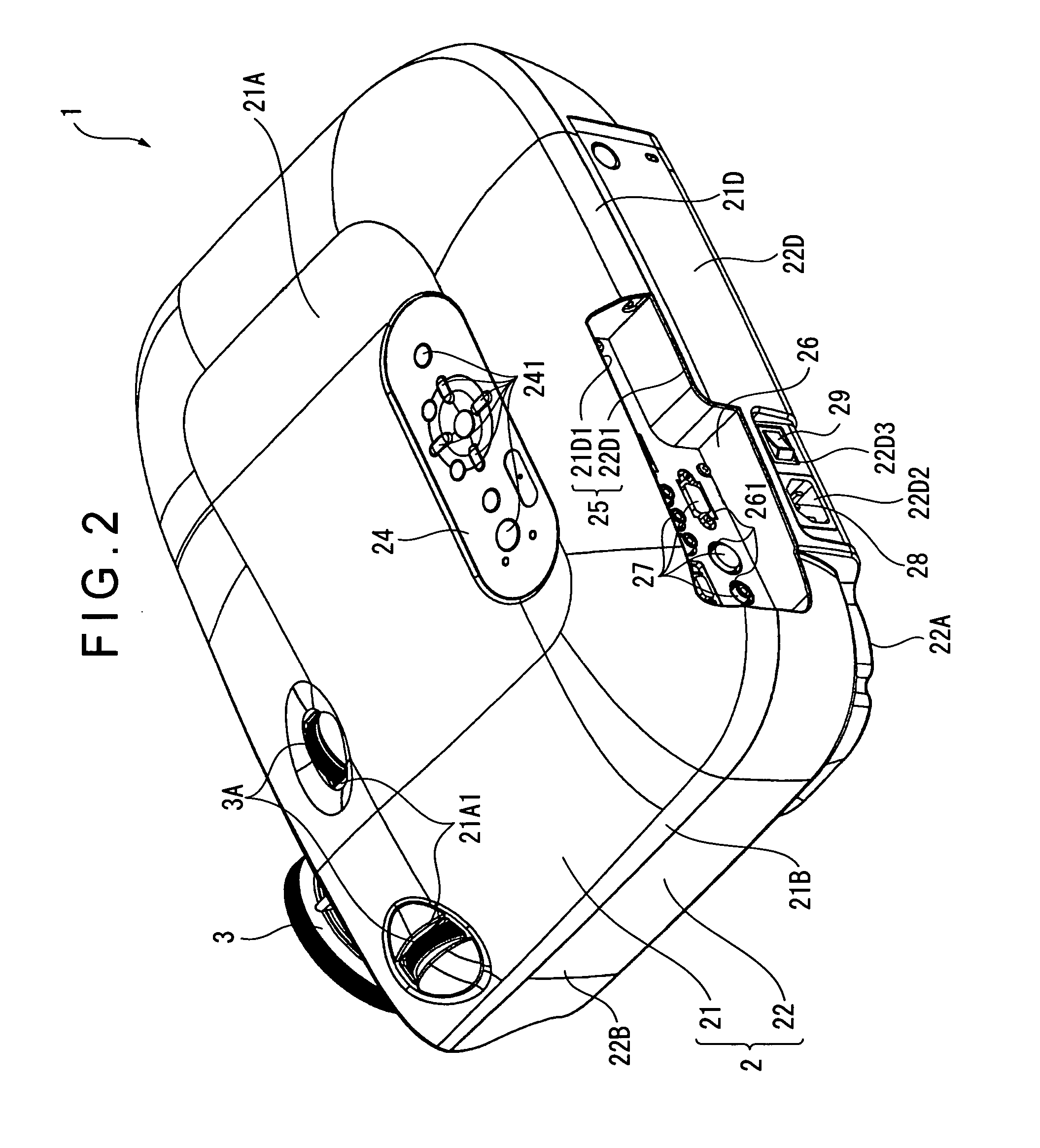

Projector

ActiveUS20070047052A1Reduce contrastReduce color variationProjectorsColor television detailsLight irradiationOptical axis

A projector includes: a light source device, a color-separating optical system for separating a light beam irradiated by the light source device into a plurality of color light components, a plurality of optical modulators for modulating each of the separated color light components in accordance with image information, a color-combining optical device for combining optical images modulated by the plurality of optical modulators and a projection optical device for projecting the combined optical images in an enlarged manner. An optical filter that reflects a predetermined spectral component of the light beam and transmits the other spectral component is disposed in an optical path between the light source device and the optical modulators The optical filter is disposed such that a light-irradiation side surface for irradiating the light beam is inclined by a predetermined angle relative to a plane orthogonal to an optical axis of the light beam.

Owner:SEIKO EPSON CORP

Light emitting element

ActiveUS20120056221A1Reduce color variationSolid-state devicesSemiconductor devicesLength waveWavelength conversion

The present invention provides a light emitting element, which includes a light emitting diode (LED) chip and a wavelength-converting layer arranged on a surface of the LED chip, the wavelength-converting layer to convert a wavelength of light emitted from the LED chip, wherein at least a portion of the wavelength-converting layer has a width greater than the width of the surface of the LED chip.

Owner:SEOUL VIOSYS CO LTD

Liquid crystal display device

ActiveUS7580099B2Increase contrastReduce color variationLiquid crystal compositionsPolarising elementsLiquid crystal cellChemistry

A novel liquid crystal display device is disclosed. The liquid crystal display device comprises a first polarizing film, a first retardation area with an Re of 60 to 200 nm and a value of Nz of less than 0.8 and not greater than 1.5; a second retardation region with an Re of not greater than 50 nm and an Rth of −200 to −50 nm; and a liquid crystal cell comprising a liquid crystal layer being aligned in parallel to the surfaces of the pair of substrates in a black state with a slow axis in a black state parallel to the transmission axis of the first polarizing film; and a second polarizing film.

Owner:FUJIFILM CORP

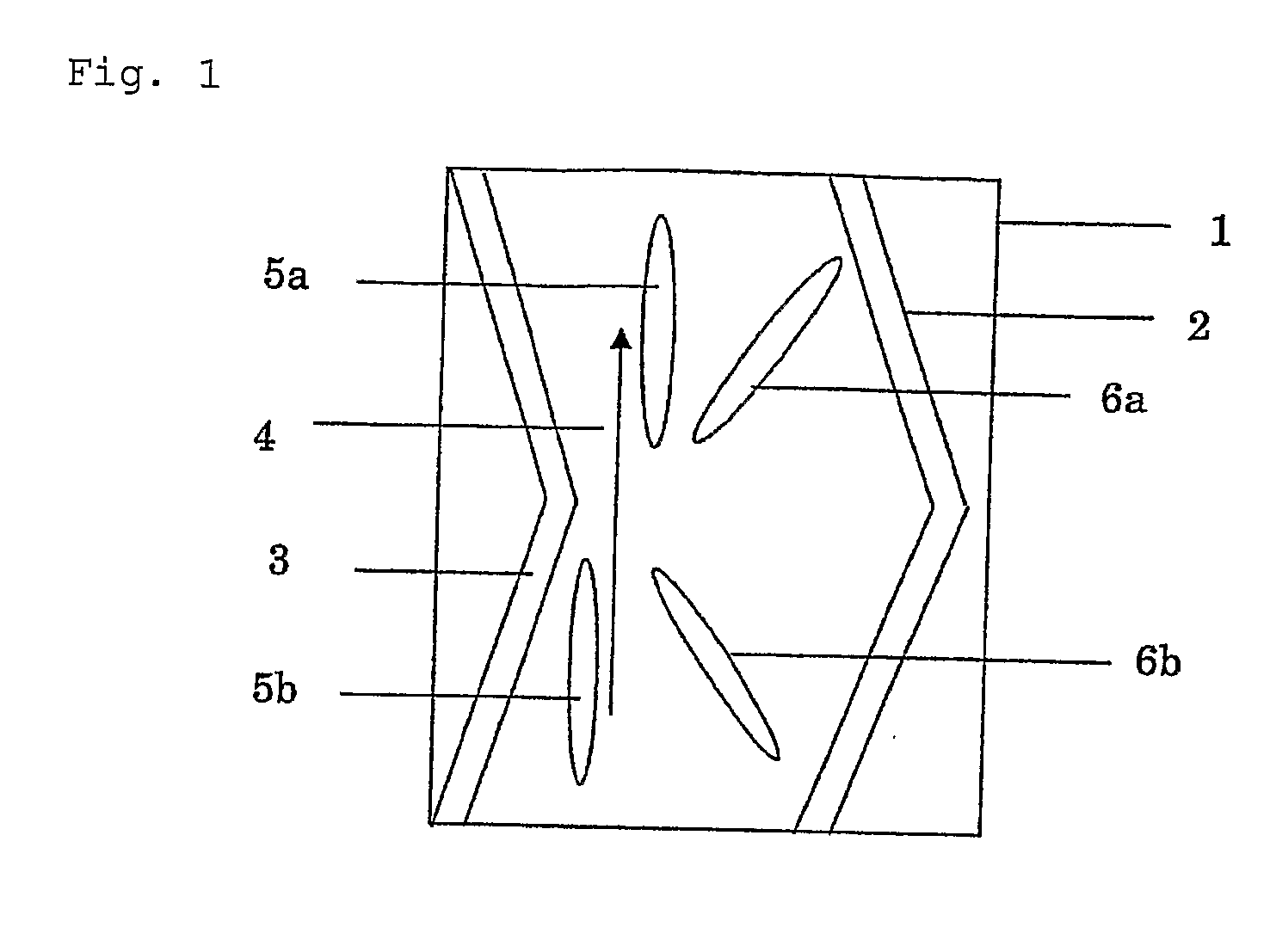

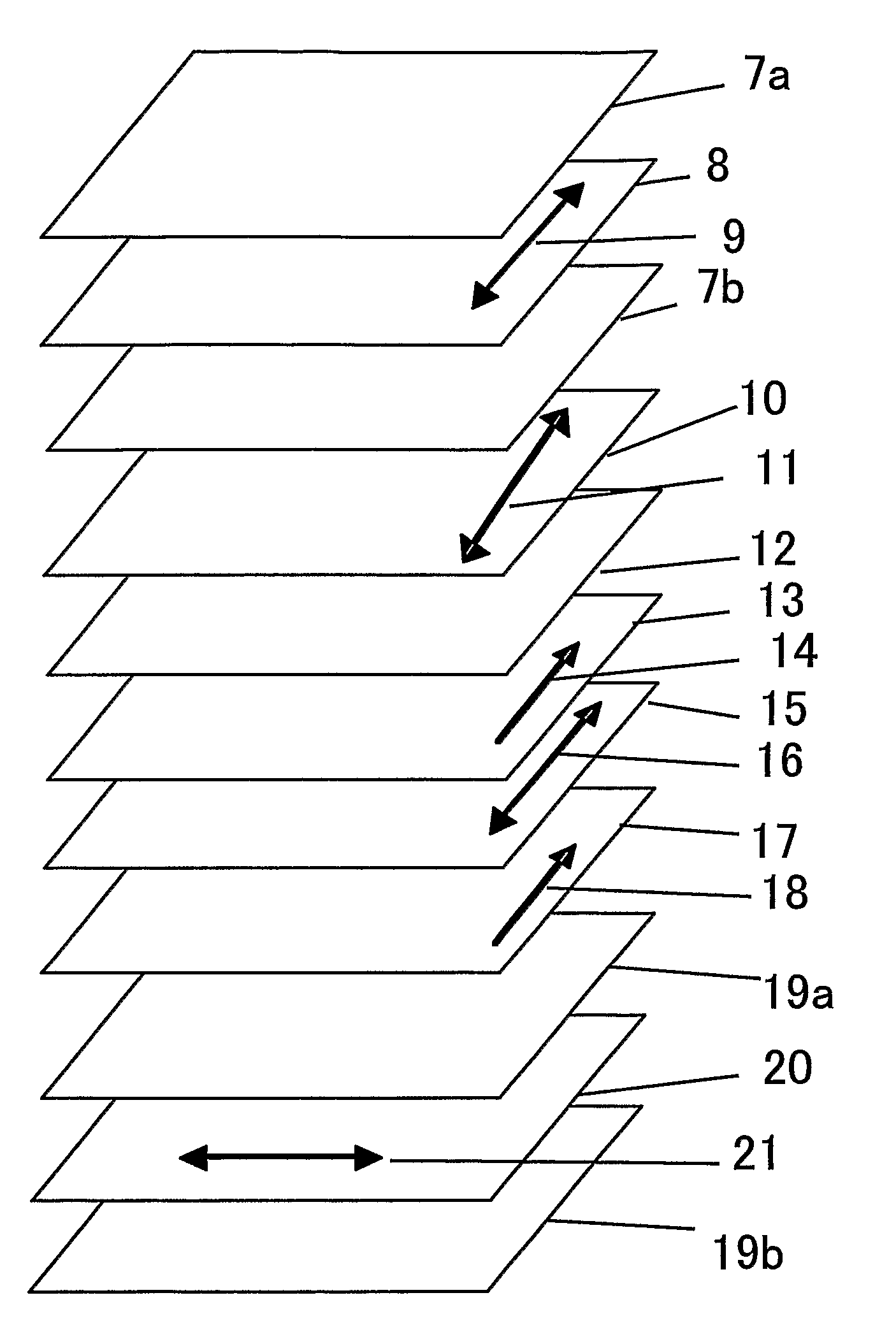

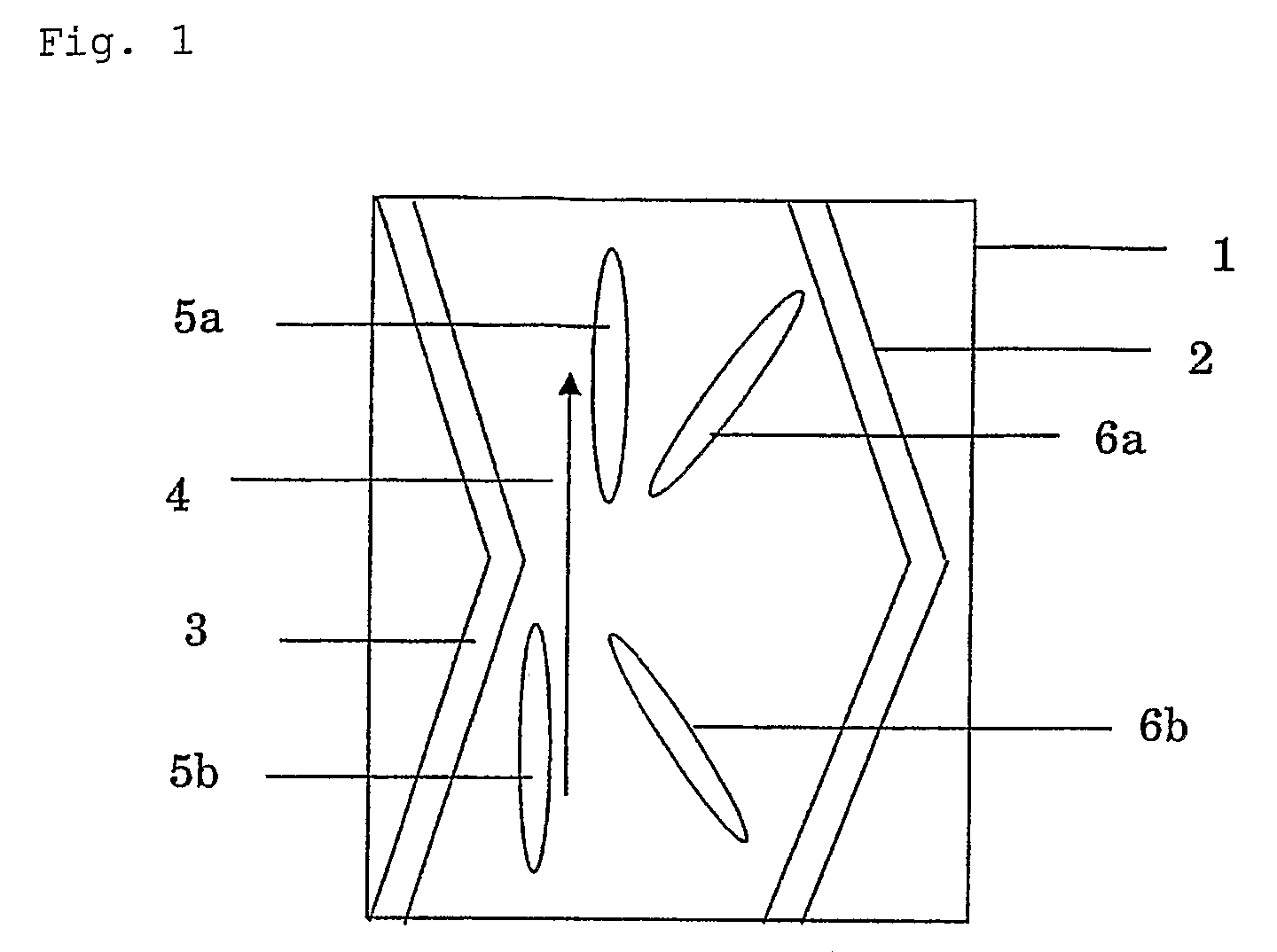

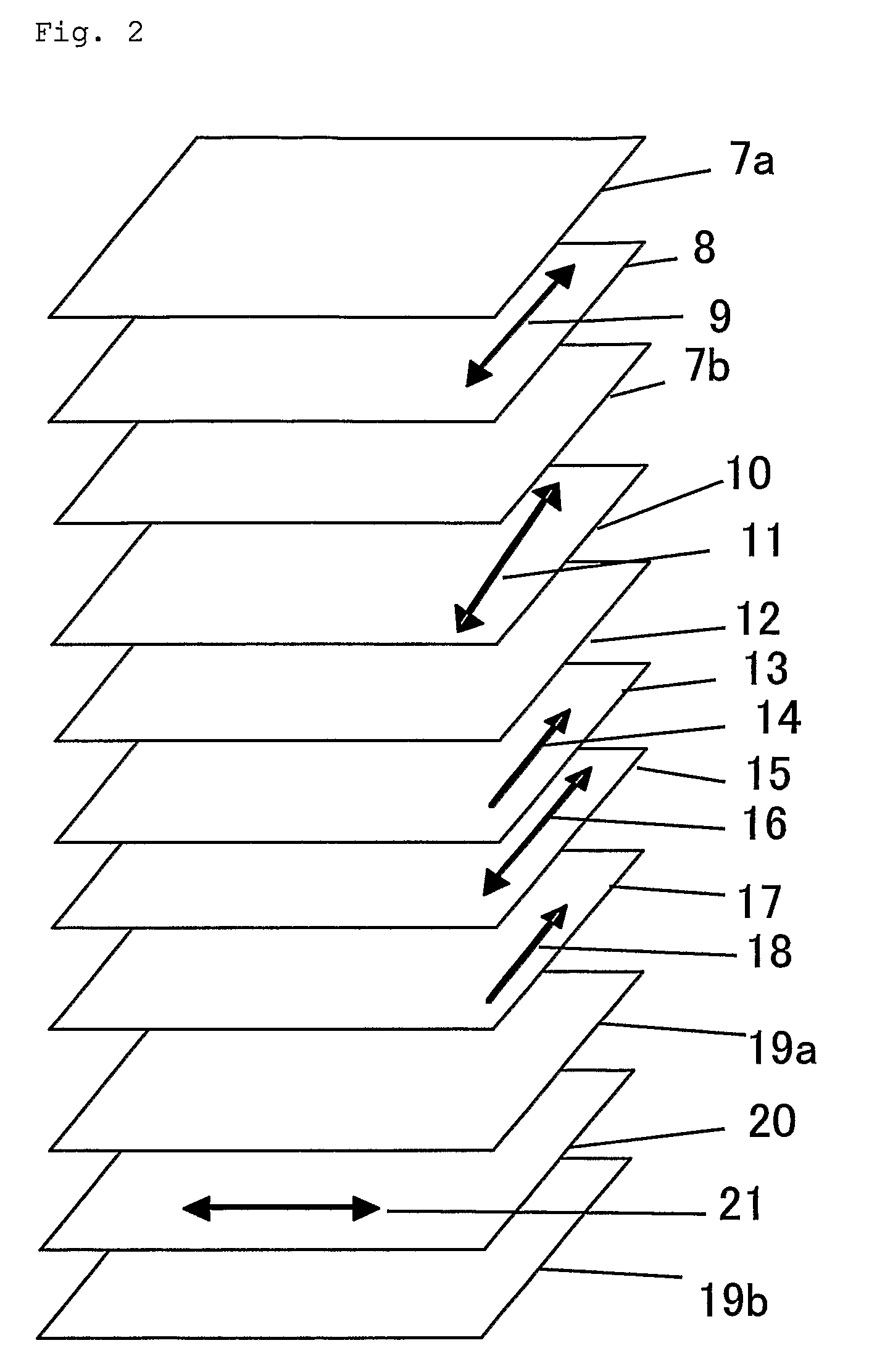

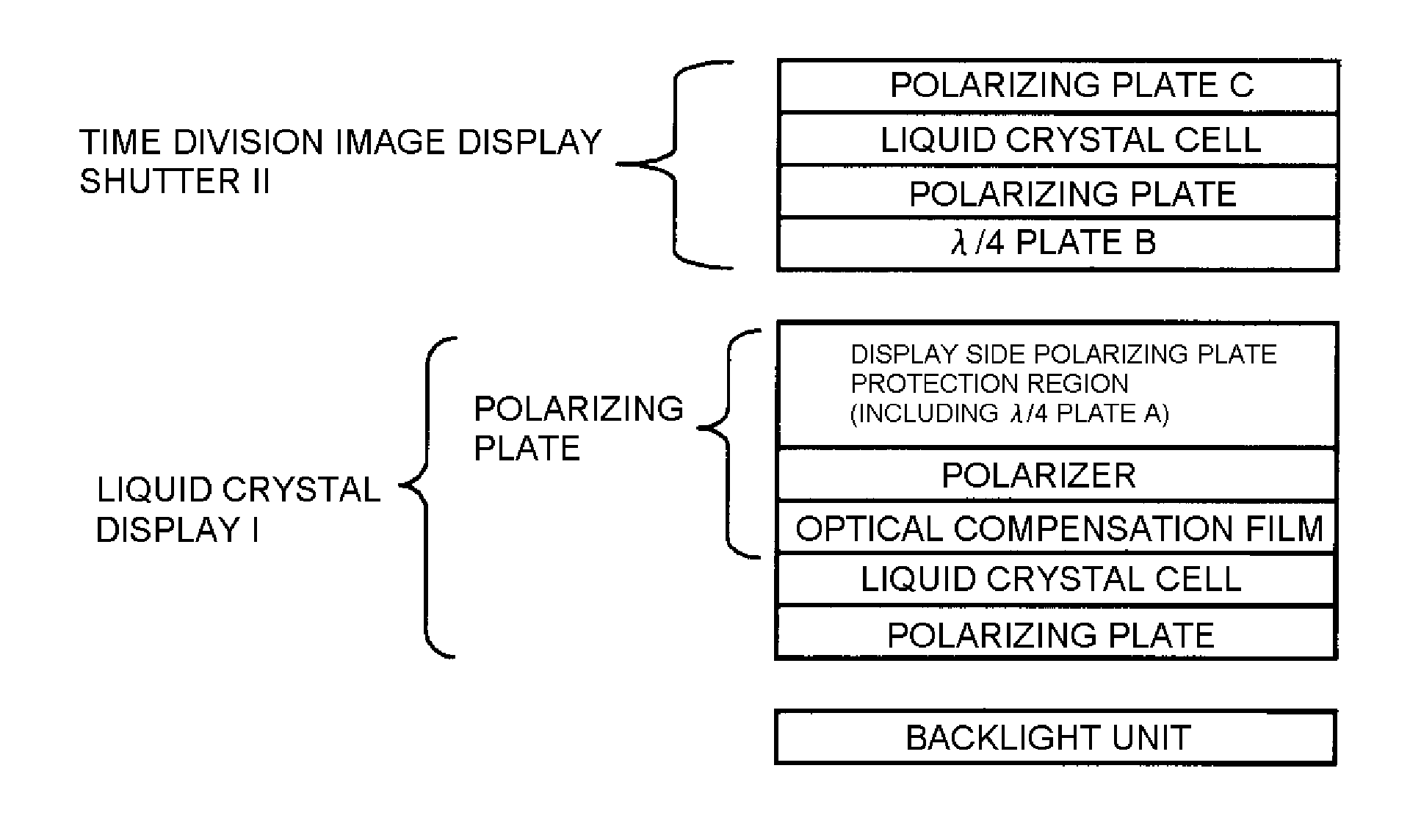

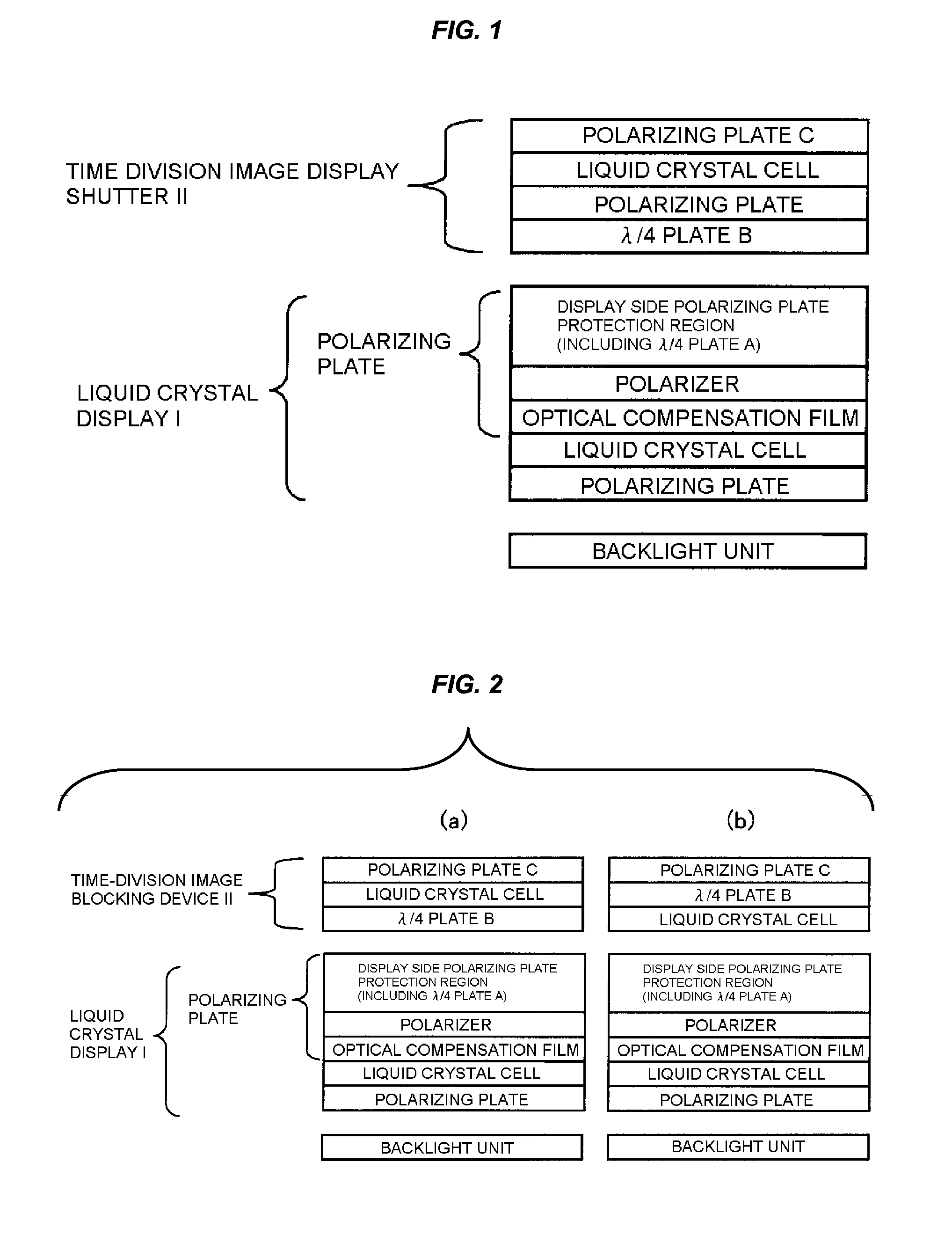

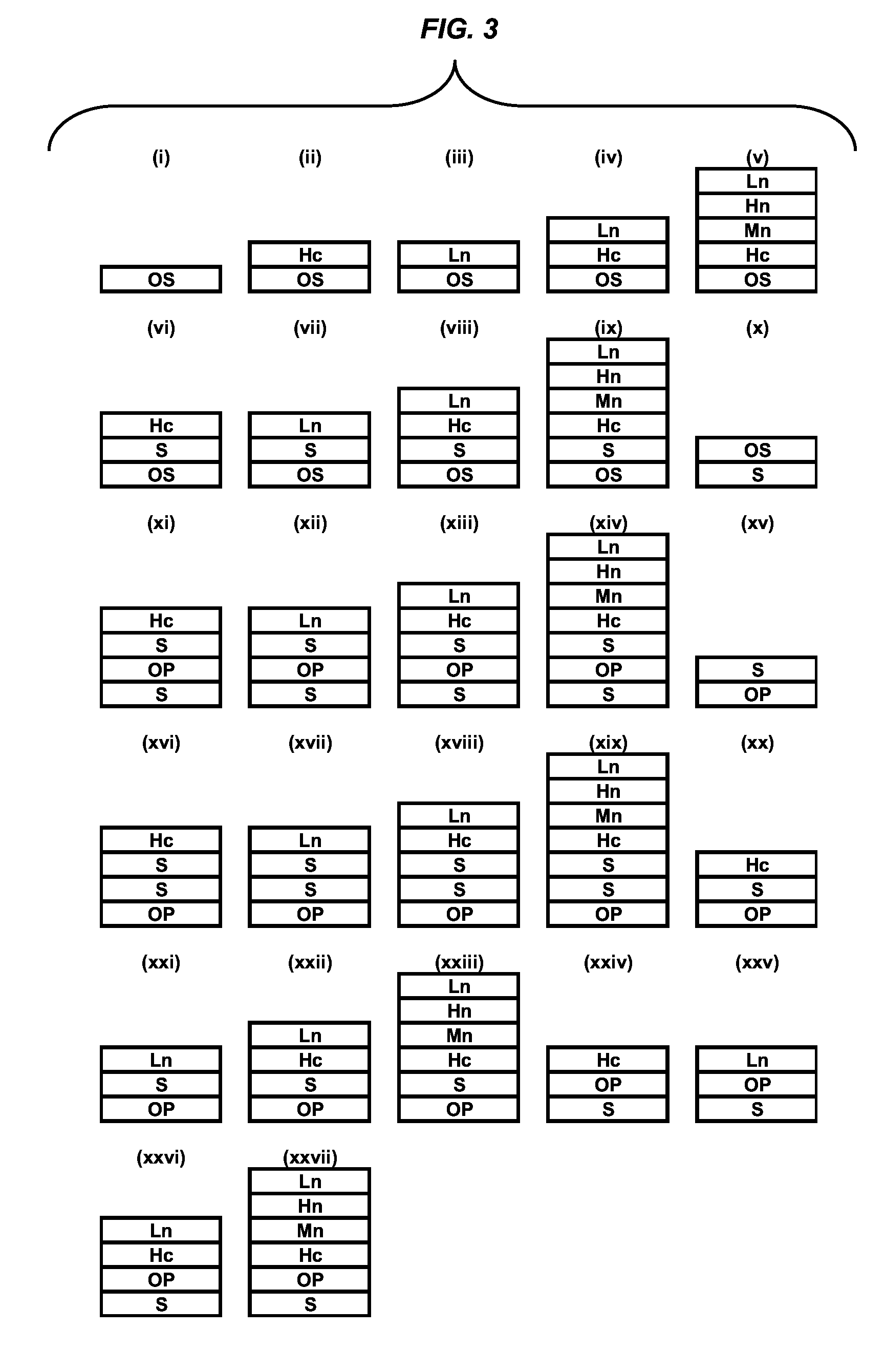

Stereoscopic image recognition apparatus

ActiveUS9316843B2Good colorStereoscopic displaySteroscopic systemsNon-linear opticsDisplay devicePolarizer

A stereoscopic image recognition apparatus is provided and includes a liquid crystal display I and a time division image display shutter II. The liquid crystal display I includes a λ / 4 plate A in a protection region for a the display side polarizing plate, the protection region being a region on the display side of a polarizer of the one of the polarizing plate. An angle formed by an absorption axis of the display side polarizing plate and a slow axis of the λ / 4 plate A is 35 to 55° or 125 to 145°, and the protection region satisfies |Rth (550)|≦160 nm. The time division image display shutter II includes a polarizing plate C between the second liquid crystal cell and the viewer and includes a λ / 4 plate B between the polarizing plate C and the liquid crystal display I. When the absorption axis of the display side polarizing plate and the absorption axis of the polarizing plate C are disposed so as to be perpendicular or parallel to each other, the slow axes of the λ / 4 plate A and the λ / 4 plate B are perpendicular or parallel to each other.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com